10 3301052

EN

and pressure regulators used in welding operations

should be handled with care.

ELECTROMAGNETIC COMPATIBILITY.

This machine is manufactured in compliance with

the instructions contained in the standard IEC

60974-10 (CL. A) and must be used solely for pro-

fessional purposes in an industrial environment.

There may be potential difculties in ensuring

electromagnetic compatibility in non-industrial

environments.

DISPOSAL OF ELECTRICAL AND ELECTRONIC

EQUIPMENT. Do not dispose of electrical

equipment together with normal waste! In ob-

servance of European Directive 2002/96/EC

on Waste Electrical and Electronic Equipment

and its implementation in accordance with national

law, electrical equipment that has reached the end

of its life must be collected separately and returned

to an environmentally compatible recycling facility.

As the owner of the equipment, you should get infor-

mation on approved collection systems from our lo-

cal representative. By applying this European Direc-

tive you will improve the environment and human

health!

IN CASE OF MALFUNCTIONS, REQUEST ASSIS-

TANCE FROM QUALIFIED PERSONNEL.

1.1 Warning label

The following numbered text corresponds to the la-

bel numbered boxes.

B. Driverollscaninjurengers.

C. Welding wire and drive parts are at welding voltage

during operation. Keep hands and metal objects

away.

1 Electric shock from welding electrode or wiring can

kill.

1.1 Wear dry insulating gloves. Do not touch elec-

trode with bare hand. Do not wear wet or dam-

aged gloves.

1.2 Protect yourself from electric shock by insulat-

ing yourself from work and ground.

1.3 Disconnect input plug or power before working

on machine.

2 Breathing welding fumes can be hazardous to

your health.

2.1 Keep your head out of fumes.

2.2 Use forced ventilation or local exhaust to remove

fumes.

2.3 Use ventilating fan to remove fumes.

3 Weldingsparkscancauseexplosionorre.

3.1 Keepammablematerialsawayfromwelding.

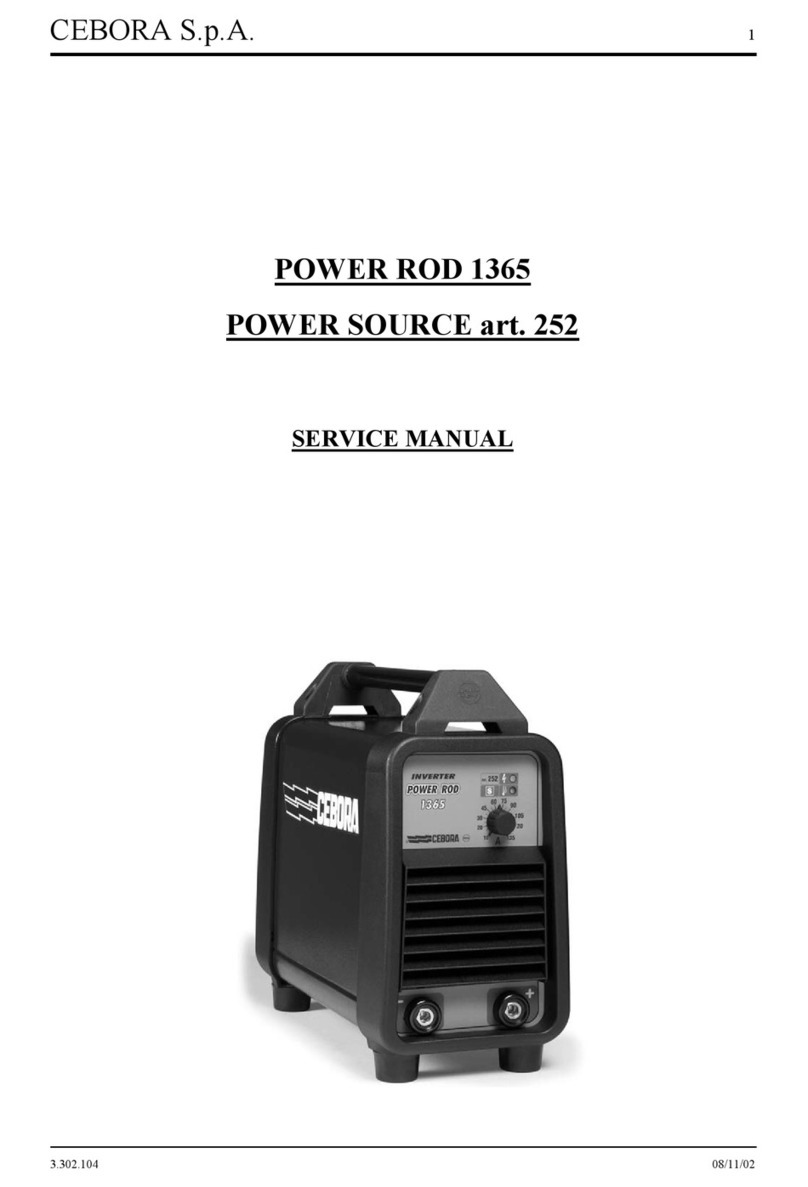

IMPORTANT: BEFORE STARTING THE EQUIP-

MENT, READ THE CONTENTS OF THIS MANUAL,

WHICH MUST BE STORED IN A PLACE FAMILIAR

TO ALL USERS FOR THE ENTIRE OPERATIVE LIFE-

SPAN OF THE MACHINE.

THIS EQUIPMENT MUST BE USED SOLELY FOR

WELDING OPERATIONS.

1 SAFETY PRECAUTIONS

WELDING AND ARC CUTTING CAN BE HARMFUL

TO YOURSELF AND OTHERS. The user

must therefore be educated against the

hazards, summarized below, deriving from welding

operations. For more detailed information, order the

manual code 3.300.758.

NOISE. This machine does not directly produce

noise exceeding 80dB. The plasma cutting/

welding procedure may produce noise levels

beyond said limit; users must therefore im-

plement all precautions required by law.

ELECTRIC AND MAGNETIC FIELDS - May be dan-

gerous. Electric current following

through any conductor causes localized

Electric and Magnetic Fields (EMF).

Welding/cutting current creates EMF

elds around cablesandpowersourc-

es.

The magnetic elds created by high currents may

affect the operation of pacemakers. Wearers of vi-

tal electronic equipment (pacemakers) shall consult

their physician before beginning any arc welding,

cutting, gouging or spot welding operations.

ExposuretoEMFeldsinwelding/cuttingmayhave

other health effects which are now not known.

All operators should use the following procedures in

order tominimizeexposure toEMF eldsfromthe

welding/cutting circuit:

− Route the electrode and work cables together.

− Secure them with tape when possible.

− Never coil the electrode/torch lead around your

body.

− Do not place your body between the electrode/

torch lead and work cables. If the electrode/torch

lead cable is on your right side, the work cable

should also be on your right side.

− Connect the work cable to the workpiece as close

as possible to the area being welded/cut.

− Do not work next to welding/cutting power source.

EXPLOSIONS. Do not weld in the vicinity of contain-

ers under pressure, or in the presence of ex-

plosive dust, gases or fumes. All cylinders