TABLE OF CONTENTS

I-1

OPERATOR’S MANUAL PRO SERIES

0INTRODUCTION

1.1 USE OF THIS MANUAL...................................................................................................0 - 3

1.1.1 Importance of this manual..................................................................................0 - 3

1.1.2 Keeping the manual ...........................................................................................0 - 3

1.1.3 Consulting the manual........................................................................................0 - 3

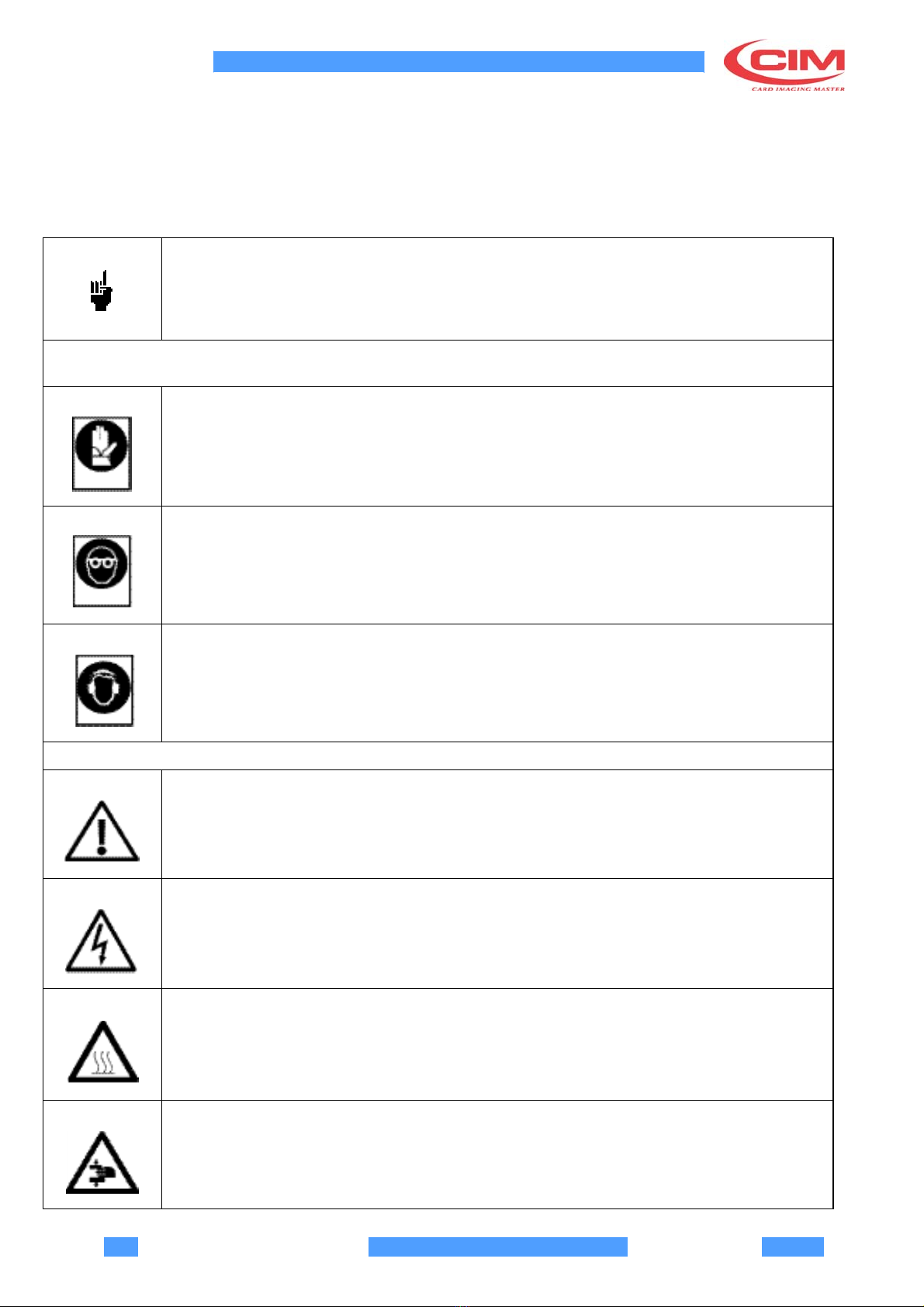

1.1.4 Symbols used.....................................................................................................0 - 4

1.1.5 Updating the manual with the machine modifications.........................................0 - 6

1.1.6 Original srlre parts..............................................................................................0 - 6

1

GENERALDESCRIPTION

1.1 GENERAL DESCRIPTION............................................................................................1 - 3

1.2 PRODUCTION CYCLE..................................................................................................1 - 3

1.3 LOADING AND ENCODING UNIT...................................................................................1 - 4

1.4 FLIP-OVER....................................................................................................................1 - 4

1.5 CLEANING UNIT...........................................................................................................1 - 5

1.6 THERMOGRAPHIC PRINTER ......................................................................................1 - 5

1.7 UNLOADING UNIT........................................................................................................1 - 6

1.8 ELECTRICAL AND TECHNICAL SPECIFICATIONS ....................................................1 - 7

1.9 EQUIPMENT CLASSIFICATION AND STANDARD REFERENCE...............................1 - 8

1.10 PHYSICAL ENVIRONMENT AND OPERATING CONDITIONS..................................1 - 8

1.11 DIMENSIONS AND WEIGHT ........................................................................................1 - 8

1.12 PRODUCTION CAPACITY............................................................................................1 - 9

1.13 POSITIONING THE MACHINE..................................................................................1 - 10

1.14 GENERAL SAFETIES ...............................................................................................1 - 11

1.15 RESIDUAL RISKS AND DANGEROUS AREAS.........................................................1 - 13

1.16 SERVICE MODE FUNCTIONING..............................................................................1 - 13

1.17 SAFETY GUARDS FUNCTIONAL CHECK ...............................................................1 - 14

1.18 DECLARATION OF CONFORMITY ............................................................................1 - 15

1.19 DIRECTIVE WEEE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 16