4

and requirements of EU Directive 2014/30/EU (EMC).

IMPORTANT INFORMATION FOR CORRECT DISPOSAL OF THE

PRODUCT IN ACCORDANCE WITH EC DIRECTIVE 2012/19/EU.

At the end of its working life, the product must be taken to a special

local authority waste collection centre or to a dealer providing

appliance recycling services.

Disposing of a household appliance separately avoids possible

negative consequences for the environment and health. It also

enables the constituent materials to be recovered, saving both energy

and resources. As a reminder of the need to dispose of household

appliances separately, the product is marked with a crossed-out

wheeled dustbin.

Please note:

•Under no circumstances should the extractor be connected to any

gas ventilation system, flue system or hot air ducting system.

• Do not vent the extractor into an attic or loft space.

•Only house the extractor in rooms with adequate ventilation.

Remember that the extractor is powerful and whatever air is

extracted needs to be replaced.

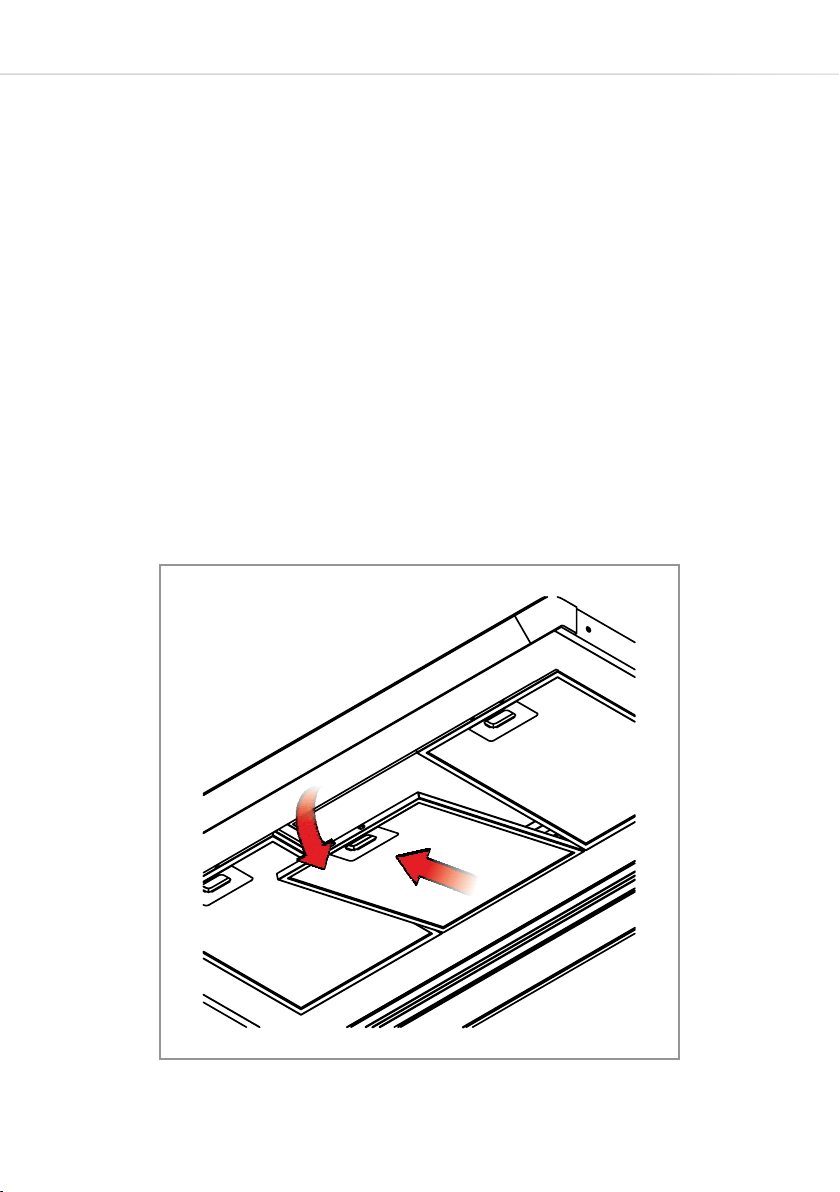

•Do not tile the extractor in. It should be removable for service or

maintenance.

•Do not use silicone sealant to secure the hood to the wall.

•You must be able to isolate the extractor from the mains electrical

supply after installation.