GB Series Cecilware®5

Installation (continued)

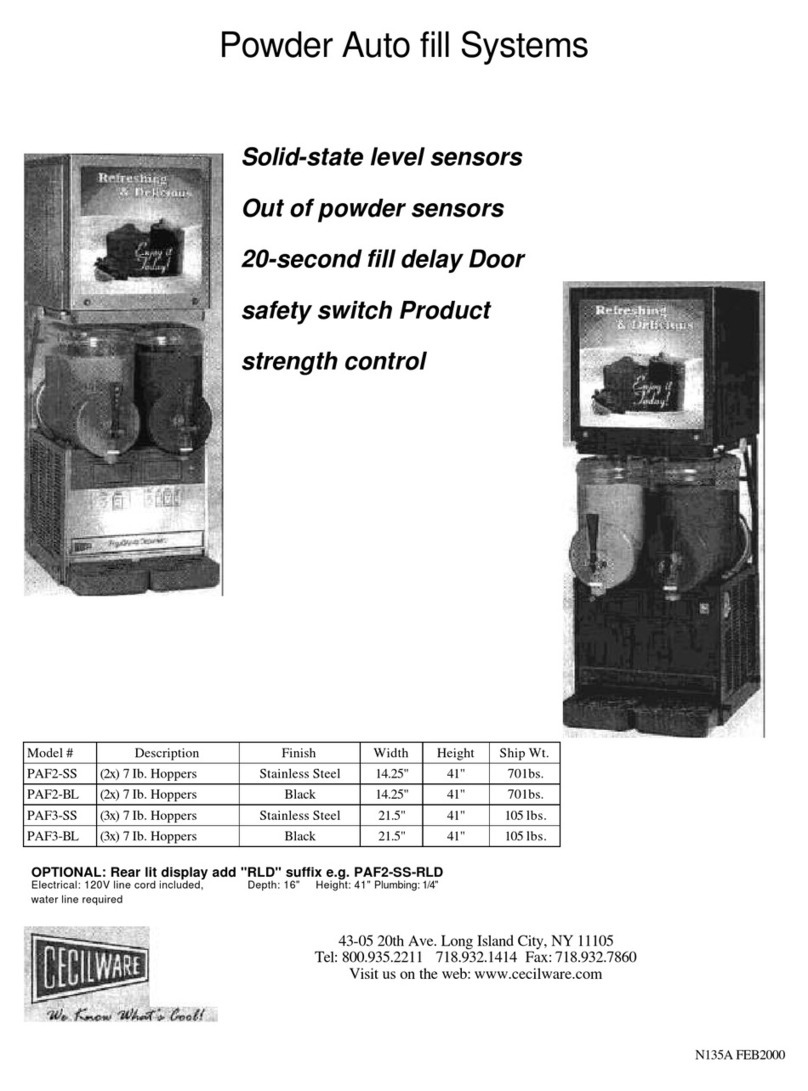

1. HOPPERS: Depress the door latch on the left

side of the door and pull door open to access

the hoppers.

• The hoppers hold up to 14 lbs. (14 kg) of

Cappuccino product and up to 1.5 lbs. (0.7kg) of

freeze dried coffee product, depending on

model.

• To remove the hoppers swing the top

compartment door open and lift out the

hoppers.

• To reposition the hoppers in the

compartment, slide the hopper base back

between the rails until the 1/4" pin at the

bottom of the hopper base falls into the 1/4"

positioning hole of the compartment base

cover.

2. RINSE SWITCH: With the door open, the rinse

switch is located on the left side of the first

Whipper chamber.

• In the RINSE position, it disengages the

hopper motors and allows only water to be

dispensed.

• It is used for flushing out the Whipper

Chambers and to adjust the water dispense

valves for proper flow rates.

3. HEATER SWITCH: This switch is located inside

the cabinet behind the right hopper. Open door

and remove right hopper to access it.

• Its primary function is to shut off the heating

element during the initial priming, start-up

operation of the machine, or whenever the

tank is being drained for service.

Note: The Power Switch and Heater Switch must

be ON in order for the elements to operate.

4. POWER SWITCH: This switch is located on the

left side of the splash panel below the door. On

120V, 1.8 KW and 120/240 or 240V, 3 KW single

element machines the power switch controls all

power to the machine including the heater

elements.

Note: On 120/240V, 6 KW machines, the Power and

Heater Switches are independent of each other.

Both switches must be OFF in order for the

machine to be completely shut down.

5. WATER LEVEL CONTROLS: Under normal

conditions and operation, the water level in the

tank should not drop more than 1/2" (1.3cm)

from the probe. If it does, the tank is not

refilling fast enough. Check the water line and

water filter; they may need cleaning or

replacing.

1. Tank Control Board Part# 349-00012

(Export 240V Part# L706AL)

2. Water Inlet Valve Part# L462AL

(Export 240V Part# L426AL)

3. Water Level Sensor Part# K695QL

Start-up Procedure

NOTICE: Make sure that the Heater Switch, located

behind right hopper with door opened, is in the OFF

position.

1. Connect the 1/4" dia. copper waterline to the

1/4" flare water inlet fitting of the valve.

2. Plug the power cord(s) into a proper receptacle.

Note: GB8M10 units use two power cords. Each cord

must be plugged into a separate receptacle.

3. Activate the Power Switch (Toggle Up). The

door display panel, the red power indicator

light and the green dispense buttons will light

up and the tank will start filling. Allow

approximately 4-5 minutes for the tank to fill.

4. Activate the Heater Switch. Allow

approximately 10-30 minutes for the water to

reach a temperature of 190°F (88°C). The heat

up time will depend on the water inlet

temperature, the input voltage, and the

wattage of the elements in the machine.

5. Place a 8 oz. (240ml) or larger cup under the left

dispense nozzle, press and hold the left

dispense switch for 6 seconds. The machine will

dispense water at the rate of 1 oz. (30ml) per

second. Repeat it several times to check for

consistent output. Repeat same for the other

dispense switches. This procedure checks that

the dispense valves are not air-locked.

6. While the tank is heating, remove the hoppers,

load them with products, and reposition them

back in the machine. When the green ready

light comes on, the tank has reached its brew

temperature and the machine is ready to

dispense the first cup of Cappuccino.

Filling the Hoppers

1. To remove the hoppers, swing the top

compartment door open and lift out the

hoppers.

2. Fill each hopper with the correct product.

3. Reposition hoppers in the hopper

compartment, making sure the hoppers are

properly seated.

If you need help, call Grindmaster-Cecilware Technical

Service Department, (502) 425-4776 or (800) 695-4500

(USA & Canada only) 8 AM - 6 PM EST.

Prior authorization must be obtained from

Grindmaster-Cecilware for all warranty claims.