INDEX

General Safety Instructions...............................................................3

Specific Safety Instructions...............................................................4

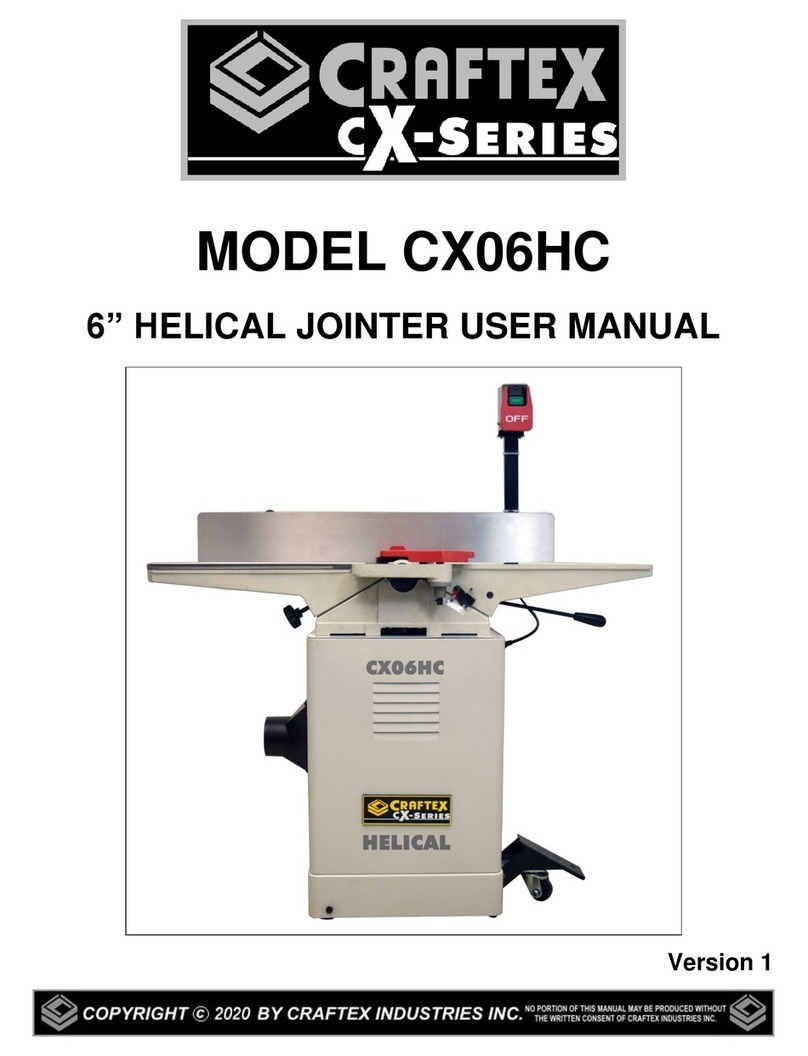

CT200-6" Jointer Features................................................................5

CT201-8" Jointer Features................................................................6

Physical Features..............................................................................7

Proper Grounding..............................................................................8

Setup................................................................................................9

Un-packing........................................................................................9

Assembly.......................................................................................10

Mobile Base ....................................................................................10

Installing Jointer to the Stand..........................................................10

Extension Table ..............................................................................11

Fence..............................................................................................11

Tilt Knob and Fence Lock Handle...................................................12

Cutter-Head Guard..........................................................................12

Dust-Hood.......................................................................................13

Pedestal Switch...............................................................................13

V-Belt..............................................................................................13

Operations & Adjustments...........................................................14

Basic Controls.................................................................................14

Test Run .........................................................................................14

Surface Planing...............................................................................15

Edge Jointing ..................................................................................15

Bevel Cutting...................................................................................16

Inspecting the Cutter-Head.............................................................17

Adjusting / Replacing Carbide Inserts.............................................17

Table Parallelism.............................................................................18

Setting Out-Feed Table Height .......................................................19

Setting In-Feed Table Height ..........................................................19

Parts Breakdown & Lists..............................................................20

CT200 Parts Breakdown............................................................20-21

CT201 Parts Breakdown............................................................22-23

CT200-6" Parts List...............................................................24-25-26

CT201-8" Parts List..........................................................27-28-29-30

Warranty ........................................................................................31

2