8

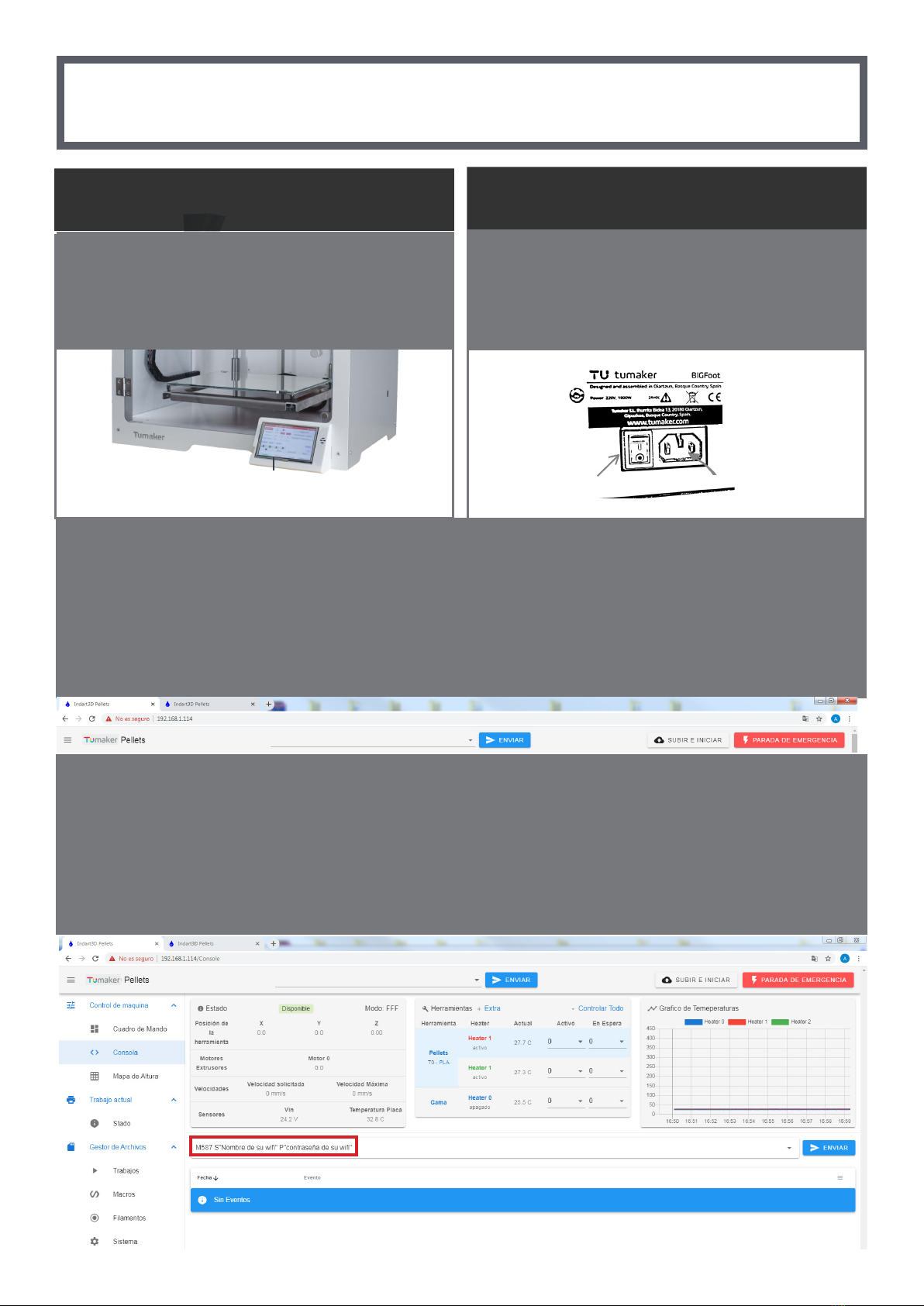

Tumaker 3D printing stations include the Simplify3D™

professional manufacturing suite, a software with all the

advanced and optimized characteristics to create the most

complex objects in the highest quality. It includes a powerful

simulator to make you more productive, visualizing the result of

the printing strategy you’re working on before you start

manufacturing.

If you have any questions about the use of the Voladora do not

hesitate to write us to the following email:

https://tumaker.com/tumaker-en/support/

You will be able to repair the imported designs in

Simplify3D itself and you will love the intelligent support

option. Spectacular functionality with which the software will

create the right support for the most complex parts.

If you have any questions about the use of the software,

please consult the following page:

https://www.simplify3d.com/support/

Simplify 3D printing sOFTWARE

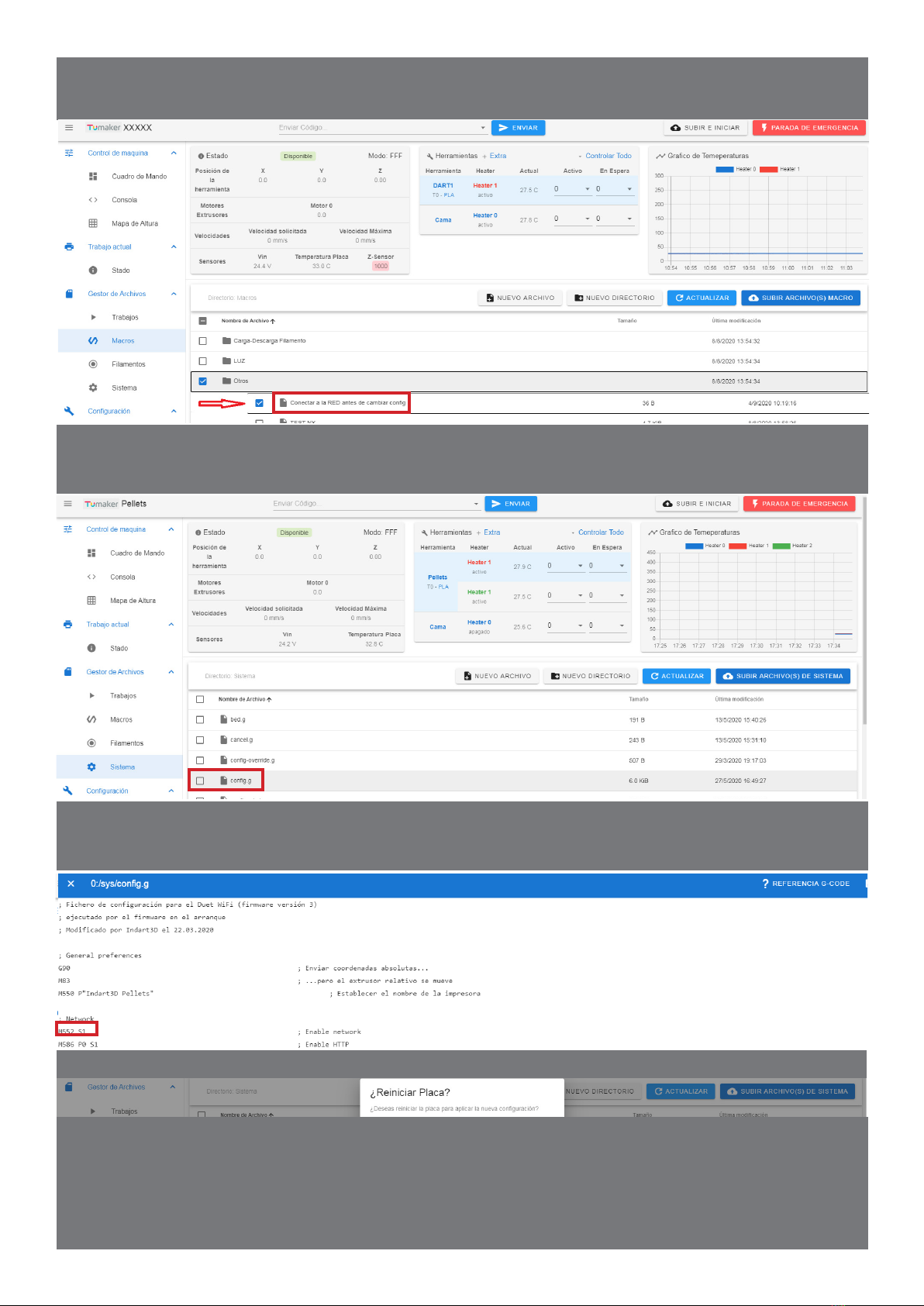

Simplify 3D loading profiles

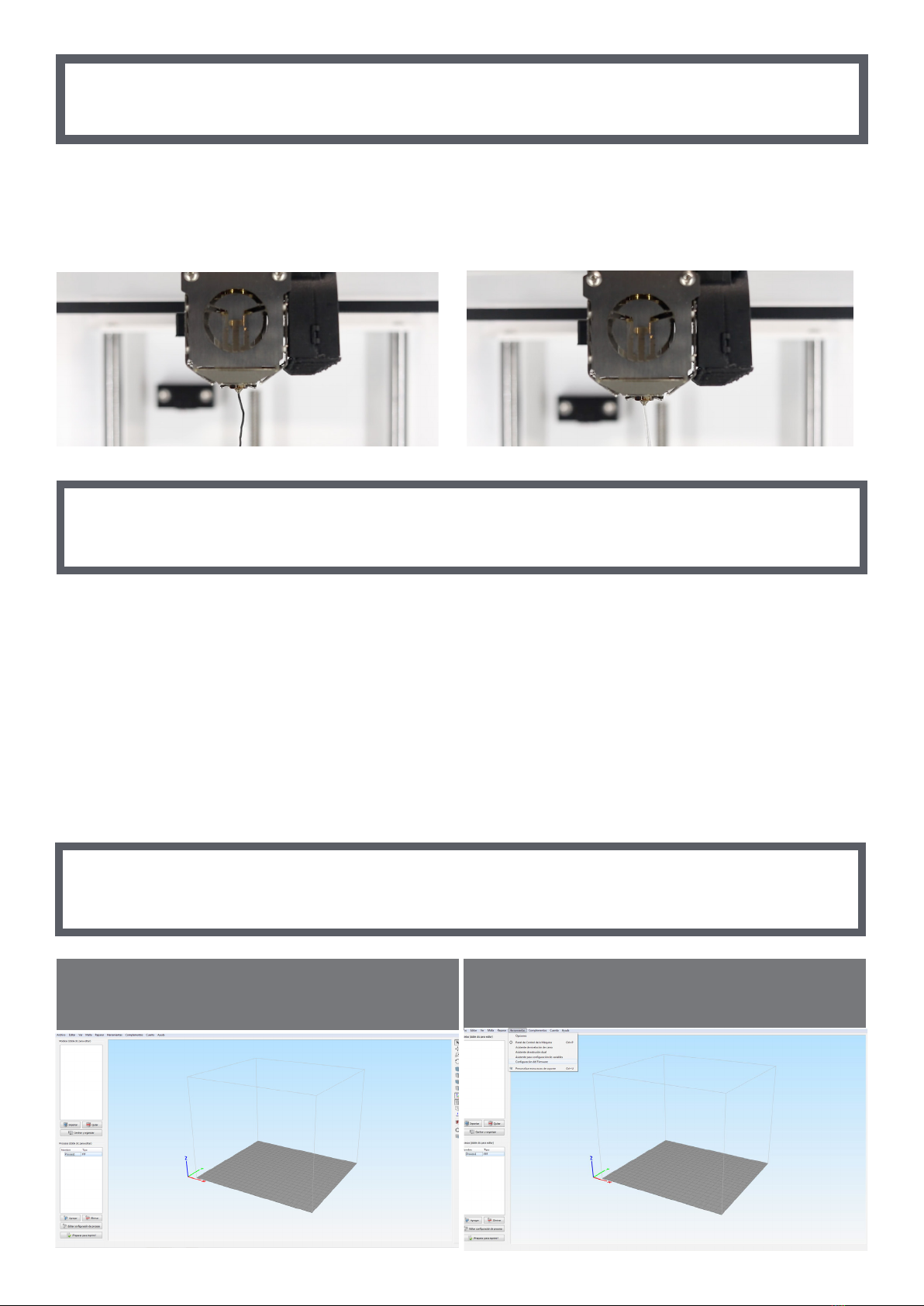

Head cleaning

Open Simplify3d In Tools go to Firmware Configuration

260º: Use ABS or materials with a similar melting temperature

range for materials over 260º. Start extruding until no trace of

the previously used material remains. Once this point is

reached, progressively lower the temperature to 250º.

260º: Use polypropylene for materials less than 260º. Start

extruding until no trace of the previously used material

remains. Once at this point, progressively lower the

temperature to 210º.