2 Online Instructions: c-m-p.com/tech

IMPORTANT WARNINGS & SAFETY INSTRUCTIONS

READ AND FOLLOW ALL INSTRUCTIONS.

• Read this manual completely before attempting installation. Failure to install in accordance with the

installation instructions could void warranty and result in injury or death.

• All permanent electrical connections should be made by a qualied electrician.

• A pressure wire connector, labeled “bonding lugs”, is provided on the outside of the unit to permit

connection to a minimum No. 6 AWG (13.3 mm2) solid bonding conductor between this point and any

metal equipment, metal enclosures of electrical equipment, metal water pipes, or conduit within 5 feet

(1.5 meters) of the unit as needed to comply with local requirements.

• Install at least 5 feet (1.5 meters) from wall of pool. Install in accordance with the installation instructions.

• Follow all applicable electrical codes.

• DANGER ELECTRIC SHOCK HAZARD: Be sure to turn power OFF and disconnect from power

source before any service work is performed. Failure to do so could result in serious injury or death.

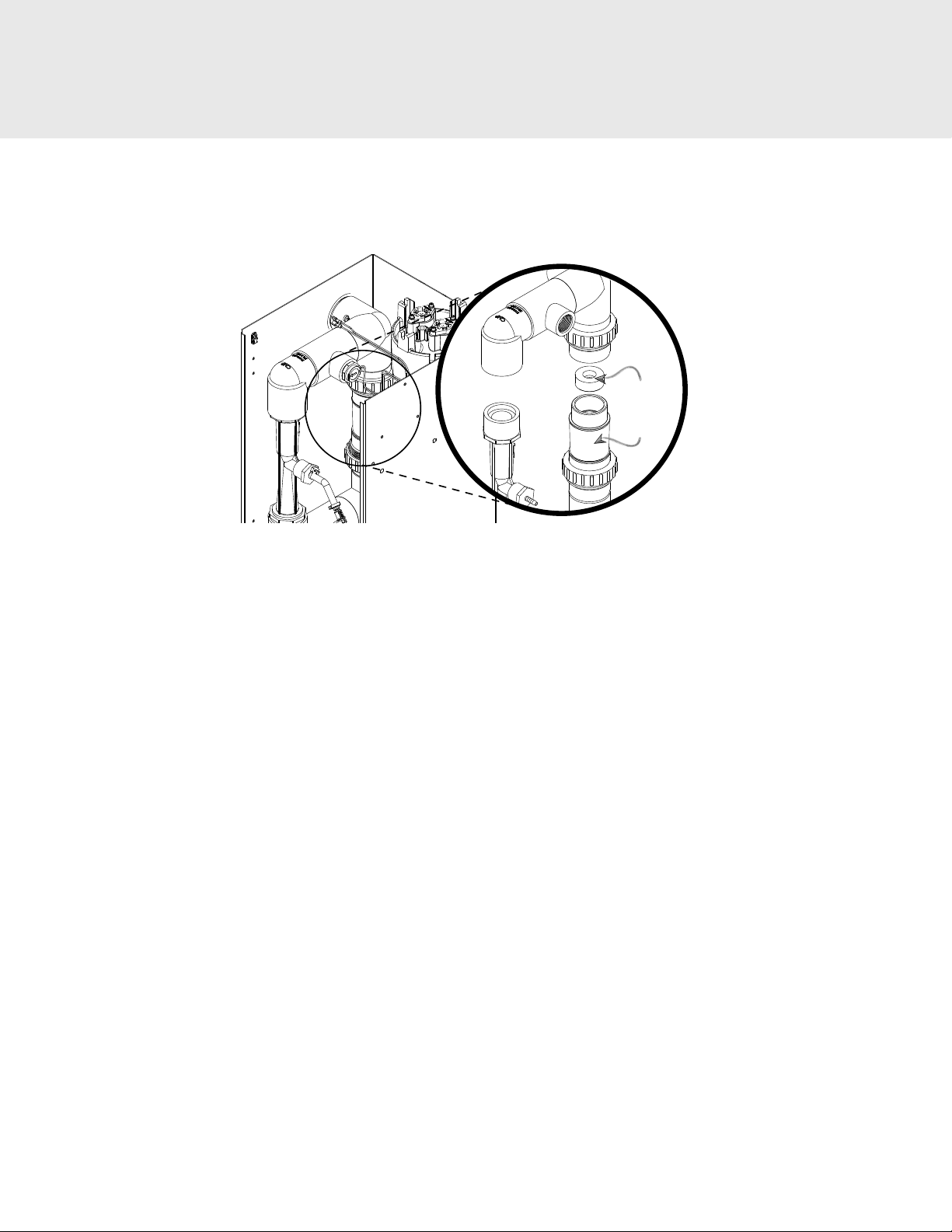

• The DEL AOP must be installed in an outdoor location, or indoors in a forced air ventilated room, and

installed so that the orientation is exactly as shown in following instructions. Install to provide water

drainage of generator to protect electrical components.

• Mount the DEL AOP so that it is inaccessible to anyone in the pool. Never attempt any servicing while

unit is wet.

• WARNING Short-term inhalation of high concentrations of ozone and long term inhalation of low

concentrations of ozone can cause serious harmful physiological eects. DO NOT inhale ozone gas

produced by this device.

• DANGER For your safety, do not store or use gasoline, chemicals or other ammable liquids or

vapors near this or any other appliance.

• NOTICE To maintain cosmetic integrity, protect this unit from direct prolonged sunlight exposure.

• WARNING To reduce the risk of injury, do not permit children to use this product.

• WARNING If unit is not operated according to instructions, high dosages of harmful substances may

potentially be released.

• ENVIRONMENTAL NOTICE - Hg-Lamp CONTAINS MERCURY. Manage in accordance with disposal

laws. See: www.lamprecycle.org

SAVE THESE INSTRUCTIONS!