Table of Contents

2 / 32

Table of Contents

0Preface .............................................................................................. 4

1IMPORTANT SAFETY PRECAUTIONS ........................................... 5

Symbols and meanings in this document ......................................................5

Markings and meanings on the device ..........................................................5

Safety precautions of operating the AC-PLC KIT ..........................................6

2General Introduction........................................................................ 8

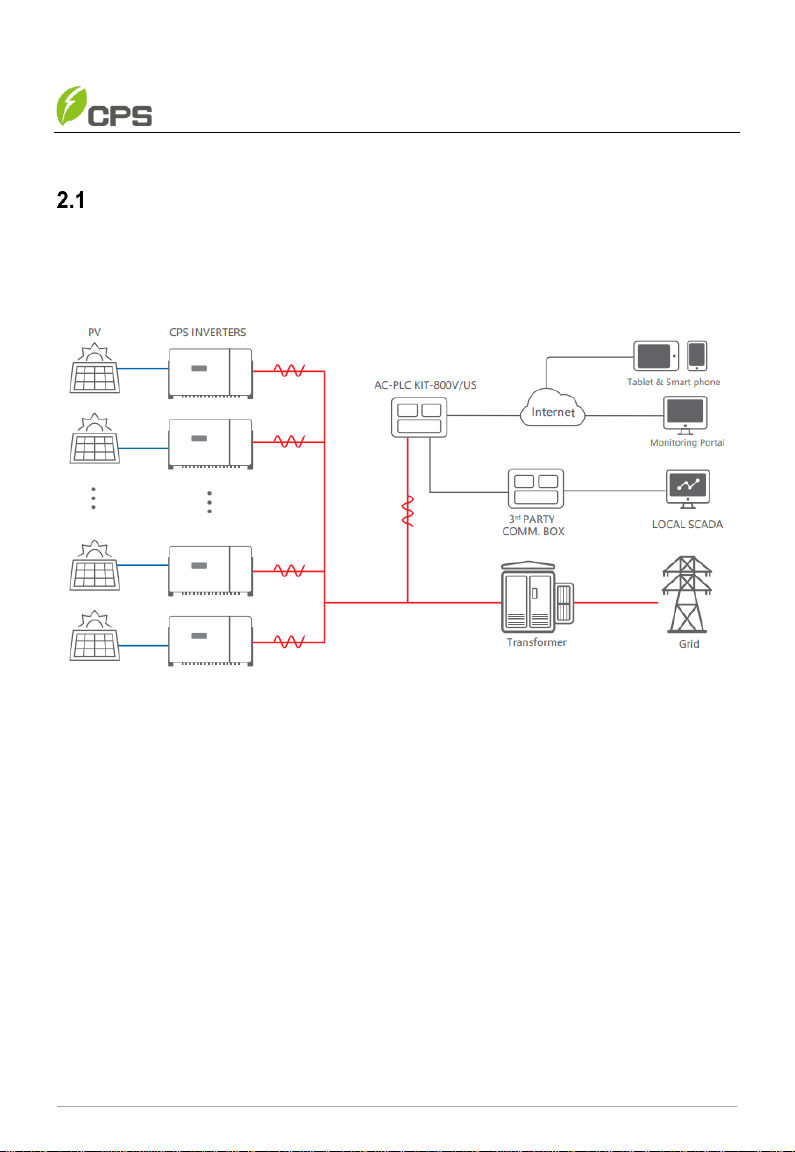

Overview of AC-PLC KIT-800V/US................................................................8

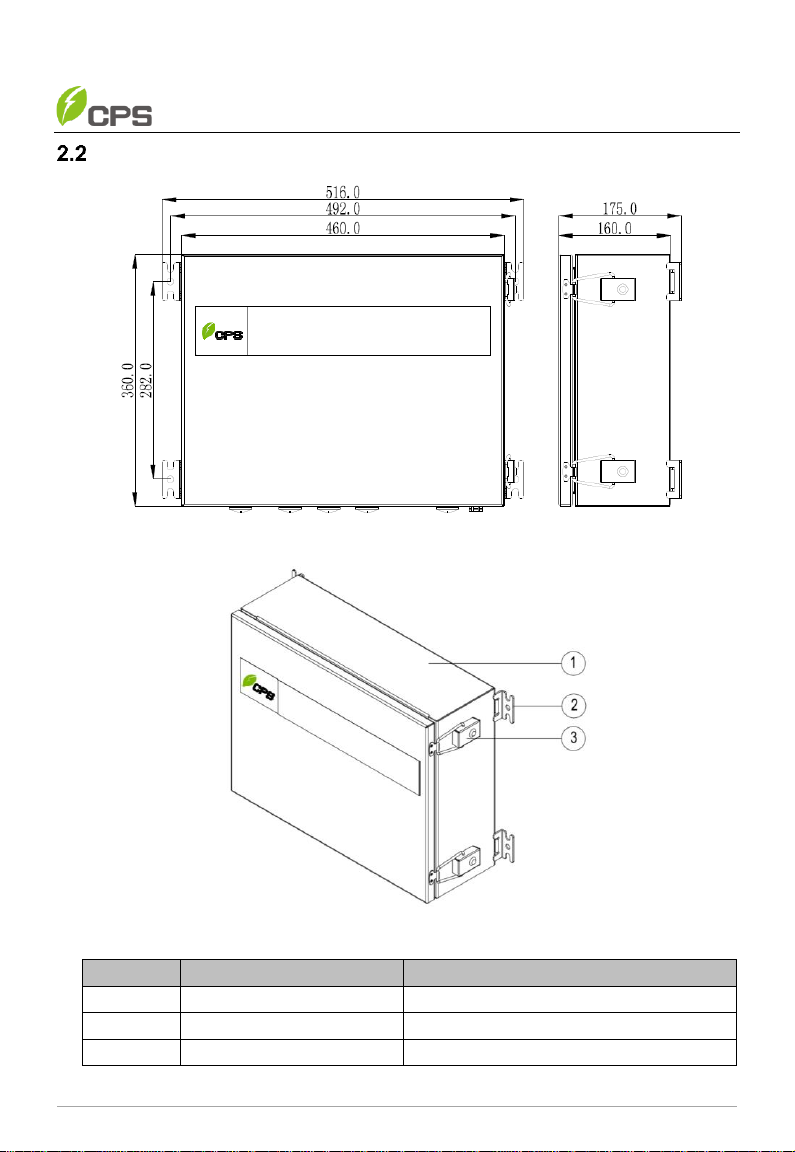

Appearance and dimension...........................................................................9

Features of AC-PLC KIT..............................................................................10

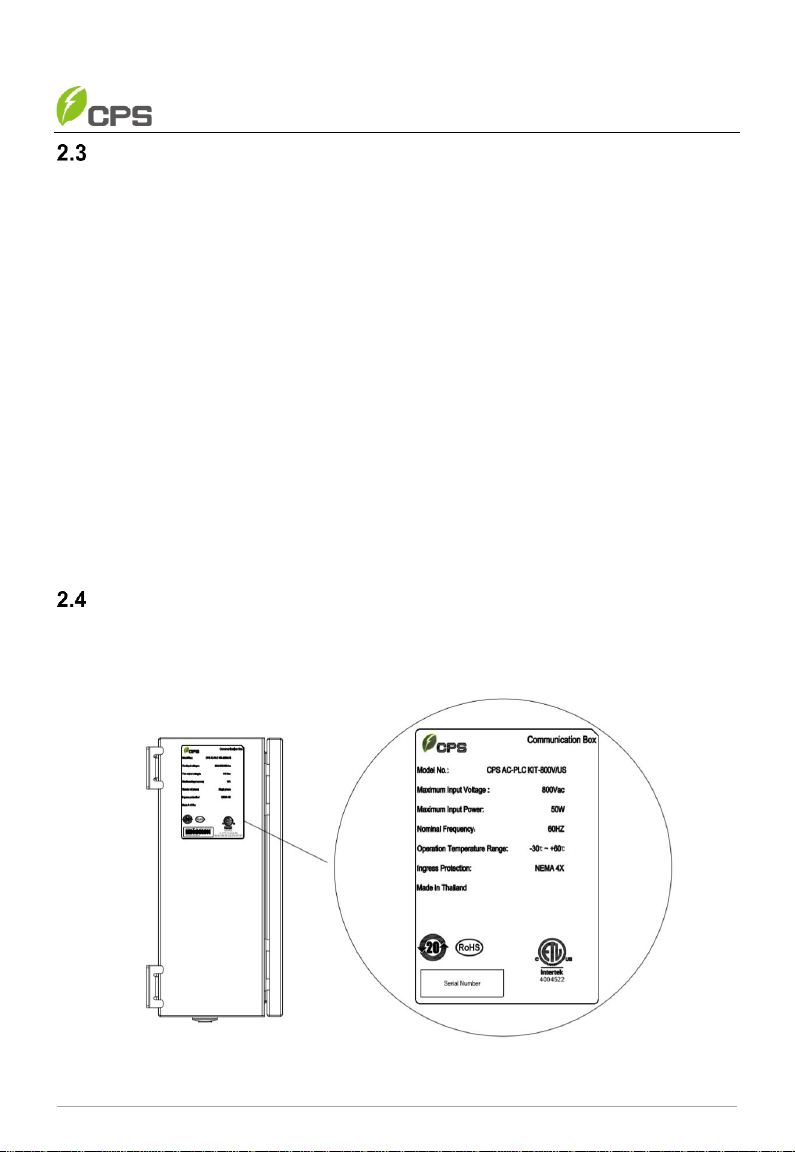

Nameplate ...................................................................................................10

Storage requirements..................................................................................11

Schematic Diagram and Circuit Design.......................................................11

3Mechanical Installation ................................................................. 12

Unpacking for Inspection .............................................................................12

Installation requirements .............................................................................12

3.2.1 Environment requirements ..................................................................12

3.2.2 Installation requirements .....................................................................13

Installation procedures ................................................................................13

4Electrical Connection .................................................................... 16

External Connection interfaces....................................................................16

Internal wiring terminals...............................................................................17

4.2.1 Appearance of PLC module ................................................................18

4.2.2 Indicator description............................................................................19

Recommended tools and torque .................................................................19

Cable connection.........................................................................................19

4.4.1 Copper bar grounding .........................................................................21

4.4.2 RS485 Communication Terminal Connection......................................21

4.4.3 Antenna Connection ...........................................................................21

4.4.4 AC Input Power Connection................................................................21

Cable Connection Notices for Joints and Seals...........................................21

5Commissioning and Maintenance ............................................... 25

Commissioning............................................................................................25

5.1.1 Inspection before Commissioning .......................................................25