EQUIPMENT MANUAL FOR RD-1820

RD-1820 QE Copyright - refer to title page Page 2

ENU Status : 1-0-0

0.2 CONTENTS

Section Page

0.2 CONTENTS.............................................................................................................................................2

0.3 INDEX TO FIGURES AND TABLES....................................................................................................4

0.4 HISTORY .................................................................................................................................................5

0.5 ISSUE CONTROL ..................................................................................................................................6

0.6 REFERENCES........................................................................................................................................7

0.7 GLOSSARY OF TERMS .......................................................................................................................8

0.8 SAFETY NOTICES AND ADMONISHMENTS...................................................................................9

0.9 SERVICING POLICY AND RETURN OF EQUIPMENT.................................................................10

0.10 READERS COMMENTS .....................................................................................................................11

1RD-1820 REPEATER INTRODUCTION...........................................................................................12

2EQUIPMENT DESCRIPTION .............................................................................................................13

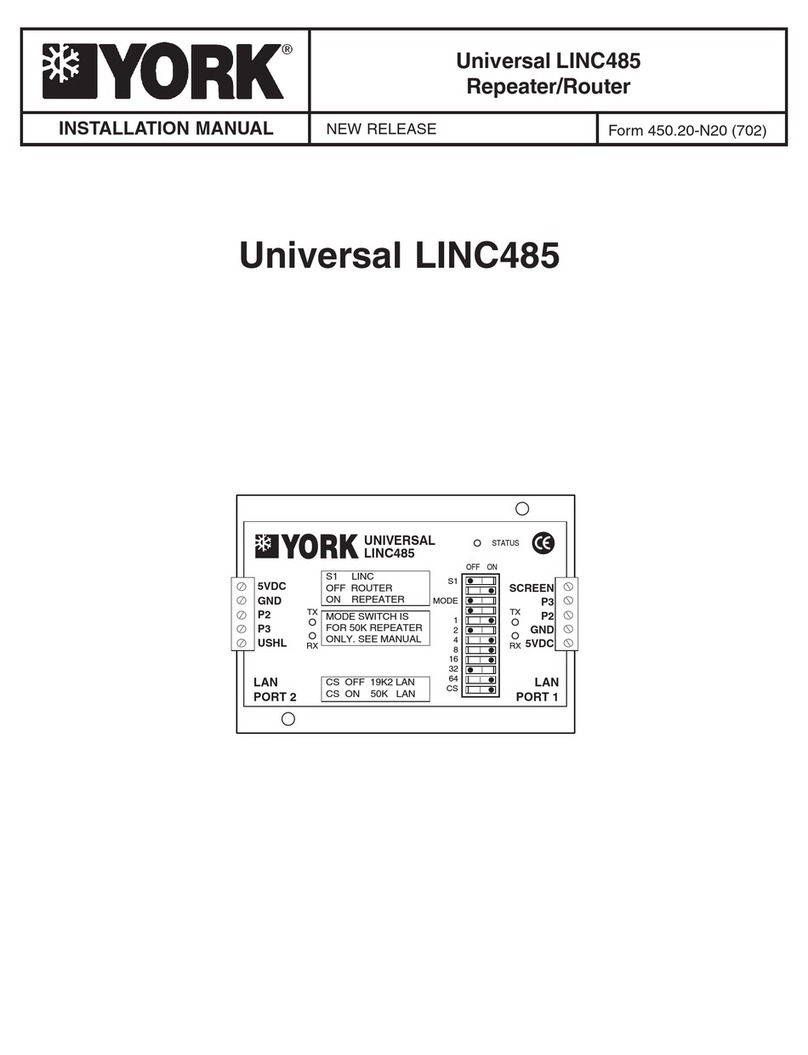

2.1 RD-1820 FUNCTIONAL BLOCK DIAGRAM ....................................................................................13

2.2 EQUIPMENT LAYOUT ........................................................................................................................13

2.3 MANUFACTURING ENTITIES ...........................................................................................................15

2.4 KIT OF PARTS......................................................................................................................................15

2.5 TECHNICAL SPECIFICATIONS ........................................................................................................16

2.5.1 ELECTRICAL AND POWER...............................................................................................................16

2.5.2 OPERATION & MAINTENANCE........................................................................................................17

3INSTALLATION.....................................................................................................................................18

3.1 WARNINGS AND ALERTS.................................................................................................................18

3.2 SITE PLANNING CONSIDERATIONS..............................................................................................19

3.2.1 REPEATER INSTALLATION CHECKLIST.......................................................................................20

3.2.2 ANTENNA INSTALLATION CONSIDERATION ..............................................................................20

3.3 INSTALLATION PROCEDURES .......................................................................................................21

3.3.1 GOODS INWARDS INSPECTION.....................................................................................................21

3.3.2 TOOLS ...................................................................................................................................................21

3.3.3 PREPARATION ....................................................................................................................................21

3.4 MOUNTING OPTIONS ........................................................................................................................21

3.4.1 WALL MOUNTING OPTION...............................................................................................................21

3.4.2 WALL MOUNTING DETAILS..............................................................................................................22

3.4.3 POLE MOUNTING DETAILS..............................................................................................................23

3.4.4 DRIP-LOOP...........................................................................................................................................23

3.4.5 EQUIPMENT CONNECTIONS...........................................................................................................24

4COMMISSIONING................................................................................................................................25

4.1 MCU LED INDICATORS .....................................................................................................................25

4.2 EQUIPMENT POWER-UP ..................................................................................................................25

4.3 OMT OVERVIEW..................................................................................................................................26

4.4 NON-VOLATILE MEMORY.................................................................................................................27

4.5 PREPARATION FOR REMOTE CONNECTION OF OMT USING WIRELESS MODEM.........28

4.6 PHYSICAL CONNECTION OF OMT TO EQUIPMENT .................................................................28

4.7 LOCAL COMMISSIONING..................................................................................................................29

4.7.1 USING OMT SOFTWARE...................................................................................................................29

4.7.2 DESCRIPTION OF PARAMETERS...................................................................................................32

4.8 COMMISSIONING PROCEDURES...................................................................................................37

5OPERATION .........................................................................................................................................38