Click Pack manual 1201

04 Static load

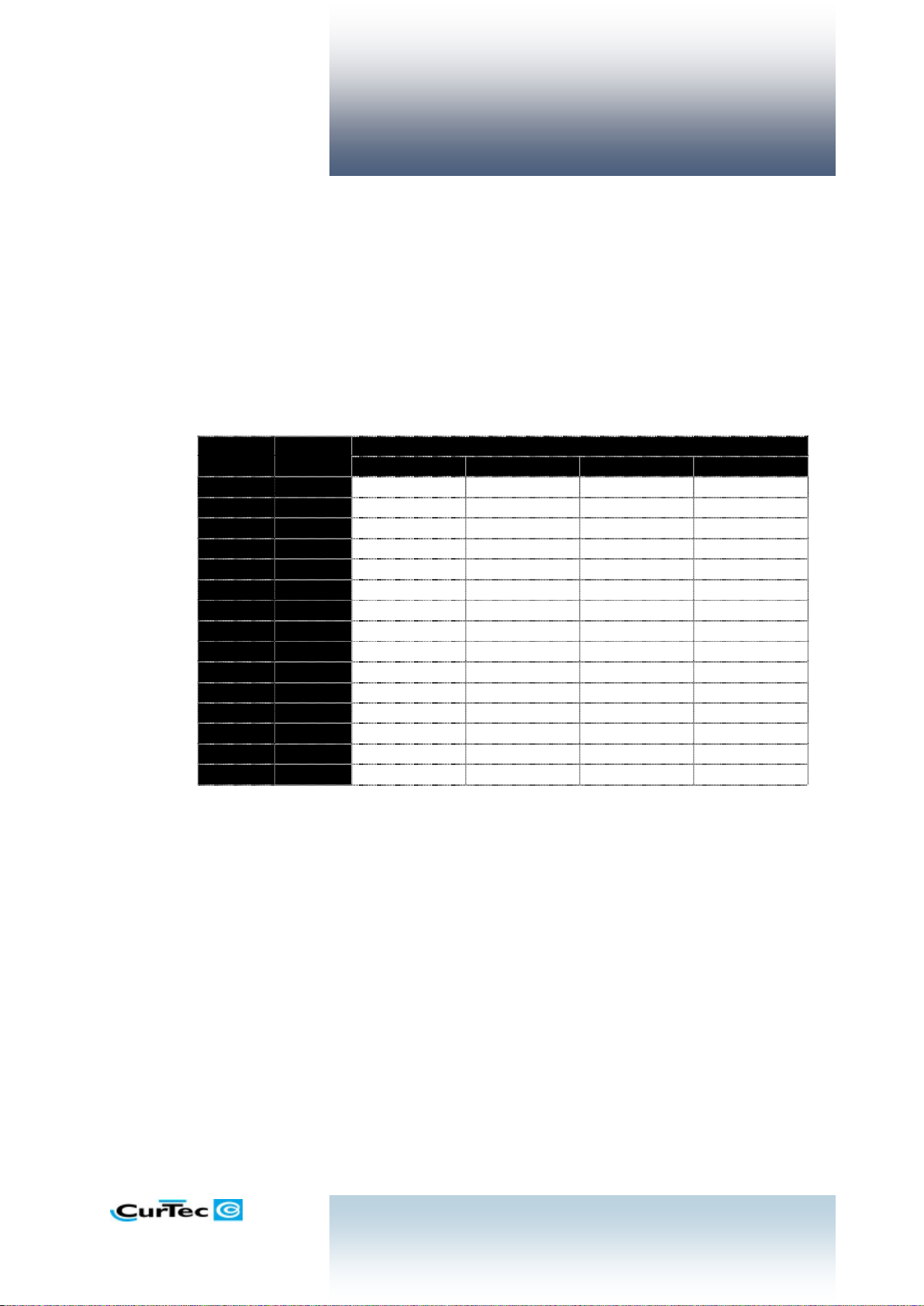

When stacking the Click Packs for storage in e.g. a warehouse or

cold store it is important to know what the maximum stacking load

can be on the bottom container. The stacking load depends strongly

on: the container weight, the number of containers to be stacked,

the weight of interlayers and pallets, surrounding temperature, the

duration of the load and the surface beneath the bottom containers.

T (°C) t (months) Product code

0 0,5 329 315 315 315

0 2 277 285 285 285

0 6 241 265 265 265

0 12 221 240 240 240

15 0,5 214 240 240 240

15 2 180 220 220 220

15 6 157 205 205 205

15 12 144 190 190 190

25 0,5 160 200 200 200

25 2 135 185 185 185

25 6 117 165 165 165

25 12 108 150 150 150

35 0,5 120 165 165 165

35 2 101 150 150 150

35 6 88 120 120 120

The table shows for each Click Pack the maximum stacking load (in

kg) at a given surrounding temperature during a certain period of

time placed on a flat and closed surface or pallet.

Attention! The loads mentioned in the table can only serve as indications.

CurTec always advises its customers to perform additional testing.

On the basis of the table the number of containers that may be

stacked can be calculated. It is the stacking load mentioned reduced

by the carrying part of the pallet’s interlayers, divided by the

container weight. This number, with figures behind the comma

smaller than eight, rounded off + 1 = total number of Click Packs.