6052504

ERIODIC MAINTENANCE

P

2

2.1 100-Hour Maintenance

Every time the lift truck is serviced or every 100 hours

of truck operation, whichever comes first, complete the

following maintenance procedures:

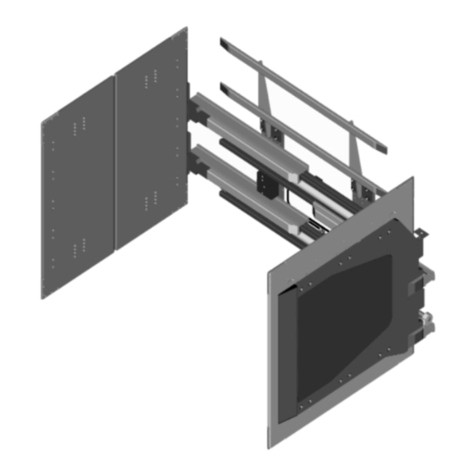

Check for loose or missing capscrews, worn or

damaged hoses, and hydraulic leaks.

Check fork shafts for bends, damage or wear. Replace

if bent. Consult Cascade if damaged or worn.

2.2 300-Hour Maintenance

After each 300 hours of truck operation, in addition to the

100-hour maintenance, perform the following procedures:

Tighten Cascade backrest (if equipped) capscrews to

the following torque values:

M12 Capscrew – 75 ft.-lbs. (100 Nm)

M16 Capscrew – 145 ft.-lbs. (195 Nm)

For other backrests, see OEM recommendations.

If equipped with zerk fittings – Apply general purpose

chassis grease to upper and lower bearings.

Inspect frame retainers for wear. Replace if necessary.

Tighten lower frame retainer capscrews to 165-200 ft.-lbs.

(225-275 Nm).

Inspect fork shaft and front of lower frame bar for

grease contamination. Remove contaminated grease

from fork shaft and lower frame bar. Apply a general

purpose chassis grease to the fork shaft. Apply a

general purpose chassis grease or Slip-Plate (or a

'paint-on' graphite equivalent) to the lower frame bar.

2.3 1000-Hour Maintenance

After each 1000 hours of truck operation, in addition to

the 100 and 300-hour maintenance, perform the following

procedures:

Inspect sideshift upper and lower bearings for wear.

If the frame is rubbing the carriage or lower bearing

capscrews, replace the entire bearing set (see Service

Manual for repair procedures).

Inspect forks for wear.

NOTE: Cascade fork safety kit 3014162 is available with

wear calipers, inspection sheets and safety poster. Also

available Cascade fork hook & carriage bar wear gauge

209560 (CL II), 209561 (CL III) and 6105257 (CL IV).

Inspect sideshift cylinder pivot pins and clevis pins for

wear. Replace part as necessary.

Inspect fork position cylinder anchor nuts for wear.

Replace if necessary.

NOTE: Anchors operate with a loose clearance.

Tighten lower bearing capscrews to 200 ft.-lbs. (270 Nm).

Tighten fork shaft retainers capscrews (if equipped) to

49 ft.-lbs. (66 Nm).

•

•

•

•

•

•

•

•

•

•

•

•

WARNING: After completing any service

procedure, always test the Fork Positioner/

Sideshifter through five complete cycles

to make sure the attachment operates

correctly before returning it to the job.

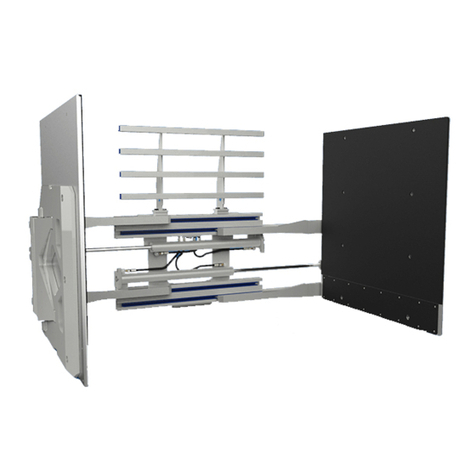

Shaft Retainer

capscrews

Fork Shaft Upper Bearing

Sideshift Cyinder

Clevis Pin Mounts

Lower

Frame Bar Lower Bearing

Front View

Back (Driver's) View

Backrest Capscrews

(if equipped)

Fork Positioner

Cylinder Anchors Lower Frame

Retainer Capscrews