PH: 330.273.6185 | Fax: 330.273.4468

Toll-Free Ph: 800.942.0829 | Toll-Free Fax: 800.942.0828

The Leader in Pedestrian Access Control

0220

1535 Industrial Parkway South

Brunswick, Ohio 44212

www.controlledaccess.com

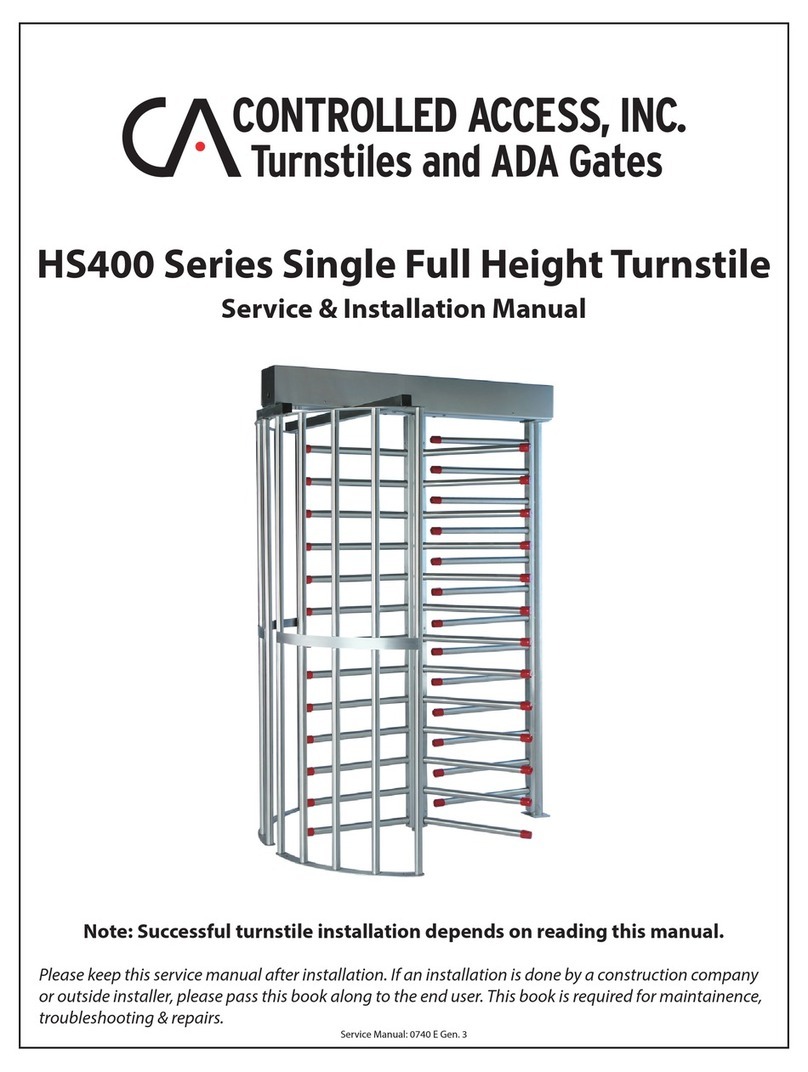

The Brute™ Series Waist-High BR5500-S

Bolt Down |Interior & Exterior Application

Applications:

The Brute turnstile is made for years of reliable

service (and offers many options) where cost

is an important consideration. It is ideal for

stadiums, convention centers, amusement

parks and landmarks.

Product Features:

Materials and Finishes:

• Lid: Our signature 304 stainless steel /

No. 4 satin nish

• Cabinet: Your choice of 8 designer powder

coat colors to match any décor. Black is

standard. Custom RAL colors can be quoted.

Design & Construction:

• Designed for secure and reliable operation

with aesthetics in mind

• Cabinet is constructed with rigid (7 gauge)

carbon steel

• Cover is constructed with (16 gauge) 304

stainless steel, No. 4 satin nish

• Arm assembly constructed with 1 5/16"

(33.4mm) diameter, (12 gauge) stainless steel

• Hub 4 1/2" (114.3mm) o.d. also made from

stainless steel

Dimensions:

•Height: 37" (939.8mm)

•Width: 22.500" (571.5mm)

•Depth: 20.125" (511.2mm)

•Arm Length: 14.5" (368.3mm)

Operation Features

6500 Series Control Head:

• Auto-indexing (self-centering) with adjustable

hydraulic shock suppression

• Hardened tool steel locking bars, cam and

roller assemblies

• Permanently lubricated bearings

• Your choice of manual or electronic control on

both directions

• Nearly universal integration to any number of

access control systems

• Your choice on each electronic direction of

locking or unlocking on power failure

Options:

• Daylight visible indicator lights

• Bi-directional key overrides

• 8 digit key resettable LCD counter with seven

year lithium battery

• Additional options available upon request

Warranty:

Units are warranted against defects in materials

and workmanship for a period of one year from

date of delivery. See warranty information for

specic details.

* Dimensions are approximate

Electrical Specications:

Input Voltage: 100-240 VAC

Input Current: 1.3 - .55 A

Frequency: 50/60 Hz

Storage Temperature: -40 to 158°F

Operating Temperature: -4 to 131°F

Operating Voltage: 24VDC

Operating Current: 1.2 A (typical)

Standards and Codes:

Austenitic stainless steel:

ASTM A240, A249, A276

Hot rolled steel:

AISI C-1020, AISI C-1018

All fasteners provided meet IFI ANSI/

ASME Fastener Standards

American Welding Society (AWS)

Standard D 1.1

The 6500 Series Control Head

is certified to conform to the

following standards:

UL 294, UL 325, UL Subject 2593,

CAN/ULC S319 & CSA C22.2#247

4008027

Our matching ADA

gate (BR5000-ADA)

is available for the

Brute Series.

Controlled Access, Inc. is certified

by Advantage International Registrar

to be an ISO 9001:2015 company

* Dimensions are subject to change without notice