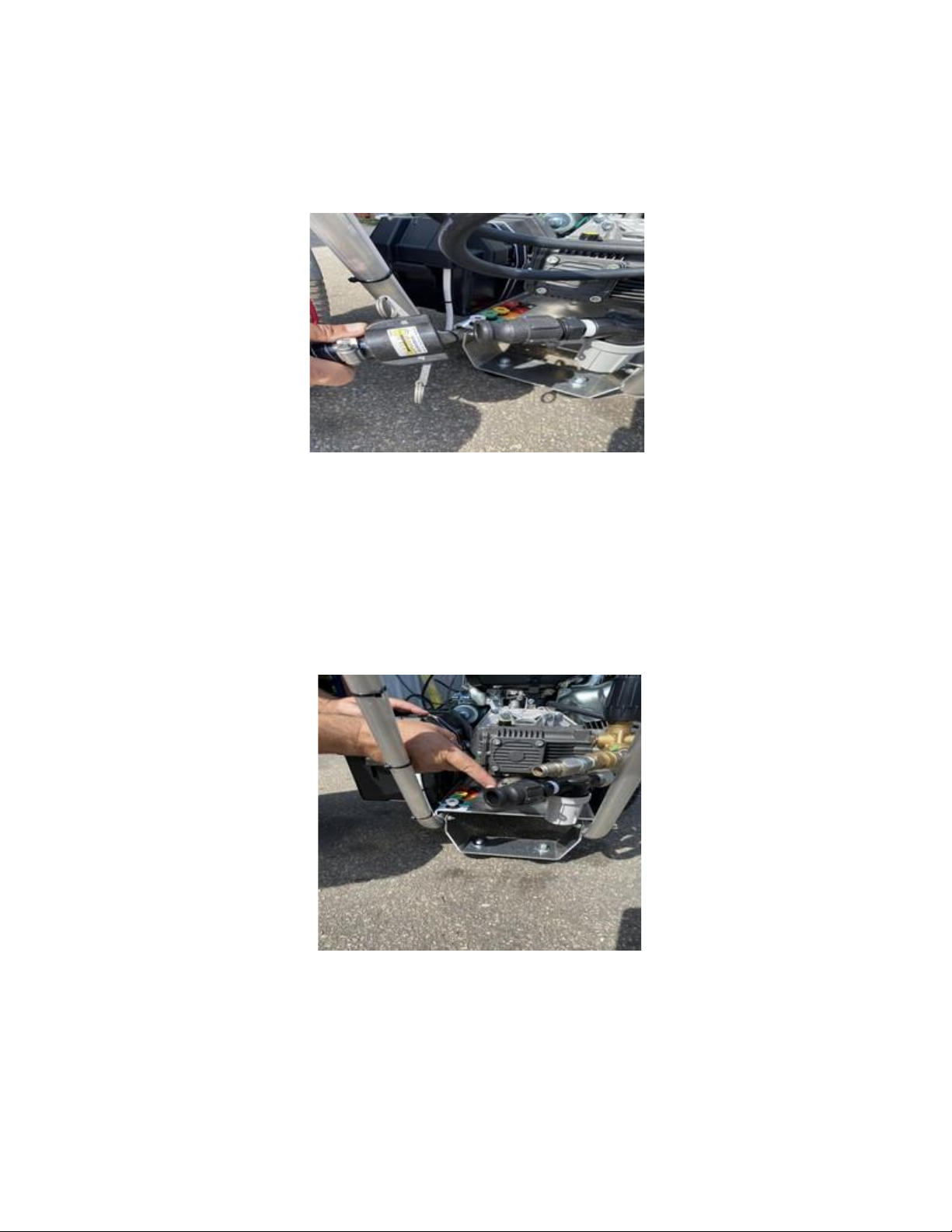

When feeding water to the CaviBlaster® power unit with the feed pump, connect

the 1″ diameter clear PVC feed hose to the cam-lock plug on the inline strainer

inlet.

The feed hose has the feed pump on one end and a cam-lock socket on the other end. Insert the

electrical plug powering the feed pump into the waterproof electrical outlet on the end of the

power unit cart under the handle. Ensure that the knob on the plug is facing up and mates with

the notch in the outlet cover. If the plug is engaged upside down, the pump will turn in reverse.

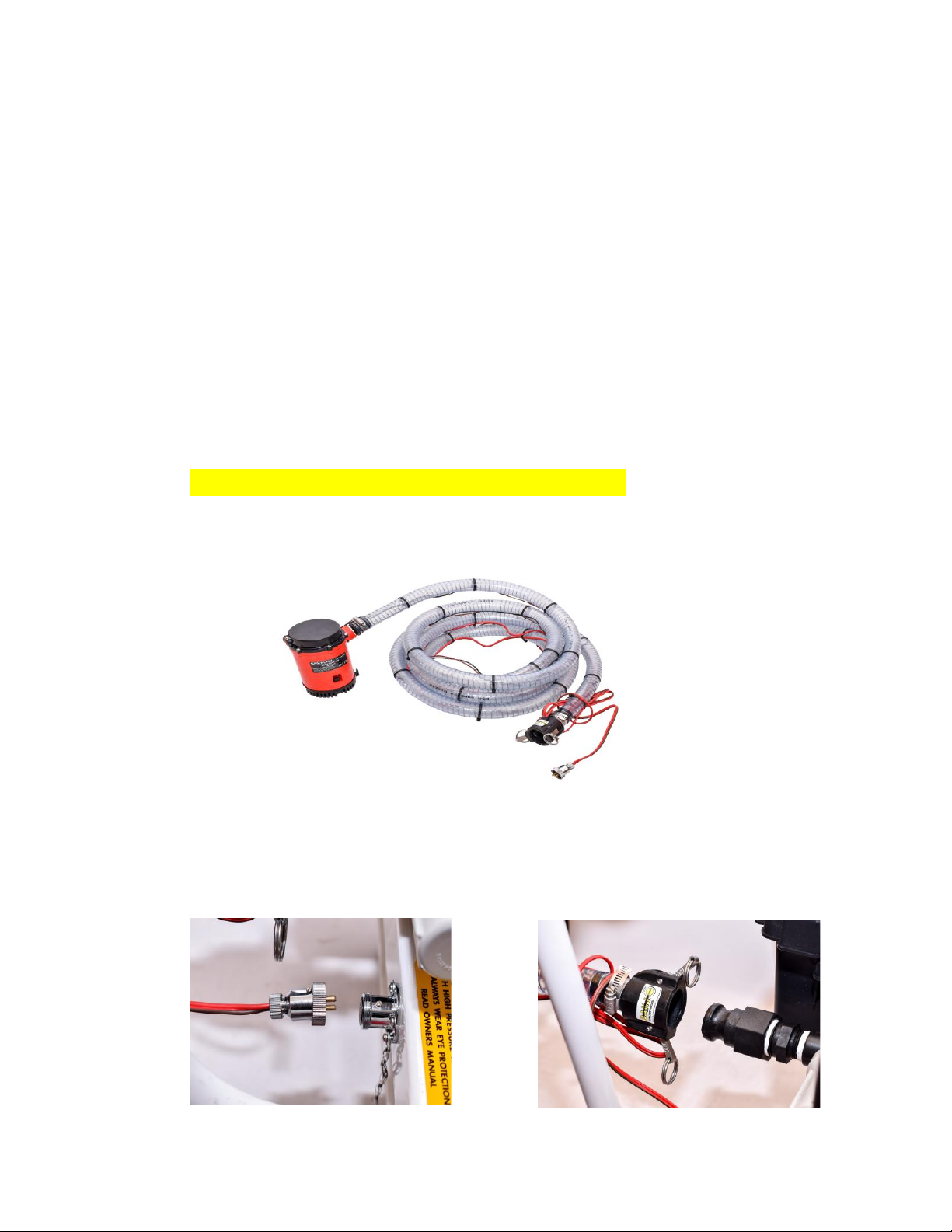

Ensure that the feed hose is connected to the pressure pump, the feed pump is submerged in

water, and the wiring splice is kept dry prior to starting the feed pump. Either fresh water or

seawater can be used with this system.

Note: The feed pump has had a neoprene check valve installed in the discharge. This valve will prevent water from

draining out of the feed hose through the feed pump when the pump is turned off. However, this check valve

somewhat restricts the flow of water from the pump. If maximum water flow is required from the feed pump, the

check valve and stainless retaining washer can be removed from the pump discharge by removing the black hose

barb fitting. NEVER TURN OFF FEED PUMP WHILE WORKING.

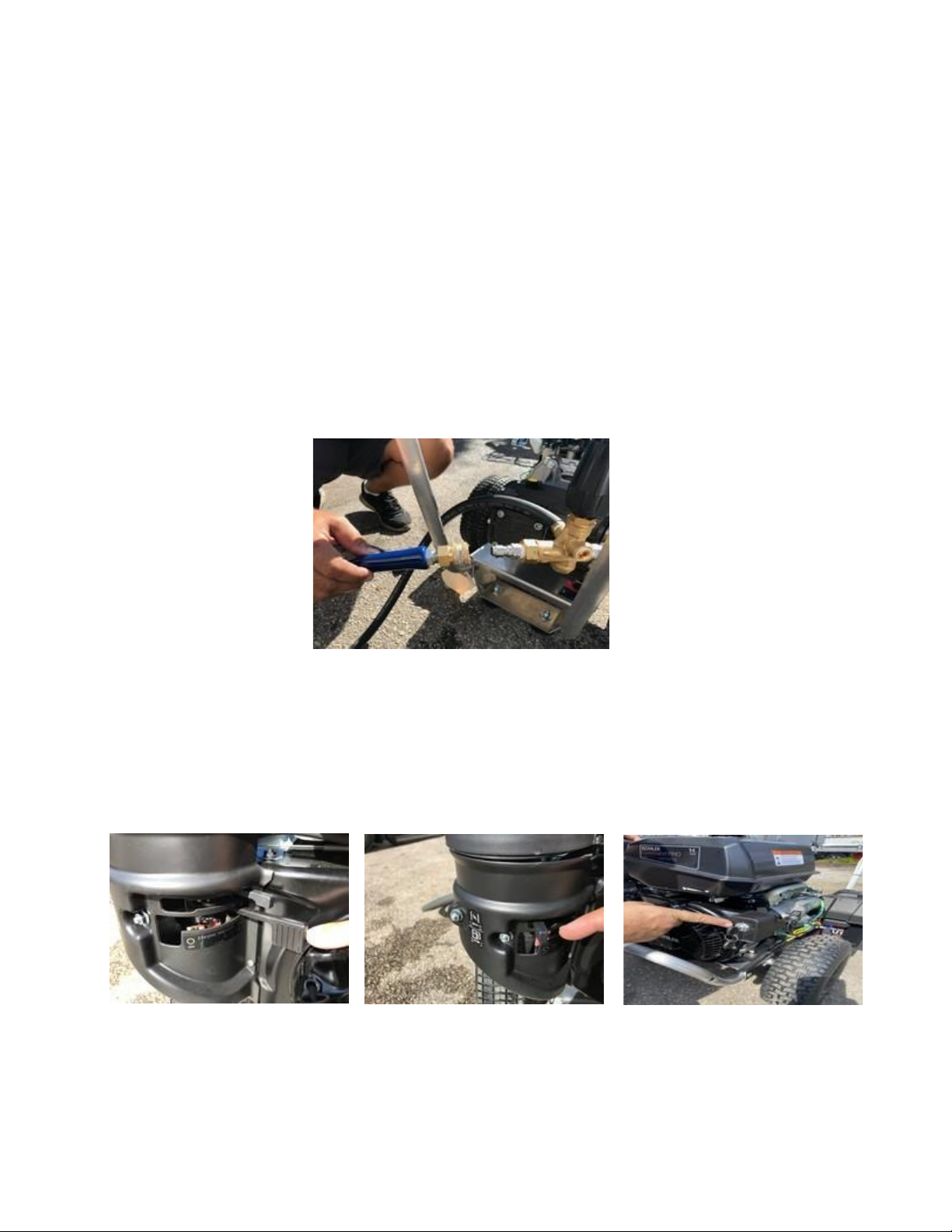

When feeding the CaviBlaster® with an alternate water source, the source must supply water at a

volume of greater than 6 gallons per minute at a maximum pressure of 70-psi. Connect the water

source to the inlet of the pressure pump (Figure 10). Ensure that the feed hose is connected to the

pressure pump and the water is on prior to starting the pressure pump.