1 2 3

TL - 360

4 ELEMENT

CEILING MOUNT

PASSIVE INFRARED DETECTOR

TALON SERIES

INSTALLATION INSTRUCTIONS

P/N 7111069 REV.1 A.Y.

TL-360 FEATURES “Super Catch”

∗ Fully sealed sensor chamber.

∗ VLSI Technology (Very Large Scale

Integration).

∗ Maximum RFI & EMI Immunity.

∗ 4 Element Pyro Sensor.

∗ Pulse Count.

∗ Sophisticated signal processing.

∗ Memory function.

∗ Hard Spherical Lens 360°coverage.

∗ Bidirectional temperature

compensation.

∗ Flourescent light stability.

INTRODUCTION

The TL-360 is a 4-element passive infrared

intrusion detector for use in electronic

security systems in ceiling mount

applications.

You will obtain optimum performance from

your TL-360 PIR detector by following this

manual.

The TL-360 reduces false alarms to an

unprecedented minimal level due to its

effective elimination of background noises

and nuisance stimuli. The TL-360 employs

Automatic Pulse Count making it extremely

adaptable to various environments. The

unique VLSI, using sophisticated signal

processing, makes this detector virtually

free of false alarms.

The TL-360 integrates VLSI & SMD (surface

mount device) to their full advantage.

The detector is easy to install, with no

necessary adjustments.

HARD SPHERICAL LENS

The TL-360 is equipped with a special hard

lens. This lens is the latest development in

the security field and complies with all the

new standards requirements. It gives wide

coverage patterns, even at low mounting

heights. It is especially immune to sunlight,

halogen lights and fluorescent lights and is

impervious to attack.

4 5 6

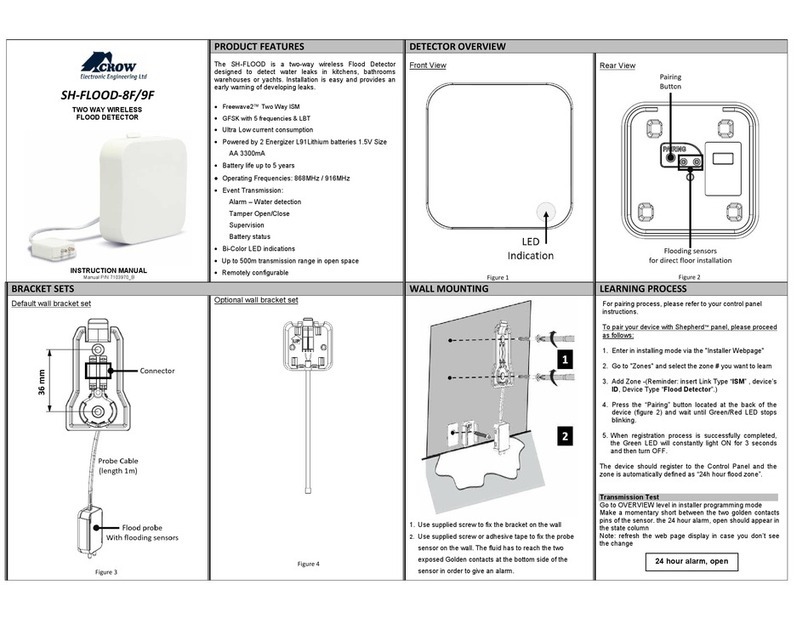

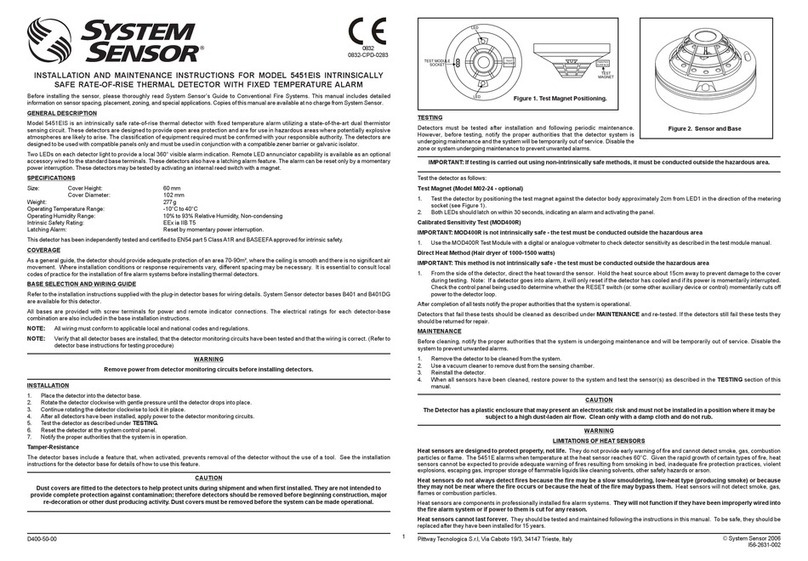

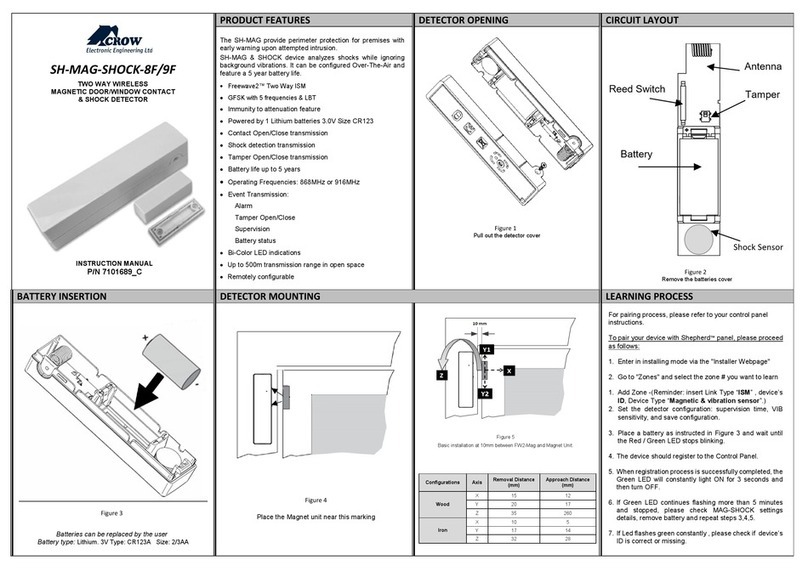

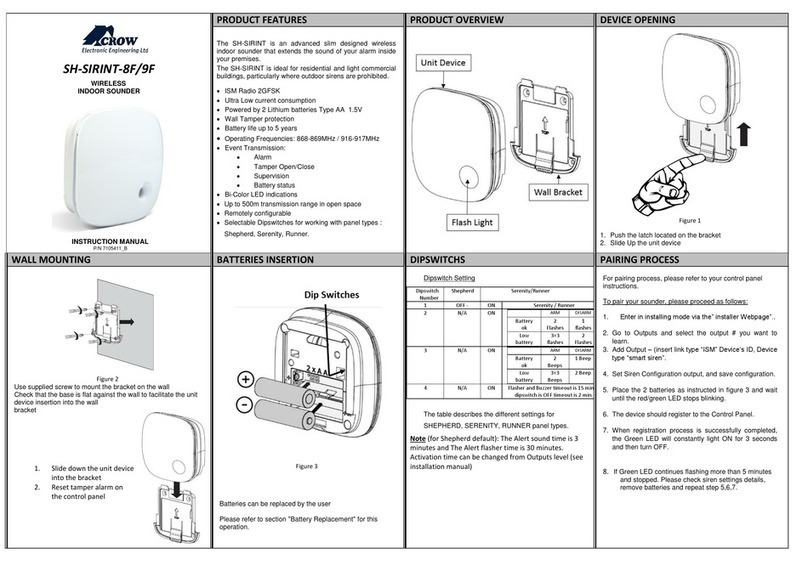

MOUNTING THE DETECTOR

Choose location most likely to intercept an

intruder. Refer to the detection pattern.

1. Hold the detector in your hand and

release the mounting plate by turning

it counter-clock-wise, and separate it

from the case (Fig. 1).

2. Insert the wires through the hole in the

center of the mounting plate (Fig. 2).

3. Mount the plate using the holes

marked mounting holes.

WIRE SIZE REQUIREMENTS

Use #22 AWG (0.5 mm) or wires with a

larger diameter. Use the following table to

determine required wire gauge (diameter)

and length of wire between the detector

and the control panel.

Wire Length m 200 300 400 800

Wire Diameter mm .5 .75 1.0 1.5

Wire Length ft. 800 1200 2000 3400

Wire Gauge # 22 20 18 16

FIG. 1 - TL-360 . EXTERNAL VIEW

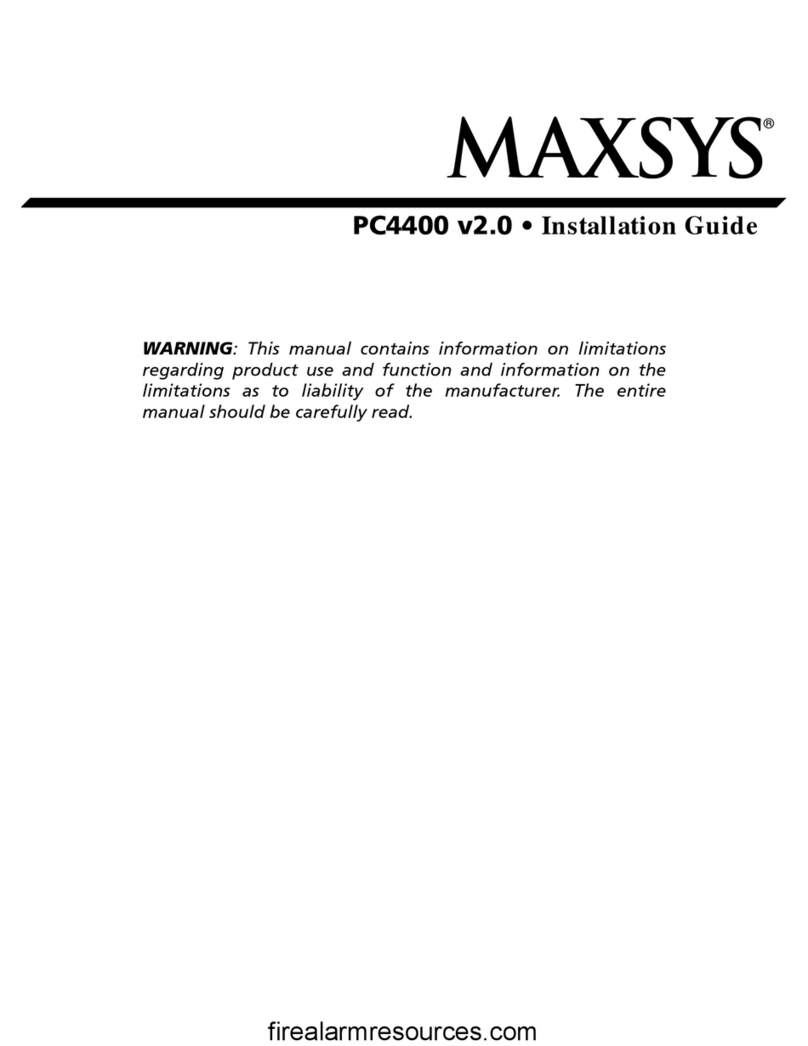

FIG. 2 - TL-360. INTERNAL VIEW

7 8 9

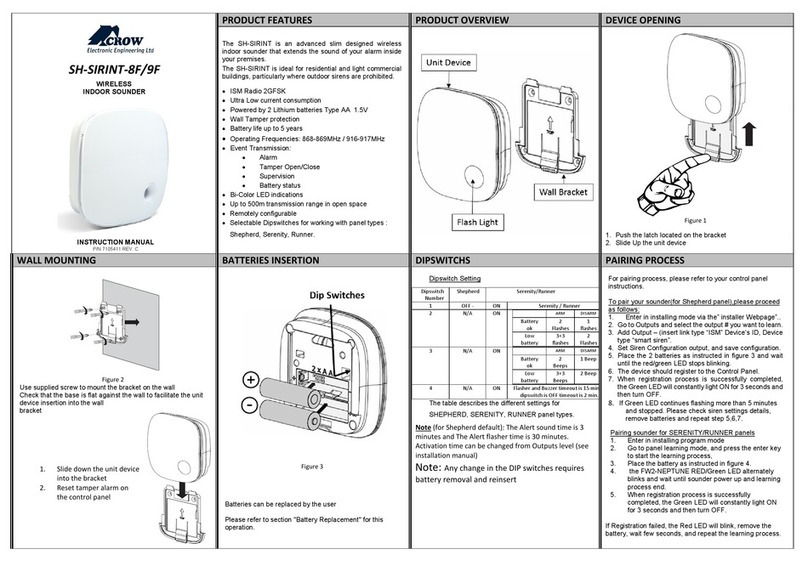

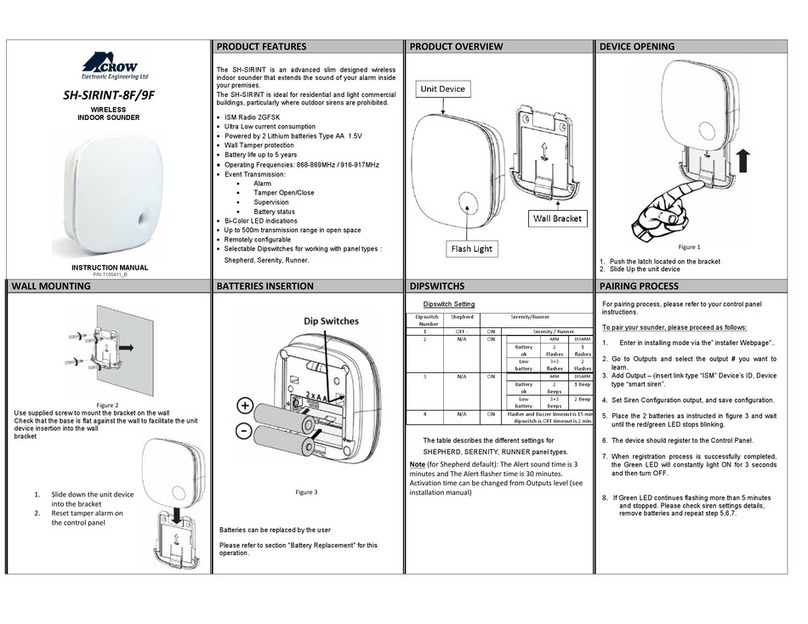

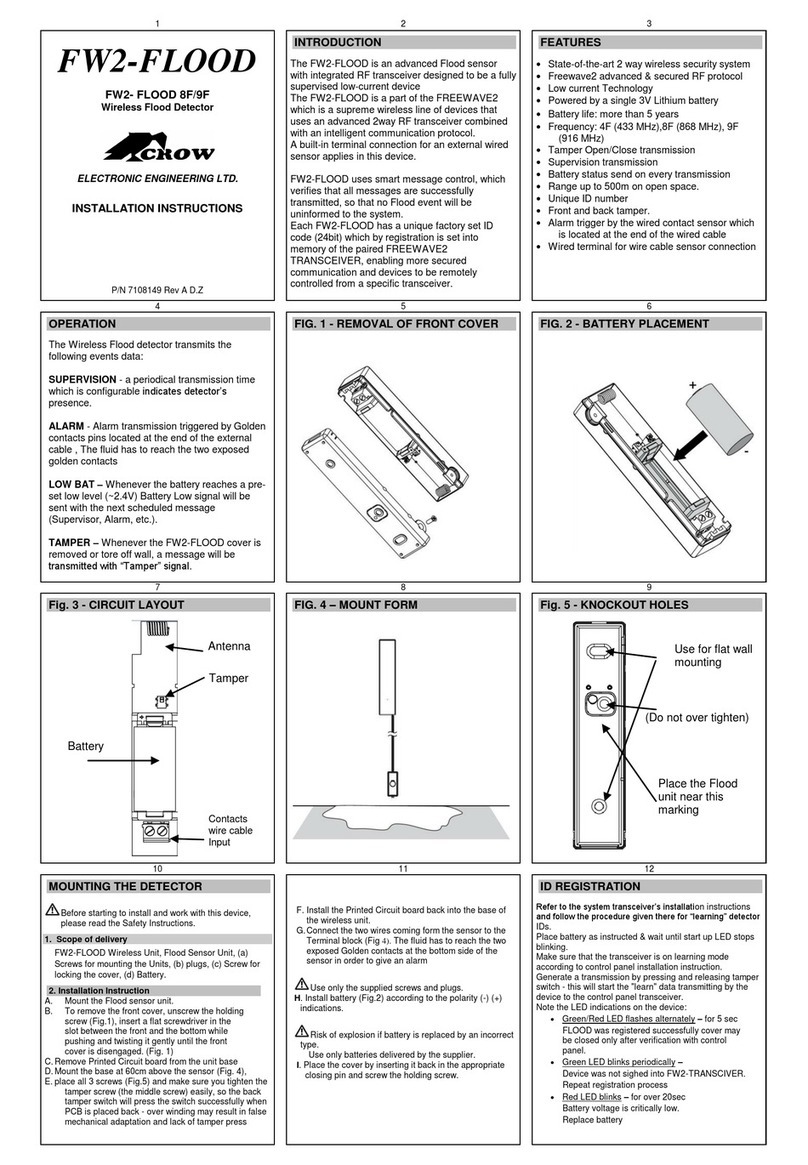

TERMINAL BLOCK CONNECTIONS

Run the cable through the cable entry hole

and connect the wires in accordance with

the following instructions:

Terminal 1 - Marked “ - ” ( GND )

Connect to ground of the control panel.

Terminal 2 - Marked “ + ” ( + 12V )

Connect to a positive Voltage output of

8.2-16 Vdc source (usually from the alarm

control unit).

Terminals 3 & 4 - Marked “ RELAY ”

These are the output relay contacts of the

detector. Connect to a normally closed

zone in the control panel.

Terminals 5 & 6 - Marked “ TAMPER ”

If a Tamper function is required connect

these terminals to a 24 hour normally

closed protective zone in the control unit. If

the front cover of the detector is opened,

an immediate alarm signal will be sent to

the control unit.

Terminal 7 - Marked “ MEM ”

The alarm memory function allows the

identification of an alerting detector out of

multiple detectors connected to one (or the

same) zone of the control unit.

To enable this function, connect (switch

on) the M terminal to a switched +12 to

+16VDC source (e.g. Arm / Disarm voltage

output from the control unit.)

In case of an alarm, the memory function

stores the alarm event in the detector.

To identify the detector that alarmed,

disconnect (switch off) (grounded) the

voltage from MEM terminal.

The LED of the detector with the alarm

event in memory will light constantly until

memory function is reset.

To reset the memory function, switch on

and switch off the M terminal.

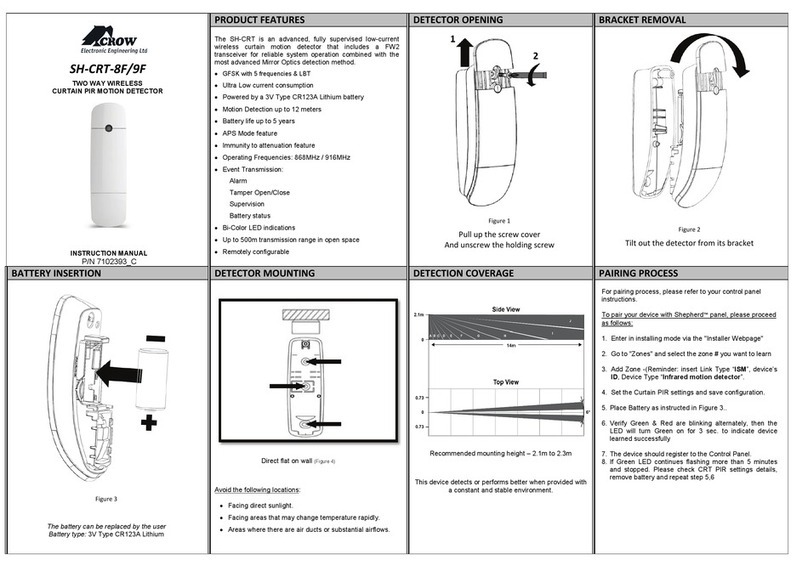

PULSE COUNT SETTING - Slide switch

(Fig.3). Provides control for normal or high

risk operating environments.

Position 1 (to left)

For stable environments.

Position AUTO (to right)

For harsh environments.

This setting enables special software to

modify detection speed.

When an intrusion is detected, the LED will

activate and the alarm relay will switch into

alarm condition (open circuit) for 1.6 sec.

To change position of the slide switch you

have to open the detector:

1. Turn the detector counter-clock wise

and separate it from the mounting base.

2. Change position of the slide switch.

3. Close the detector and reinstall

assembly screws.

1 2 3 4 5 6 7

12VDC RELAY TAMPER MEM

- + NC NC MEM

Pulse Count

Switch

Sensitivity/Range

Adjustment

Rubber

Insulation

Terminal Strip

OPEN CLOS

OC

Separate cover

from base