SM-A10616-A CONTENTS

iv

CONTENTS

PREFACE........................................................................................................................... i

SAFETY INFORMATION.................................................................................................. ii

Product precautions.......................................................................................................iii

Disposal precautions .....................................................................................................iii

CONTENTS...................................................................................................................... iv

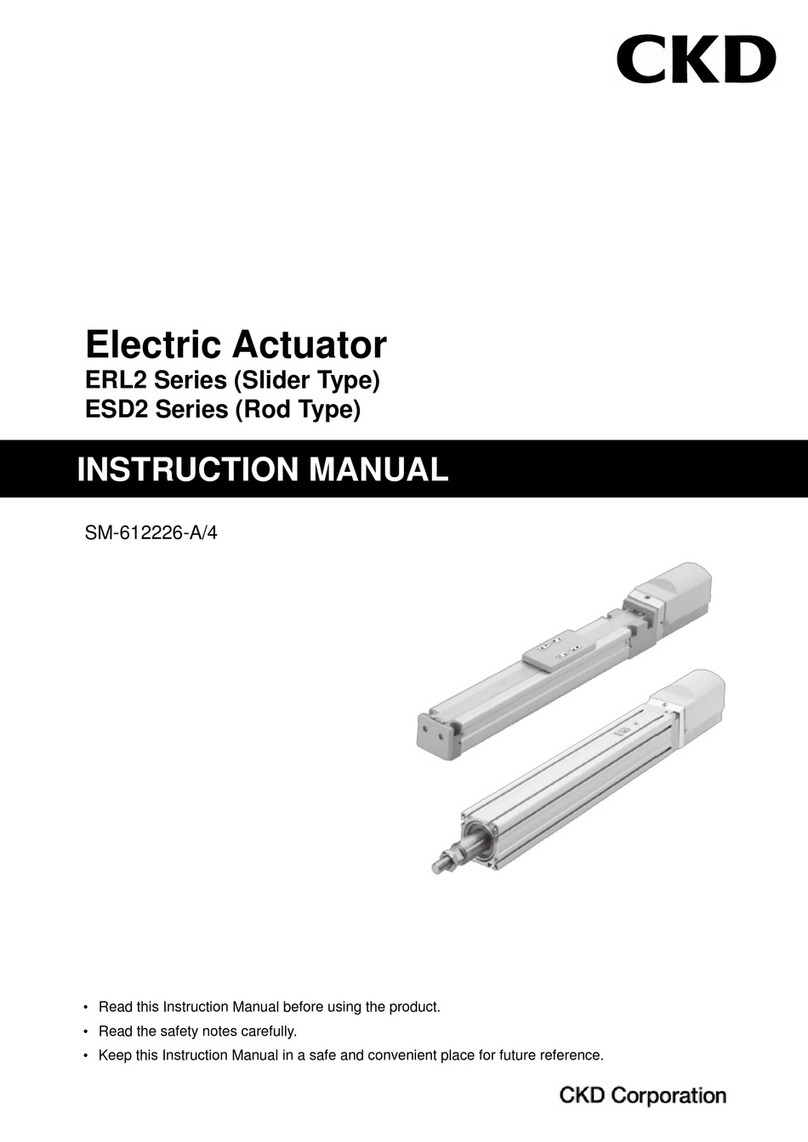

1. PRODUCT OVERVIEW............................................................................................. 5

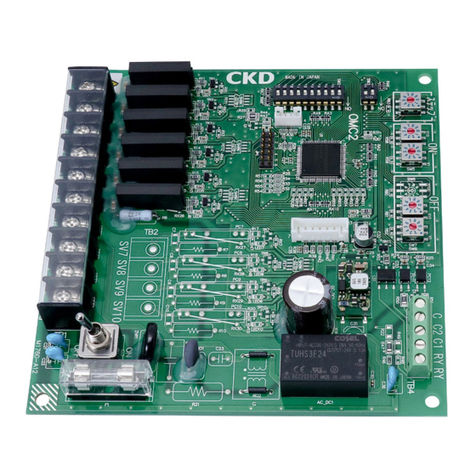

1.1 Product configuration..........................................................................................5

1.2 System configuration..........................................................................................6

1.3 Specifications......................................................................................................7

1.3.1 Communication specifications...................................................................... 7

1.3.2 Communication status display ..................................................................... 8

2. INSTALLATION ......................................................................................................... 9

2.1 Connection........................................................................................................ 10

3. USAGE..................................................................................................................... 11

3.1 Data communication..........................................................................................11

3.2 IODD files.......................................................................................................... 12

3.3 IO-Link device settings .....................................................................................13

3.4 Communication format...................................................................................... 14

3.4.1 Process data............................................................................................... 14

3.4.2 Data Index and Subindex........................................................................... 20

3.4.3 PIO mode process data details.................................................................. 28

3.5 Data access......................................................................................................37

3.5.1 Process data............................................................................................... 37

3.5.2 Service Data............................................................................................... 38

3.5.3 Return error codes ..................................................................................... 41

3.5.4 IO-Link Master Unit error reset................................................................... 41

3.6 Operation mode................................................................................................42

3.7 Operation time chart......................................................................................... 43

3.7.1 Servo ON.................................................................................................... 43

3.7.2 When powered on...................................................................................... 44

3.7.3 Home position return operation.................................................................. 45

3.7.4 Positioning operation.................................................................................. 46

3.7.5 Errors and obtaining error codes................................................................ 51

3.8 Data Storage function....................................................................................... 52

3.8.1 IO-Link Master settings .............................................................................. 52

3.8.2 Operation mode switching.......................................................................... 52

3.8.3 Download/Upload....................................................................................... 53

3.9 Error events ......................................................................................................55

4. WARRANTY PROVISIONS..................................................................................... 56

4.1 Warranty Conditions .........................................................................................56

4.2 Warranty Period................................................................................................ 56

4.3 Remarks............................................................................................................56