ODPMT200 Series DryLine®Dehydrator User Manual

3

1.1 Introduction

This manual contains the information you need

to install, operate and maintain your ODPMT200

Series DryLine™ dehydrator. Please take the

time to read this manual before attempting to

operate or service the unit.

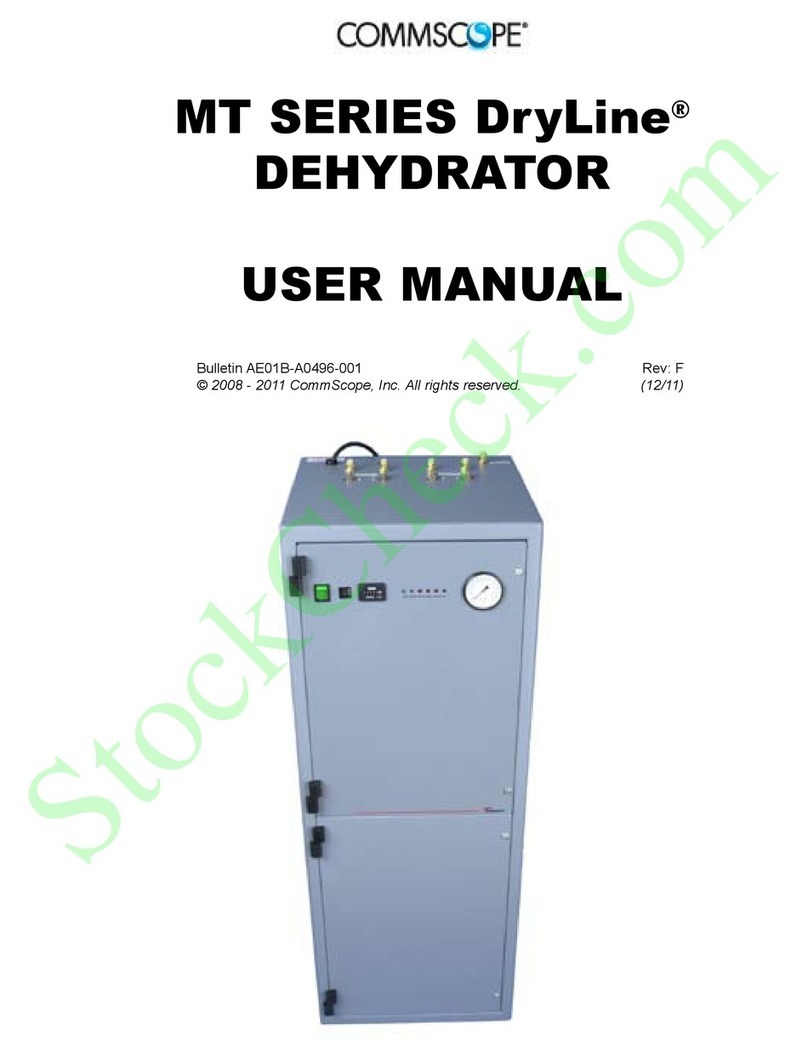

1.2 Description

ODPMT200 Series dehydrators provide dry air

for pressurizing small (up to 40 cubic feet, or

560 liters, in volume) antenna and transmission

line systems. The dehydrators produce -49ºF

(-45ºC) dewpoint dry air at an output rate of 0.2

cubic feet (1.4 liters) per minute.

Each dehydrator consists of an electrically-

driven air compressor, a membrane dryer

assembly, an automatic transmission line

pressure sensing system and a low-pressure

alarm output housed in a rigid metal chassis.

Theyaredesignedtomounttoaslaboor.

Optional brackets are available for pole

mounting capability. Their front panels feature

a pressure gauge, an indicating on/off switch, a

resettable circuit breaker, and a run time meter.

For easy serviceability, power connections,

alarmoutputconnectionsandalllterelements

are accessible from the front of the unit.

The ODPMT200 maintains transmission line

pressures at 5.0 lb/in2 (34 kPa). It is intended

for standard microwave antenna applications

and any other transmission line pressurization

requirement that supports a relatively high

pressure limit.

1.3 Operation

ODPMT200 Theory of operation.

The ODPMT200 series of DryLine™

dehydrators, while similar in moisture removal

technology, operates differently than the rest of

the DryLine™ series of dehydrators. In order to

provide a constant supply of dry air to small air

volume systems, and to maintain an acceptable

moisture level in the product air stream, a high-

pressure reservoir tank is needed. This reservoir

tank is connected to a pressure regulator and

oricetoyieldaxedoutputpressureof5.0psig

andanominalowrateof0.2CFM.Inaddition

to supplying the output air, the reservoir tank

also provides the dry air for the feedback loop.

The feedback loop is necessary to maintain the

dryness of the membrane cartridge.

During normal operation, the bleed air in the

feedback loop will cause the pressure to drop in

the internal reservoir tank, and the ODPMT200

compressor will cycle automatically. These

cycles will take place regardless of the system

volume or condition of the transmission line the

dehydrator is connected to. The rate of these

cycles, however, will vary. During the purge

cycle,thedehydratorwillcycleapproximately

every 2 to 4 minutes while showing 0 psig on

the pressure gauge and providing a constant 0.2

SCFM of dry air.

When connected to a very tight system, or

the output is capped, the dehydrator will

cycleapproximatelyevery60to90minutes

and maintain 5.0 psig system pressure while

providing close to 0 CFM of dry air. A system

that leaks will have a cycle time somewhere in

between, depending on the severity of the leaks.

Section 1

General Information