4 Important Safeguards

Vessel Safeguards

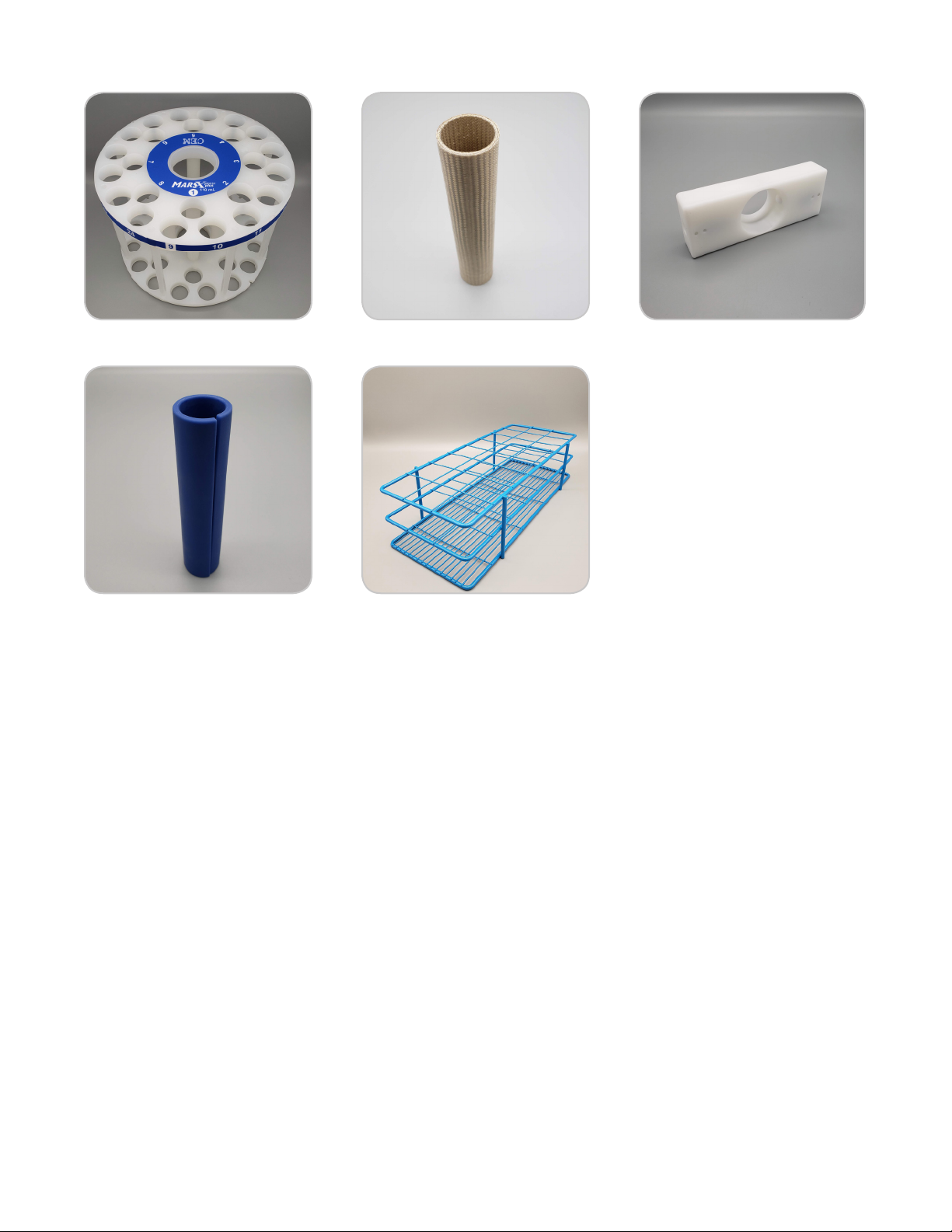

• Only use consumables, accessories, vessels and vessel components purchased directly from CEM or through its

authorized dealer network.

• All vessel components must be dry prior to use.

• Always condition new liners, plugs, and caps.

• Minimum vessel requirement:

• Fiber Optic Control Vessel: 1 Vessel.

• iWave or IR control only: 2 Vessels.

• Do not batch old liners with new liners unless new liners have been conditioned.

• Ensure vessels are assembled properly.

• Group liners with similar sample history and usage.

• Segregate liners for HNO3and non-HNO3applications.

• Do not use a new liner with a set of liners that has been run consistently until the new liner has been

conditioned with that sample type.

• Bake out liners and plugs to remove residual HNO3& NOx gases.

• See "Liner Bake-Out Procedure" for details.

• Bake out liners if TempGuardTM is triggered.

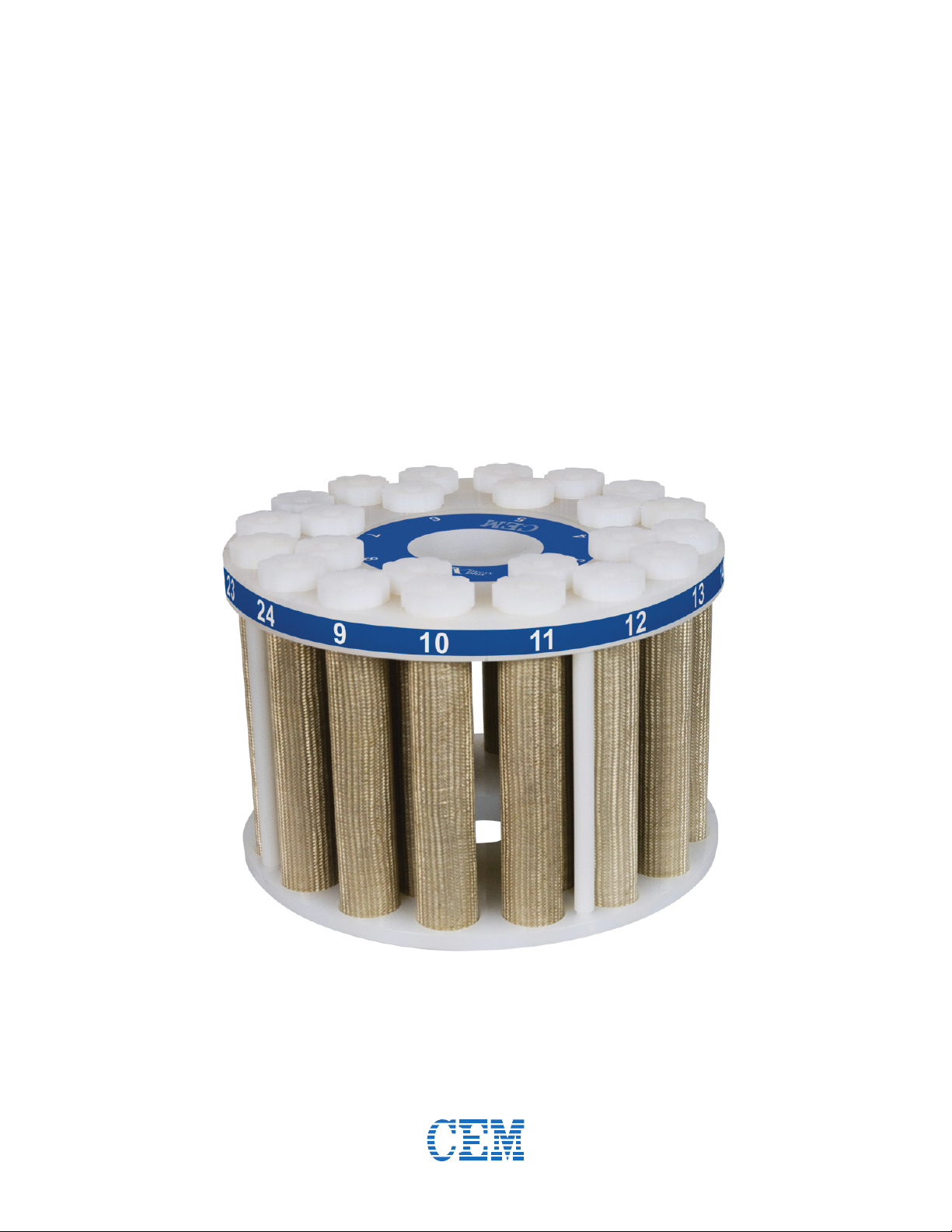

• The fully loaded turntable without sample may be heavy (>25 pounds (11 kg)). Use caution when lifting and

loading into the cavity. Do not place ngers beneath the turntable when placing in the cavity.

Compounds Unsuitable for Closed Vessel Microwave Digestion

WARNING

CEM will not be responsible for damage to equipment and facilities or personal injuries resulting from

microwave digestion of samples that are deemed unsuitable for closed vessel microwave digestion.

Acid decomposition of certain chemical compounds or types of samples constitutes unreasonable, hazardous

misuse of CEM microwave digestion systems. The classes of compounds listed below are unsuitable for closed

vessel microwave digestion because they are highly reactive with oxidizing acids and/or may become nitrated and

potentially explosive. Absence of a particular chemical compound from this list does not imply microwave acid

decomposition of such a sample is safe under all conditions.

• Explosives (TNT, Nitrocellulose, etc.)

• Propellants (Hydrazine, Ammonium Perchlorate, etc.)

• Pyrophoric chemicals

• Hypergolic mixtures (Nitric Acid and Phenol, Nitric Acid and Triethylamine, Nitric Acid and Acetone, etc.)

• Animal Fats (Esters of glycerol capable of nitration and the formation of nitroglycerin or other nitrated organic

compounds)

• Aviation Fuels (JP-1, etc.)

• Acetylides

• Glycols (Ethylene Glycol, Propylene Glycol, etc.)

• Perchlorates (Ammonium, Potassium, etc.)

• Ethers (Cellosolve - Ethylene Glycol Phenyl Ether, etc.)

• Lacquers

• Alkanes (Butane, Hexane, etc.)

• Ketones (Acetone, Methyl Ethyl Ketone, etc.) and Alcohols (Methanol, etc.)