Intro 3

Design & Selection

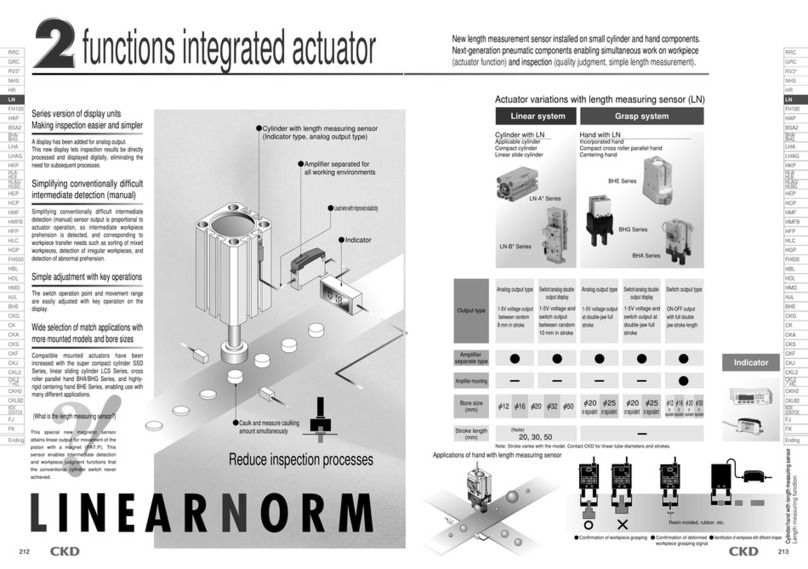

Pneumatic components (digital electro pneumatic regulator)

Safety precautions

Always read this section before starting use.

Thoroughly understand the characteristics of com-

pressed air before designing the pneumatic circuit.

The same functions as mechanical, hydraulic, or electrical methods cannot be

anticipated if instantaneous stop holding is required during an emergency stop.

Pop-out, air discharge, and leakage are caused by com-

pression and expansion of air characteristics.

Confirm that the product will withstand the working

environment.

This product cannot be used in an environment containing cor-

rosive gas, chemical liquids, solvents, water, vapor, or ozone. If

water drip, oil or metal chips (spatter or cutting chips, etc.) could

come in contact with the product, provide appropriate guarding.

This product cannot be used in the environment containing flammable gas.

Take care of electrical circuits during emergency stops

and cylinder operation during a service interruption.

Install a "pressure switch" and "shut-off valve" on the

device's compressed air inlet.

The pressure switch will disable operation until set pressure

is reached. The shut-off valve will exhaust compressed air in

the pneumatic pressure circuit, and will prevent accidents

caused by operation of pneumatic components by residual

pressure.

If the regulator is left with power off and primary pres-

sure applied, secondary pressure may rise to the

primary level. Due to the structure, a small amount

of air is consumed from the EXH port when second-

ary pressure is generated.

Set the primary regulator to 0 or use a valve on the

primary side to shut off the supply source when not

using the regulator.

WARNING Response is affected by the working pressure and

load volume. If repeatability with stable response is

required, install a regulator before the product.

Do as follows to prevent malfunction due to noise.

Insert a line filter in the AC power supply line.

Use a surge suppressor, such as a CR or diode on the

conductive load (solenoid valve, relay, etc.), and remove

noise where generated.

Keep wiring to the device separate from strong magnetic

fields.

Connect wiring to the device with a shield wire.

Ground the shield wire on the power supply.

Keep the power cable as short as possible.

Do not share power with noise-generating devices such as

inverters or motors.

Do not lay power, signal, or other power cables in parallel.

Due to wiring, power ground and signal common are

the same for the current input type.

When driving several electropneumatic regulators with 1 PLC

and D/A, the D/A's circuitry could prevent the correct signal

from being input. Check with the PLC maker.

Current input is used with a 1-5 V input signal

but impedance is less than other voltage input

(250 ).Use an appropriate signal generator.

Poor air quality adversely affects function and life.

For the pneumatic pressure source, supply air free of sol-

ids, moisture, and oil using a dryer, air filter, or oil mist filter.

Air containing oil could adversely affect function.

When secondary pressure is lowered by an input signal, etc.,

secondary air passes through and is discharged from the

EXH port. Contamination of secondary piping and internal

load adversely affects function, so piping should be kept as

clean inside as possible.

Ifpoweristurnedoffduringpressurization,secondarypres-

sure is maintained.

To set exhaust, lower the set pressure with the input signal

before turning power off or exhaust with a shutoff valve. There

is no guarantee that this held state can be maintained for a

long time.

CAUTION

Indicate the maintenance conditions in the device's

instruction manual.

The product's function can drop markedly with working sta-

tus, working environment, and maintenance, and can pre-

vent safety from being attained. With correct maintenance,

the product functions can be used to the fullest.

Confirm that power used is constant voltage.

Check leakage current to prevent the product from mal-

functioning due to leakage current from other controls.

When using a programmable controller, etc., leakage cur-

rent could cause the electro pneumatic regulator to mal-

function.

For 24 VDC 1.8mA or less

Regulator

Air filter

5 m

Air dryer Oil mist filter

(Oil removing)

<Recommended air circuit>

(Pressure switch)