2

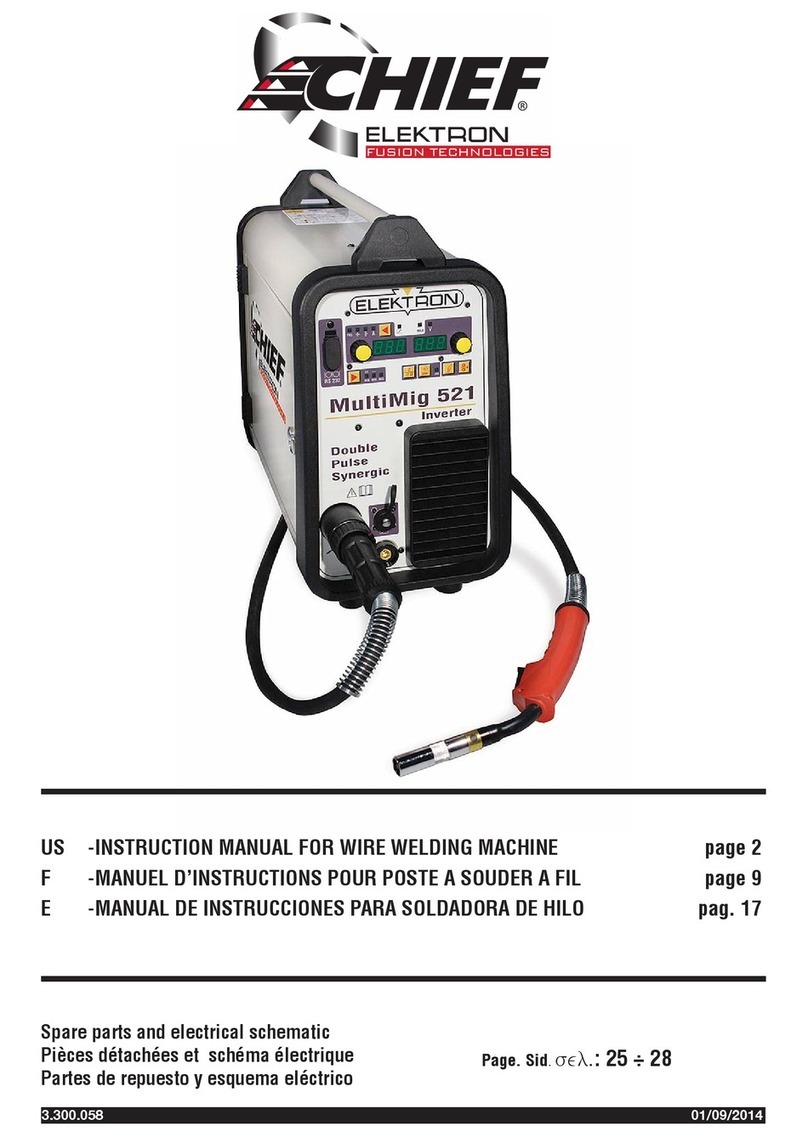

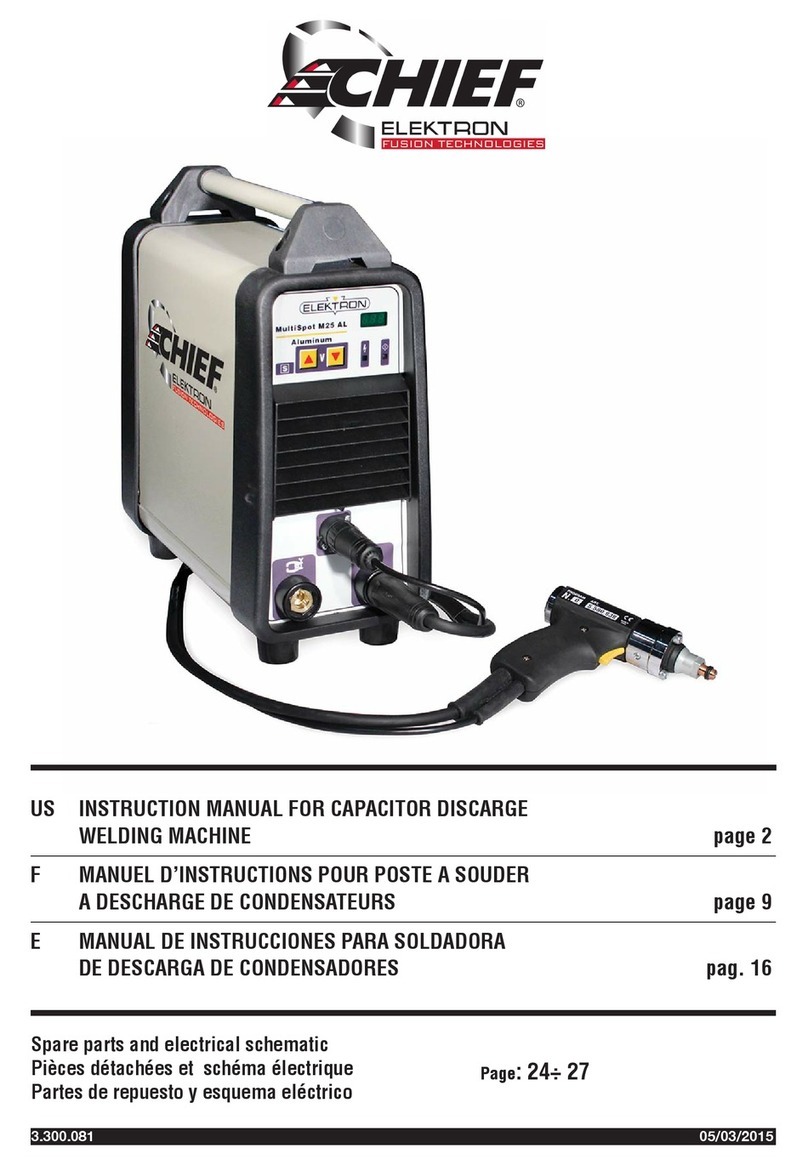

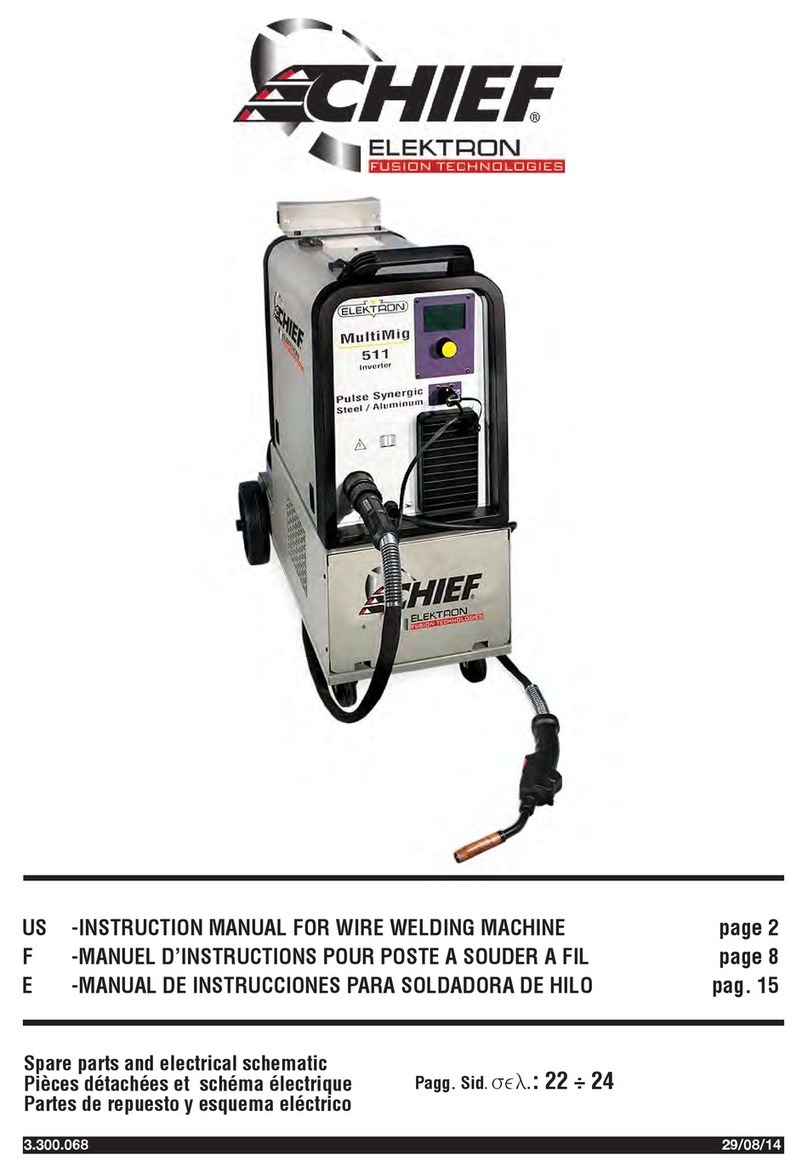

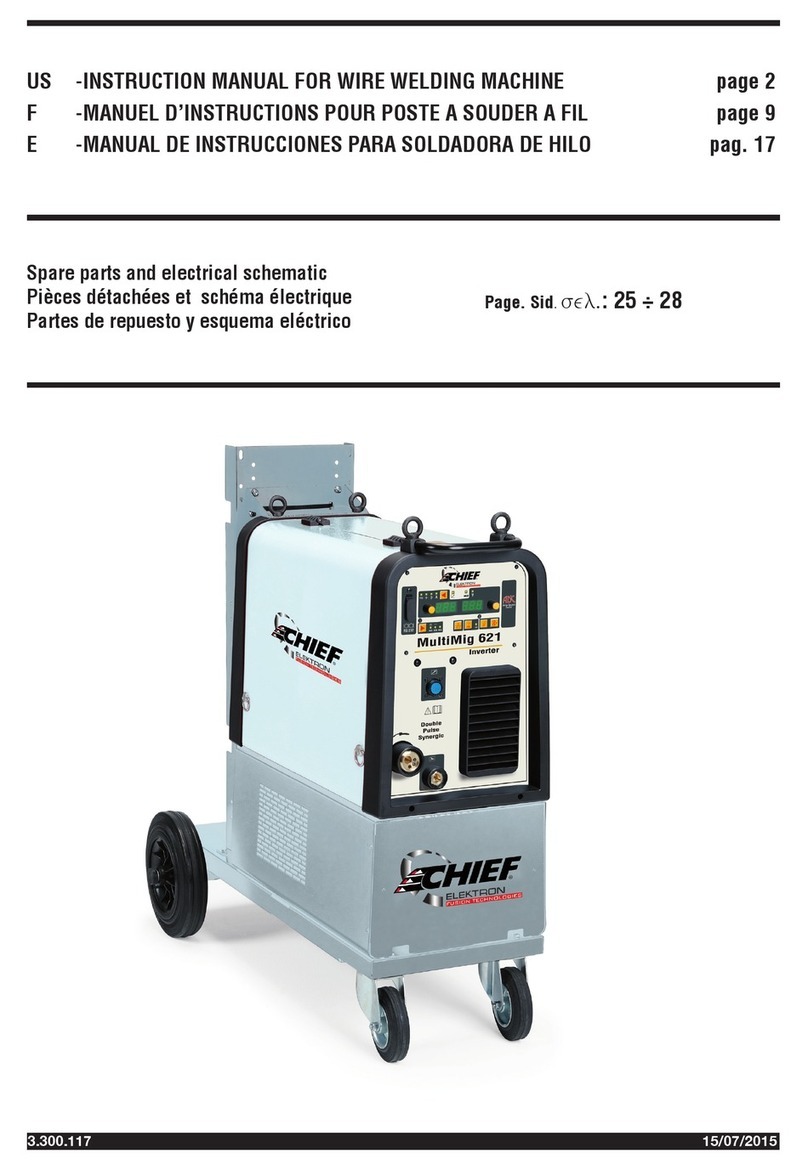

OPERATION MANUAL

Read this manual carefully before using the machine.

Failure to respect the rules described herein shall exempt the manufacturer from any liability.

The machine has been designed, built and protected for the functions described below. Any other use not

explicitly included shall be considered unacceptable.

The machine must be used in suffiently ventilated rooms, in the absence of dust and moisture; in any case,

where there is no risk of fire, explosion, or flooding.

The machine must be started, used and serviced by qualified personnel. Always follow current safety

regulations.

The manufacturer shall not be held responsible for any damage caused by incorrect use of the machine.

INTRODUCTION

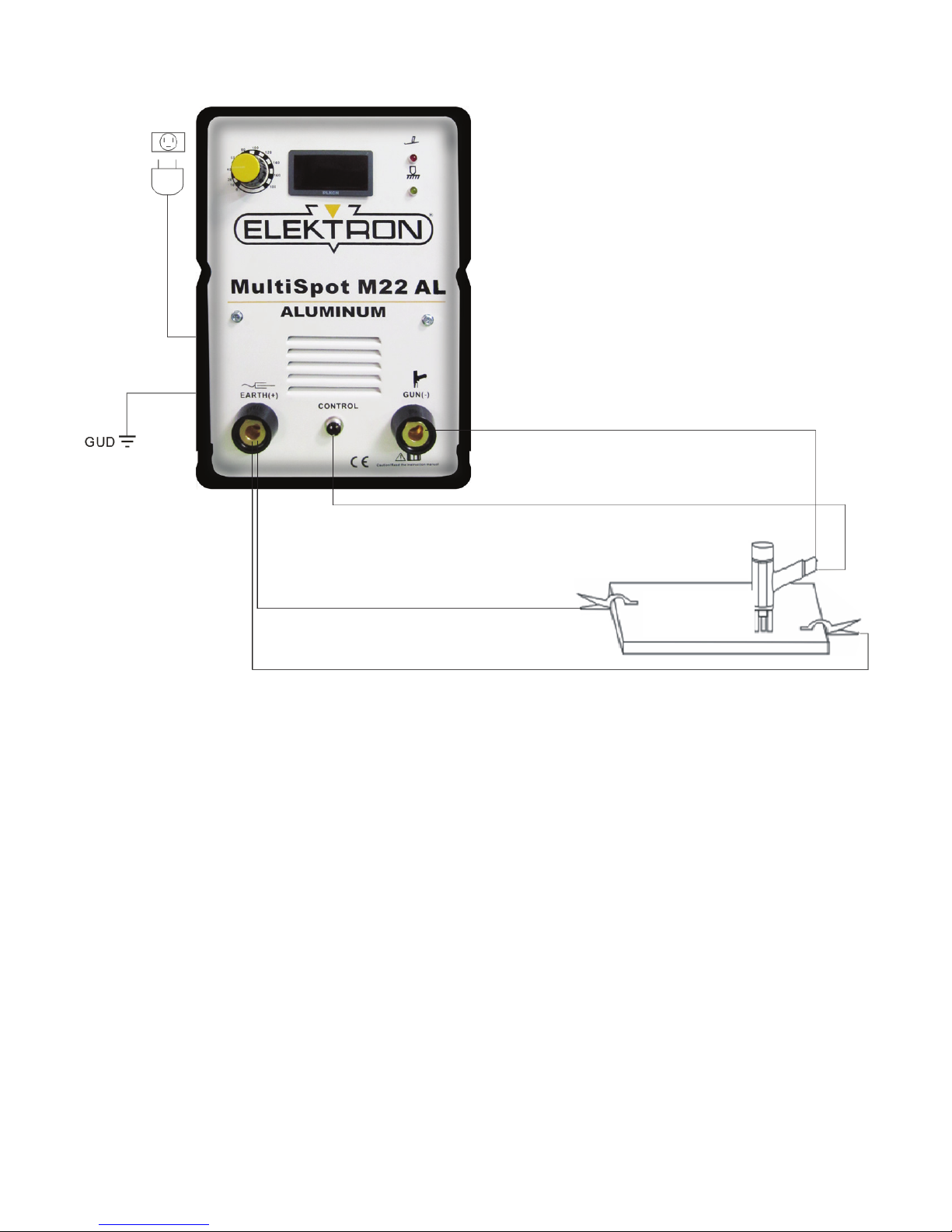

This device must be used exclusively for stud welding on electrically conductive materials (metals and

alloys).

Welding takes place due to the high temperature generated by a concentrated electric arc, and thus highly

dangerous situations may arise; it is therefore essential to pay the utmost attention to the chapter entitled

SAFETY PRECAUTIONS.

This manual must be kept carefully in a place familiar to everyone using the machine. It must be consulted

whenever doubts arise and be kept for the entire life-span of the machine; it will also be used for ordering

replacement parts.

NOTE

*Only use original replacement parts.

*Always replace any damaged part of the unit.

*Do not use any torches other than the original.

*Do not use the unit without covers. This is dangerous for the operator and for those who are surrounding the

work area. This also prevents the unit from cooling efficiently.

DESCRIPTION OF TECHNICAL SPECIFICATIONS

NOTE

Should there be a claim for losses or damages it must be made by the purchaser directly to the shipper who

handled the unit.

When requesting information about this welding machine please state the machine’s part number and serial

number to ensure receiving accurate information relating to your machine.

The content is for your reference.

Please be subject to the actual products if anything is different or updated.