CEM Razor User manual

Other CEM Laboratory Equipment manuals

CEM

CEM Discover SP-D User manual

CEM

CEM Discover SP-D 10/35 Configuration guide

CEM

CEM liberty User manual

CEM

CEM DT-982 User manual

CEM

CEM MARS 6 User manual

CEM

CEM Discover SPS User manual

CEM

CEM MARS 6 User manual

CEM

CEM Q-Dry User manual

CEM

CEM Razor User manual

CEM

CEM Discover Protein Hydrolysis User manual

CEM

CEM EDGE User manual

CEM

CEM Smart Trac II User manual

CEM

CEM DT-986H User manual

CEM

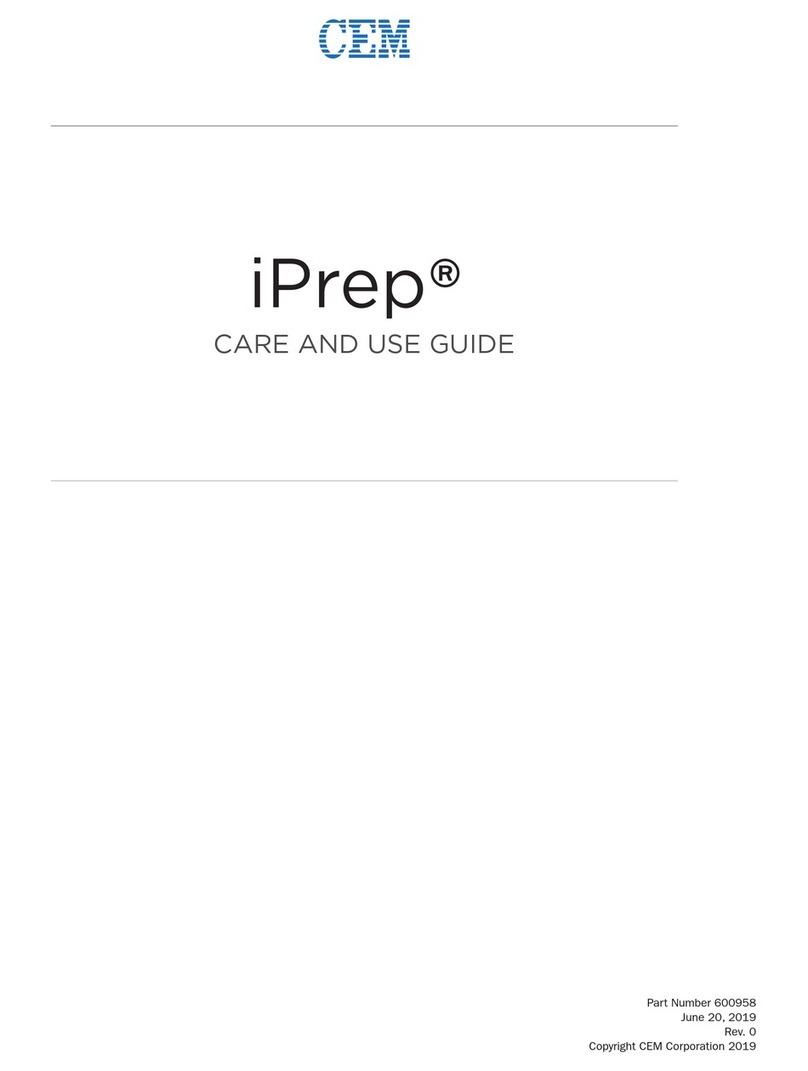

CEM iPrep Series User manual

CEM

CEM MARS Series User manual

CEM

CEM EasyPrep Series User manual

CEM

CEM MARS 6 iWave User manual

CEM

CEM Liberty Blue 551290 User manual

CEM

CEM EDGE User manual

CEM

CEM MARSXpress Plus User manual

Popular Laboratory Equipment manuals by other brands

Belden

Belden HIRSCHMANN RPI-P1-4PoE installation manual

Koehler

Koehler K1223 Series Operation and instruction manual

Globe Scientific

Globe Scientific GCM-12 quick start guide

Getinge

Getinge 86 SERIES Technical manual

CORNING

CORNING Everon 6000 user manual

Biocomp

Biocomp GRADIENT MASTER 108 operating manual