If your Statim unit has been idle for a prolonged period of

inactivity, (e.g. for > 2 weeks) Scican recommend that a series

of checks and set-up procedures are undertaken before the

unit is returned to clinical use so that its operation will not

compromise the ecacy of your instruments when rst used.

The following procedure is based on the assumption that

during the period of inactivity, the unit and its accessories

have been dismantled and stored away from the clinical area.

If that is not the case, then certain parts of this procedure

may be ignored.

STATIM®G4 Cassette Autoclaves | Product Advice Sheet

1. MAIN UNIT

1.1. Check that all the following component parts of

the system are readily available.

Statim main unit

Cassette(s)

Instrument rack for cassette

Drying plates for cassette (5000 only)

Power cord

Waste bottle complete with lid, connector

tting and condenser

Exhaust tube

1.2. If appropriate, relocate the main unit in the clinical

area where it will be used.

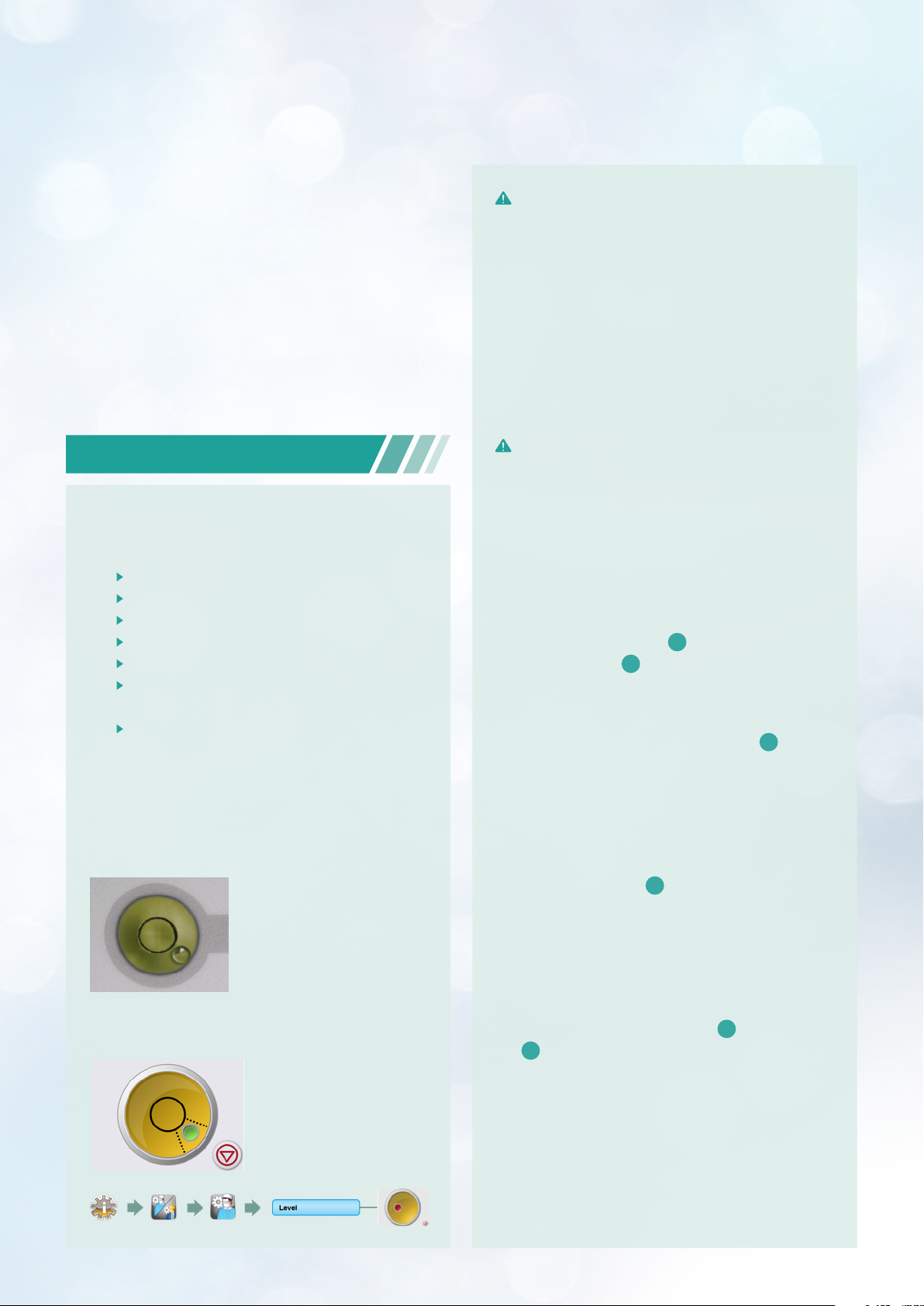

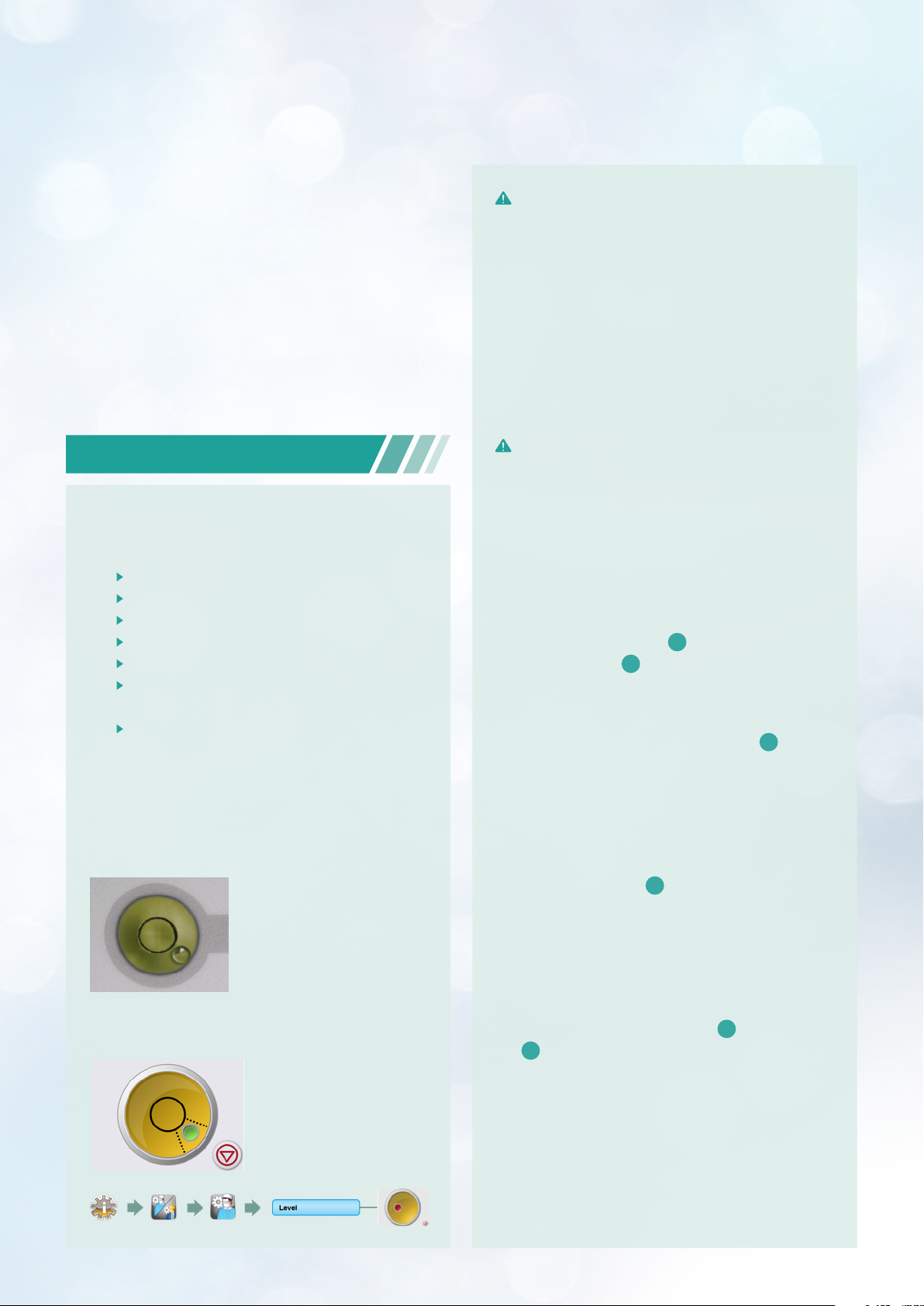

1.3. Check the level of the unit and adjust if necessary.

The level bubble on Statim

Classic unit is visible on the

front, right hand side of the

fascia.

NOTE: that the correct level

is with the bubble in the ‘4

O-clock’ position, NOT in the

centre.

The level bubble on Statim

G4 unit is an electronic level

that is displayed on the touch

screen when the correct menu

selection is made. The menu

order is:

NOTE

That the correct level is with the bubble in the ‘4 O-clock’

position, NOT in the centre. It will be GREEN when in the correct

position and RED when out of position.

1.4. Before returning the unit to service, Scican

recommend cleaning the external surfaces of the

unit with OPTIM™Cleaning and Disinfection wipes.

These have been tested on the external surfaces of

Statim units and are compatible with the materials

used.

NOTE

We do not recommend the use of any other type of chemical on

the unit as they have not been tested. In the absence of OPTIM™

use a soft, lint free cloth moistened with soap and water to wipe

down the surfaces. Dry the surfaces thoroughly after cleaning.

1.5. If appropriate, reassemble the system components

as follows;

I. Insert the exhaust tube 2into the tting on the

back of the unit 3(ensure it is FULLY inserted) and

pull gently to conrm a tight t.

II. Insert the other end of the exhaust tube into the

waste bottle tting. Tighten the tting 4to ensure

the exhaust tube is sealed in the tting. Tip – at

this stage it may be appropriate to check that all

the parts of the tting are tightened to ensure the

condensing coil is not loose and a good seal is

made with the lid.

III. Fill the waste bottle 1to the minimum level

shown on the side of the bottle with water. (A

low-level disinfectant, prepared according to the

manufacturer’s instructions, may be added to the

waste bottle to prevent bacterial growth in the

wastewater.)

IV. Attach (screw) the waste bottle 1and lid assembly

5together and locate the waste bottle assembly

close to the unit but BELOW the unit.

Check that the exhaust tube is not bent or

kinked as this will restrict the ow of steam and

condensate out of the unit.