5

PIN SCAN

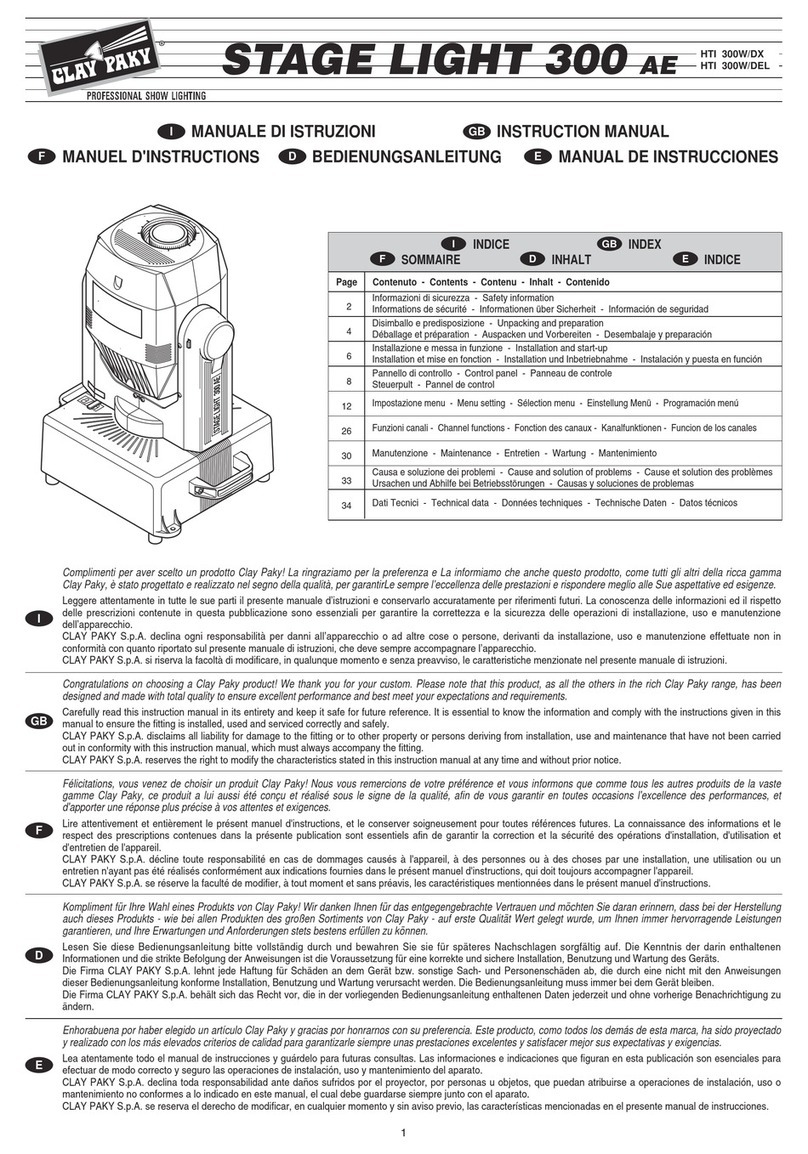

•

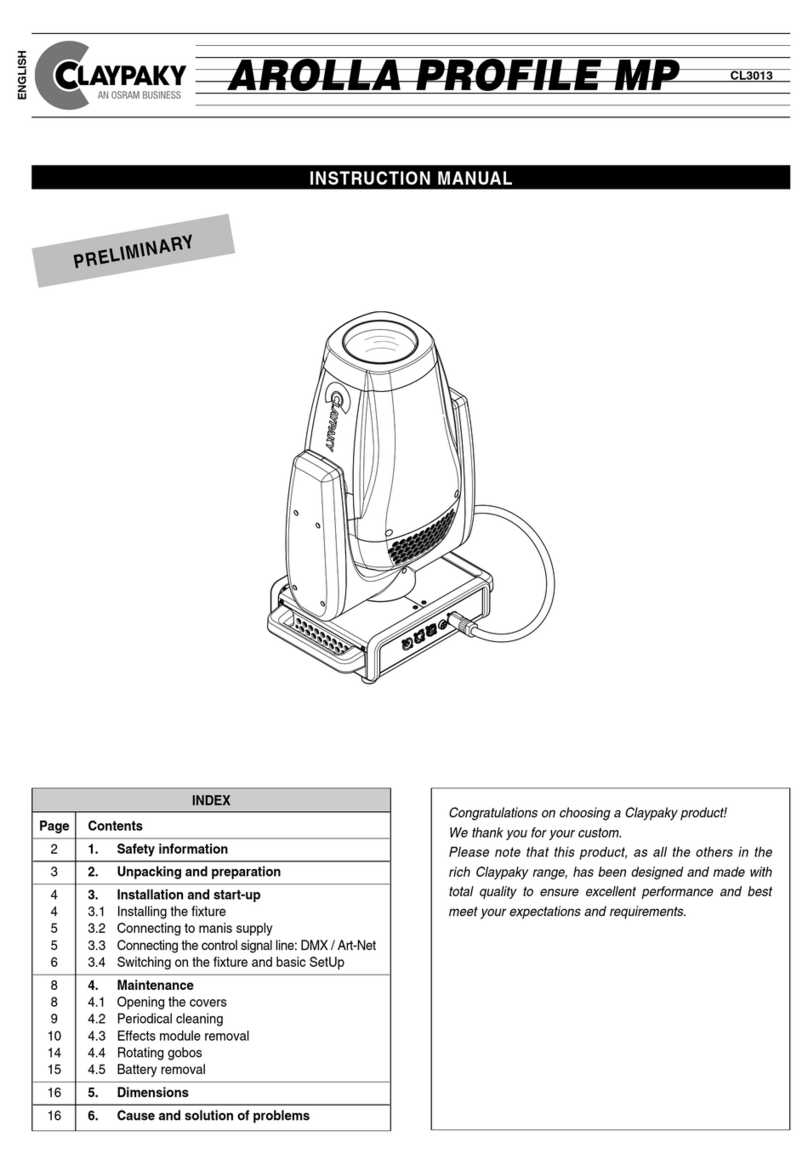

Unpacking

Open the box, remove the projector

from the packing and place it on a

flat, horizontal surface.

Unpack the standard accessories

supplied with the fixture. Inspect the

lamp change label (1) and replace it

with one of the optional language

versions if necessary.

Make sure that the label is never

removed, as it displays important

safety information.

•

Connecting to the electrical power supply

The operations described in this heading must be carried out by a licensed electrician.

The projector must be wired up to the electrical power supply using the special socket

connector provided (4).

It is good policy to connect projectors to the power supply by way of dedicated

switches, so that each can be turned on and off individually from a remote station.

The projector is designed to operate at the voltage and frequency indicated on the

electrical data plate (5). Check that these two values correspond to the mains voltage

and frequency.

IMPORTANT: the projector must be connected to a power supply circuit

having a proper earth system (Class I appliance).

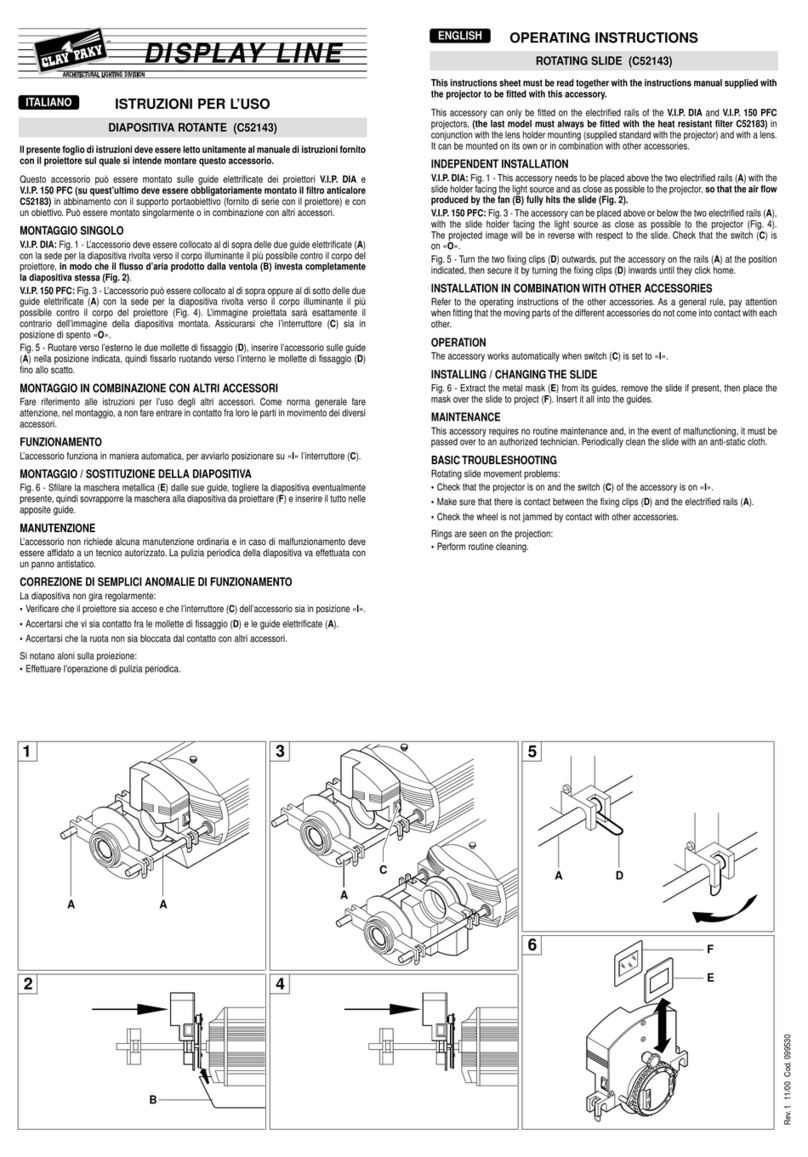

• Connecting the control signals

RS 232/423(PMX) - DMX 512

•

Fitting the lamp

Refer to the directions for replacement of the lamp given under heading 4 MAIN-

TENANCE.

•

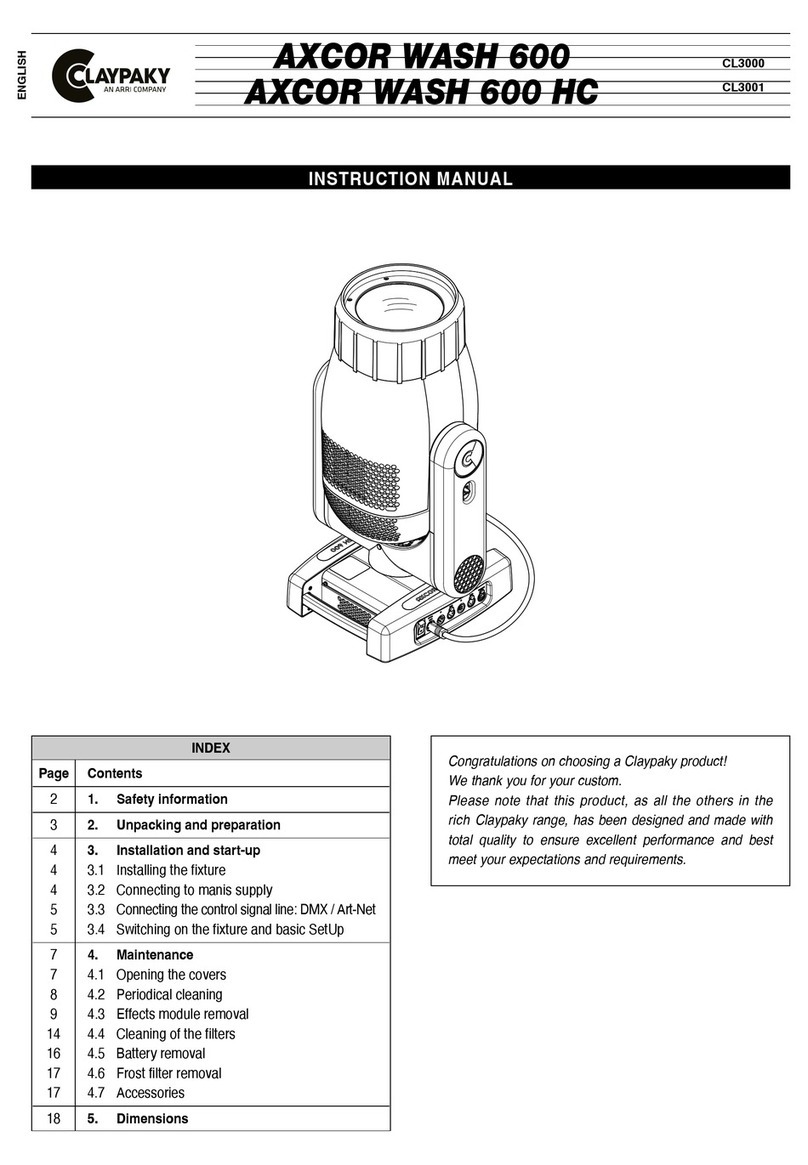

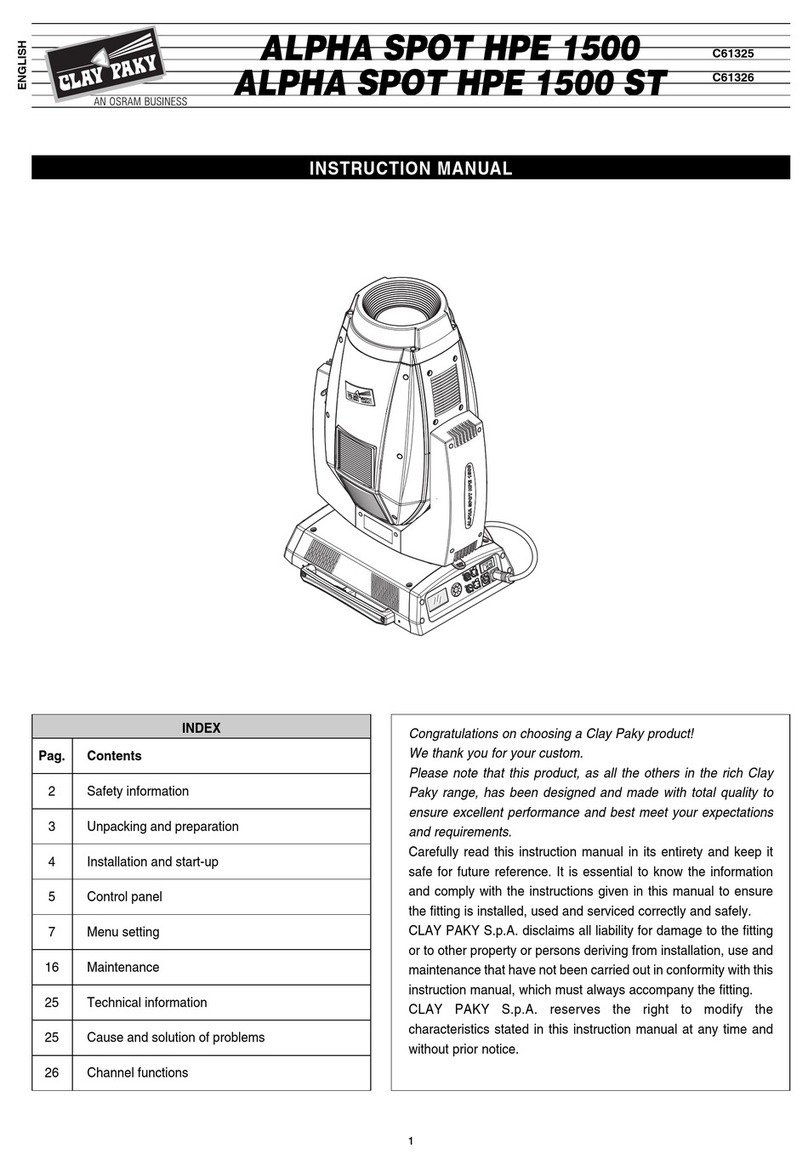

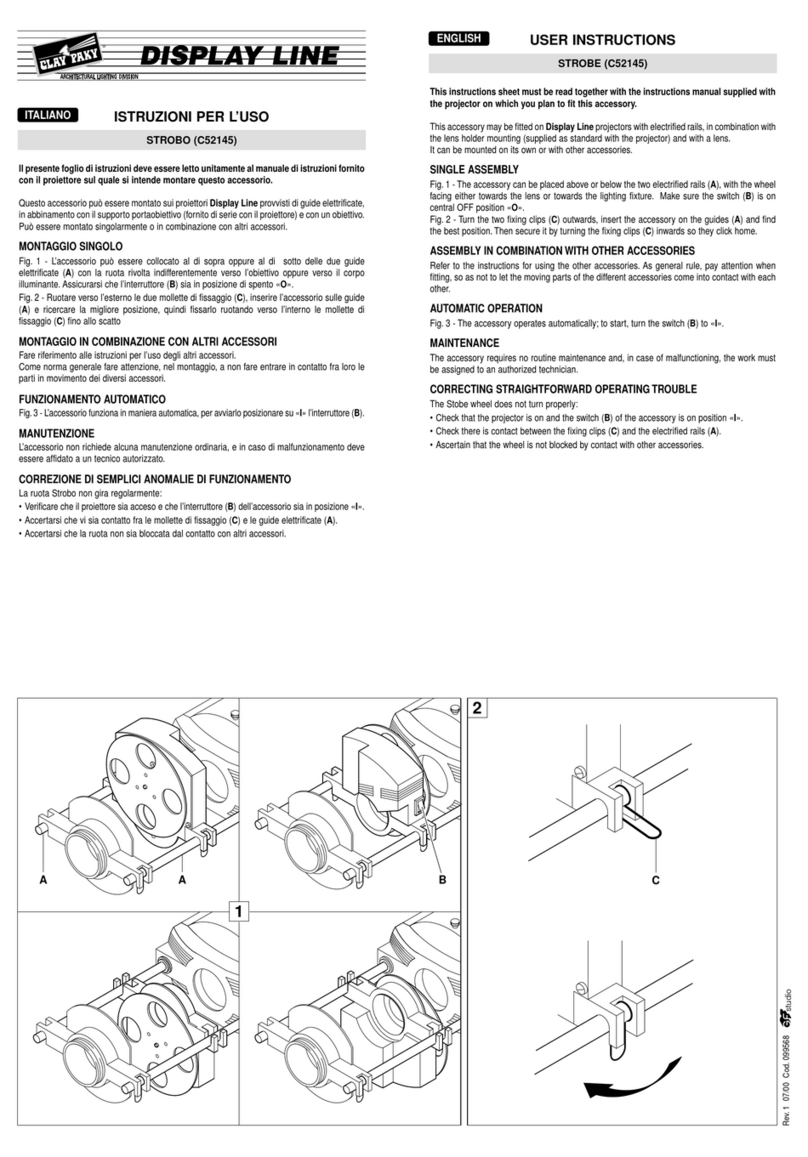

Installing the projector

The projector can be placed on the floor on the rubber feet (2) or installed on the ceil-

ing or wall using the holes (3) in the base.

Make certain that the anchorage is stable before positioning the projector.

•

Minimum distance from target objects

The projector must be positioned in such a way that

objects struck by the beam are located at least 1.3

m (4’ 3”) from the lens.

•

Minimum distance of inflammable materials from any part of the fixture:

m 0.1 (4”).

The fixture may be mounted on surfaces rated normally inflammable.

IMPORTANT: For better and more reliable operation of the fixture, the ambient

temperature must not exceed 35° C (95° F). Protection factor IP 20: the fixture is

protected against penetration of solid bodies more than 12mm (0.5”) in diameter (first

digit 2), but can be damaged by spray, jet, drip or rain water (second digit 0).

23

1

POWER SUPPLY AND INTERFACE

2

Projectors are wired up to the controller and one to the next using two-core

screened cable and Cannon 5 pin XLR type plug/socket connectors.

To connect a DMX line, a terminating plug (8) with a 100Ωresistor wired between

pins 2 and 3 must be fitted to the last projector connected in series; the plug is not

required when using an RS232/423(PMX) signal.

ENGLISH

INSTALLING THE PROJECTOR

1

IMPORTANT:Read carefully. It is essential for the correct and safe use of the

equipment that erectors and operators should be fully conversant with the

information and instructions given in this manual.

INSTRUCTION MANUAL

ENGLISH

7

6