Cozzia EC-326G-CO Manual

Maintenance Service Manual

MODEL: EC-326G-CO

By Customer Service Department

CATALOG

1: Precautions for inspection and repair

2: Massage chair auto-check list

3: Common Troubles and Maintenance Methods list.

4: Tools List

5-1:Guidance of disassemble the backrest pad assy

5-2: Guidance of disassemble the backrest

5-3: Guidance of detach front cover & rear cover of backrest.

5-4: Guidance of detach up & down limit sensor

5-5: Guidance of detach the kneading motor.

5-6: Guidance of change the counting sensor of rolling motor

5-7: Guidance of disassemble the massage mechanism

5-8: Guidance of change rolling motor unit.

5-9:Guidance of service the seat pad assy

5-10:Guidance of disassemble the side board.

5-11: Guidance of disassemble main PCB

5-12: Guidance of disassemble the Transformer

5-13: Guidance of disassemble the Air valve.

5-14: Guidance of disassemble Inflator Pump

5-15: Guidance of disassemble the remote control

5-16: Guidance of disassemble footrest actuator and backrest actuator

5-17: Guidance of change the lower side board

5-18: Guidance of service the footrest.

6: Main PCB connecter diagram.

1. Precautions for inspection and repair

Inspection

Verify that the power cord is tightly connected on the machine.

Be careful to avoid electric shock.

Repair

Power off the supply before repair work begins.

Keep things tidy and in order during repair work.

When changing more than one part, identify the parts that are damaged and reuse the

serviceable parts.

During the dismantling or assembling process, do not damage other parts and PCB.

Be on the alert for loose or disconnected connectors during repair.

Do not leave any screws or other foreign objects in the unit after it is assembled.

Carry out test operation of the machine after the repair work is done.

It is preferable to perform the repair work on a carpet to prevent scratching or dirtying the

unit.

Clean the workplace after repair work is completed.

2:massage chair auto-check list

ON/OFF: KNEAD + TAP + POWER(buttons on the controler), press and hold the three buttons in two

senconds to turn on the automatic analysis system model.

After activating the "auto-checking model", the display screen of the controller keeps flashing; if

there is something wrong with the chair, the time area will show you the exact code of the

malfunction, meanwhile the buffer will make noise.

Code

Phenomenon

Malfunction description

Solutions

Remarks

01

remote control

tested any key

pressed more

than 25 seconds

1.one of the KEY has been

blocked.

1.check the key of the

remote control

turn on the

chair

02

remote control did

not connected

1.the remote control wire

is broken or the remote

control wire is

disconnected

1.reconnecte the

remote control wire or

change the remote

control wire.

turn on the

chair

03

backrest signal is

abnormity

1.backrest wire(black) is

not well connected.

2.up & down limit sensor

is broken

1.check whether the

backrest wire(black) is

well connected

2.change the up &

down limit sensor

turn on the

chair

04

backrest signal is

abnormity

1.backrest wire(black) is

not well connected.

2.the counting sensor of

the rolling motor is broken

1.check whether the

backrest wire(black) is

well connected

2.change the counting

sensor of the rolling

motor

activate the

Rolling

function

07

tested more than 2

wideth inspection

signal

1.wideth inspection board

is broken

2.wideth inspection wire is

not well connected

1.change wideth

inspection board

2.change backrest

wires.(black)

activate the

Rolling

function

08

more than 5

seconds did not

tested the wide

signal

1.wideth inspection board

is broken

2.the wire connect to the

wideth inspection board is

1.change wideth

inspection board

2.change backrest

wires.(black and gray)

activate

auto-check

model

disconnected

3.kneading motor is

broken or kneading belt is

lost

3.change kneading

motor

09

more than 5

seconds did not

tested the middle

signal

1.wideth inspection board

is broken

2.the wire connect to the

wideth inspection board is

disconnected

3.kneading motor is

broken or kneading belt is

lost

1.change wideth

inspection board

2.change backrest

wires.(black and gray)

3.change kneading

motor

activate

auto-check

model

10

more than 5

seconds did not

tested the narrow

signal

1.wideth inspection board

is broken

2.the wire connect to the

wideth inspection board is

disconnected

3.kneading motor is

broken or kneading belt is

lost

1.change wideth

inspection board

2.change backrest

wires.(black and gray)

3.change kneading

motor

activate

auto-check

model

12

when not

kneading but the

wideth inspection

signal still can be

tested

1.Main PCB is broken

1.Change PCB

activate

auto-check

model

13

tested signals

from up & down

limit sensor at the

same time.

1.up & down limit sensor

are broken

2.backrest wire(black) is

disconnected.

1.Change up & down

limit sensor

2.check whether the

backrest wire(black)is

well connected

activate

auto-check

model

14

more than 40s

didn't tested the

signal from the up

limit sensor

1.upper limit sensor is

broken.

2.backrest wires( black

and gray) are

disconnected

3.rolling motor is broken

or rolling motor wire

disconnected

1.change upper limit

sensor

2.check whether the

backrest wire(black) is

well connected.

3.change rolling motor

or rolling motor wire.

activate

auto-check

model

15

height counting

signal error

1.the counting sensor of

the rolling motor is broken

2.backrest wire(black) is

disconnected

1.change the counting

sensor of the rolling

motor.

2.check whether the

backrest wire(black) is

well connected.

activate

auto-check

model

16

can't test signal

from foot rest

recline actuator

1.down limit sensor is

broken

1.change down limit

sensor

2.check whether the

backrest wire(black) is

well connected.

3.change rolling motor

activate

auto-check

model

17

more than 40s

didn't tested the

signal from the up

limit sensor

1.down limit sensor is

broken

2.the backrest wire(black)

is disconnected.

3.rolling motor is broken

or disconnected

1.change down limit

sensor

2.check whether the

backrest wire(black) is

well connected.

3.change rolling motor

activate

auto-check

model

18

after tested signal

from down limit

sensor then

tested signal from

up limit sensor in

2 seconds.

1.upper limit sensor is

broken.

1.change upper limit

sensor

activate

auto-check

model

25

when start the

backrest recline

actuator, there is

no counting signal

for more than 2.5

seconds

1.backrest recline actuator

is broken

2.backrest recline actuator

wire is disconnected

3.the signal wire of the

backrest recline wire is

disconnected

1.change backrest

recline actuator

2.check whether the

backrest recline

actuator motor wire is

well connected.

3.check whether the

signal wire of the

backrest recline

actuator is well

connected

activate

auto-check

model

3: Common Troubles and Maintenance Methods are listed as following:

Serial

NO.

Phenomenon

Description

Maintenance Methods

01

No Function

When Starting.

The LCD isn’t illuminating:

①Fuse melts (in the Power Source Box or on

the transformer wire).

②Power supply circuit poorly connected.

③main PCB fails.

①Replace Fuse.

②Replace Power Box.

③Replace main PCB.

02

No function

when starting.

The LCD is illuminating:

①Mechanical switch fails or it’s wire is

opened.

②Up or Down Stroke Photo-electricity fails.

③Main PCB fails.

④Kneading is on without pressing any key

when starting and no response by pressing

other keys.

①Replace mechanical switch or it's

wire.

②Replace Stroke Photo-

electricity.

③Replace the main PCB.

④Width Inspection Board of PCB

fails, replace it.

03

No Width

switchover.

①The terminals of Width Inspection on main

PCB and wires are poorly connected.

②The terminals of Width Inspection on

massage mechanical and wires are poorly

connected.

③Width Inspection fails.

④Main PCB fails.

①&②Plug the terminal securely or

replace the wires.

③Replace Width Inspection.

④Replace the main PCB.

04

No Partial

Function.

①Height Inspection Terminal or wire poorly

contacts.

②Height Counting Subassembly fails.

①Plug the terminal securely or

replace the wires.

②Replace Height Counting Sub

-assembly.

05

No Rolling.

①Terminal or Wire Poorly Contacts.

②Down-stroke Photo-electricity

Subassembly Fails.

③Up-stroke Photo-electricity

Subassembly Fails.

④Rolling Motor Fails.

⑤Main PCB Fails.

①Plug the terminal securely or

replace the wires.

②Replace Down-Stroke Sub-

assembly.

③Replace Up-Stroke Sub-

assembly.

④Replace Rolling Motor.

⑤Replace main PCB.

06

No kneading.

①The terminals on main PCB and wires are

poorly connected.

②Kneading motor fails.

③Main PCB fails.

①Plug the terminal securely or

replace the wires.

②Replace the kneading motor.

③Replace main PCB.

07

No tapping.

①The terminals on main PCB and wires are

poorly connected.

②Tapping motor fails.

③Main PCB fails.

①Plug the terminal securely.

②Replace the tapping motor.

③Replace main PCB.

08

No response

when pressing

the keys on the

remote

controller.

①The terminals and wires are poorly

connected.

②The PCB in the remote controller fails.

①Plug the terminal securely or

replace the wires.

②Replace the remote controller.

09

Back rest

cannot be

reclined or

raised

①The terminals of reclining actuator and

wires are poorly connected.

②The reclining actuator fails.

③Main PCB fails.

①Plug the terminal securely.

②Replace reclining actuator.

③Replace main PCB.

10

Foot rest

cannot be

raised or

lowered.

①The terminals of foot rest actuator and

wires are poorly connected.

②The foot rest actuator fails.

③Main PCB fails.

①Plug the terminal securely.

②Replace foot rest actuator.

③Replace main PCB.

11

No vibration by

the motors in

the seat-pad.

①Print motors fail.

②The terminals and wires are poorly

connected or the wires fail.

③Main PCB fails.

①Replace the print motor.

②Plug the terminal securely or

replace the wires.

③Replace main PCB.

12

No gas charging

in the seat-pad.

①The terminal of the snuffle valves and

wires are poorly connected.

②The snuffle valves fail.

③The inflator pump fails.

④Main PCB fails.

①Plug the terminal securely.

②Replace the snuffle valves.

③Replace the inflator pump.

④Replace main PCB.

13

No gas charging

in the foot rest.

①The terminal of the snuffle valves and

wires are poorly connected.

②The snuffle valves fail.

③The inflator pump fails.

④Main PCB fails.

①Plug the terminal securely.

②Replace the snuffle valves.

③Replace the inflator pump.

④Replace main PCB.

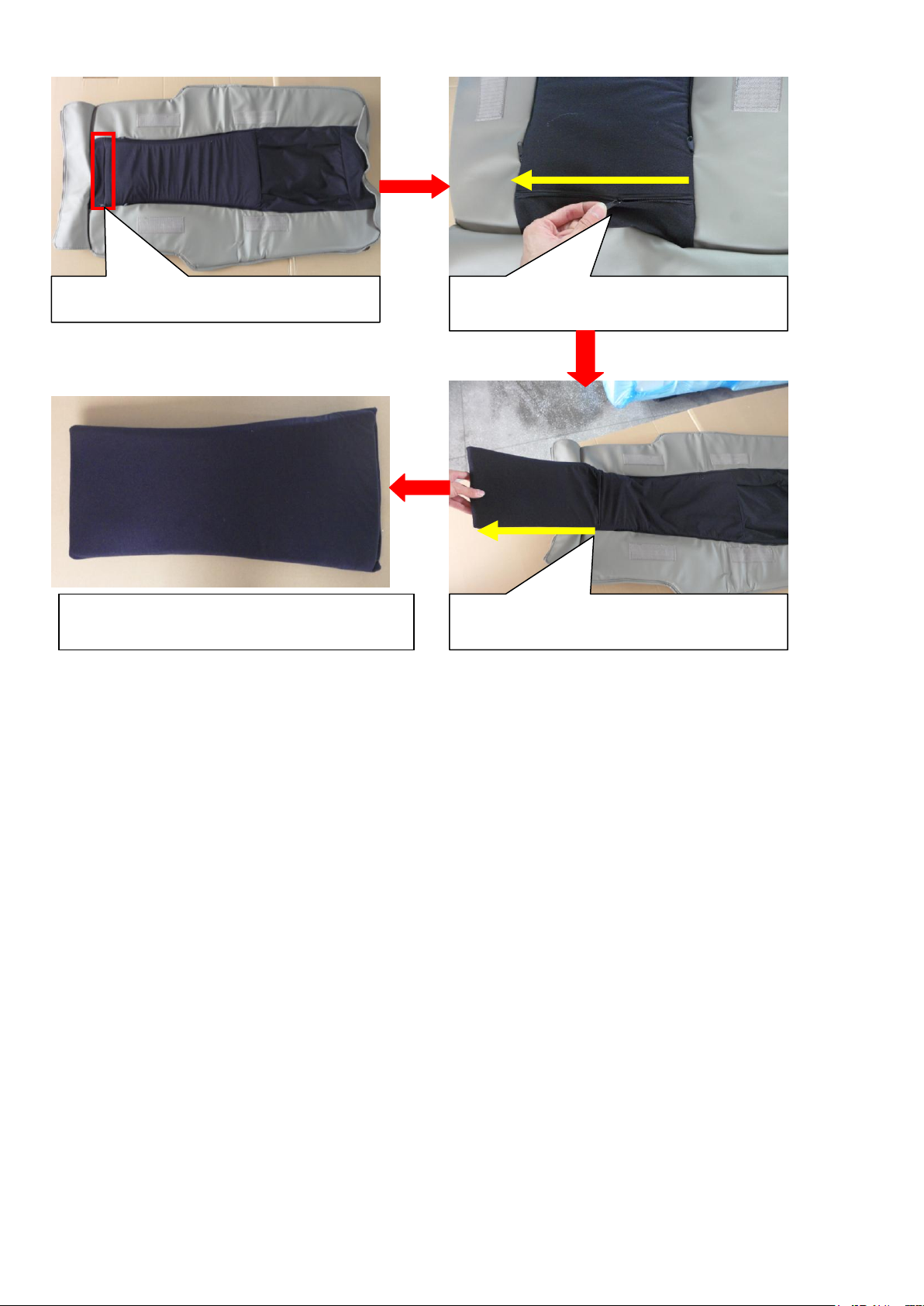

5-1:Guidance of disassemble the backrest pad assy.

A: Unzip the zipper between backrest pad and backrest. (As the pictures below show.)

B: Find the other zipper between backrest pad and seat pad. Then unzip it. (As the pictures

below show.)

C: Take off the backrest pad.

D:At the bottom of the rear of the backrest pad, we can find one zipper. Unzip the zipper then

Locate the zipper.

Unzip the zipper

Locate the zipper

Unzip the zipper

Backrest pad has been taken off.

we can find a sponge assy inside. (As the pictures below show)

Locate the zipper

Unzip the zipper.

The sponge assy has been taken off.

Pull the sponge assy out.

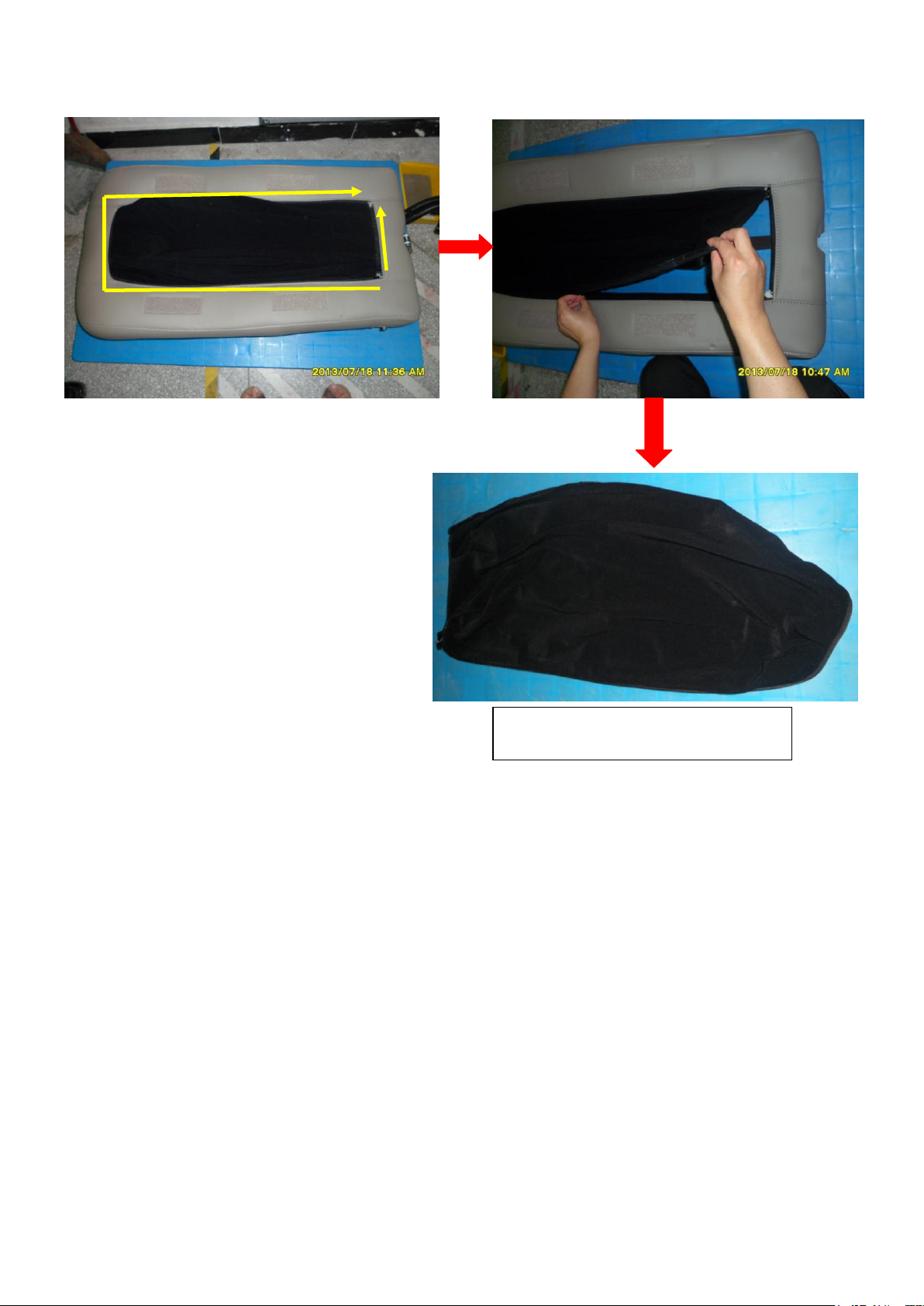

5-2: Guidance of disassemble the backrest.

A: Unzip the zipper between backrest and backrest pad. Then detach the Backrest pad Assy

from the backrest Assy and rest it on the Seat cushion Assy . ( As picture below show.)

B: There is a hook at the bottom of the backrest. Pull the hook up then push the backrest

forward. And then lay the backrest above the seat pad assy. ( As pictures below show.)

Locate the zipper.

Unzip the zipper

Locate the hook.

Pull the hook as the yellow

arrow show!

D: Disconnect backrest wire connecters. ( One is gray, one is black)

E: At the front of the backrest actuator there is a bolt. The bolt fixed by a bin. Use pliers take

off the bin first, Then remove the bolt. ( As pictures below show.)

Pull the hook up then push

the backrest forward.

The backrest has been lay above the

seat pad assy.

Locate backrest wire connecters.

Backrest wire has been disconnected.

E: Hold the backrest vertically and pull it up, then we can take off the backrest. ( As pictures

below show.)

Locate the bolt.

The bolt has been detached.

5-3: Guidance of detach front cover & rear cover of backrest.

A: Lay the backrest above seat pad. ( Refer to Guidance of disassemble the backrest.)

B: Slacken and remove the screws which fixing the rear cover of backrest. Then take off the

rear cover.

The backrest has been lay above the

seat pad assy.

Locate screws.

Rear cover has been taken

off.

C: Slacken and remove the four screws which fixing front cover to the backrest frame. Then we

can take off the front cover of backrest. ( As pictures below show.)

Locate screws.

Slacken and remove the screw.

Front cover of backrest

has been detached.

D: There are two zippers attach the fabric the front cover of backrest. Unzip these two zippers

then we can detach the fabric.

The fabric has been detached.

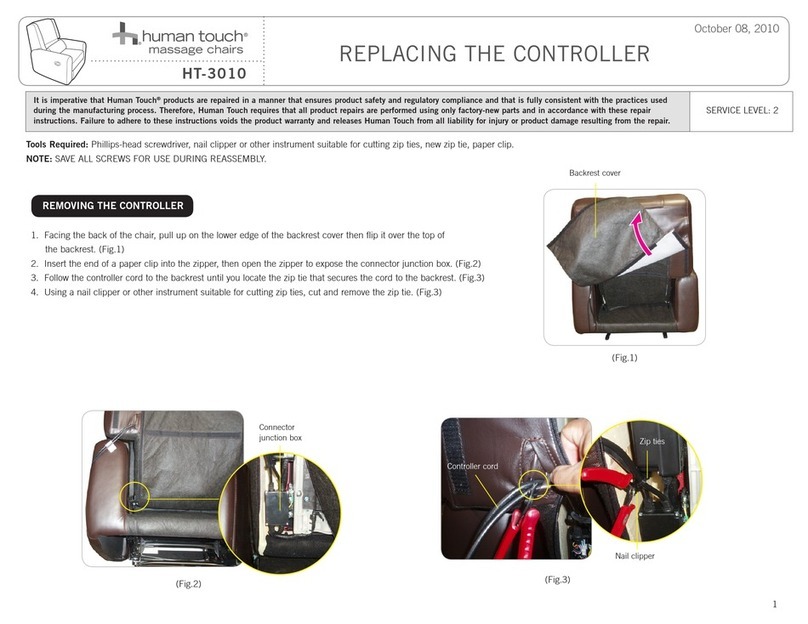

5-4: Guidance of detach up & down limit sensor.

A: Detach the rear cover of backrest. Then we can find up & down limit sensor. ( Refer to

Guidance of detach rear cover of backrest.)

B: Cut cable ties which fixing the limit sensor wire to the frame.

C: Use long nose pliers slacken and remove the screw nuts.

Locate up limit sensor.

Locate down limit sensor.

Locate cable tie.

Use diagonal cutter get

ride of the cable tie.

Remove the screw nuts.

Limit sensor has been detached.

Other manuals for EC-326G-CO

1

Table of contents

Other Cozzia Massager manuals