Table of Contents

Chapter 1 –Introduction ........................................................................................................................................ 5

1.1 Explanation of Symbols .................................................................................................................................................... 5

Chapter 2 –Safety Instructions ............................................................................................................................. 6

Chapter 3 –Contents of This Package .................................................................................................................. 7

3.1 End of Line Filter Use............................................................................................................................................................ 8

Chapter 4 –System Flow Diagram ........................................................................................................................ 9

Chapter 5 –Description ....................................................................................................................................... 10

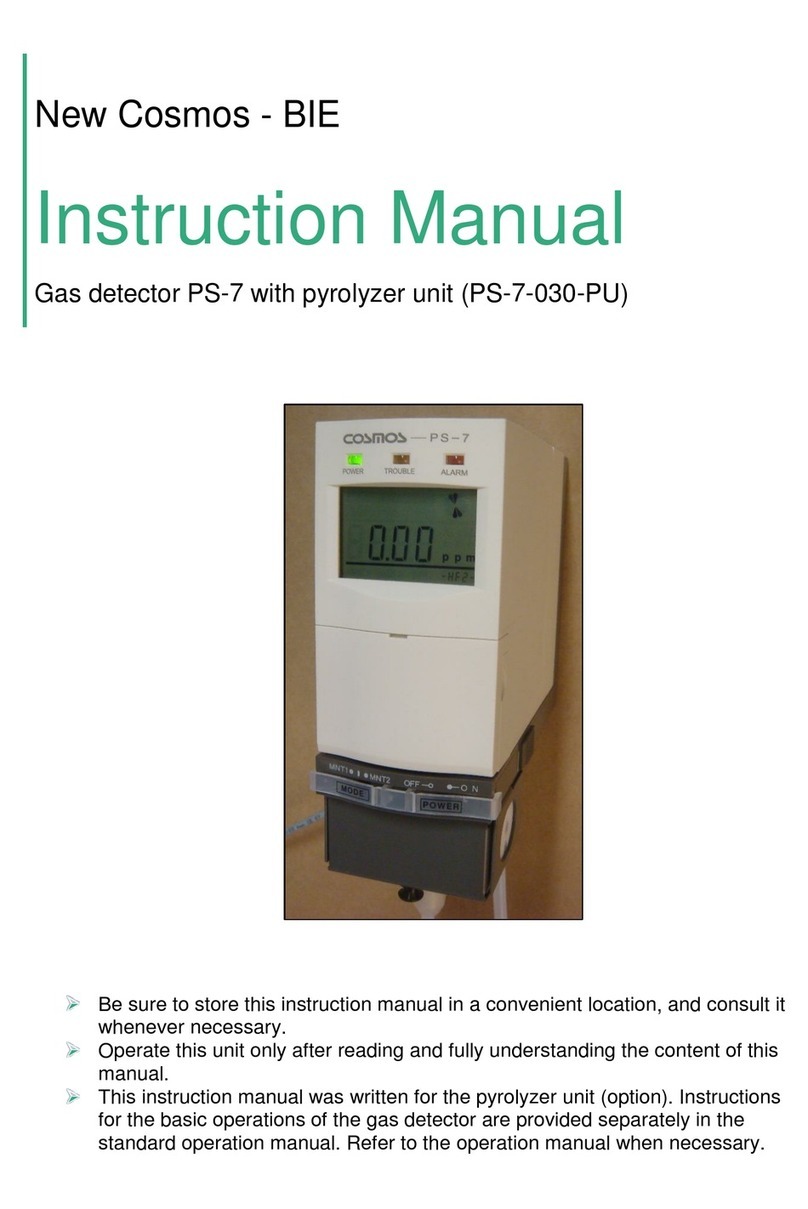

5.1 Components on the Main Unit ........................................................................................................................................... 10

5.2 Details of the Key Switch Section...................................................................................................................................... 12

5.3 Details of the LCD Screen Display ..................................................................................................................................... 13

Chapter 6 –Installation and Wiring ..................................................................................................................... 14

6.1 Installing the Main Unit ...................................................................................................................................................... 15

6.2 Wiring Instructions ............................................................................................................................................................. 16

Chapter 7 –Operation .......................................................................................................................................... 18

7.1 Operation Procedures......................................................................................................................................................... 18

7.2 Gas Alarm Operating Instructions ..................................................................................................................................... 30

7.3 Trouble Alarm Operating Instructions............................................................................................................................... 32

7.4 Test Mode Settings and Operating Instructions .............................................................................................................. 33

7.5 Maintenance Mode Settings and Operating Instructions................................................................................................ 34

Chapter 8 –Maintenance and Inspection............................................................................................................ 35

Chapter 9 –replacing Consumables.................................................................................................................... 38

9.1 Replacing the Filter Element (FE-1)................................................................................................................................... 38

9.2 Attach/Replacing the Sensor Unit ..................................................................................................................................... 39

9.3 Replacing the Sampling Unit.............................................................................................................................................. 41

Chapter 10 –Troubleshooting ............................................................................................................................. 44

Chapter 11 –Specifications................................................................................................................................. 45

Chapter 12 –Warranty ......................................................................................................................................... 46

Chapter 13 –Detection Principles ....................................................................................................................... 46

13.1 Electrochemical Sensor ................................................................................................................................................... 46

13.2 Hot-wire Semiconductor Sensor..................................................................................................................................... 47

13.3 Galvanic Cell Sensor......................................................................................................................................................... 47

Chapter 14 –Glossary.......................................................................................................................................... 48

Administrator Manual........................................................................................................................................... 49

Chapter 1 –Passwords........................................................................................................................................ 50

1.1 Password Protected Settings ............................................................................................................................................ 50

1.2 Releasing the Password Lock............................................................................................................................................ 50

Chapter 2 –Changing Settings ............................................................................................................................ 51