TUNING TIPS:TUNING TIPS:

TUNING TIPS:TUNING TIPS:

TUNING TIPS: These are some general guidelines for optimizing handling performance.

None of these “tips” are EVER set in stone. On any given day this manual or any chassis

engineering book or guru can be proved wrong by the stop watch. A good way to approach

chassis set-up is to try one change, practice it, think how the car felt different from before, and

compare lap times from the stop watch…..this will never fail.

CONGRATULATIONS!!!CONGRATULATIONS!!!

CONGRATULATIONS!!!CONGRATULATIONS!!!

CONGRATULATIONS!!!

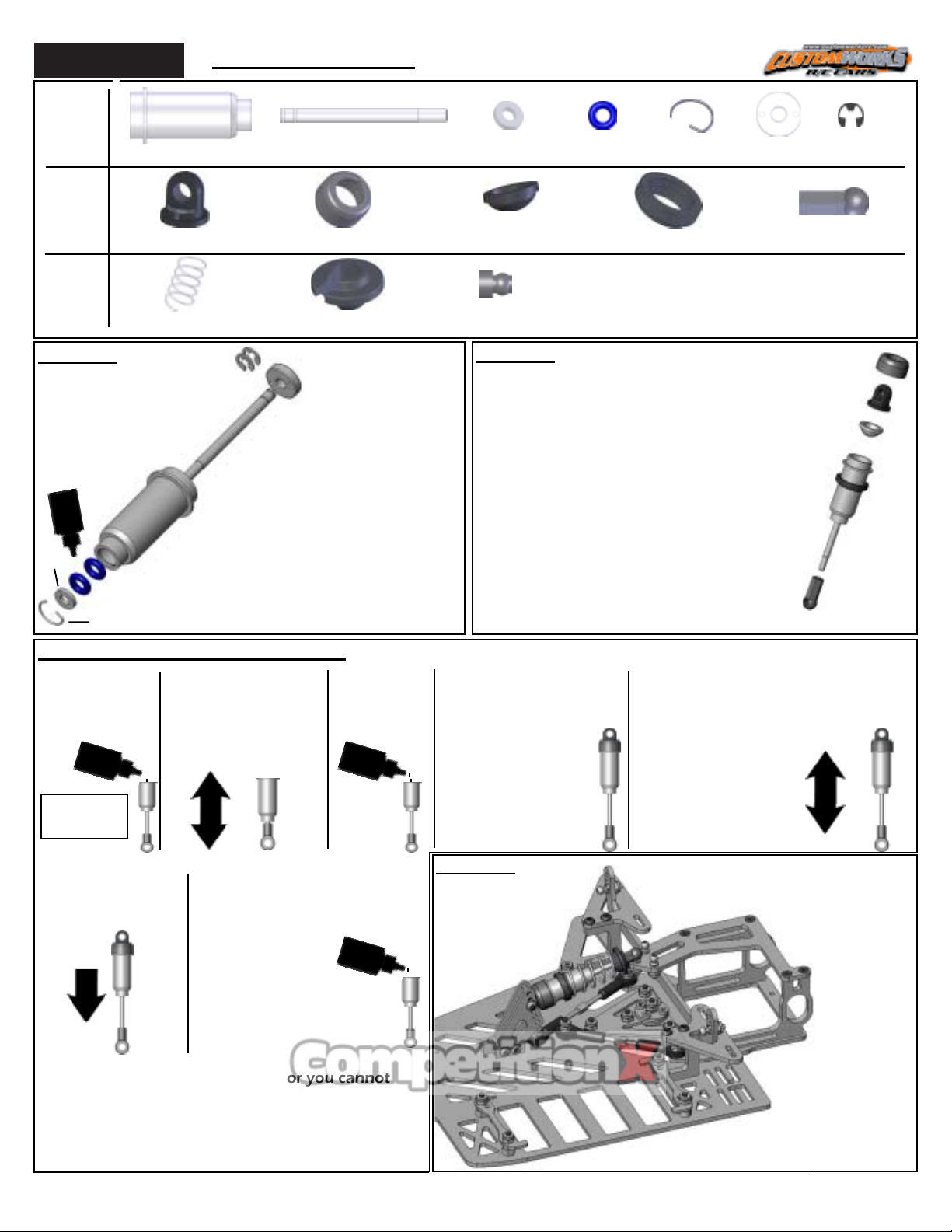

You have now completed the assembly process of your

new Custom Works AGGRESSOR SE. In the next section of this manual you will find some

basic setup hints and advice. It is important to remember that all tracks and racing surfaces

are different. Therefore the suggestions we give you are general in nature and should by no

means be treated as the only options.

- Bent Suspension Pin, check for free movement.

- Bound Ball Joint: Links should spin free on

balls while mounted to the car.

- Bent or Loose Links: Pod movement should

be free

- Wore out Bearings or Completely Seized

Bearings

- Chunked Tire: Check to see if foam or rubber

tire is still glued to wheel.

- Loose Screws: Especially chassis screws,

add Blue Loctite to prevent.

- Shocks: Either Bound-up or Out of Oil.

Must swivel freely on mounts.

- Foreign Objects: Unlucky Dirt/Stones

preventing Suspension or Steering Movement.

- Blown Differential

- Radio Problem: Bad Servo, Weak Servo Saver

Spring, Transmitter Pot blown.

- Install wing to rear of car

- Slide rear wing toward rear

- More wing angle, NOT FLAT!

- Add tweak/wedge to chassis

using side shocks

- Softer side shock springs

- Stifffer front springs

- Softer center shock spring

- Decrease center shock collar,

lower chassis ride height

- Harder front tire or just RF

- Softer rear tires

- Raise front ride height

- Lower rear ride height

- Move front suspension mounts

to the right

- Bring RR closer to pod, LR away

- More Castor, Less Camber

Car Is Loose (oversteers):Car Is Loose (oversteers):

Car Is Loose (oversteers):Car Is Loose (oversteers):

Car Is Loose (oversteers):

Car Pushes (understeers):Car Pushes (understeers):

Car Pushes (understeers):Car Pushes (understeers):

Car Pushes (understeers): Car Is Erratic:Car Is Erratic:

Car Is Erratic:Car Is Erratic:

Car Is Erratic:

MAINTENANCE:MAINTENANCE:

MAINTENANCE:MAINTENANCE:

MAINTENANCE:

- Occasionally dirt will get into the moving and pivoting locations in your car. It is best to

periodically clean you car to keep all the suspension components moving freely. Read the tips

below to keep your car running at its best!

- The rear link pivot system lacks the simplicity of the standard t-bar car especially in terms of

crashes. It is IMPORTANT that after a good wreck to pop the shocks off the rear pod to double

check the pod movement is still free in all directions. All to often this is over looked after a crash and

a day of frustration begins due to the pod movement binding.

- Since the entire suspension is held up by the center shock it will require a little more attention as

well. Conversely there are ALOT more tuning options you can now do with the car by simply

changing various dynamics of your center shock set-up.

- Differential Maintenance is needed when the action of the diff feels “notchy”. Usually cleaning the

diff parts, re-sand the thrust and diff plates with 400 paper, and lube appropriately will be all that is

needed to bring back to new. Ignoring your differential will lead to handling woes and increase

transmission temps, which will cause part failure.

SPECIAL THANKS to Steve and Eric Salvas.

- Slide rear wing forward

- Less wing angle

- Less tweak/wedge to chassis

using side shocks

- Stiffer side shock springs

- Softer front springs

- Stiffer center shock spring

- Increase center shock collar,

raise chassis ride height

- Softer front tires

- Stiffer rear tires

- Lower front ride height

- Raise rear ride height

- Move front suspension mounts

to the left

- Push RR away from pod, LR

closer to pod

- Less Castor or More Camber