CHNT Power CPS SCA-T Series User manual

Edition:1.1

USER MANUAL

CPS SCA-T Series Grid-tied PV Inverter

Preface

WARNING

CAUTION

DANGER

NOTICE

NOTE

Scope

This manual describes the installation, electrical connection, commissioning and maintenance, APP

operation of the inverter. Please first read the manual and related documents carefully before using the

product and store it in a place where installation, operation and maintenance personnel can access it at

any time. The illustration in this user manual is for reference only. This user manual is subject to change

without prior notice.

Tagert Group

Inverters must be installed by professional electrical engineers who have obtained relevant qualifications.

Indicates a potentially hazardous situation which, if not correctly

followed, will result in serious injury or death.

Indicates a potentially hazardous situation which, if not correctly

followed, could result in moderate or minor injury.

Indicates a potentially hazardous situation which, if not correctly

followed, could result in equipment failure to run, or property damage.

Call attention to important information, best practices and tips:

supplement additional safety instructions for your better use of the

inverter to reduce the waste of you resource.

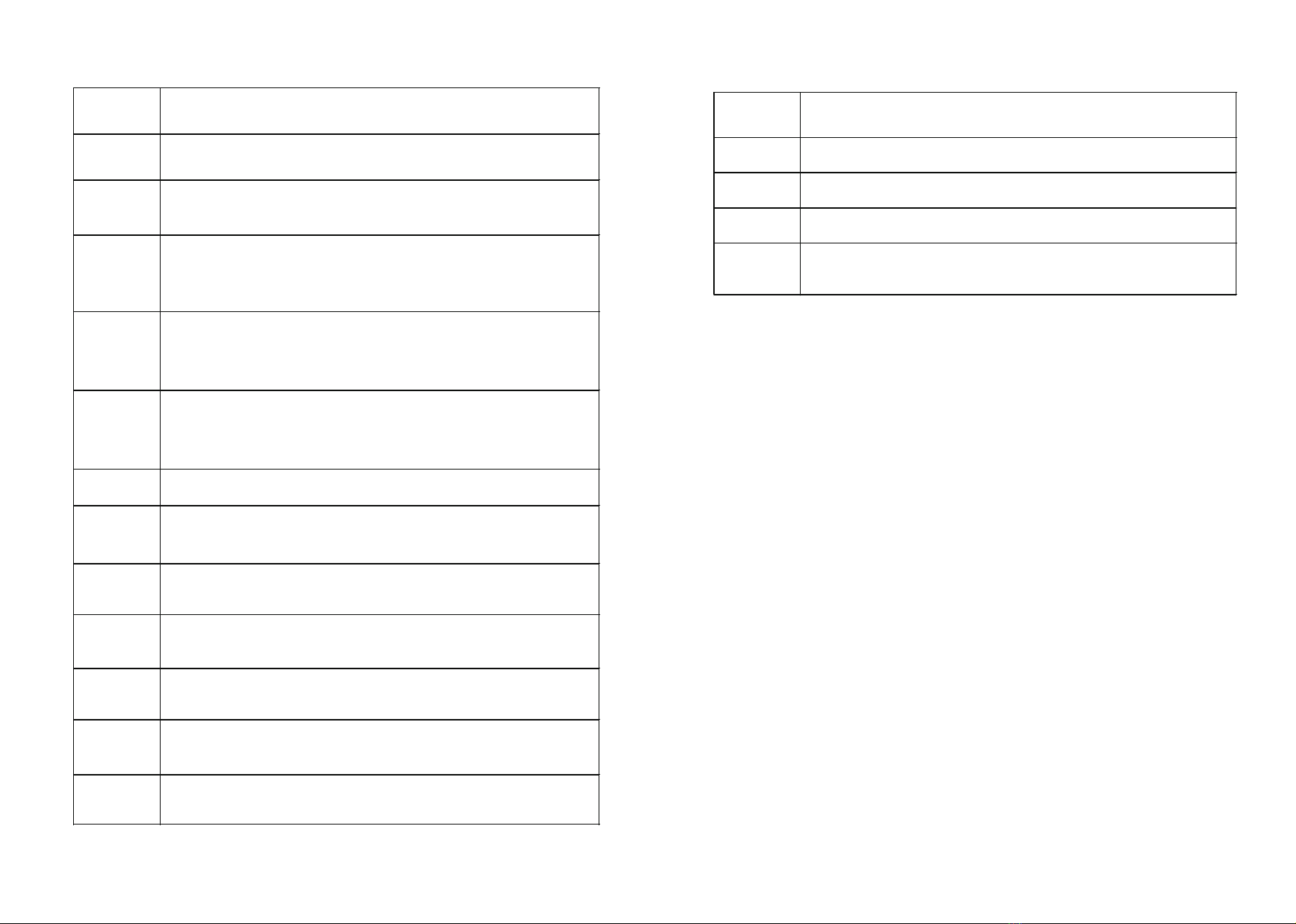

VERSION ISSUED COMMENTS

3

Conventions

Indicates an imminently hazardous situation which, if not correctly

followed, will result in serious injury or death.

Natural cooling series Fan cooling series Fan cooling series

CPS SCA5KTL-T1/EU

CPS SCA6KTL-T1/EU

CPS SCA8KTL-T1/EU

CPS SCA10KTL-T1/EU

CPS SCA10KTL-T2/EU

CPS SCA12KTL-T1/EU

CPS SCA15KTL-T1/EU

CPS SCA12KTL-T2/EU

CPS SCA15KTL-T2/EU

CPS SCA17KTL-T1/EU

CPS SCA20KTL-T1/EU

CPS SCA22KTL-T1/EU

CPS SCA25KTL-T1/EU

History

About This Manual

The following safety instructions and general information are used within this user manual.

This manual is applicable to following inverters:

1.0 11-Nov.-22 First release

1.1 17-Apr.-23 Optimize the scope, safety and shutdown procedure contents.

CONTENTS

1. Safety

2. Product Introduction

3. Upack and Storage

4. Installation

5. Electrical Connection

About This Manual

Target Group

Scope

Conventions

1.1 Symbols Used

1.2 Safety Instruction

2.1 Product Overview

2.2 Model Definition

2.3 Product Appearance

3.1 Upack and Check

3.2 Storage Inverter

3.3 Identify Inverter

6. Startup/Shutdown Procedure

7. User Interface

8. Troubleshooting and Maintenance

9. Technical Specifications

4.1 Selecting the Mounting Location

4.2 Mounting

5.1 Grounding

5.2 AC Connection

5.3 DC Connection

5.4 Communication Connection

6.1 Check before startup/shutdown procedure

6.2 Startup Procedure

6.3 Shutdown Procedure

8.1 Inverter Troubleshooting

8.2 Maintenance

7.1 LED Indicator

7.2 Bluetooth Connection Setting

8.2.1 Routine Maintenance

8.2.2 Fan Maintenanc

8.2.3 Removing the Inverter

5

4

Preface

1. Safety

Before using the inverter, please read all instructions and cautionary markings on the unit and manual.

Put the instructions where you can take them easily.

The inverter of us strictly conforms to related safety rules in design and test. Local safety regulations shall

be followed during installation, operation and maintenance. Incorrect operation work may cause injury

or death and damage to the inverter and other operator or a third party.

To avoid injury and damage to the inverter and other operator,please follow the safety precautions.

1.1 Symbols Used

7

6

Safety Safety

The sign of caution stick on inverter.

1.2 Safety Instruction

Installation and maintenance of inverters must be performed by qualified personnel, in accordance with

local electrical standards, wiring regulations and requirements of local power authorities.

The temperature of some parts of the inverter may exceed 60℃ during operation, do not touch the

inverter during operation to avoid being burnt.

Ensure children are kept away from inverters.

Take appropriate measures to avoid electric shock.

Don’t open the front cover of the inverter. Apart from performing work at the wiring terminal,

touching or changing components without authorization may cause injury to people, damage to

inverters and annulment of the warranty.

Ensure the output voltage of the proposed PV array is lower than the maximum rated input voltage of

the inverter; otherwise the inverter may be damaged and the warranty annulled.

When exposed to sunlight, the PV array generates dangerous high DC voltage. Please operate according

to our instructions, or it will result in danger to life.

Don’t insert or pull the terminals when the inverter is running.

After the inverter is powered off, the remaining electricity and heat may still cause electric shock and

body burns. Do not touch parts of inverter for 10 minutes after disconnection from the power sources.

Danger of high voltage!

Only qualified personnel may perform work on the inverter.

Grounding terminal

Safety Symbol Description

Residual voltage exists after the inverter is powered off. It

takes 5 minutes for system to discharge to a safe voltage.

Danger of hot surface

Do not disconnect under load!

5 mins

Environmental Protection Use Period

Refer to the operating instructions

Do not disconnect under load, otherwise there will be

a danger of fire.

Don’t dispose of the inverter with the household waste.

The labels are for reference only.

This series inverter is an important part of PV system and it is suitable for household use, commercial

use, fishery use, agricultural use and other scenarios.

2.1 Overview

2. Product Introduction

2.3 Product Appearance

PV strings Inverter AC Distribution Unit Grid

(The appearance of the fan cooling series is taken as an example.)

TN-S

L1

L2

L3

N

PE

PE

Transformer

TN-C

L1

L2

L3

PEN

PE

TN-C-S

L1

L2

L3

N

PE

PE

TT

L1

L2

L3

N

PE

PE

This series inverter is suitable for TN-S, TN-C, TN-C-S and TT grid system. Refer to the following figures:

Transformer Transformer Transformer

The following is only for reference, specific please in kind prevail.

2.2 Model Definition

208.5mm 414.27mm

398mm

23

1

Number Description

1 DC Switch

2 LED Indicators

3 External ground terminal

Natural cooling series Fan cooling series

(The appearance of the fan cooling series is taken as an example.)

460mm

9

8

Product Introduction Product Introduction

190.5mm

480.5mm

Inverter Inverter Inverter Inverter

Model number descriptions(using CPS SCA10KTL-T1/EU, CPS SCA10KTL-T2/EU as an example):

CPS 10KTL-T1/EU

Brand

Power(10KW)

CPS 10KTL-T2/EU

Brand

Power(10KW)

10

Natural cooling series Fan cooling series1Fan cooling series2

5 6 7

8

Number Description

4 PV terminal

5 RS485 communication port

6 WiFi/GPRS communication port

7 AC output port

8 External fan(It is only suitable for fan cooling series)

Complete test and strict inspection shall be done before the inverter is sent out.

When receiving the inverter, check that the packing materials are intact.

After unpacking, examine the PV inverter and its fittings for damage and check that the deliverables

are complete.

3.1 Upack and Check

3. Upack and Storage

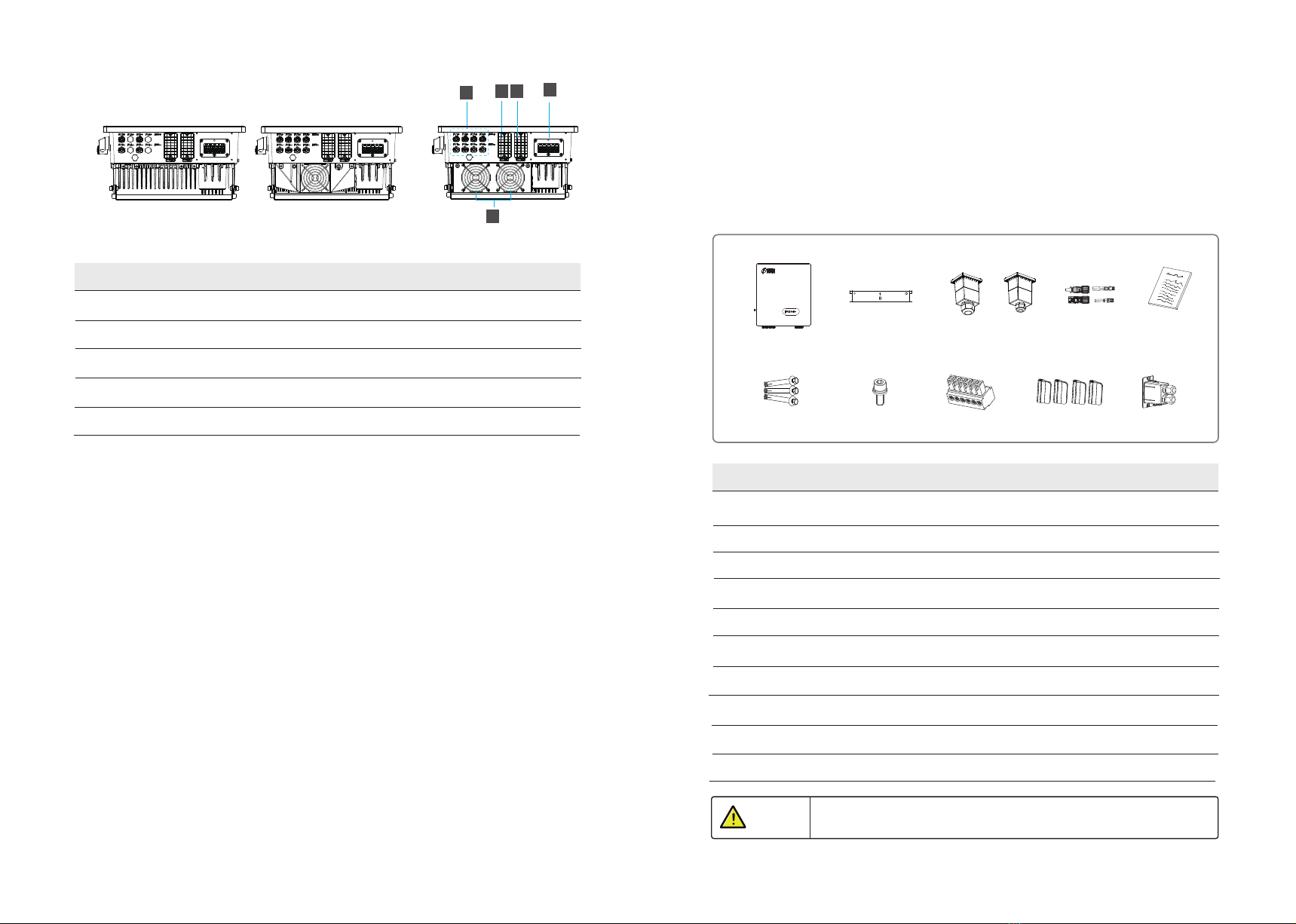

A B CDE

FGH I J

Number Description Quantity

A Inverter 1

B Mounting bracket 1

C AC cover(with 4× M4 security screws1

D DC terminal connector groups 2 or 4

E File package 1

F Expansion screws 3

G M6 Security screws 2

H 6-Pin terminal 2

I AC inserting pieces (Only for 17-25K model) 4

J RS485 cover 1

4

11

Product Introduction Upack and Storage

NOTICE Contact your dealer immediately if there is any issue found during operation.

Or

If the inverter is not used immediately, please keep the inverter in a specific environment according to the

following requirements:

Do not unpack the inverter and put desiccant in the original box if the PV inverter is unpacked.

Store temperature range: -25°C~+60°C; Relative humidity range: 0~100%.

Don’t position the inverter leaning forward, excessively leaning backward, tilting laterally, or upside down.

Ensure that qualified personnel inspect and test the inverter before use if it has been stored for a long time.

3.2 Storage Inverter

Inverter body label. The following is only for reference, specific please in kind prevail!

3.3 Identify Inverter

Number Description

1 Product name and modle

2 Product technical parameters

3 SN Barcode

4 Approve and Safety identification

Ensure there is no electronical connections around ports of the PV inverter

before installation.

4. Installation

1

2

3 4

DANGER

After checking the outer packing, move the PV inverter to the designated installation position horizontally.

CAUTION

1. Please place the inverter horizontally on the foam or other soft pads and

ensure that the ports are free of load-bearing pressure to avoid inverter damages

or scratches.

2. The inverter is heavy, be careful to prevent the inverter from slipping

and hurting the operator when moving the inverter.

4.1 Selecting the Mounting Location

a. The storage inverter protection class is IP66 and can be mounted indoors or outdoors.

b. To ensure optimum operation and long service life, the ambient temperature must be below 50℃.

c. Do not install the inverter in a rest area since it will cause noise during operation.

d.The inverter carrier must be fire-proof. Do not mount the inverter on flammable building materials.

e. Ensure that the wall meets the requirements of the inverter installation.

f . Product label and warning symbols shall be clear to read after installation.

g. The installation height should be reasonable and make sure it is easy to operate and view the display.

h. Please avoid direct sunlight, rain exposure, snow lay up.

4.1.1 Installation Environment Requirements

No direct sunlight No rain exposure No snow lay up

Snow lay up

12 13

Upack and Storage Installation

RoHS

www.chintpower.com

d.c.Max.Input Voltage:

d.c.Input Voltage Range:

d.c.Max.Input Current:

Isc PV:

a.c.Rated Output Voltege:

a.c.Rated Output Frequency:

a.c.Max.Output Power:

a.c.Rated Output Power:

Max.Apparent Power:

Power Factor Range:

Name:

Product Model:

Enclosure:

Temperature Range:

Protective Class:

MADE IN CHINA

Serial Number

XX

XX

xx

xx

xx

xx

xx

xx

xx

xx

xx

xx

xx

xx

x

Rain exposure

Direct sunlight

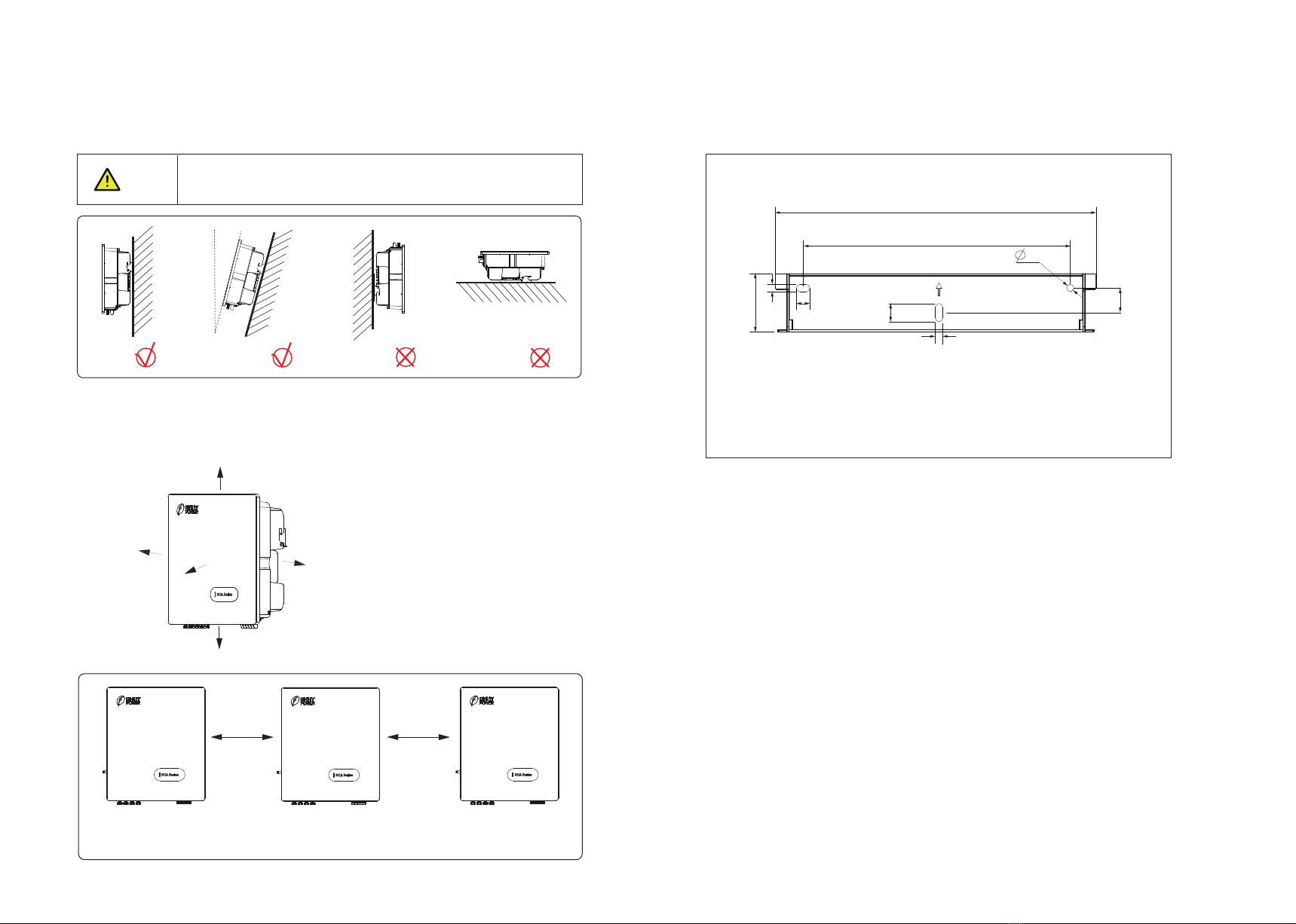

Upright Lean back ≤15° Horizontally

Mount the inverter vertically or tilted backward by max 15°. In order to facilitate the heat dissipation

of the inverter.

≤15°

Upside-down

≥600

≥600

≥600

≥600

Above: 600mm

Below: 600mm

Front: 1000mm

Both sides: 600mm

600mm 600mm

≥1000

NOTICE

4.1.3 Installation Space Requirements

4.1.2 Mounting Requirements

The wrong installation mode causes the inverter to be damaged or unable to

work properly.

To ensure the operation of the inverter normally and easily, there are requirements on available spaces

of theinverter, e.g. to keep enough clearance. Refer to the following figures.

14 15

Installation Installation

Installation perspective schematic

354

64

8

8

15

20

294

27

8

Bracket size drawing

Unit: mm

Installation along the same line for multiple inverter

(The appearance of the fan cooling series is taken as an example.)

1 ) Use a horizontally ruler to mark the position of the 3 holes on the wall. Refer to Step 1. And drill 3 holes,

10mm in diameter and 63 mm in deep. Refer to Step 1 and Step 2.

2) Knock the expansion screw kit into the hole with a hammer. Refer to Step 3.

Note: Do not remove the nut unit.

3) After tightening 2-3 buckles, the expansion bolts are tight and not loose, and then unscrew the bolts,

spring washer, gasket. Refer to Step 3.

4) Install the bracket on the wall, the bracket screw is pointed at the expansion tube on the wall, then install

the gasket and tighten screw. Refer to Step 4.

To prevent damage of the inverter, please hang the inverter on the bracket and

confirm the reverse, do not loosen the handle until the inverter is fixed.

CAUTION

4.2 Mounting

DANGER

Step 1. Install the mounting bracket Step 2. Install the inverter.

Install the inverter on the bracket accurately and tighten the screws at both sides, as shown in Step 5 and

Step 6.

1.The walls must be fileproof and non-flammable materials, othewise there is a fire

risk.

2.Before drilling holes, check whether there are electric power pipes buried in the

walls in case of danger.

(M6; 3 sets)

A B C D

Expansion screw group

Ø:10mm; Depht: 63mm

Set bracket horizontally.

M6 Expansion screws; 2~2.5N.m

Install bracket.

1Mark the holes position on the wall. 2Drill the holes.

3Install the expansion tubes.

4

5

6

2*M6 screw; 3N·m

Tighten the screws at both sides.

Install the inverter.

16 17

Installation Installation

C & D

A & B

System Connection

CAUTION

According to regulations, the secondary protection grounding can’t replace the

PE terminal connection of the AC cable. Ensure that both are grounded

reliably. Otherwise, fatal injury can occur due to the high voltage.

WARNING

5. Electrical Connection

5.1 Grounding

Electrical Connection Electrical Connection

If the positive pole or negative pole of the PV array is required to be grounded,

then the inverter output (to AC grid) must be isolated by transformer in

accordance with IEC63109-1,-2 standards.

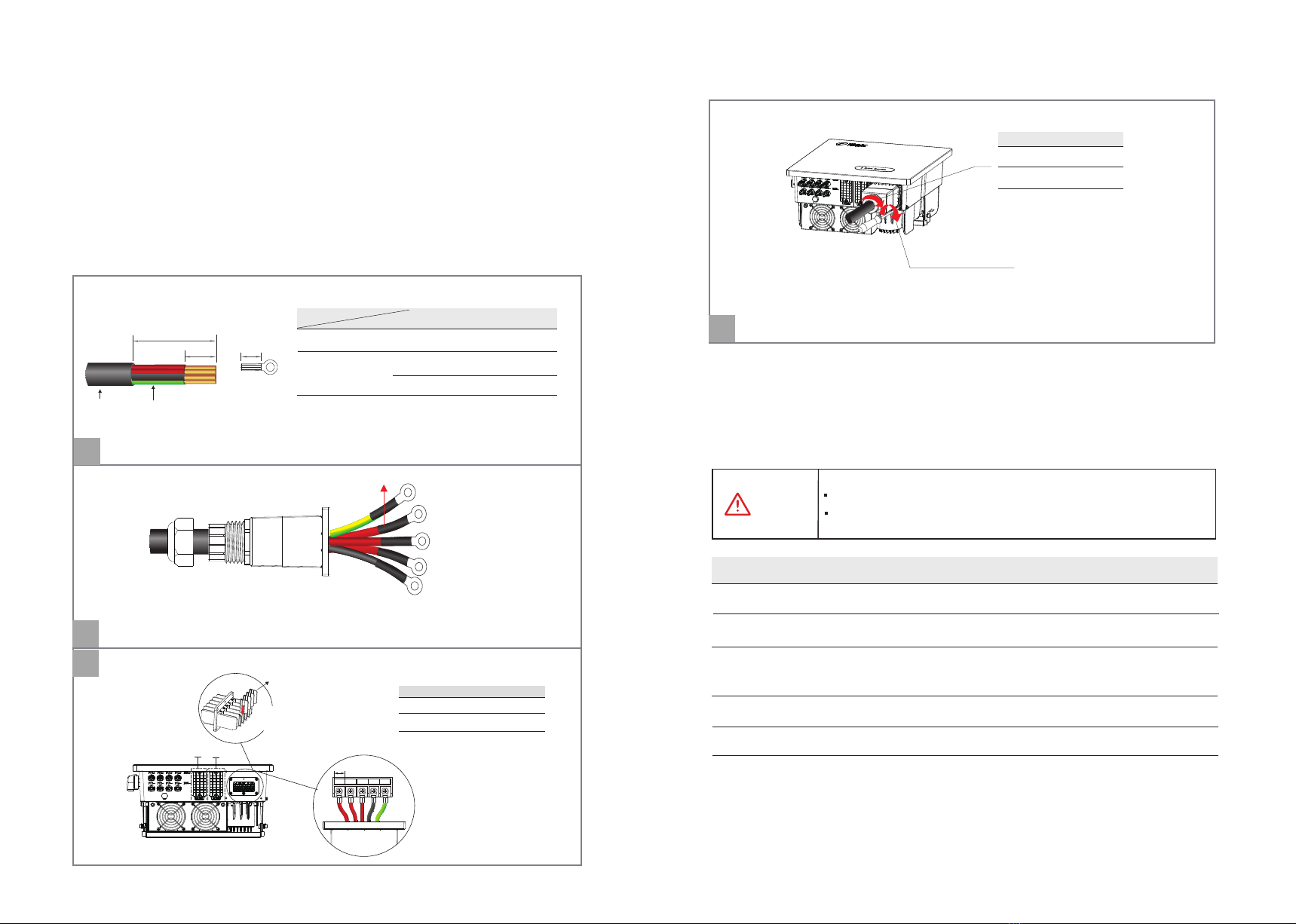

Step2.Insert the exposed core wires into the crimping areas of the OT terminal and crimp them

using hydraulic pliers.

Step3.Remove the ground screws from the ground points.

Step1.Remove an appropriate length using a wire Stripper.

According to the EN50178 requirement, the right side of the device has a protective grounding connection.

Be sure to connect the protection ground cable to this port when installing the inverter.

The user can perform the ground connection according to the on-site condition.

PE

DANGER

Before electrical connection, please ensure

that both the AC and DC ends are powered off,

otherwise there will be a high voltage shock.

Grid

PE

N

L3

L2

L1

PE

PV+

PV-

18 19

Screw M6 × 12mm; 3 N.m

OT Terminal OT6-6(5K-15K); OT16-6(17K-25K)

Ensure that the grounding resistance is less than 10Ω.

Items Remark

Yellow green lines S(Yellow green lines) ≥ S(PE line of DC cable)

S is the cross-sectional area.

L1L2L3 N PE

5.2 AC Connection

1. Measure and access the voltage and frequency of the point to ensure that it meets the grid-tied

specifications of the inverter.

2. PE wire (GND) must be well grounded to ensure that impedance between Neutral wire and Earth wire

is less than 10Ω.

3. Disconnect the circuit breaker or fuse from the inverter and grid-connected access point.

4. Use the copper wire.

5. Follow these steps.

Select proper AC cables and OT terminals (5 wires).

Unscrew the nut of the cover and thread the AC cable (5 wires) cross the nut, threaded sleeve and the

the cover. Then crimp the OT terminal and use heat shrink tubing or insulation tape for protection.

1

5.2.1 AC cable connection

To ensure that the inverter disconnect from the grid of safely, the independent AC breaker must be

configured for each inverter as a protective device.

5.2.2 AC Breaker and Leakage current protector

Inverter Model Recommended Value

CPS SCA5KTL-T1/EU,CPS SCA6KTL-T1/EU,CPS SCA8KTL-T1/EU 20A

CPS SCA10KTL-T1/EU,CPS SCA10KTL-T2/EU,CPS SCA12KTL-T1/EU,CPS SCA12KTL-T2/EU 32A

CPS SCA15KTL-T1/EU,CPS SCA15KTL-T2/EU

CPS SCA20KTL-T1/EU 50A

CPS SCA22KTL-T1/EU,CPS SCA25KTL-T1/EU 63A

Internal current detection equipment for inverter, the inverter detects the leakage of the power

grid that is greater than the reduced value, and will be disconnected quickly from the power grid. If the

external installation leakage protection device is installed, Its action electricity must be greater than equal

to 300mA.

Multiple inverters are not allowed to share a circuit breaker.

Load is not allowed to connect between the inverter and the AC breaker.

WARNIMG

40A

Range 4-6 6-16 10-1

Recommended 6 10 16

A Wire outer diameter(mm) 11-18 24-32 24-32

B Cross-sectional

area(mm²)

Note:It is recommended to use outdoor dedicate cables

with multiple copper cores.

Model 5K-15K 17K-20K 22K-25K

No. Name

L

100mm(Recommended)

AB

L+2mm

Heat shrinkable tube

Wires threading and pressing.

Lock the AC cable to the corresponding AC terminals.

①Align the AC cover with the 4 holes and tighten it firmly with 4×M4 screws.

②Fasten the nut(waterproof cap).

Nut Torque

5K-15K M25 5.5N.m

17K-25K M40 12N.m

① 4*M4 screws;1.2N.m

②

4

Electrical Connection Electrical Connection

20 21

3

2

CPS SCA17KTL-T1/EU

Note①is for WiFi/GPRS communication

②is for RS485 communication

Screw Torque D

5K-15K M4 1.5N.m 10mm

17K-25K M5 3N.m 12.5mm

(Only take 25K model as an example

in appearance)

D

This operation is

only required for

17-25K models.

AC terminal inserting pieces

②①

5.3 DC Connection

DANGER

PV modules generate electric energy when exposed to sunlight and can create an electrical

shock hazard. Therefore, when connecting the PV modules, shield them with opaque cloth

and ensure that DC switches are OFF.

To avoid electric shock, don’t touch the charge part and connect the terminals carefully.

Before connecting power cables, ensure the AC/DC switches are OFF.

When the inverter is connected to the grid, don’t plug in or plug out the PV strings.Don’t

perform any operation until the inverter is shut down.

WARNING

PV modules connected in series in each PV string must be of the same specifications.

The maximum open-circuit voltage of each PV string must be always lower than or equal

to its permitted range.

The maximum short circuit current of each PV string must be always lower than or equal

to its permitted range.

Ensure that the positive and negative terminals of each PV strings connected to the

inverter correctly.

The positive or negative terminals of PV strings can’t be connected with short circuit.

The total output power of all PV strings can’t exceed the maximum input power of the

inverter.

NOTICE

The positive and negative terminals of PV modules can’t connect to PE wire(GND) ,

otherwise, the inverter will be damaged.

Ensure that the voltage of each PV string doesn’t exceed 1100V under any circumstance.

When the input voltage is 1000V to 1100V, the inverter will enter the standby state. When

the voltage returns to the MPPT operating voltage, namely 160V-1000V, the inverter will

return to the normal state.

Electrical Connection Electrical Connection

5.3.1 Preparation

Inverter module PV input configuration

CPS SCA5KTL-T1/EU,CPS SCA6KTL-T1/EU PV strings circuit15A, All PV strings are connected into one group

CPS SCA8KTL-T1/EU,CPS SCA10KTL-T1/EU PV strings circuit<12A, All PV strings are connected into two groups

CPS SCA12KTL-T1/EU,CPS SCA15KTL-T1/EU PV strings circuit≤15A, All PV strings are connected into two groups

CPS SCA10KTL-T2/EU,CPS SCA12KTL-T2/EU, PV strings circuit≤15A, All PV strings are connected into two groups

CPS SCA17KTL-T1/EU,CPS SCA20KTL-T1/EU PV strings circuit<12A, All PV strings are connected into four groups

CPS SCA22KTL-T1/EU,CPS SCA25KTL-T1/EU All PV strings are connected into four groups

PV strings circuit≥12A≤15A, All PV strings are connected into three groups

PV strings circuit15A, All PV strings are connected into two groups

PV strings circuit>12A, All PV strings are connected into one group

CPS SCA15KTL-T2/EU PV strings circuit>15A, All PV strings are connected into one group

Before connecting the PV input to the inverter, ensure that the package meets the following

electrical specifications.

Inverter module Limit of each input open-circuit voltage Maximum allowable input terminal current

All 1100V 20A

Open-circuit voltage altitude derating curve of the inverter as shown in the following figure

2000m 3000m 4000m

1100V

950V

850V

Elevation(m)

Open-circuit voltage altitude derating curve of the inverter

NOTE To ensure that the inverter reaches the enclosure of IP66, it can only use the

connector provided by supply.

22 23

Different PV module input configuration module table (All PV strings are connected to the inverter in the

corresponding groups number)

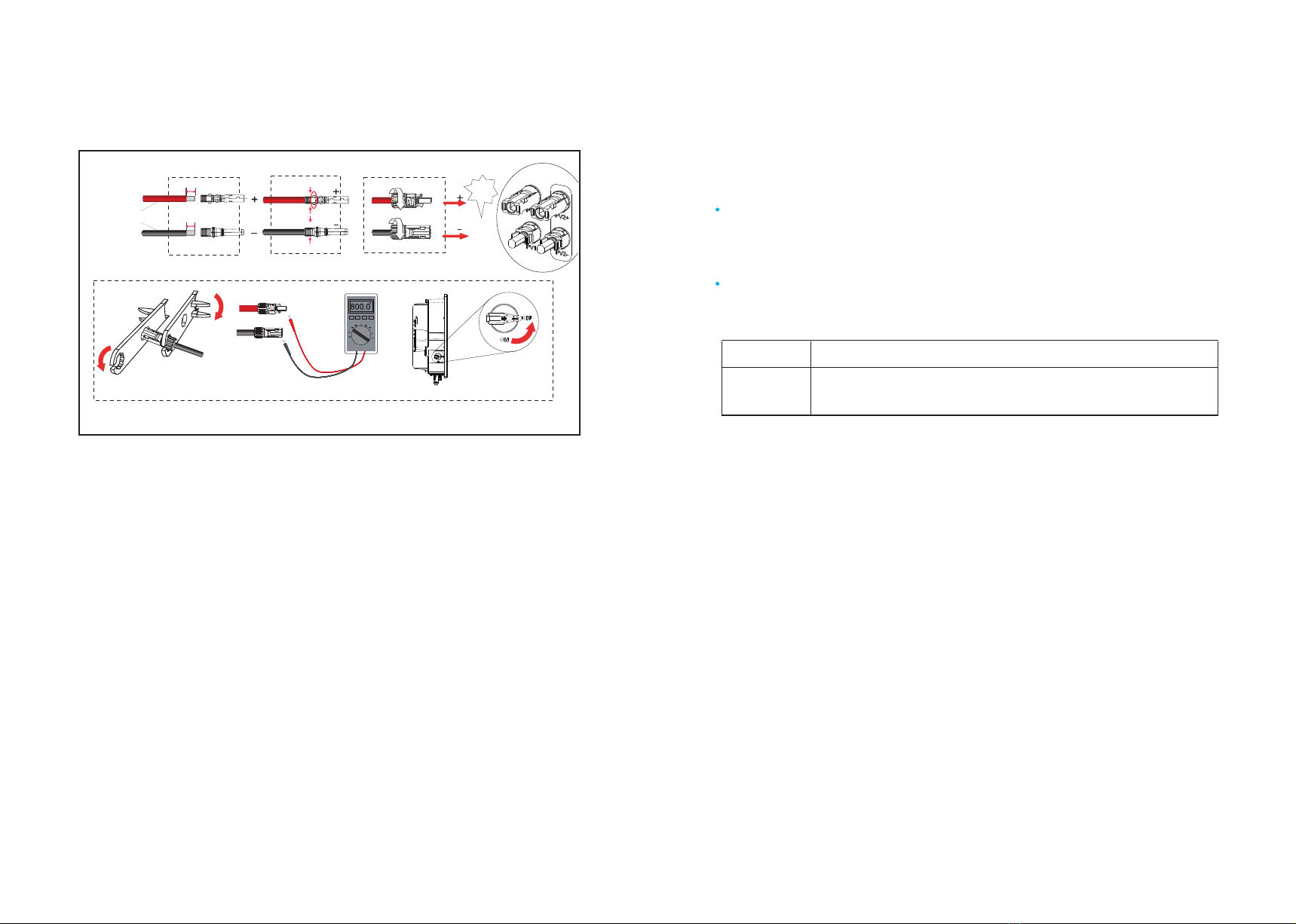

5.3.2 PV Connection

PV connection please refer to below.

5.4 Communication Connection

RS485

RS485 Modules

5.4.1 Communication Mode Description

Electrical Connection

Positive Connector

8~10mm

Note:DC cable should be dedicate PV cable(suggest using 4~6mm² PV1-Fcable).

Click

Use crimping tool to stitch.

Limit buckle can’t be crimped.

Negetive Connector

Tighten the waterproof nuts

on each connector with a wrench

to avoid loosening.

PC

Test string voltage and confirm string polarity. Ensure taht the DC switch is OFF.

8~10mm

Diameter

5~8mm

~~

~

~

Limit buckle

RS485 switching module monitors PV inverter’s data status through collecting

and uploading data to Cloud server.

Module Function description

Table 5.4 Communications module description

You can use the following communication modes to implement communication:

Bluetooth and RS485 which are described as follows.

24 25

Electrical Connection

Bluetooth Module

You can turn on the Bluetooth function of the mobile phone, and set parameters and monitor data

of the inverter through the mobile APP.

Through DB9 communication interface is transferred to other communication modules to monitor

the inverter. The module and functions are shown in Table 5.4.

5.4.2 RS485 Connection 6. Startup/Shutdown Procedure

6.1 Check before the startup/shutdown procrdures

Check follwing this procedures after installtion.

No. Items

1 The inverter is firmly installed.

2 There is enough heat dissipation space, no external objects or parts left on the inverter.

3 It is convenient for operation and maintenance.

4 The wiring of the system is correct and firm.

5 Check whether the DC and AC connection are correct with a multimeter, and whether

there is a short circuit, break, or wrong connection.

6 Check whether the waterproof nuts of rach part are tightened.

7 The vacant port has been sealed. And all gaps at the cable inlet and outlet holes have

been pluged with fireproof/waterproof materials, such as fireproof mud.

8 All safety labels and warnig labels on the inverter are complete without occulusion or

alteration.

6.2 Startup Procedure

8mm

≤60mm

RS485 Communication

cable (22AWG)

Nut

Threaded sleeve

1

2

3

4

5

6

A

B

A

B

PE

DO1

ALM

SIG

D12

D11

GND

Connect the differential positive and negative signal

wires of the first RS485 cable from the data logger to

Pin1 and Pin2 of the 6-Pin terminal respectively. If

there is more than one inverter, connect Pin3 and Pin4

to Pin1 and Pin2 of another inverter.

Pin1 and 2

Pin3 and 4 Pin1 and 2 Data Logger

Pin3 and 4

Pin1 and 2

2 × M4 screw; 0.8N·m

COM2

PE

0.8~1.5N·m

1

23

4

Electrical Connection Electrical Connection

Pin Inverter

1 A

2 B

3 A

4 B

5 PE

6 PE

1 DO1

2 ALM

3

EXT_SIG

4 DI2

5 DI1

6 GND

OFF

ON

1

OFF ON

AC Circuit Breaker

Supply Main Switch

Startup the inverter following the procedures:

2

DC Switch

3

Switch to ON

LED icon

4

Blue on (normal status)

5

Your system has started up

Finishing

(The figure is only for reference)

See if there’s any on site

Switch to ON

(The figure is only for reference)

26 27

Note: RS485 is only applicable to data logger or other device you use. Skip this part if you use wifi monitoring.

RS485 communication mode with multiple inverters

Wires making, threading and wiring.

Loosen the screws

and remove the

cover plate.

Insert the 6-Pin terminal into

the RS485 communication port. Install the RS485 cover.

7. User Interface

LED indicator is on the inverter display panel as below.

6.3 Shutdown Procedure

7.1 LED Indicator

It may be necessary to shut down the inverter sometimes during the daily use. If necessary, please follow

the procedures:

WARNING

LED indicator

Startup/Shutdown Procedure User Interface

Table 7-1 LED status descriptions

It takes 5 minutes for

system to discharge to

a safe voltage.

4

5 mins

1

OFF ON

AC Circuit Breaker

Supply Main Switch

2

DC Switch

3

Switch to OFF

See if there’s any on site

Switch to OFF

(The figure is only for reference)

5

Your system has shut down

Finishing

OFF

ON

(The figure is only for reference)

28 29

LED status Explanation

Blue blinks slowly(1s/time) Standby

Blue on Normal status

Green on Power limited status

Red blinks slowly(1s/time) Output side fault

Red blinks fast(0.25s/time) Input side fault

Red on Inverter internal fault

Red/green/blue light

up in turn (0.25s/color) 1. Inverter firmware updating

2. Initial status of power-on

After the inverter is powered off, the remaining electricity and heat may still

cause electric shock and body burn. If need to disconnect the inverter cables,

please wait at least 10 minutes before touching these parts of inverter.

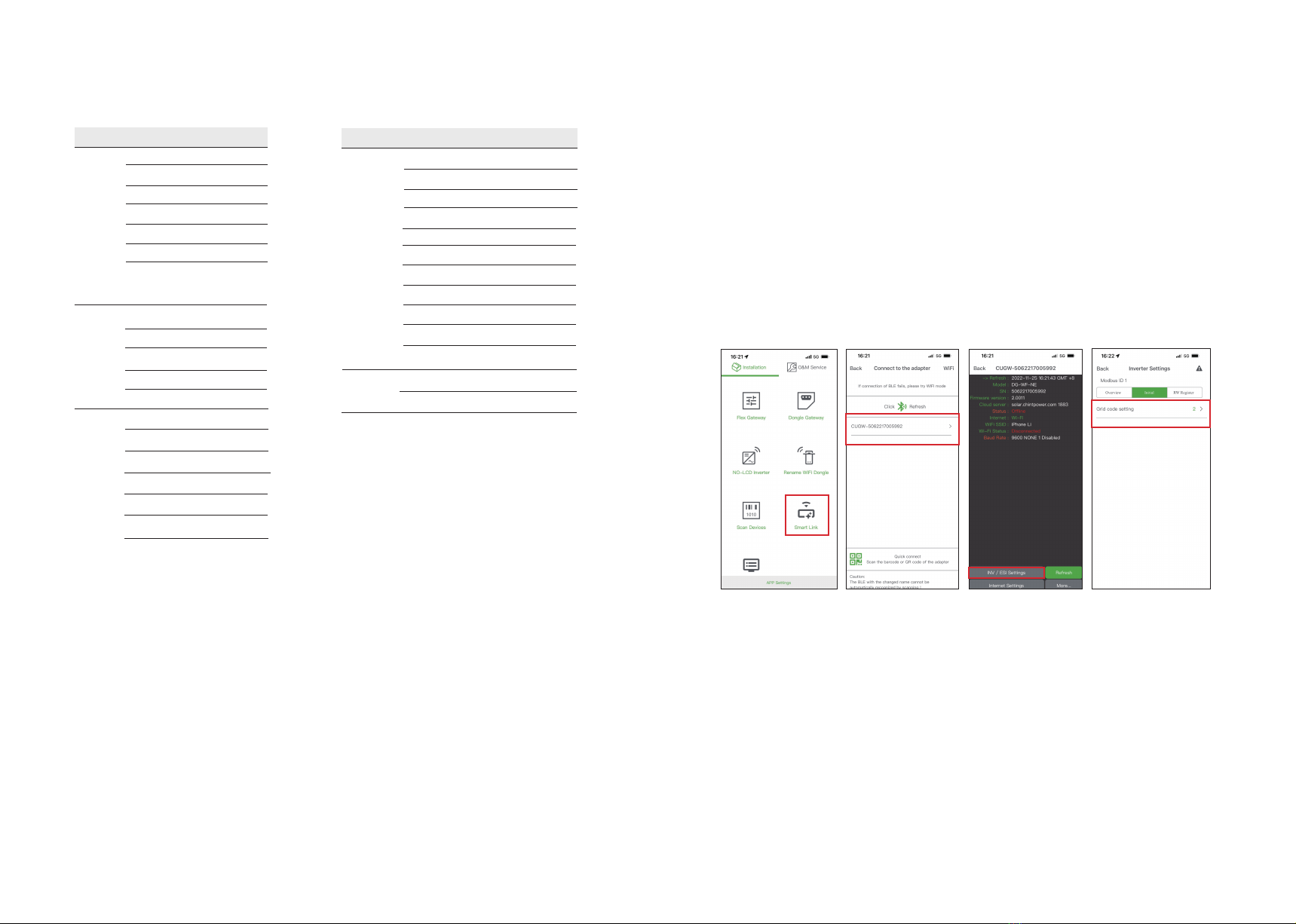

7.2 Bluetooth Connection Setting

User Interface

30 31

Warning Table

User Interface

1. Scan the QR code to download "Chint Connect" APP.

2. Install WiFi module into the COM1 port of the inverter.

3. Power on the inverter.

4. Open the Bluetooth function on your own phone, then open the APP and operate as below.

Note: You need to grant all access rights in all pop-up windows when installing the APP or

setting your phone.

4-1. Touch "Smart Link" icon to enter smart link interface and then click "Next" button to enter

the "Connect to the adapter" interface.

4-2. Choose correct wireless network name (can be found on the WiFi module) from the Bluetooth List, the

inverter will connect to WiFi dongle.

4-3. Click "INV/ESI settings" button to enter the “Inverter Settings” page.

4-4. Click "Initial" button to set grid code, then get back and click "RW Register" button to set register parameters

or modbus address if necessary. Now you can click "Overview" button to see basic information.

Control power abnormal C0

Arc fault C1

High DC component of output current C2

Inverter relay abnormal C3

Inverter over temperature C5

Leakage current HCT abnormal C6

Status Details Warning code

Software incompatibility CC

EEPROM error CD

Consistent warning CE

Inverter abnormal CF

Boost abnormal CG

Master Lost CH

Meter lost CJ

Fan abnormal C8

Remote off CN

Red

blink

slowly

Grid over voltage A0

Grid under voltage A1

Grid absent A2

Grid over frequency A3

Grid under frequency A4

Grid abnormal A6

Grid high average voltage A7

Grid N abnormal A8

PV over voltage B0

PV Insulation resistance abnormal B1

Leakage current abnormal B2

PV Strings reverse B7

PV under voltage B4

Red

blink

quickly

Red on

Red on

/

Status Details Warning code

System type error

DC link voltage unbalanced C9

DC link over voltage CA

Internal communication error CB

C7

Troubleshooting and Maintenance

Troubleshooting and Maintenance

32 33

8. Troubleshooting and Maintenance

WARNING

Before maintaining and commissioning inverter and its peripheral distribution unit,

switch off all the charged terminals of the inverter and wait at least 10 minutes after

the inverter is powered off,otherwise there will be a high voltage shock..

DANGER

Wrong maintenance will result in personnel injury or equipment damage!

Before performing any maintenance operations, you must follow these steps:

First, disconnect the AC circuit breaker on the grid side, and then disconnect

the DC switch.

Wait at least 10 minutes after the inverter is powered off,otherwise there will be a

high voltage shock.

Use testing equipment to make sure there is no voltage or current.

8.1 Troubleshooting

NOTICE

Comply with ESD protection specifications and power distribution ESD bracelets.

Avoid unnecessary contact with the circuit board.

Touching printed circuit boards or other electrostatic sensitive components may

cause damage during the process.

If the inverter is break down, the LED indicator will turn to red.

Alarm Information Measures Recommended

A0-Grid over

voltage

1. If the alarm occurs accidentally, possibly the power grid is abnormal accidentally. No extra action is

needed.

2. If the alarm occurs repeatedly, contact the local power station. After receiving approval of the local

power bureau, revise the electrical protection parameter settings on the inverter through APP.

3. If the alarm persists for a long time, please confirm that:

1) The AC circuit breaker is not tripping frequently (generating an instantaneous high voltage);

2) The wiring of AC cable is followed by the guide in user manual, and high cable impedance can

cause a voltage rise on the grid;

3) The voltage of three-phase inverter between the neutral wire and the ground line exceeds 30V; and

please correct the grid wiring if it exceeds;

If the above problems are excluded, please contact customer service to report a repair.

A1-Grid under

voltage

1.If the alarm occurs accidentally, possibly the power grid is abnormal temporarily. No extra action is

needed.

2.If the alarm occurs repeatedly, contact the local power station. After receiving approval of the local

power bureau, revise the electrical protection parameter settings on the inverter through APP.

3.If the alarm persists for a long time, please confirm that:

1) The AC circuit breaker is disconnected;

2) The AC circuit breaker is damaged (under closed status, please check that the voltage of the inlet is

consistent with that of the outlet);

3) The AC terminals are in good contact.

If the actual measuring voltage is within the specified range, please contact customer service to report

a repair.

A2-Grid absent

1. If the alarm occurs accidentally, possibly the power grid is abnormal temporarily. No extra action is

needed.

2. If the alarm occurs repeatedly, contact the local power station. After receiving approval of the local

power bureau, revise the electrical protection parameter settings on the inverter through APP.

3. If the alarm persists for a long time, please confirm:

1) The AC circuit breaker is disconnected;

2) The AC circuit breaker is damaged (under closed status, please check that the voltage of the inlet is

consistent with that of the outlet);

3) The AC terminals are in good contact;

4) Whether the power supply line failure.

If exclude all possibilities, please contact customer service to report a repair.

A3-Grid over

frequency

1. If the alarm occurs accidentally, possibly the power grid is abnormal temporarily. No extra action is

needed.

2. If the alarm occurs repeatedly, contact the local power station. After receiving approval of the local

power bureau, revise the electrical protection parameter settings on the inverter through APP.

3. If the alarm persists for a long time, please contact customer service to report a repair.

A4-Grid under

frequency

1. If the alarm occurs accidentally, possibly the power grid is abnormal temporarily. No extra action is

needed.

2. If the alarm occurs repeatedly, contact the local power station. After receiving approval of the local

power bureau, revise the electrical protection parameter settings on the inverter through APP.

3. If the alarm persists for a long time, please contact the customer service.

A6-Grid abnormal

(Only for three-

phase inverter)

1. If the alarm occurs accidentally, possibly the power grid is abnormal temporarily. No extra action is

needed.

2. If the alarm occurs repeatedly, please:

1) Measuring three-phase voltages (L1-N, L2-N,L3-N) and check whether the imbalance is more than

30%. If yes, please contact energy company.

2) Measuring three-phase voltages at input and output sides of AC circuit breaker to check whether

breaker is damaged. If yes, please replace a new breaker.

3) Short circuit input and output ports of neutral wire on AC breaker, then check the alarm status. If it

returns normal, please replace a 3-pole breaker and keep neutral wire shorting. If not, please contact

customer service.

A7-Grid over mean

voltage

1. If the alarm occurs occasionally, the inverter can be automatically recovered. No extra action is

needed.

2. If the alarm occurs repeatedly, the inverter cannot work properly. Please contact customer service.

A8-Grid N

abnormal

1. If the alarm occurs occasionally, the inverter can be automatically recovered. No extra action is

needed.

2. If the alarm occurs repeatedly, the inverter cannot work properly. Please contact the customer

service center.

B0-PV over voltage Check whether the maximum input voltage of a single PV string exceeds the MPPT working voltage.

If yes, modify the number of PV module connection strings.

B1-PV insulation

abnormal

1. If the alarm occurs accidentally but the inverter can generate power, check whether the installation

environment of cables and the components are damp. Please improve the installation environment.

2. If the alarm occurs repeatedly and the inverter can generate electricity occasionally, check whether

the positive and negative polarity of the PV component are short-circuited to ground. And check if the

component is damaged or the connection cable is broken.

3. If the alarm continues and equipment cannot generate power, please contact customer service to

report a repair.

B2-Leakage current

abnormal

1. If the alarm occurs accidentally but the inverter can generate power, probably the power grid causes. The

inverter can be automatically recovered. No extra action is needed.

2. If the alarm occurs frequently and is accompanied by an insulation impedance alarm. Check for the

abnormal alarm of the insulation.

3. If the alarm continues and the equipment cannot generate electricity, please contact customer

reservice to export a repair.

B4-PV under

voltage

1. If occurs when the light is weak (such as the early morning or evening, rainy weather and dust

storms), the component voltage is lower than normal. No extra action is needed.

2. If not related to light intensity, please check whether the string has a short circuit or open circuit.

B7-PV string

reverse

Check and modify the positive and negative polarity of the input string.

34 35

Information on how the inverter can comply with the earth fault alarm requirements of AS/NZS 5033.

Troubleshooting and Maintenance

Troubleshooting and Maintenance

C0-Internal power

supply abnormal

1. If the alarm occurs occasionally, the inverter can be automatically recovered. No extra action is

needed.

2. If the alarm occurs repeatedly. Please contact customer service.

C1-Electric arc

abnormal If the alarm occurs, the inverter cannot work properly. Please contact customer service.

C2-Inverter over

dc-bias current

1. If the alarm occurs occasionally, the inverter can be automatically recovered. No action is required.

2. If the alarm occurs repeatedly, the inverter cannot work properly. Please contact customer service.

C3-Inverter relay

abnormal

1. If the alarm occurs occasionally, the inverter can be automatically recovered. No action is required.

2. If the alarm occurs repeatedly, for single-phase inverter, check whether the live line and neutral line

on the AC side is reversed. For three-phase inverter, check the voltage of the live line and neutral line

to the ground. If the grid side is normal, please contact customer service to report a repair.

C5-Inverter over

temperature

1. If the alarm occurs occasionally, the inverter can be automatically recovered. No action is required.

2. If the alarm occurs repeatedly, please check whether the installation site has direct sunlight, bad

ventilation, or high ambient temperature (such as installed on the parapet). Yet, if the ambient

temperature is lower than 45° C and the heat dissipation and ventilation is good, please contact

customer service.

C6-GFCI abnormal

1. If the alarm occurs occasionally, it could have been an occasional exception to the external wiring.

The inverter can be automatically recovered. No action is required.

2. If it occurs repeatedly or cannot be recovered for a long time, please contact customer service.

C7-System type

error

If the alarm occurs, and the inverter cannot work, please restart the inverter. If the alarm continues,

please contact customer service.

C9-Unbalance Dc-

link voltage

1. If the alarm occurs occasionally, the inverter can be automatically recovered. No action is required.

2. If the alarm occurs repeatedly, the inverter cannot work properly. Please contact customer service.

CA-Dc-link over

voltage

1. If the alarm occurs occasionally, the inverter can be automatically recovered. No action is required.

2. If the alarm occurs repeatedly, the inverter cannot work properly. Please contact customer service.

CB-Internal

communication

error

1. If the alarm occurs occasionally, the inverter can be automatically recovered. No action is required.

2. If the alarm occurs repeatedly, the inverter cannot work properly. Please contact customer service.

CC-Software

incompatibility

1. If the alarm occurs occasionally, the inverter can be automatically recovered. No action is required.

2. If the alarm occurs repeatedly, the inverter cannot work properly. Please contact customer service.

CD-Internal storage

error

1. If the alarm occurs occasionally, the inverter can be automatically recovered. No action is required.

2. If the alarm occurs repeatedly, the inverter cannot work properly. Please contact customer service.

CE-Data

inconsistency

1. If the alarm occurs occasionally, the inverter can be automatically recovered. No action is required.

2. If the alarm occurs repeatedly, the inverter cannot work properly. Please contact customer service.

CF-Inverter

abnormal

1. If the alarm occurs occasionally, the inverter can be automatically recovered. No action is required.

2. If the alarm occurs repeatedly, the inverter cannot work properly. Please contact customer service.

CG-Boost

abnormal

1. If the alarm occurs occasionally, the inverter can be automatically recovered. No action is required.

2. If the alarm occurs repeatedly, the inverter cannot work properly. Please contact customer service.

CH-Data logger lost1. If the alarm occurs occasionally, the inverter can be automatically recovered. No action is required.

2. If the alarm occurs repeatedly, the inverter cannot work properly. Please contact customer service.

CJ-Meter lost

If the alarm occurs, please check the RS485 connection. If it is abnormal, please revise the connection;

if it is normal, please contact customer service.

C8-Fan abnormal

1. If the alarm occurs occasionally, please restart the inverter.

2. If it occurs repeatedly or cannot be recovered for a long time, check whether the external fan is

blocked by other objects. Otherwise, please contact customer service.

36 37

Figure 9.1 Removing DC input connector

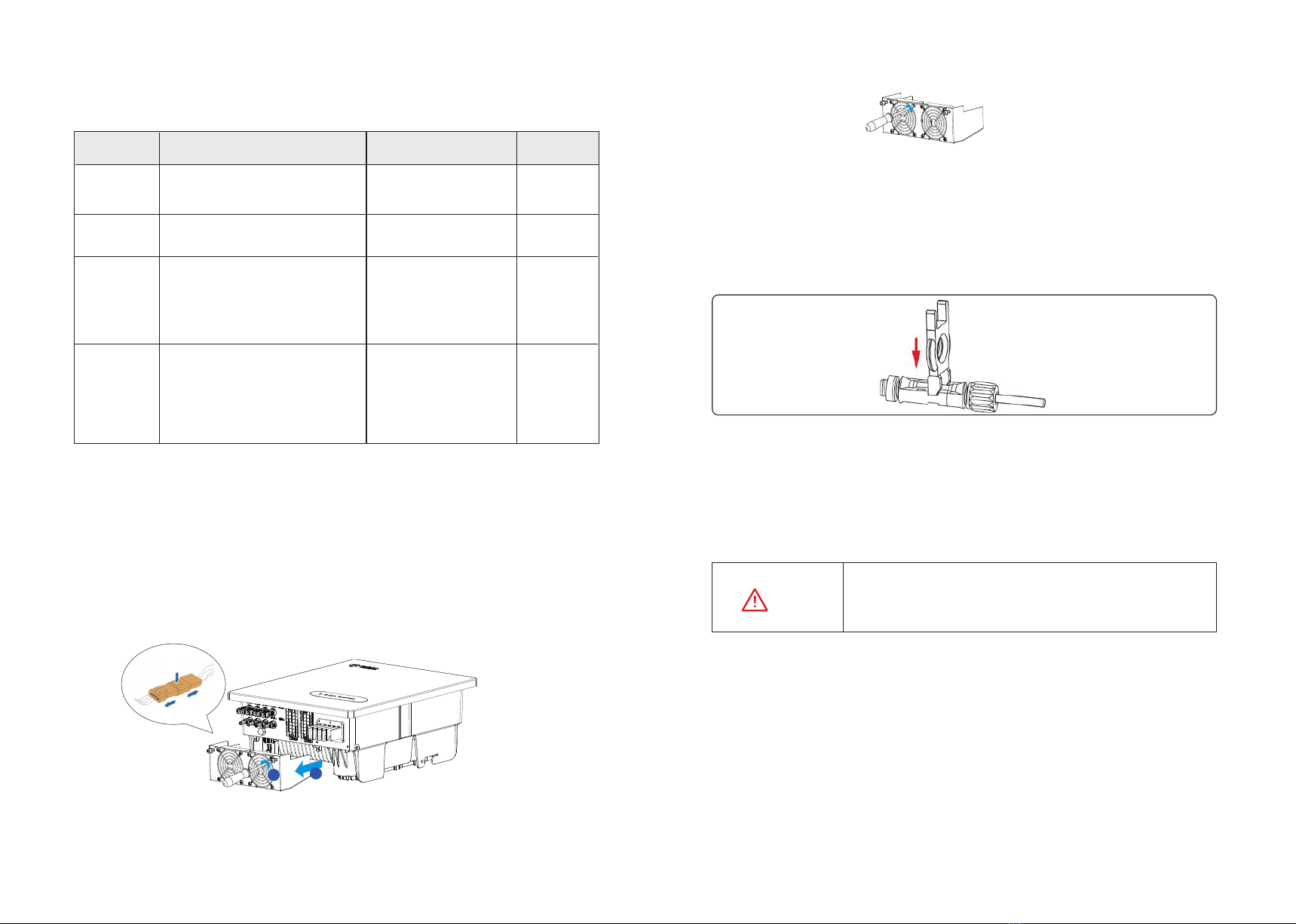

Step5 Use a soft brush to clean the fan. If you need to replace the fan, use a screwdriver to unscrew

the fan bracket and remove the fan.

Step6 Install the new fan in the opposite steps, and then power on the system.

------Ending

8.2 Maintenance

Routine Maintenance of inverter

Check Item Check Content Maintain content Maintenance

Interval

Inverter output

status

Statistically maintain the status of

electrical yield, and remotely monitor

its abnormal status.

Inverter Check periodically and ensure that the

appearance heat sink is free from dust and blockage.

Clean periodically the

heat sink.

NA Weekly

Yearly

Inverter

running

status

a.Check that the inverter is not damaged

or deformed.

b.Check for normal sound emitted

during inverter operation.

c.Check and ensure that all inverter

communications is running well.

If there is any abnormal

phenomenon,replace the

relevant parts.

Inverter

Electrical

Connections

a.Check and ensure that AC, DC, and

communication cables are securely

connected;

b.Check and ensure that PGND cables

are securely connected;

c.Check and ensure that cables are

intact and free from aging;

If there is any abnormal

phenomenon,replace the

cable or re-connect it.

Mouthly

Semiannually

Table 9-1.Maintenance checklist and interval

Fan Maintenance

When the external fan of the inverter can’t work normally, the inverter may not cool effectively. It may affect

the efficiency of the inverter or cause derating operation. Keep the fan clean and replace the damaged fan in

time.

Step1 Shutdown the inverter.

Step2 Refer to electrical connection installation and disconnect the inverter in the opposite steps.

Step3 Refer to mechanical installation and remove the inverter in the opposite steps.

Step4 Screw down two security screws anticlockwise which on the inverter fan bracket .

Troubleshooting and Maintenance

Troubleshooting and Maintenance

WARNING

Inverter Uninstsall

Inverter uninstall requires below procedure:

Step1. Disconnection all electric connections including these of communications

cables, DC input cables, AC output cables and the PGND cables.

Step2. Remove the inverter from its rear panel.

Step3. Remove the rear panel.

Note:

When uninstalling DC input connectors, insert removal wrench into the bayonet

shown in Figure, press the wrench down, and take out the connector.

Before uninstalling all electric connections, DC input connector, AC output

cables and the PGND cables, please ensure that both the AC terminal and

the DC terminal are powered off. And the DC switch is OFF to avert

equipment damage or personal injury.

12

(Only take 25k modle as an example)

9. Technical Specifications

38 39

M

ODEL CPS SCA5K-T1/EU CPS SCA6K-T1/EU CPS SCA8K-T1/EU CPS SCA10K-T1/EU CPS SCA10K-T2/EU CPS SCA12K-T1/EU CPS SCA15K-T1/EU

Input(PV)

M

ax. PV power voltage (V)

R

ated input voltage (V)

M

ax. input current (A) 15A/15A 15A/15A 15A/15A 15A/15A 15A/30A 15A/30A 15A/30A

M

ax. short-circuit current (A) 20A/20A 20A/20A 20A/20A 20A/20A 20A/40A 20A/40A 20A/40A

Starting voltage/Min. operating

voltage

M

PPT operating voltage range

MPPT voltage range @full load (V)

170V-850V 210V-850V 270V-850V 340V-850V 510V-850V 270V-850V 340V-850V

M

ax. numbers of input strings

N

umbers of MPPT input

O

utput(Grid)

R

ated output power 5KW 6KW 8KW 10KW 10KW 12KW 15KW

M

ax. apparent power 5.5KVA 6.6KVA 8.8KVA 11.2KVA 11KVA 13.2KVA 16.7KVA

M

ax. active power 5.5KW 6.6KW 8.8KW 11.2KW 11KW 13.2KW 16.7KW

M

ax. output current 3*8.4A 3*10.1A 3*13.4A 3*17A 3*16.8A 3*20.2A 3*25.3A

R

ated ouput current 3*7.6/7.2/6.9A 3*9.1/8.7/8.3A 3*12.1/11.6/11.1A 3*15.2/14.5/13.9A 3*15.2/14.5/13.9A 3*18.2/17.4/16.7A 3*22.7/21.7/20.8A

R

ated ouput voltage (V)

A

C voltage range

R

ated grid frequency

G

rid frequency range

T

HDI

c

urrent DC off-sets

A

djustable power factor range

D

C switch

A

nti-islanding protection

A

C Overcurrent protection

A

C short circuit protection

D

C reverse connection

S

urge Arrester

I

nsulation impedance detection

L

eakage current protection

T

opology

P

rotection grade

P

ower consumption at night

C

ooling type

O

perating temperature range

O

perating relative humidity range

M

ax. operation altitude

N

oise emission

D

imensions (W*H*D)

W

eight (kg)

Display & Communication

D

isplay

Communication

LED

Bluetooth&WiFi,RS485/GPRS/4G(Optional)

(398*460*190)mm

16.8

18.7

<30dB representative value (natural-cooling)

-25

℃-

60

℃

(Maximum 45

℃

without derating)

Support

Support

Support

Support

0~100%

4000m

Support

IP66

5~15K(natural-cooling)/15~25K(air-cooling)

General

<1W

DC TypeⅡ; AC Type Ⅱ

Support

Support

2

Protection

Support

380V/400V/415V 3W+N+PE

45Hz-55Hz/55Hz-65Hz

50Hz/60Hz

260V-510V(Adjustable)

<3% Rated power

<0.5%In or 50mA

>0.99@full load power (adjuestable 0.8LG-0.8LD)

2

(

1/1

)

3

(

1/2

)

160V-1000V

1100V

620V

180V/160V

Technical Specifications Technical Specifications

Other manuals for CPS SCA-T Series

1

This manual suits for next models

13

Table of contents

Other CHNT Power Inverter manuals

Popular Inverter manuals by other brands

SEW-Eurodrive

SEW-Eurodrive MOVIDRIVE system Compact operating instructions

Huawei

Huawei SUN2000-3KTL-M0 quick guide

SMA

SMA MEDIUM VOLTAGE POWER STATION 500SC-JP System manual

Mitsubishi Electric

Mitsubishi Electric FR-A720-0.4K instruction manual

Gyrus Acmi

Gyrus Acmi PlasmaKinetic user manual

Savch

Savch S2800 Series Service manual