EV1253EC

INTRODUCTION

Please read these instructions carefully and keep in a safe place for future reference.

General Installation Requirements

The installation must comply with regulations of the Local Water Authority as contained in their

bylaws. All of the taps in this range are single flow (the hot and cold water mix in the body) and

should therefore be supplied with hot and cold water at balanced pressures, both from the tank or

both from the mains (via a combination boiler for example). If the taps are not supplied at balanced

pressures then the mixer will not function correctly. The mixer is provided with non-return valves

on both hot and cold feeds. It is very important that al pipe work is flushed thoroughly after

installation to avoid damaging the ceramic discs.

Standard Specifications

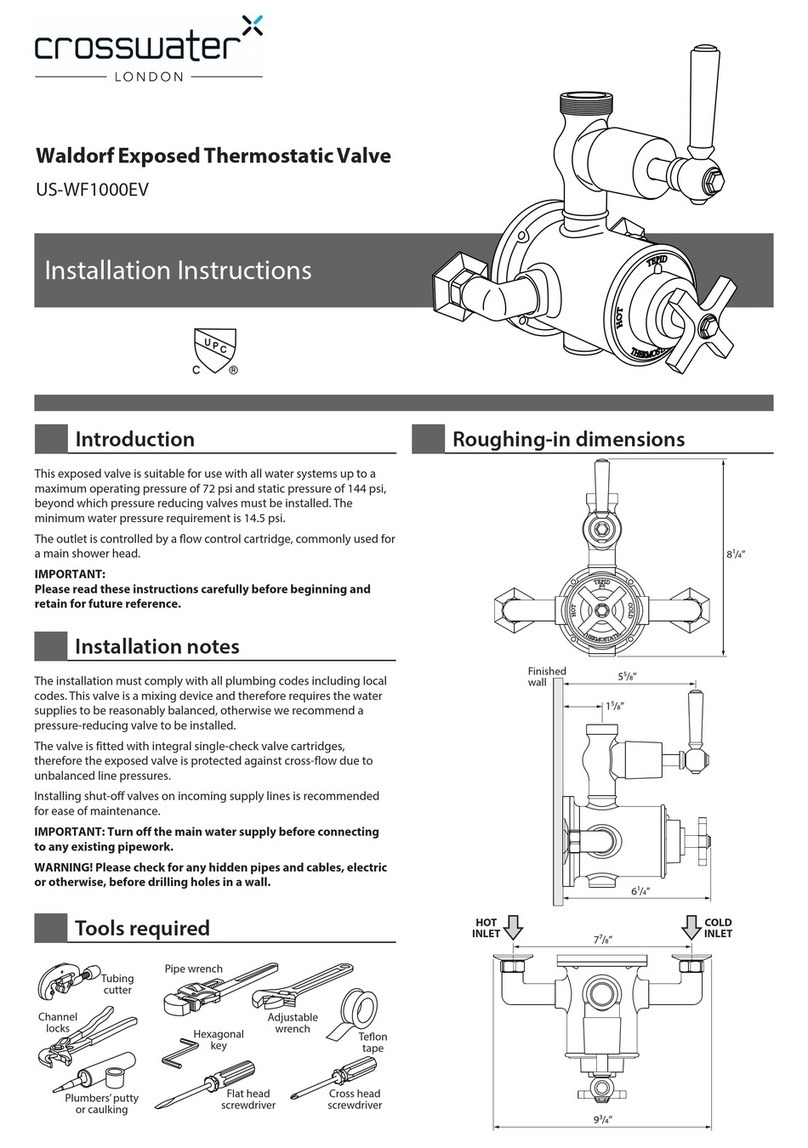

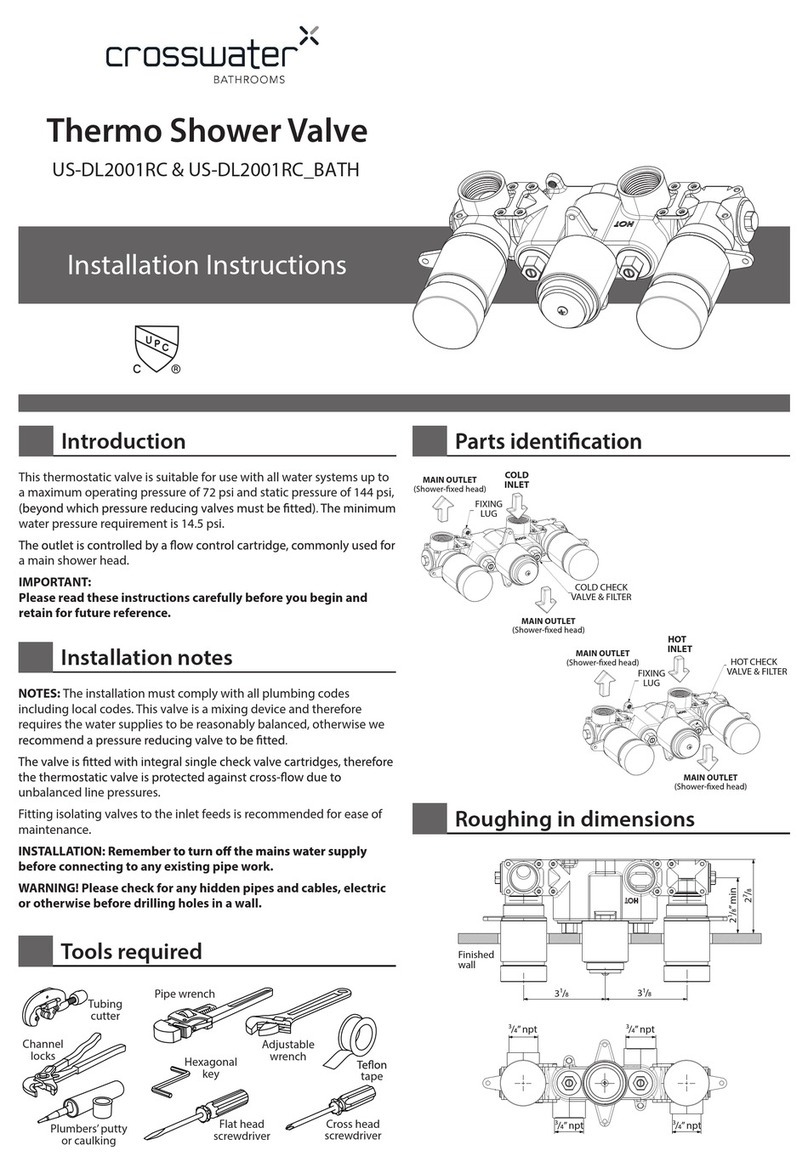

1. Recommended working pressure:..................................................................... 0.2 - 5 bar

2. Maximum test pressure: .........................................................................................10 bar

3. Maximum hot water temperature : .......................................................................... 80 °C

4. Recommended temperature: .............................................................................. 50-60 °C

5. Pressure difference between hot and cold water: ......................................... max. 1,0 bar

6. We recommend to install filters in the water system and if necessary in the product.

7. Warning :

- if the above mentioned conditions (see points 1,4,5 and 6) are not observed, the

product may not correctly work or not work at all.

- if during installation, before setting the product on the sanitary fittings, faults due to

the special finishing are evident you may require the replacement of the tap.

Approvals

All two hole taps are manufactured complying with requirements of European Standard

UNI EN 1111 : 2000.

Preparation and bylaw requirements

These taps are single flow so the hot and cold water mix in the body. Water bylaws require

that where the hot water is supplied from a tank and cold from the mains, non return valves

are fitted on both hot and cold pipes as close as possible to the tap.

Where combination boilers are fitted it is only necessary to shut off the incoming mains and

turn the boiler off and non return valves are not required.

WARNING

- Installation Performed By Qualified Personnel Only!

- Clean Carefully The Water Pipes Before Installing The Tap.

6

1

CLEANING

CALIBRATION

to a safe showering temperature under ideal conditions

at the factory, appropriate for most systems.

Proceed to the 38 setting by turning the spindle under the following conditions

- Hot water temperature at least 55 C

- Cold water temperature from 10 C to 25 C

(9)

covering plate(1) (9)

(10)

handle in place

Make sure that the hot water temperature is at least 55°C and that there is

sufficient supply.

Before testing the mixer, make sure that the hot and cold water is flowing

correctly by exercising the temperature selector knob between the cold and hot

stops.

Caution!

of

the water from the shower outlet is hot enough.If hot temperature is not the

disered, rotate slowly the handle to position 45º.

If disered hot temperature stil can not be reached, follow next steps.

Position temperature handle to 38º .

Remove the of temperature handle with carefull and use a

suitable screwdriver to uncrew the screw handle .

Remove temperature handle without change position of stop assembly.

Insert temperature handle so that 35º is in line with the stop assembly.

The mixer has been adjusted

:

°

° °

Turn the temperature handle to 38º position and test that the temperature

depress the override button and

position

Rotate temperature handle to 38º and wait for the water to stabilise.If desired hot

tempertaure is not acheived, repeat procedure.

Do not exceed maximum safe temperature at position 45º.

Once finished, put the and proceed in the opposite way to

assemble.