Chapman MG Series User manual

Page 2

Contents

3Introduction

4HSE Information

8 Important Safety Information

Definitions

Safety Information

Transportation Safety

10 Description

Machine Identification

11 Implement Decals

12 Transporting & Lifting

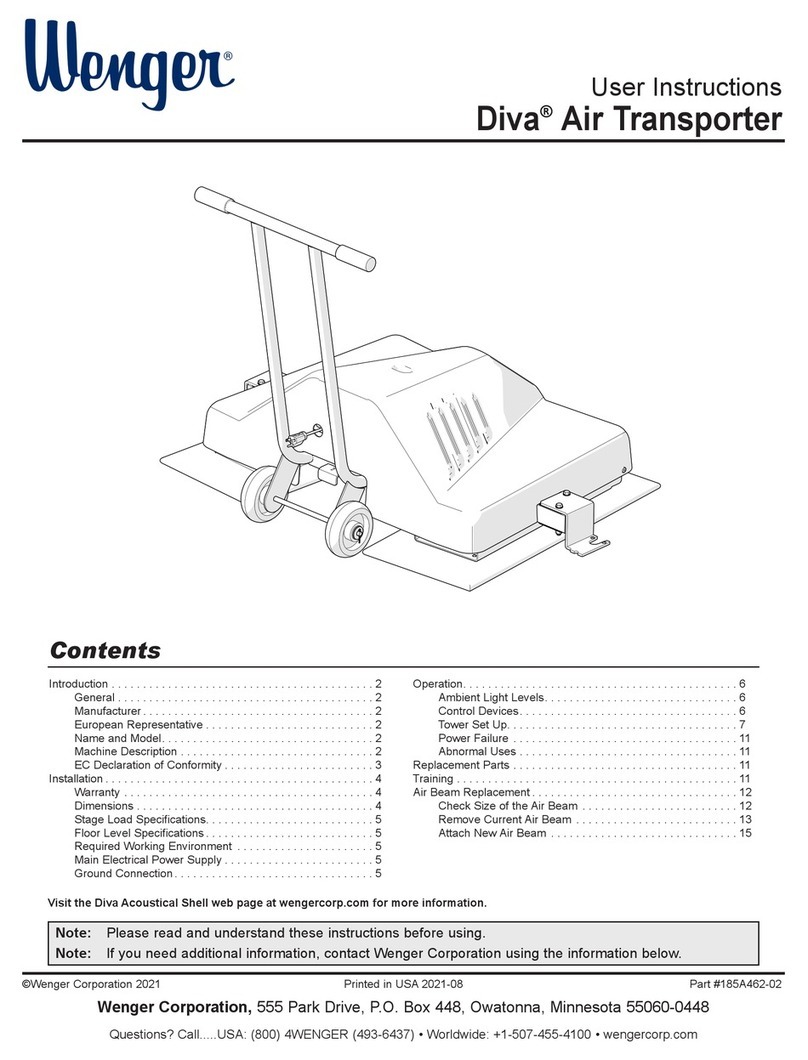

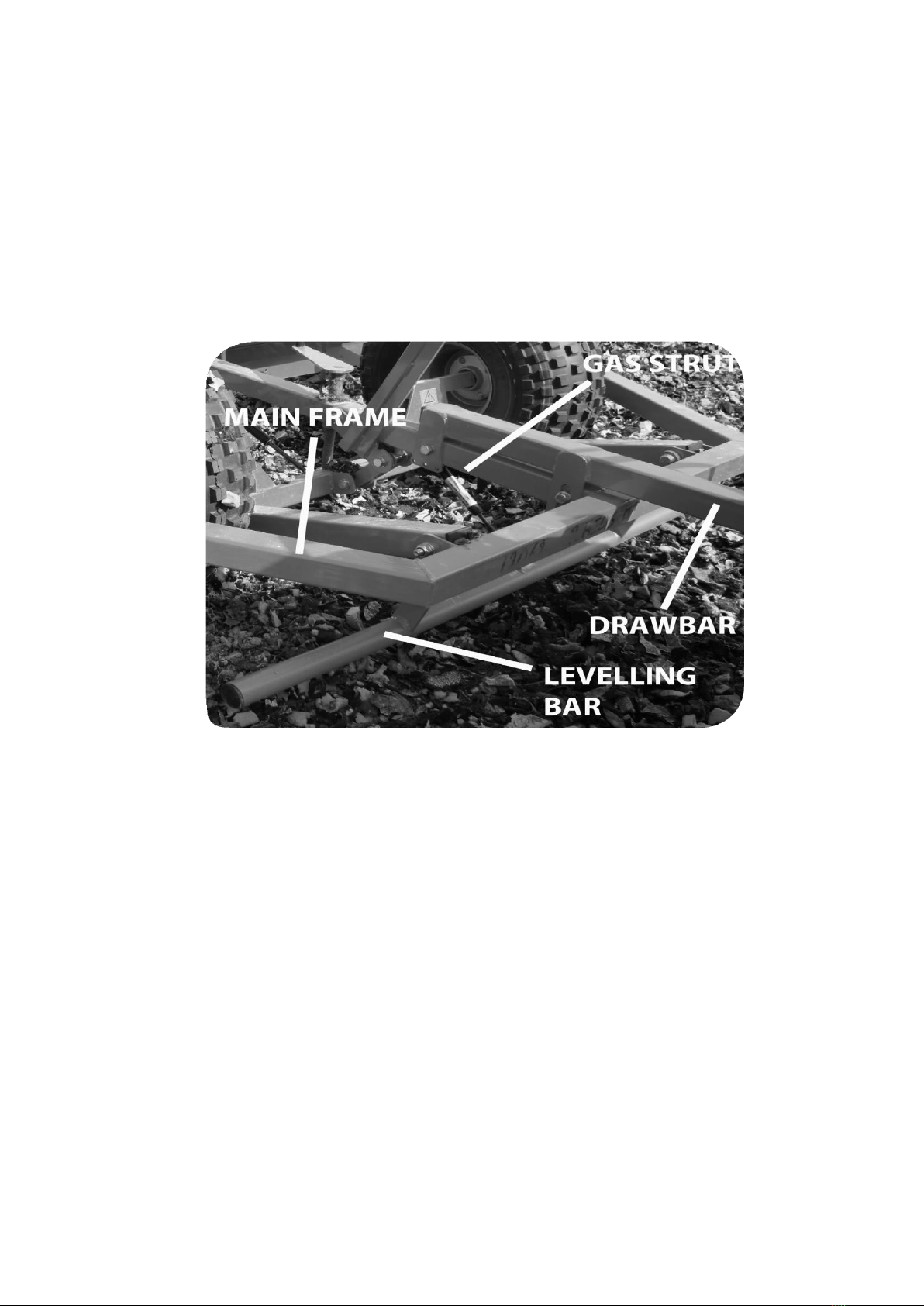

12 Implement Layout

13 Operating Principles

Spring Tines (Optional)

Levelling Blades

Rear Roller (Optional)

16 Assembly

Drawbar Fitment

Tine Kit Fitment

Rear Roller Fitment

Attachment to Towing Vehicle

18 Adjustment

Working Depth

19 Grading Procedure

1Perimeter Grading

2Primary Grading

3Secondary Grading

21 Maintenance & Service

Tyre Pressure

Depth Adjustment Screw

Spring Tine Wear

Blade wear

22 Warranty

The Chapman Warranty

Warranty Conditions

Extended Warranty

Extended Warranty Conditions

Transfer of Warranty

24 Specification

25 CE Declaration

Page 3

Introduction

By purchasing a Chapman Machinery MG250 Manége Grader you have purchased

a product designed to give a first class finish and also have a long life span, if used

and maintained correctly as detailed in this manual.

A variety of options are available from the factory, and many of these are also suit-

able for retro-fitment if your requirements change, or you purchase this machine

used, and wish to use a different set-up. We are more than happy to offer advice &

support throughout the lifetime of the machine.

This manual also contains important Health & Safety Executive information and

guidelines.

NOTICE:

THIS MANUAL MUST BE HANDED TO THE OPERATOR BEFORE USE. THE OPERATOR

MUST UNDERSTAND FULLY THE CONTENT OF THIS HANDBOOK BEFORE USING THE

MACHINE FOR THE FIRST TIME. OF THE IMPLEMENT IS RESOLD, THIS MANUAL

MUST ACCOMPANY THE MACHINE.

Note:

The information contained in this manual is correct at the time of going to press.

However, in the course of development, changes in specification are inevitable.

Should you find the information given differs from your machine, please

contact Chapman Machinery direct for any after sales advice.

Chapman Machinery Ltd

Hele Barton

Week St.

Mary

Holsworthy

Devon

EX22 6XR

Tel:01288 308149

Page 4

HSE information sheet

Safe use of all-terrain vehicles (ATVs)

in agriculture and forestry

HSE Information

Agriculture Information Sheet No 33

Introduction

This information sheet gives advice on the safe use of

ATVs. It covers the two main types used in off-road

working in agriculture and forestry, which are:

●

sit-astride ATVs: any motorised vehicle designed

to travel on four low-pressure tyres on unpaved

surfaces, with a seat designed to be straddled by

the operator and handlebars for steering control.

They are intended to be used by a single operator

with no passenger. However, this type also

includes ATVs intended for use by a single

operator, but with a special seat for a passenger

behind the operator. These vehicles are generally

called ATVs in agriculture, quad bikes in leisure

use and all-terrain cycles (ATCs) in forestry;

●

sit-in machines: side-by-side mini-utility vehicles,

usually with a steering wheel, where the driver sits

in a conventional seat and there is generally

seating for one or more passengers. These are

often called ATVs in both agriculture andforestry.

The ATVs covered by this sheet are those designed for

off-road use only. However, agricultural, horticultural

and forestry users can register an ATV as a ʻLight

agricultural vehicleʼ for limited on-road use in

connection with their business (see ʻRoad useʼ).

Accidents

Both types of machine are designed to cope with a

wide variety of terrain types, including steep slopes, but

if used outside their safe operating parameters they

can very rapidly become unstable. This is why most

ATV accidents involveoverturning.

On average, two people die each year in ATV

accidents. Non-fatal accidents are estimated to amount

to over 1000 serious injuries per year. The underlying

causes of accidents were usually one or more of the

following:

●

lack of structured training and/orexperience;

●

incorrect/lack of protectiveclothing;

●

excessive speed;

●

carrying a passenger or an unbalancedload;

●

tipping on a bank, ditch, rut or bump;

●

a steep slope combined with other factors, eg

ground or load conditions;

●

towing excessive loads with unbrakedequipment.

Route planning and stability

Most accidents with these machines have occurred

where they have either been driven on new routes over

steep ground for the first time, or have been carrying or

dragging destabilizing loads. When travelling over

rough terrain, get to know your own ground and stick to

planned routes where possible. Walk new routes if

necessary to check for hidden obstructions. Allow for

changes in ground conditions and for the destabilizing

effect of loads orattachments.

Sit-astride ATVs (quad bikes/ATCs)

REMEMBER - GET PROPERLY TRAINED AND

ALWAYS WEAR HEAD PROTECTION

Training

Under the Provision and Use of Work Equipment

Regulations 1998 (PUWER), there is a legal

requirement for employers to provide adequate training,

and to ensure that only employees who have received

appropriate training in their safe use, including the use

of any towed equipment or attachments, are permitted

to ride ATVs. The same requirements apply to the self-

employed. HSE regards training provided by

recognized training providers as being adequate for the

purposes of PUWER.

You can get details of suitable training courses from

franchised ATV dealers, manufacturers’ websites, EASI

(European ATV Safety Institute), the Forestry

Commission and Lantra Awards. Training is also

available from agricultural trainers and colleges

accredited by these bodies.

Page 5

Protective clothing

More than half of all ATV riders have been thrown off at

some time. As these machines are not fitted with either

a cab or roll bar, your only protection is what you wear.

●

Head protection is vital. The majority of ATV

fatalities in the UK in the last ten years have been

caused by head injuries. Nobody who died from

head injuries was wearing a helmet. Helmets

would certainly have prevented most, if not all, the

deaths. You should always wear a helmet when

riding an ATV. Helmet types suitable for ATV

operations, depending on the circumstances, are

motorcycle helmets to BS 6658:1985 or UN ECE

regulation 22.05, equestrian helmets to BS EN

1384:1997, including specialist ATV helmets, cycle

helmets to BS EN 1078:1997 and mountaineering

helmets to BS EN 12492:2000. All helmets should

have a chinstrap and be capable of being used

with suitable eye protection. The type of helmet

chosen should be based on an assessment of the

circumstances in which the ATVwill be used, eg

the types of surface travelled over and anticipated

speeds. The harder the surface and higher the

speed the greater the degree of protection

needed. NB: Forestry helmets and industrial

hard hats are not acceptable for any ATV

operations.

●

Wear clothing that is strong and covers your arms

and legs. Gloves are useful for protection and to

keep hands warm in cold weather for good control

of the ATV.Wear sturdy, ankle-covering footwear,

eg boots or wellingtons that are strong, supportive

and have good wet grip.

●

Protect your eyes from insects and branches with

either a visor or goggles.

Passengers

Never carry a passenger on a sit-astride ATV unless

it has been designed for, and is suitable for, that

purpose. The long seat is for operators to shift their

body weight backwards and forwards for different slope

conditions, not for carrying passengers. Passengers on

specially adapted ATVs must wear a safety helmet. Do

not carry a passenger in a trailer behind an ATV as any

movement can make the machine unstable, particularly

with independent rear suspension and trailers with

axles wider than the ATV.

Safety checks and maintenance

Off-road use is especially harsh on equipment so it is

essential to carry out safety checks and maintenance in

accordance with the manufacturerʼs recommendations.

In particular, pre-ride safety checks should always

include:

●

tyre pressures. These are low, eg around 2-7 psi,

so even a 1 psi (0.07 kg/cm2) difference in

pressure can cause vehicle control problems.

Use a gauge that is designed for measuring and

displaying low pressures –usually supplied with

the ATV;

●

brakes and throttle. Check that the brakes give a

safe straight stop and that the throttle operates

smoothly in all steering positions. Brakes can

have a relatively short life in farming or forestry

environments and need frequent cleaning, regular

adjustment and propermaintenance.

Safe driving methods

ATVs are rider-active machines, so rider positioning is

vital to operate them correctly. The position of the rider

on the machine needs to be changed depending on the

terrain and motion. Riders must have the ability to

move and balance the momentum of the ATV with their

own body weight. Plan routes (and review the plan if

the route is used regularly) to assess risks.

The following advice is no substitute for formal

training.

●

Most ATVs have no differential and so do not

handle in the same way as other machines. This

means that when you turn, the ATV tries to keep

going in a straight line.

●

When cornering on an ATV with no differential or

with the differential lock engaged, where your

body weight needs to be positioned depends on

how sharp the corner is and on how fast you are

going. Correct body position allows you to transfer

weight to the outside of the turn through the

footrests while maintaining balance with the torso.

This lets the inside wheels skid slightly allowing

the ATV to make the turn properly.

●

Youmust understand how the transmission

system of your machine will affect engine braking

for both riding, and recovery of stalled ATVs, on

slopes.

●

When riding across a slope, keep your weight on

the uphill side of the ATV.

●

When going downhill, slide your weight

backwards, select a low gear and use engine

braking, reducing the need to use the brakes.

●

When going uphill, it is important to review the

route before starting the climb. Move your weight

forwards and maintain a steady speed. It is

important to shift your body weight forwards as

much as possible. If necessary stand up and lean

forward, keeping both feet on the footrests at all

times and always maintain momentum.

●

Avoid sudden increases in speed, as this is a

common cause of rearward overturning accidents,

even from a standing start on flat ground where

there is good grip.

Page 6

●

Never put your foot onto the ground to

stabilise an ATV when riding, but shift your

weight across the ATV away from the imbalance.

●

Always read the owner’s manual.

Trailed equipment and loads

Ensure all riders know the manufacturer’s

recommended towing capacity and drawbar loading

limit. Always operate within these requirements.

Remember that your ability to control the ATV by your

body movements will be considerably reduced when

carrying a load or towing a trailer.

●

When selecting trailed equipment look for:

-

over-run brakes;

-

a swivel hitch drawbar;

-

bead lock rims on wheels;

-

a low center of gravity and a wide wheel

track;

-

a long drawbar; and

-

attachment points for securing a load.

●

Check the weight ratio between your ATV and its

trailed load. This needs to be assessed for each

operation. As a general guide, on level ground,

braked trailed equipment can be a maximum of

four times the unladen weight of the ATV.For

unbraked trailed equipment the maximum should

be twice the unladen weight. These loads should

be reduced when working on slopes, uneven

ground or poor surface conditions. Follow the

manufacturer’s advice for your particular machine.

●

Weight transfer is also important. Stability and

resistance to jack-knifing is improved if some load

is transferred onto the ATVʼs drawbar.

Approximately 10% of the gross weight of the

loaded trailer is recommended, but this should not

exceed the manufacturer’s drawbar loading limit.

Remember that weight transfer can change

dramatically when you start going up or down hill.

●

When selecting mounted equipment, make sure it

is within the manufacturer’s approved weight limit,

with a low center of gravity, and controls which are

easy to operate but do not create a hazard. Where

equipment is added to one end of the machine,

add ballast at the other end to maintain stability.

●

Loads carried on racks must be well secured, e.g.

with ratchet straps, and be evenly balanced

between the front and rear, except where they are

deliberately altered to aid stability when going up

or down a slope.

●

Only tow a load from the hitch point. Loads towed

from other points such as the rear rack have

caused sudden rear overturning even on slight

slopes or with slight acceleration. Ropes or chains

should not be used to drag a load where they can

become caught on a wheel. This may lead to

entanglement with the brake cable, causing

unexpectedbraking.

Using sprayers

●

Pesticides should be used in accordance with the

Code of Practice for using plant protection

products published by Defra. (Available from

Defra Publications, ADMAIL 6000, London SW1A

2XX Tel: 08459 556000.)

●

Sprayers should meet the requirements of BS EN

907 and be fitted with an induction hopper unless

the filling point is less than 1.5 m from the ground

and within 0.3 m from the edge of the sprayer. A

separate clean water tank for washing must be

provided containing at least 15 litres of clean

water and a tap that allows the water to run

without being continuouslypressed.

●

When buying a sprayer look for a low center of

gravity and internal baffles to reduce liquid surge

to improve stability when turning on slopes.

●

ATVs should only be used with rear-mounted

spray booms or other equipment that reduces the

risk of pesticide exposure to the operator.

●

Do not hold a spraying lance while riding your

ATV,as two hands are needed for safe control.

Accessories

Beware of the potential dangers of accessories which

are not approved by manufacturers, e.g. home-made

gun racks and boxes. Either use accessories

supplied/approved by manufacturers or seek their

advice as to the suitability of those sourced elsewhere.

Any weight added above the center of gravity will

decrease the ATVʼs stability.

Children

●

Never carry a child as a passenger. It is illegal and

will reduce your ability to control the ATV.

●

Children under 13 are prohibited from using an

ATV at work. Over 13 they should only ride ATVs

of an appropriate size and power, after formal

training on a low-power ATV.

●

Check and adhere to the manufacturer’s

minimum age recommendations for your ATV.

The ratio of a child’s weight to that of the ATVis

significant, as weight transfer is the key to safe

handling.

●

Always refer to the owner’s manual and warning

labels on the machine.

Roll bars, lap straps and weather cabs

●

Roll bars are not recommended for sit-astride

ATVs. Research has shown that they are more

likely to increase injuries by obstructing the rider,

either when thrown off or when jumping off during

an overturn. This causes the rider to fall to the

ground alongside the ATV and increases the

likelihood of injury. PUWER does not require roll

bars where they would increase the overall risk.

Page 7

●

Lap straps should not be fitted. They prevent

active riding and would be potentially lethal

without a full cab or roll cage.

●

Weather cabs restrict a rider’s ability to jump clear

in an overturn. The rider is likely to be crushed

within the cab unless it is strong enough to

withstand the forces involved. Carefully assess the

risks for your particular conditions of use before

fitting any such structure and consult the

manufacturer forinformation.

Road use

For road use, ATVs and trailers have to comply with the

Road Vehicles Construction and Use Regulations 1986

(as amended) and the Road Vehicles Lighting

Regulations 1989 (both enforced by the police) and be

licensed in the appropriate class. They do not require

an MOT and the maximum permitted speed is 20 mph.

The minimum age for drivers is 17 and they need a

Category B licence.

Sit-in ATVs

Sit-in ATVs include the Mule, Rhino, Argocat, Scot-

Track, Gator, Ranger, Hiler, Goblin and other similar

machines. They all have conventional sit-in seats and

the driver does not use weight transfer to steer or

control stability, although load balance is important in

this respect. They range from machines designed for

purely rough terrain to utility vehicles, which are also

commonly used fully off-road.

Training

The legal requirements for training are the same as for

the sit-astride ATVs. You should request advice on

training from your suppliers, the training providers

previously mentioned or, for forestry operations, from

the Forestry Commission.

Rollover protection and seat belts

The requirements for these machines are quite different

to those of sit-astride ATVs.

●

Where there is a risk of the machine rolling over,

PUWER requires an employer to fit some device

to protect employees (the self-employed have the

same duty to themselves). This would normally be

a cab, rollover frame or roll bar. Such a structure

could either be provided as part of the original

machine or, if added afterwards, should be CE

marked and approved by a recognized test body.

●

Restraining devices such as seat belts should be

fitted and worn by the driver and passengers

where a roll bar or cab is fitted.

●

Where a machine is amphibious and used on

deep water as opposed to marshland, then the

seat restraints (and possibly roll frame) could

increase the overall risk rather than reduce it. In

this case, do not use seat restraints while on the

water. Assess the risk from the roll frame

according to its design and the likelihood of

trapping the occupants if the machine should sink.

●

If there is a risk of overturning, employees at work

who are carried in the rear of sit-in ATVs should

be protected by rollover protection and seat

restraints.

●

Children should only be carried in these vehicles if

they are in a passenger seat and wearing a

properly designed and fitted seatbelt.

Parking

If you have to park on a slope, always park across it

unless it is too steep. Accidents have occurred where

machines have run down slopes because of poor brake

maintenance or application, particularly while they are

being loaded, and movement or the increase in weight

sets the machine into motion.

Further information

HSE priced and free publications are available by mail

order from HSE Books, PO Box 1999, Sudbury, Suffolk

CO10 2WA Tel: 01787 881165 Fax: 01787 313995

Website: www.hsebooks.co.uk (HSE pricedpublications

are also available from bookshops and free leaflets can

be downloaded from HSEʼs website: www.hse.gov.uk.)

For information about health and safety ring HSEʼs

Infoline Tel: 0845 345 0055 Fax: 0845 408 9566

Text phone: 0845 408 9577 e-mail:

hse.infoline@natbrit.com or write to HSE Information

Services, CaerphillyBusiness Park, Caerphilly CF83 3GG.

© Crown copyright This publication may be freely

reproduced, except for advertising, endorsement or

commercial purposes. First published 05/99. Please

acknowledge the source as HSE.

This leaflet contains notes on good practice which are not

compulsory but which you may find helpful in considering

what you need to do.

Page 8

Important Safety Information

Always read this manual before fitting or operating the machine –whenever

any doubt exists contact your dealer or the Chapman Machinery Service

Department for advice and assistance.

Use only Chapman Genuine Service Parts on Chapman Machinery equipment and at-

tachments.

Ensure to:

-Maintain the machine correctly as per this manual

-Ensure all nuts, bolts and fixings are secure before first use, and check at

-regular intervals during operation

-Avoid excessively steep ground or adverse land conditions likely to damage

the machine

-Follow all recommended service instructions

-Attach to a vehicle suitable to the purpose

DEFINITIONS

The following definitions apply throughout this manual:

WARNING

An operating procedure, technique etc., which –

can result in personal injury or loss of life if not observed carefully.

CAUTION

An operating procedure, technique etc., which –

can result in damage to either machine or equipment if not observed carefully.

NOTE

An operating procedure, technique etc., which –

is considered essential to emphasis.

LEFT & RIGHT HAND

This term is applicable to the machine when attached to the towing vehicle and is

viewed from the rear –this also applies to tractor references.

Page 9

Safety Information

-

Do not operate this equipment unless you have studied this manual in full

-

Only use this machine for its designated task - improper use is both highly

dangerous and damaging to machine components

-

Both operators & maintenance fitters should be familiar with the machine and

fully aware of dangers surrounding improper use or incorrect repairs

-

Before starting, carry out a visual check on both machine & towing vehicle as re-

grads functionality, road safety & accident prevention rules

-

During checks or repairs, ensure the machine cannot be started or moved by other

persons by mistake

-

Never wear loose clothing which could get caught in rotating equipment

-

Never carry passengers on the towing vehicle

-

Do not stand near the machine when operating

-

Damaged or missing safety decals must be replaced immediately

-

Do not operate whilst under the influence of drugs, alcohol or similar substances

-

Exceed maximum towing speed of 10mph

-

Leave the machine unattended where animals could come into contact with it

Transportation Safety

-

When transporting, especially over rough ground, reduce speed to prevent damage

to machine.

-

This machine is not road legel. DO NOT tow on public highways

Page 10

Description

The MG range of equipment are non-powered machines designed to be towed by a

suitable vehicle such as a 4x4, UTV or ideally an ATV.

Designed around a base machine suitable for simple pure sand areas, options and

accessories can be added quickly and easily to enable the MG250 to tackle almost

any arena surface type.

With a 2.4m working width, you can spend less time maintaining your arena and

more time actually using it. Built from heavy duty box section steel, with easily re-

place able wearing parts, and top quality zinc primer & powder coated finish, the

MG250 will withstand years of use.

These machines should however only be used to perform tasks for which they were

designed - use of the machine for any other function may be both dangerous to per-

sons, and potentially damaging to components. Use of the machine beyond the stated

usage may invalidate any applicable warranty, as well as being potential in breach of

applicable safety regulations.

Identification

Each machine is fitted with a serial plate which details the following:

1. Model No.

2. Date of Manufacture (DOM)

3. Serial No.

4. Mass

When enquiring regarding spares or additional equipment, ensure you have this infor-

mation to hand.

Page 11

Implement Decals

If your implement does not contain all of the decals shown below, please contact

Chapman Engineering for replacement decals before use.

*Carefully read operators manual before handling this machine. Observe instructions

and safety rules when operating.

*Never reach into the crushing danger area as long as parts may move.

Page 12

Transporting & Lifting

Ensure that the vehicle used to transport or operate the Ménage Grader has adequate

lifting and towing capacity. Follow towing vehicle manufacturer capacity guidelines.

When lifting or moving the Ménage Grader for transport or delivery purposes, ensure

to locate the lifting straps evenly across the frame to take the implement weight safe-

ly. When transporting the product in assembled form ensure it is adequately strapped

down to prevent movement during transportation, and ensure the transportation

complies with all applicable highway laws.

Under no circumstances should the machine be towed on public highways.

Implement Layout

Page 13

Operating Principles

The grader has three main operating principles, depending on optional accessories fit-

ted:

Spring Tines

The spring tines agitate the surface, causing stirring and flicking of the arena mate-

rial, which fills in divots and levels surface lumps. This is an essential component of

good surface maintenance for rubber crumb and fibre-stabilised sand surfaces, but is

also highly useful for plain sand surfaces.

The working depth of the tines is recommended to be 45mm for most surfaces (the

middle bolt holes). Greater tine depth will mean greater surface lift, giving a ‘softer’

resulting ride, however, a greater static load is placed on the towing machine, so only

large towing machines (large ATVs, UTVs etc.) will have adequate traction to work to

design spec.

The tines are attached by an elegant single-bolt mechanism, to facilitate quick and

easy replacement should one fail, or when the tines wear out. Replacement tines are

easy to fit, and are available for a very reasonable price direct from Chapman Engin-

neering.

Levelling Blades

The rear levelling blades smooth the surface and move material forwards to fill in

divots and give a level arena. The effect of the blades passing over the material then

firms the surface lightly to give a consistent surface. The blades feature a special an-

glad profile to more effectively draw material forward and level it.

The use of the perimeter blade is twofold:

-In the parallel position the blade works to level and consolidate across the entire

width of the machine. This is used for the bulk of the arena grading. The machine

should only be towed to/from the arena with the blade in this position.

-In the angled position the blade draws material towards the center of the machine.

This is used primarily to draw material in from the edge boards, and is especially

useful when circular schooling work has been done, as it can quickly draw in and

level the banking that inevitably occurs. The two edge roller wheels prevents damage

to the edge boards whilst ensuring the grader blade can operate right up to the edge

boards. For arenas with low kick boards, an optional low-height roller wheel can be

fitted - contact your distributor for details.

Page 14

Rear Roller (Optional)

The rear is an optional fitment specifically designed for use with advanced surfaces

such as CLOPF, Turf float and other fibre-stabilised surfaces. The roller works well on

any arena type, consolidating and ‘firming’ the surface, to give a true one-pass finish

for busy liveries & riding schools. A useful attachment which save you the expense of

a separate roller & the hassle of changing implements regularly.

There are three operating modes:

-

No roller. This mode is used when drawing material in from the edge boards, or

when a firmed surface is not desired. The machine locks in this position with the use

of two clips, for transportation & storage. *Note: This places a considerable negative

load on the ball hitch. TAKE CARE when unhitching the machine in this configuration.

-

Following roller. This mode is used so that the roller is following both the spring

tines & blades. This is the primary mode of use, giving an agitated, level and firmed

surface in one pass.

Page 15

Rear Roller Notice:

The rear roller is, by the very essence of its purpose for rolling & consolidating the

surface, HEAVY. The design of the roller mounting arrangement is such that the

roller automatically lifts off the surface when the machine is changed from “work

mode” to “transport mode”.

A gas strut is fitted as standard to ease lifting of the roller, however a reasonable

amount of force is still required in order to do so. An optional electric lift and depth

control system can be fitted, please contact your Distributor for details.

It is recommended NOT to attempt to lift the machine out of work mode with the

roller set in the upright position, as shown by the image below, and to instead raise

the roller to this position after lifting the machine out of work.

The gas strut does a lot of work when lifting the roller, and therefore it is essential

that this is maintained. If the gas strut becomes worn, or the roller becomes heavy to

lift, replacement is quick and simple.

Page 16

Assembly

Drawbar Fitment & Adjustment

With the machine on the ground raise the transport lever so that the machine is in

‘work’ position. With the supplied bolts, attach the drawbar through the two fixing

holes located on the frame and tighten to hand-tight only. Attach the gas strut to the

mounting brcket using the fixings supplied. For most surfaces attach the gas strut to

the middle attachment point.

Attach the grader to the towing machine, and adjust drawbar angle until the main

frame of the machine runs approximately parallel with the ground when in working

mode. Tighten mount bolts firmly before use, and CHECK TIGHTNESS OF ALL BOLTS

after first use.

Tine Depth Adjustment

It is recommended that the middle tine setting is used for the initial fitment, giving

a tine working depth of approximately 45mm below the surface.

Adjust the depth of the tines by moving the main bar up or down on the mounting

brackets. Ensure the mounting bolts are suitably tight after adjusting.

Page 17

Rear Roller Fitment & Adjustment

Safety Notice

CAUTION - REAR ROLLER IS HEAVY

Lower the machine to the ground by engaging ‘work’ mode. maneuver the roller at

the rear of the machine so that the mounting holes align. Attach the roller using the

two supplied M12 x 60mm bolts, washers and nuts utilizing the rearmost holes, as

shown below.

Attachment to Towing Vehicle

Any vehicle with a 50mm ball hitch can tow the machine. Ensure the hitch is securely

fastened, and the machine is in transportation mode (transport lever raised) before

moving off.

The recommended towing vehicle for this grader is either an ATV or UTV or 4x4 due

to the optimum balance between weight, maneuverability and traction.

Safety Notice

ATVs 250cc or under are not recommended for machines with tine kits and/or rear

rollers fitted due to tractive limitations. Some small ATVʼs may be ok, depending on

tyre condition and towing capacity. Four-wheel drive (if applicable) should be engaged

at all times.

Page 18

Adjustment

Working Depth

Note: Ensure both tyres operate under the same working pressure (Recommended

4-6psi, 8psi for graders equipped with rear roller)

-Move the grader to the arena that is suitable for test grading

-Ensure the perimeter blade is in the parallel position

-Lower the machine to the ground by engaging working position. Screw the working

height adjustment down so that it contacts the axle crossbar. Lift the machine of the

ground by engaging transport mode, and screw the adjuster down a further rotation.

This provides a good basis to begin with.

-Move forward slowly to assess the grading depth, and adjust as necessary.

-An element of trial-and-error is required to find the best settings for each arena,

and the optimum working depth will change through the year due to variables such

as surface temperature, water content etc.

-Once you find a good depth setting for your arena, the screw adjuster can be left

in this position so that you can easily grade the arena next time with minimal adjust-

ment.

NOTE: The transport lever should ALWAYS be raised away from the working position

to adjust the working depth adjustment screw to prevent unnecessary cosmetic dam-

age to the axle assembly

Page 19

Grading Procedure

There are three main parts to the grading process:

1Perimeter Grading

The edge material of the arena should always be levelled first upon entering the site,

and is extremely important in preventing the material becoming banked around the

perimeter of the arena.

Page 20

How to use the perimeter blade on the MG250 (Sept 2016 onwards)

1. Your machine will have the perimeter blade attached to the main frame on the

right hand side as shown below.

2. With the machine in transport mode remove steel pin and turn the blade to a 90-

degree angle (see below) making sure the pin holes are aligned. The perimeter

blade can also be used on the left hand side of the machine.

3. Slide the pin back into place, ensuring the blade is secure.

This manual suits for next models

1

Table of contents

Other Chapman Farm Equipment manuals

Popular Farm Equipment manuals by other brands

Redexim

Redexim Verti-Drain 1513 User manual and parts book

BIG BALE

BIG BALE Transtacker Standard Operation and maintenance manual

USC

USC LPV Series Operator's manual

KUHN

KUHN GA 8001 H Assembly and operators manual

KUHN

KUHN FC 4000 R Owner's/operator's manual

Rabe

Rabe KORMORAN PL V 180 operating instructions