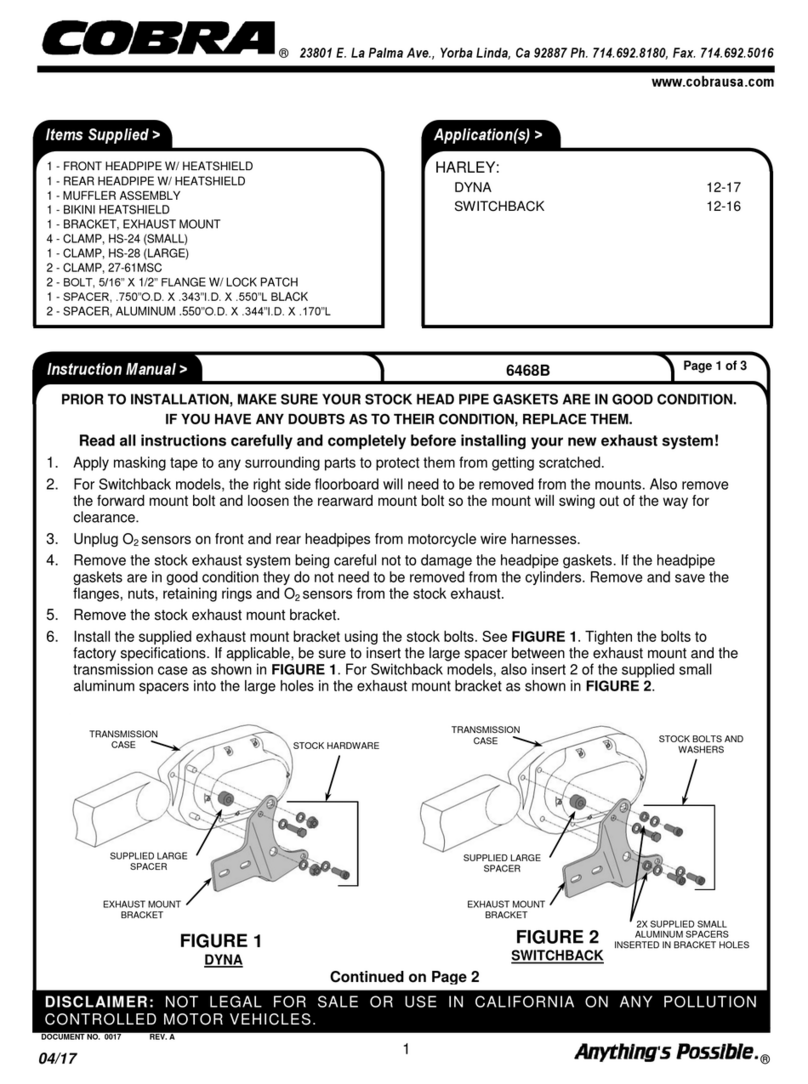

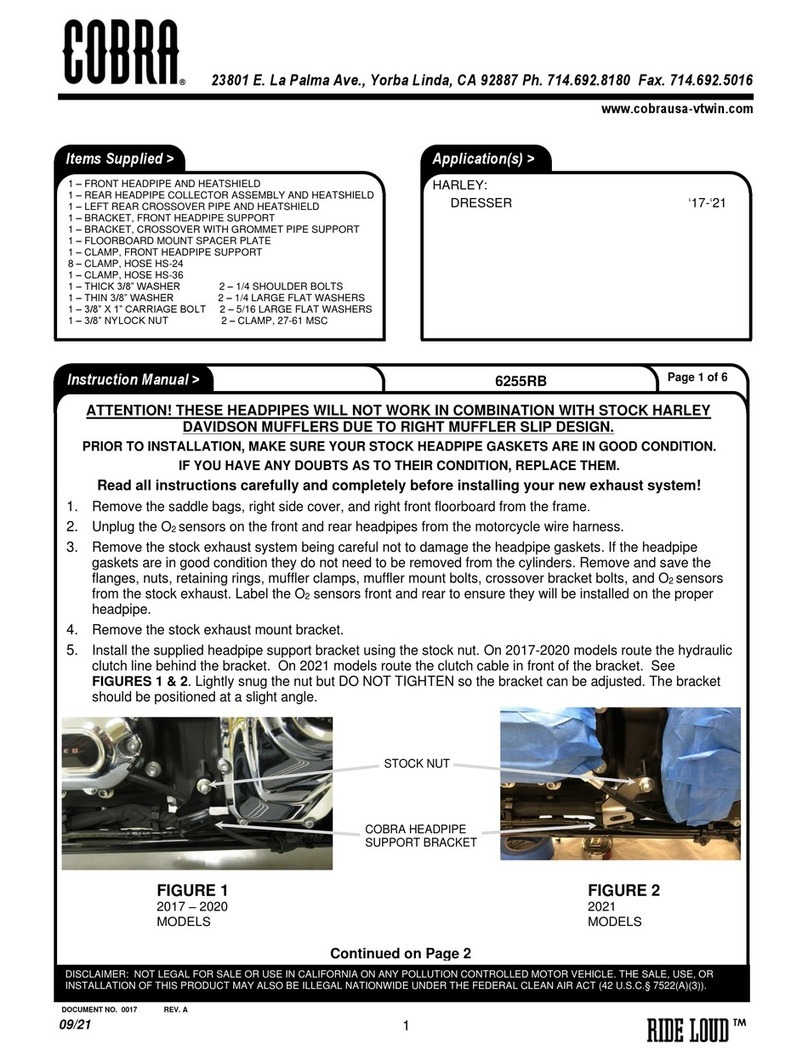

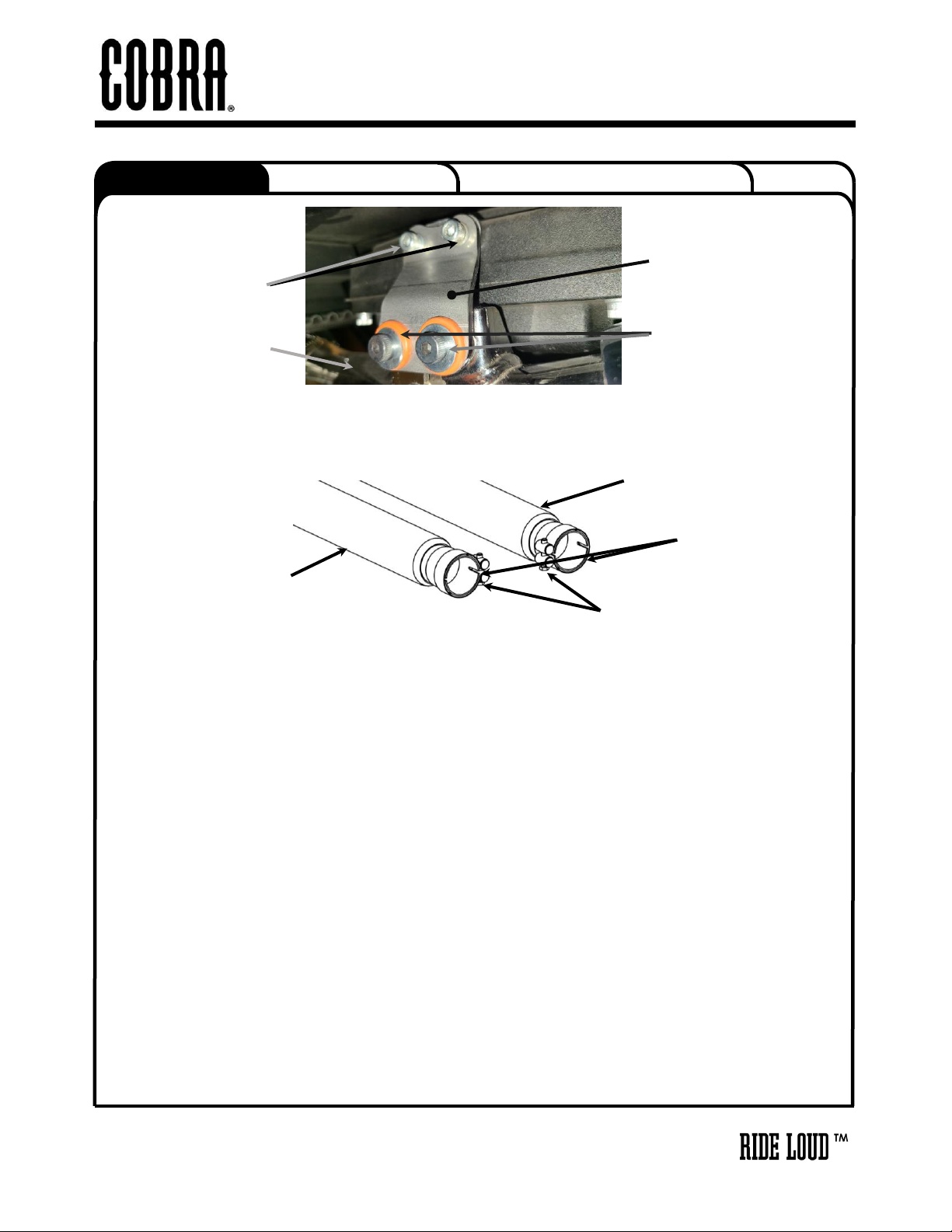

23. Install the right front heatshield over the right front headpipe. (Hint: Spread the hose clamps apart slightly to

make it easier to slide them over the headpipes.) Align the heatshield with the headpipe and the collector

heatshield. There should be an even gap around the collector heatshield. If the heatshield does not align

well with the collector heatshield then the rear crossover pipe may need to be loosened and pushed

forward or backward. When the heatshield is aligned properly snug the clamps but DO NOT TIGHTEN at

this time. See FIGURE 9 & 10.

24. If the heatshields will not align properly with the collector heatshield then the collector heatshield may need

to be loosened and moved forward or backward. Loosen the two button head bolts to adjust the collector

heatshield forward or backward. See FIGURE 10.

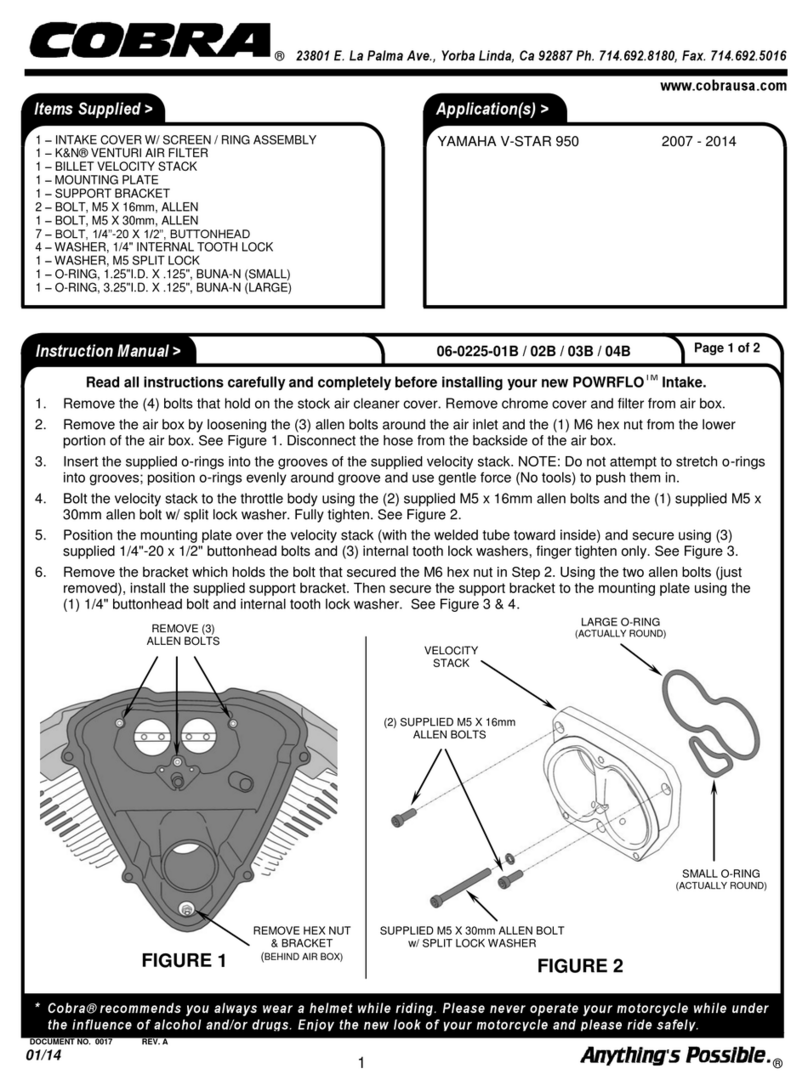

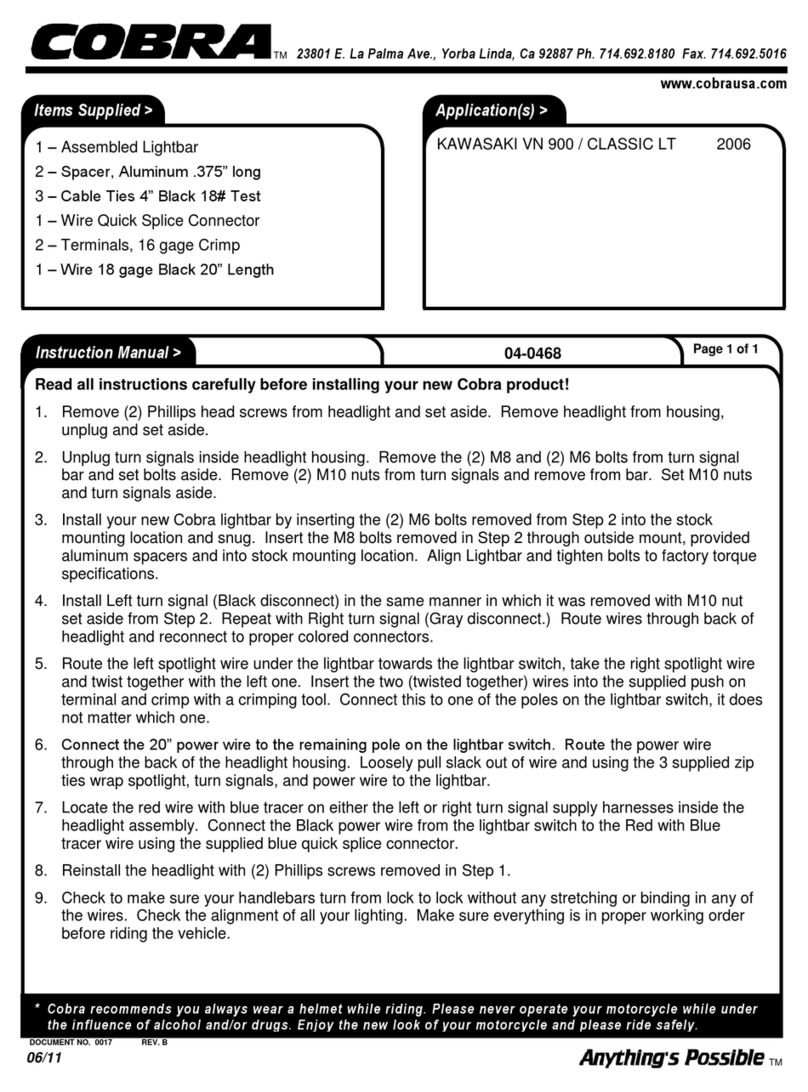

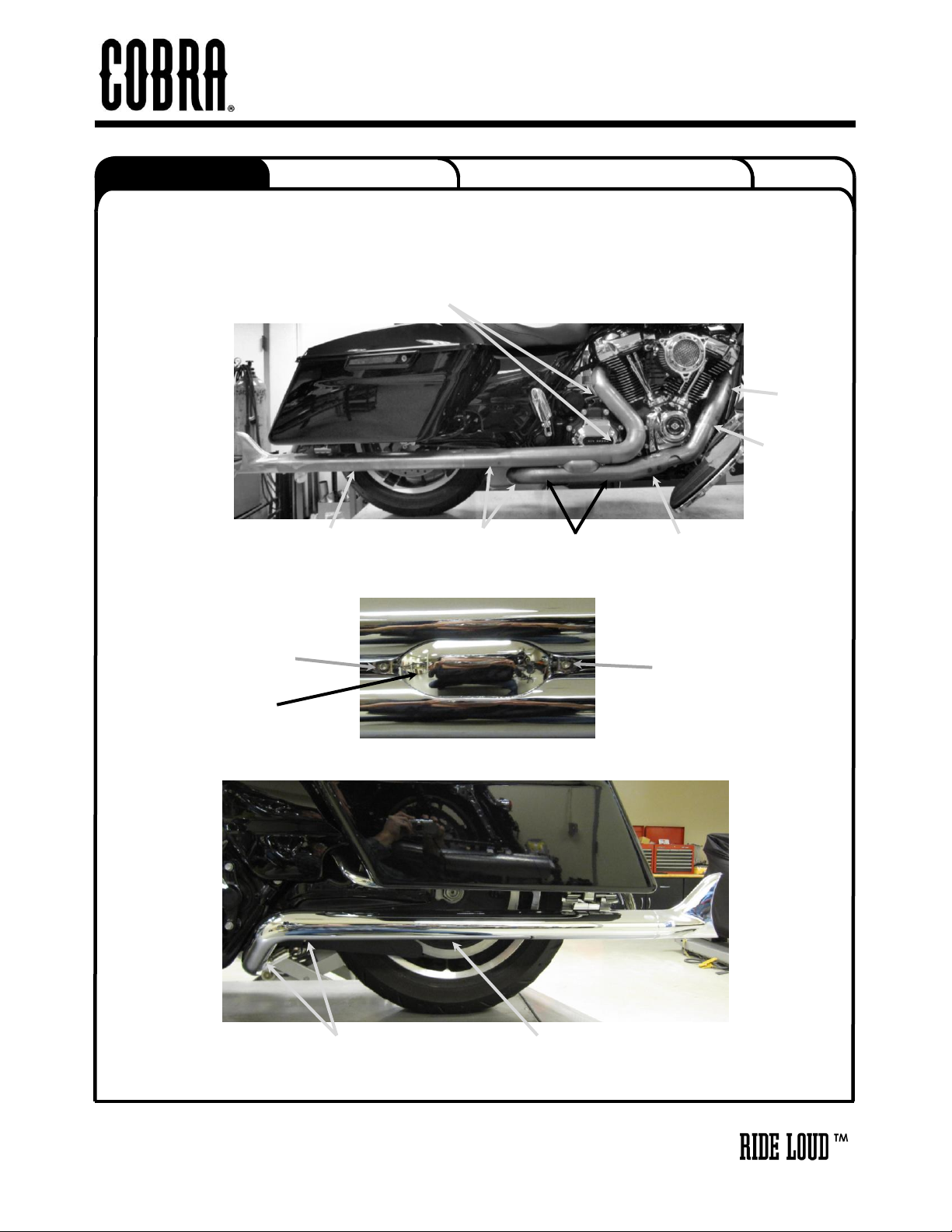

25. Install the left rear heatshield over the left rear muffler and crossover headpipe by first sliding the rear

portion of the heatshield over the muffler. Continue to slide the heatshield forward while pushing the front of

the heatshield gently into position. (Hint: Spread the hose clamps apart slightly to make it easier to slide

them over the headpipes.) Make sure the muffler clamp does not interfere with the heatshield and are

aligned as shown in FIGURE 11. Align the heatshield with the muffler and crossover headpipe and snug

the clamps but DO NOT TIGHTEN at this time.

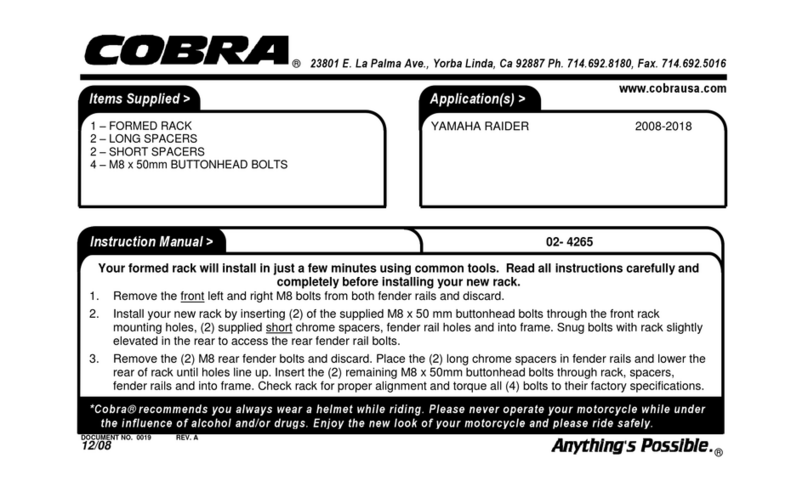

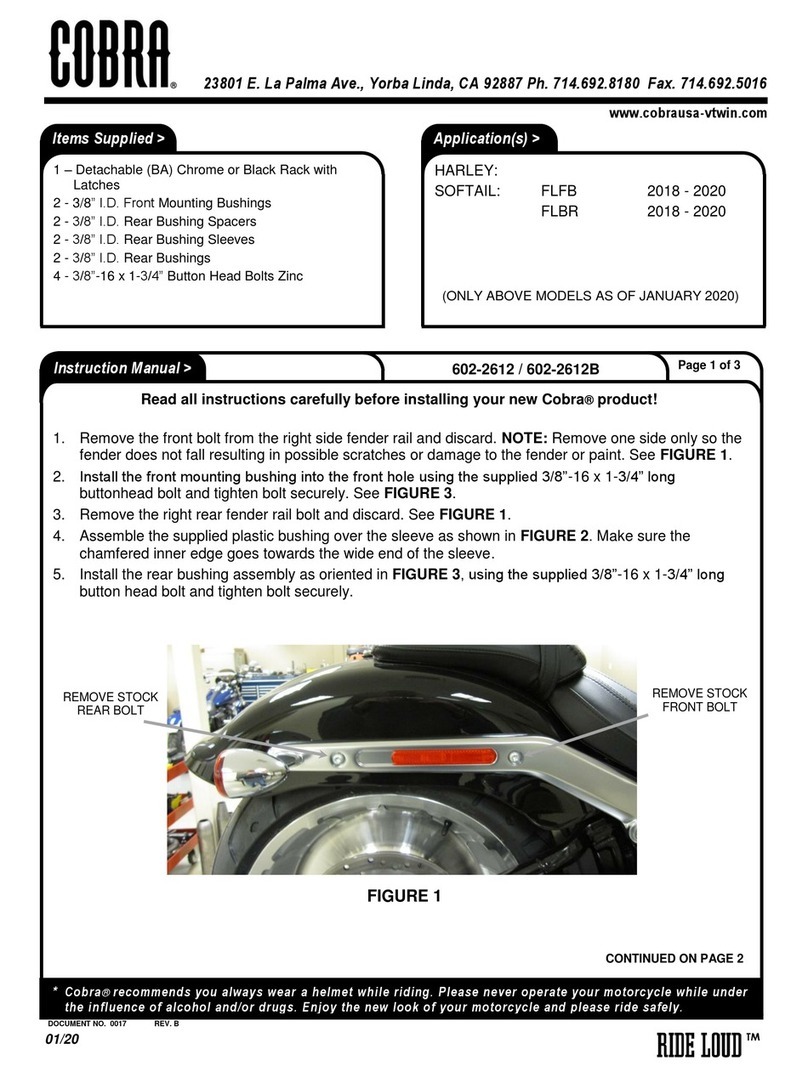

26. Align the threaded holes in the side of the fishtail tip with the holes in the muffler heatshield and slide it into

the rear of the heatshield and muffler. (NOTE: If it is difficult to slide the tip into the heatshield loosen the

clamps on the muffler heatshield. Failure to do this may cause damage to the tips.) Fasten the tip with (2)

of the supplied ¼-20 button head screws making sure there is no gap between the tip and muffler

heatshield when tightened. Do this for both left and right sides.

27. Make sure the rear of both fishtail tips are even on the back with each other.

28. Once the tips and heatshields are aligned properly tighten all hose clamps securing the heatshields.

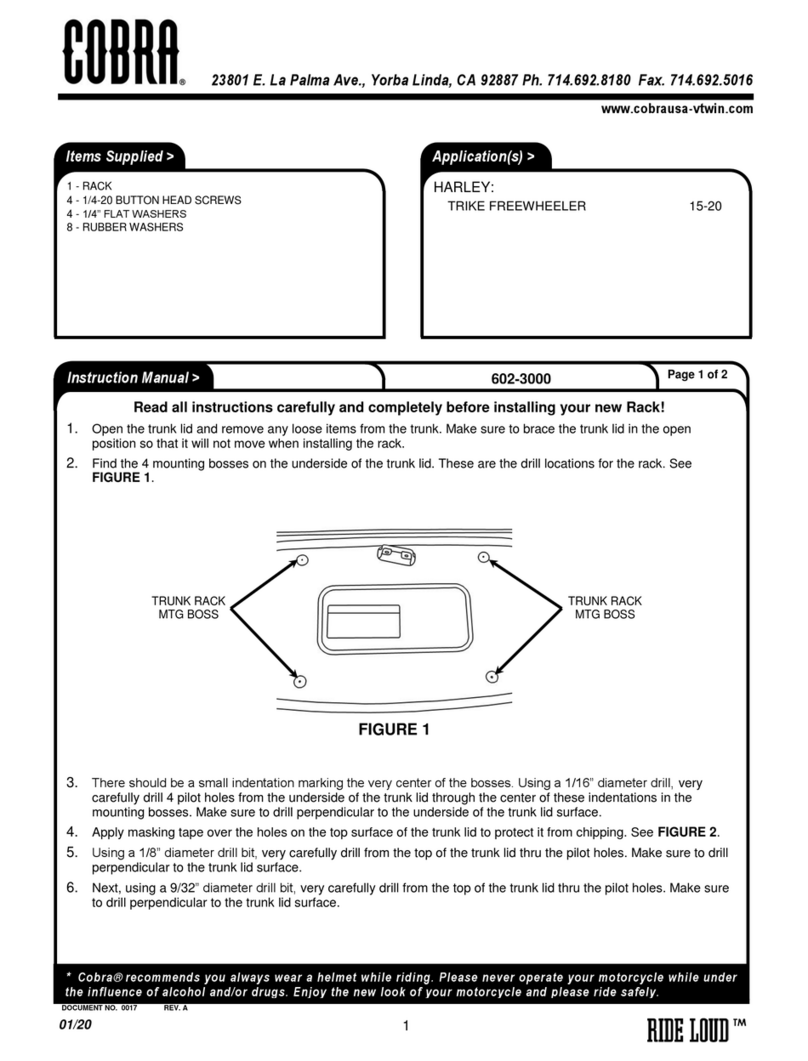

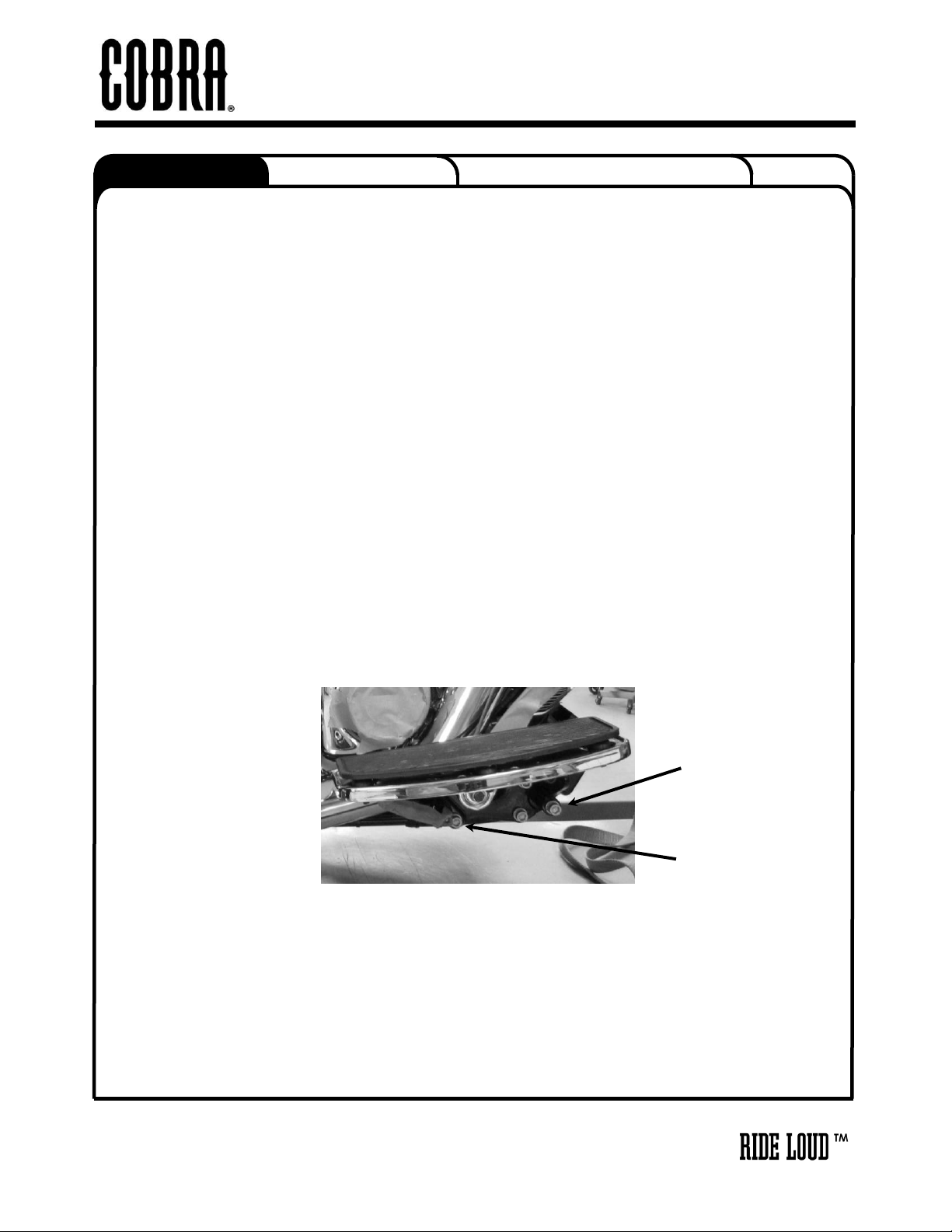

29. Insert the supplied floorboard spacer plate between the rear floorboard mount and the frame, then align the

dowel pin and reinstall the allen bolt. Tighten to factory specifications. See FIGURE 12.

30. Remove the allen bolt from the right front floorboard mount. Place the supplied thick washer between the

front floorboard mount and the frame. Reinstall and tighten the allen bolt to factory specifications. See

FIGURE 12.

28. Reinstall any other previously removed items. Tighten to factory specifications.

29. Make sure all the hardware (brackets, headpipes, heatshields, mufflers and floorboards) have been

tightened appropriately. Recheck after first 500 miles and again at each oil change.

30. IMPORTANT: Before starting your engine remove all fingerprints from chrome with a quality wax or

chrome polish. Failure to do so can cause chrome discoloration. Due to fluctuations in fuel delivery

settings, timing, etc., Cobra Engineering does not warrant against chrome discoloration.