Head Office :

Press for more than 5 seconds

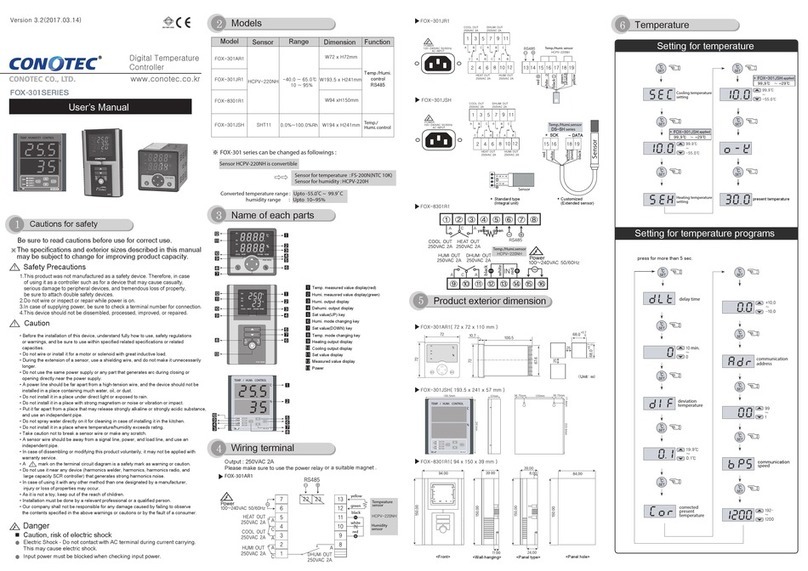

Temperature Program Setting

Common

Applicable to 2PD/2CD models

Applicable to 2PT/2CT models

Applicable to 2PT/2CF models

Press the KEY for 5 seconds under the current temperature indicating

condition to change the Program Setting Mode.

All the programs are to be either completed or automatically returned to

current temperature after 60 seconds by pressing the KEY for 2 seconds

after completion of setting procedure.

Detail Description on Function

Set the 1st stage temperature(Applicable model : 2PD, 2PT, 2PF, 2CD, 2CT, 2CF)

Set the 2nd stage temperature(Applicable model : 2PD, 2PT, 2PF, 2CD, 2CT, 2CF)

Set the 3rd stage temperature(Applicable model : 2PT, 2PF, 2CT, 2CF)

Set the 4th stage temperature(Applicable model : 2PF, 2CF)

Set the upper limit of user Set-up temperature.(Max. set point

allowed to the last user.) Prohibited setting value above

ex) When setting

Setting temperature cannot be increased over 25.0

Set the upper limit of user Set-up temperature.(Min. set point

allowed to the last user.) Prohibited setting value below

ex) When setting

Setting temperature cannot be increased below

Current temperature correcting function

Function of correcting the current temperature

against any errors generated by External Signal

Input Sensor and the difference with reference

temperature.(Example: Mercury thermometer or

existing thermometer or temperature controller used)

ex Actual temp.

Displayed temp.

difference with actual

temperature.

Correct the from 0.0

to -3.0 to display as

at the Indicating LCD window

Setting DATA locking function

A sort of safety device prohibiting the change of

various set-up values except with Primary User.

When setting : Lock all setting values except with temperature

setting value

When setting : Release all setting values except with temperature

setting value

Function selecting TEMP 1 Cooling and Heating

Applicable model

TEMP 1 output delay time

Applicable model

Used when the control object repeats the ON/OFF

frequently creating troubles. (Freezer, Compressor & etc.)

Function protecting product from instantaneous power

outage, or when re-engaging the power supply.

ex

Set temp.

Set value

set value

which point to be output ON?

In increasing current temp, if passes

26.0 at , after 1 min 30sec as

setting time, Relay is to be ON at .

The reason why applied output delay time

not from but is set to be interval

as .

Setting TEMP 1 temperature deviation

Applicable model

Constant interval required between ON and OFF

with ON/OFF control

Excessive actions of ON and OFF accelerates

the damage and/or wear of output contact of

relay or other devices, or creates haunting

phenomenon due to the external noise & other

interferences.

This function protects the contacts and other

components of device by setting the temperature

deviation in order to prevent above said phenomenon.

When used for freezing When used for heating

Main output

Output

Output

Current temp.

Current temp.

Setting temp.

Set

Current temp. > Setting temp. + Deviation temp.

Main output

Current temp. < Setting temp. - Deviation temp.

Output

Current temp.

Current temp.

Setting temp.

Output

Set

TEMP 2 Cooling ( ) and Heating selecting function

Refer to Item 9. (Applicable model: 2PD, 2PT, 2PF, 2CD, 2CT, 2CF)

TEMP 2 Output Delay Time

Refer to Item 10. (Applicable model: 2PD, 2PT, 2PF, 2CD, 2CT, 2CF)

Setting TEMP 2 Deviation Temperature

Refer to Item 11. (Applicable model: 2PD, 2PT, 2PF, 2CD, 2CT, 2CF)

TEMP 3 Cooling ( ) and Heating selecting function( )

Refer to Item 9. (Applicable model: 2PT, 2PF, 2CT, 2CF)

TEMP 3 Output Delay Time

Refer to Item 10. (Applicable model: 2PT, 2PF, 2CT, 2CF)

Setting TEMP 3 Deviation Temperature

Refer to Item 11. (Applicable model: 2PT, 2PF, 2CT, 2CF)

TEMP 4 Cooling ( ) and Heating selecting function

Refer to Item 9. (Applicable model: 2PF, 2CF)

TEMP 4 Output Delay Time

Refer to Item 10. (Applicable model: 2PF, 2CF)

Setting TEMP 4 Deviation Temperature

Refer to Item 11. (Applicable model: 2PF, 2CF)

Example of Temperature Controller Application

Main output

Main output

What are the temperature

and program setting values

to turn the Heater OFF at

30.0℃ and ON at 25.0℃

again?

<Temperature Setting >

(Refer to the Temperature Setting Mode.)

Setting: 30.0℃

< Program Setting >

(Refer to the Program Setting Mode.)

(One side deviation, Setting point OFF)

(Because the on/off width is 5.0℃.)

What are the temperature

and program setting values

to turn the Cooler OFF at 0.0℃

and ON at 2.0℃ again?

<Temperature Setting >

(Refer to the Temperature Setting Mode.)

Setting

< Program Setting >

(Refer to the Program Setting Mode.)

(One side deviation, Setting point OFF)

Because the on/off width is 2.0℃.)

The above product specifications are subject to change

without advanced notice to improve the performance

Please be well-acquainted with and keep the above

-mentioned cautions.

Factory :

A/S Inquiry TEL : +82-51-819-0425~7

Please send the product for A/S to the address

of head office.

Main product and development

Digital temp./humi. controller

Digital timer,Current/Voltage meter

Development of other products.

min

sec

min

sec

min

sec

min

sec

min

sec

min

sec

min

sec

min

sec