5

SPECIFIC SAFETY INSTRUCTIONS FOR CX618

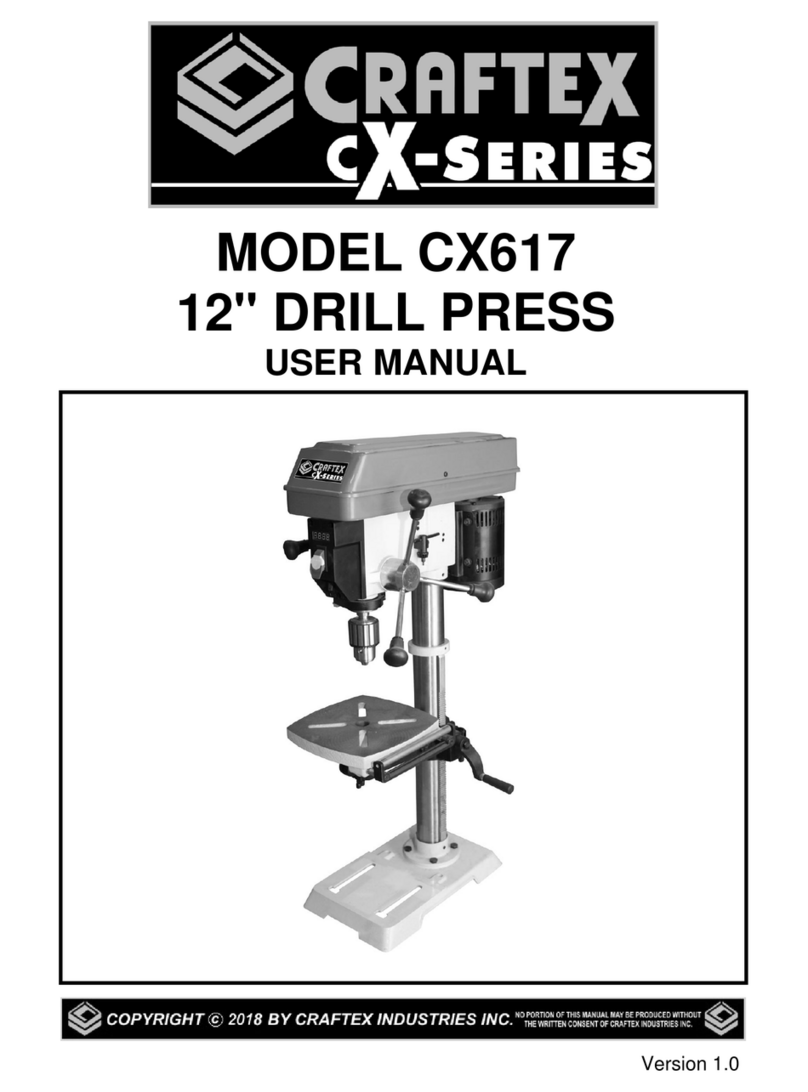

READ AND UNDERSTAND the user

manual before operating the CX617.

ALWAYS WEAR safety glasses for the

protection of your eyes while operating

this machine.

WEAR PROPER APPAREL. Loose

clothing, gloves neckties, rings,

bracelets, or other jewelry may get

caught in moving parts of the machine.

Wear protective hair covering to contain

long hair. Do not wear gloves and keep

your fingers and hair away from rotating

parts.

KEEP GUARDS in place. Safeguards

must be kept in place and in working

order. Do not operate the drill press

unless the chuck guard is in its position,

guarding the chuck.

MAKE SURE the workpiece is properly

clamped to the table before operating the

machine. Never hold the workpiece by

hand when using the mill.

MAKE SURE the cutting tool is sharp,

not damaged and properly secured in the

chuck before you start the machine.

SELECT The proper spindle speed for the

type of work and material you are cutting.

Let the spindle reach to its full speed

before beginning a cut.

NEVER LEAVE the machine unattended

while it is running.

ALWAYS turn off the power before

removing scrap pieces and cleaning the

machine.

SHOULD ANY PART of your tool be

missing, damaged or fail in any way, shut

off the machine immediately and remove

the plug from power source. Replace any

damaged or missing parts before

resuming operation.

MAKE SURE before installing and

removing any parts, servicing, cleaning, or

making any adjustments, the switch is in

the “OFF” position and the cord is un-

plugged from the power source.

BEFORE OPERATING your dill press

make sure you have read and understood

all the safety instructions in the manual

and you are familiar with your

DO NOT force the machine to do a job for

which it is not designed Always use the

machine for the purpose for which it was

designed.

NEVER turn the power ON with the cutting

tool contacting the workpiece