pag. 2 / 22

WARNING!

•Carefully read the manual before the installation or use.

•This device is to be installed by qualified personnel, complying to current standards, to avoid damages.

•Before any maintenance operation on the device, remove supply inputs.

•The manufacturer cannot be held responsible for electrical safety in case of improper use of the equipment.

•Products illustrated herein are subject to alteration and changes without

prior notice.

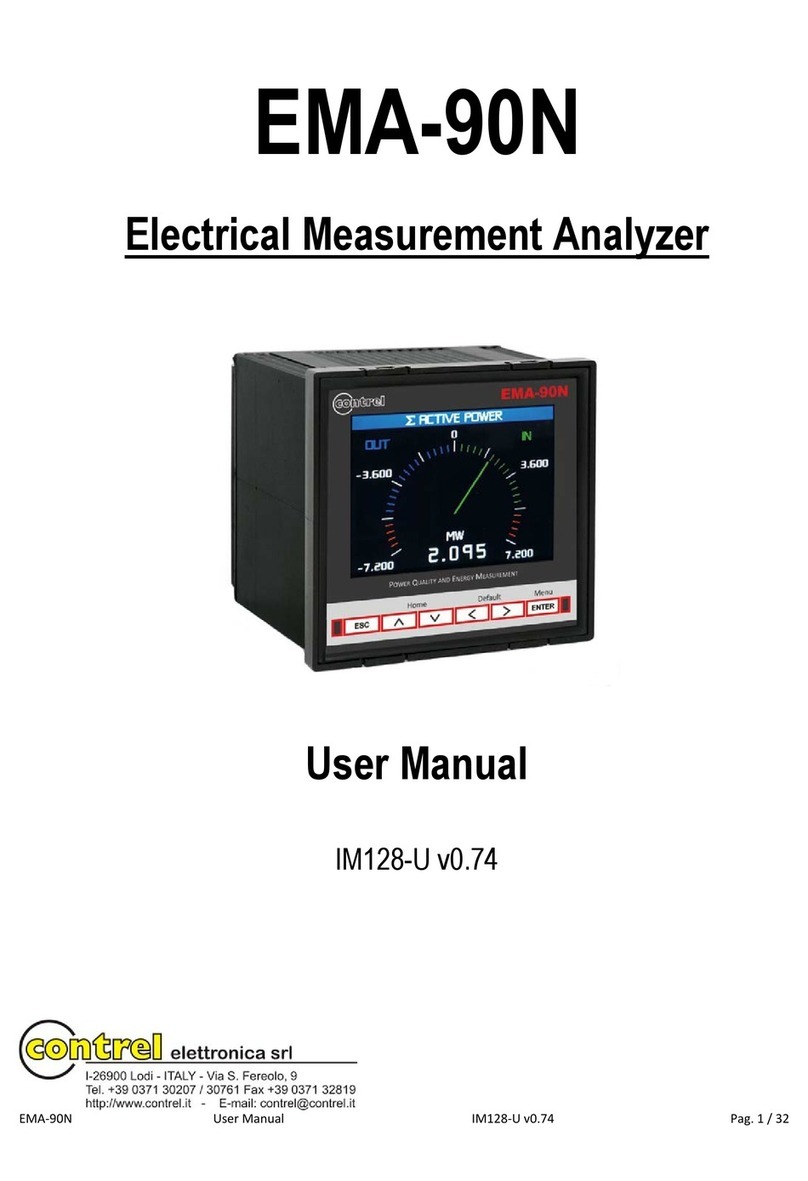

Introduction

The EMA-D6 is a Network Analyzer for displaying all the relevant system parameters in low and medium voltage power distribution. It is capable of single-phase,

two-phase or three-phase measurement and can be used in two-wire, three-wire, four-wire, TN, TT and IT systems.

Thanks to its large measured voltage range, the EMA-D6 with multi-range power supply can be connected in any low and medium voltage system up to a rated

system voltage of 690 VAC.

Higher voltages can be measured using voltage transformers. For measuring current, either x/1 A or x/5 A current transformer can be used or Rogowski coil

(optional), TT/TTA sensors (optional) or 333 mV (optional).

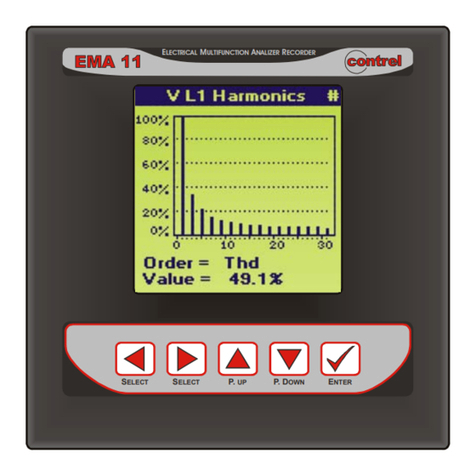

The combination of four function keys with the multi-language plaintext displays makes intuitive user prompting possible. The graphic color LCD offers user-friendly

interface.

The RS-485 or Ethernet interface or an optionally available interface module can be used for communication. In addition, the EMA-D6 has a multifunctional digital

output using an alarm. The analyzer can accept up to 4 digital inputs. The parameters can be set either direct on the device or via the communications interface.

Password protection is integrated via the front of the device to guard against unauthorized access.

Description

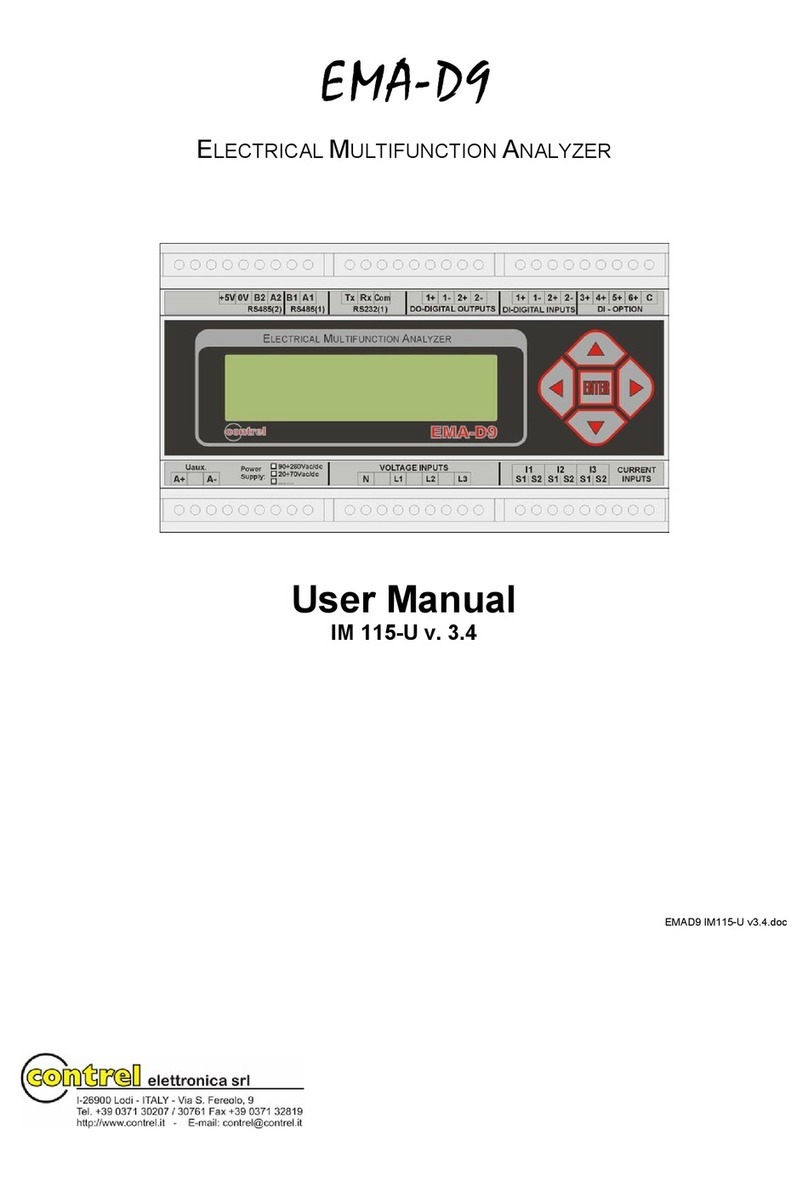

•Modular DIN-rail housing, 6 modules

•Backlighted LCD display

•True RMS measurements

•For current transformers x/1 A and x/5 A, Rogowski coil (optional), TT/TTA sensors (optional), 333 mV (optional)

•Keyboard with 4 keys for viewing and setting

•Easy and fast navigation

•Derivation of more than 50 measured variables from the basic measured variables with maximum, minimum, average and max demand values

•Continuous sampling (128 @ waveform)

•High measuring accuracy

•Harmonics V, I up to 63th order (optional)

•Up to 4 digital outputs

•Up to 4 digital inputs

•Up to 2 RS-485 communication (Modbus RTU protocol) (COM2 optional)

•ETHERNET interface (Modbus TCP protocol) (optional)

Voltage measurement

- Direct measurement on the system or using voltage transformers. External voltage transformers are required to measure higher voltages than the permissible

rated input voltages.

- Measuring voltage to 400 VAC / 690 VAC with multi-range power supply. The device is designed for measuring input voltages up to 400 VAC to the neutral

conductor and 690 VAC to Vph-ph.

Current measurement

- Measuring current of 1 A or 5 A for connecting standard current transformers. Rogowski coil (optional), TT/TTA sensors (optional).

Neutral or differential measurement

- The fourth current input channel (I4) is used to measure the current on the neutral line or differential current.

- If the CT for the neutral wire is not available, the measure of I4 input will be calculated from the phase currents.

LED and keyboard functions