2

Thank you for purchasing the Outlaw 4 Sprint Car! The Outlaw sprint car platform has been developed for loose dirt

buggy tire racing. In this kit you will find the 4th evolution of the car which features several improvements including a

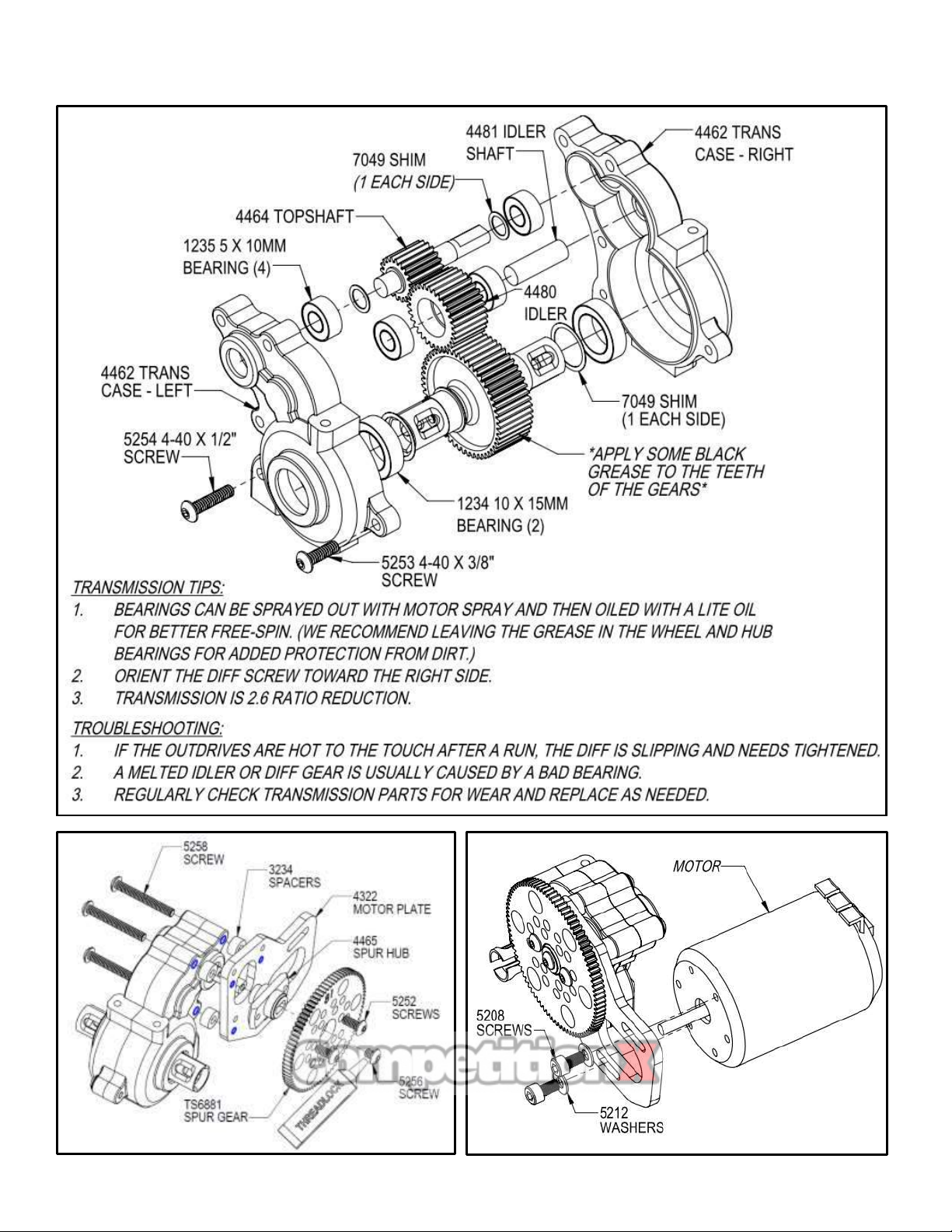

new 2.6 to 1 transmission and front and rear axles for hex wheels.

This kit includes most of the parts required for the build. The following additional equipment must be added to complete

the car. (Be sure to check if the track you plan on racing at has any motor, battery or speed control restrictions.)

Surface transmitter and receiver (minimum 2 channel.)

1/10th scale electronic speed control

540 size brushless motor

Pinion gear (48 pitch, appropriate size for motor)

2S hard case “shorty” LiPo battery

Steering servo (standard or low profile)

Front and rear wheels and tires (2.2” diameter AE style hex wheels)

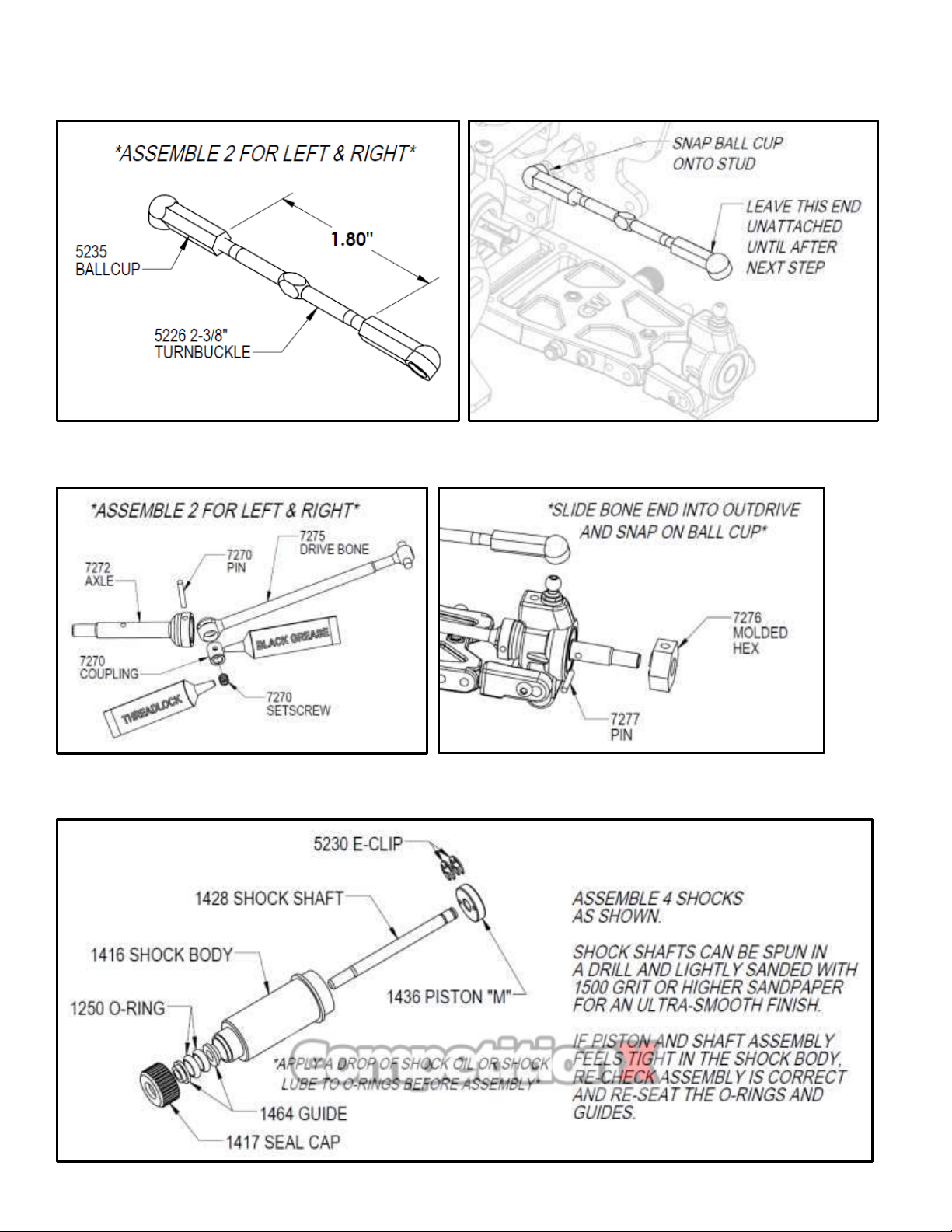

Silicone shock oil (30 weight recommended)

Lexan paint and/or vinyl wrap for body

Tools

The following tools are provided in the kit and will get you started. We suggest that you purchase higher quality tools for

future maintenance.

•.050 Allen key •1.5mm Allen key •1/16 Allen key •5/64 Allen key •3/32 Allen key •Turnbuckle & 3/16 wrench

Additional tools

These tools are recommended for the build and may be required to complete.

•Curved scissors •Needle nose pliers •Hobby knife •Blue thread-lock •Assorted sandpaper •7mm hex driver

Building tips

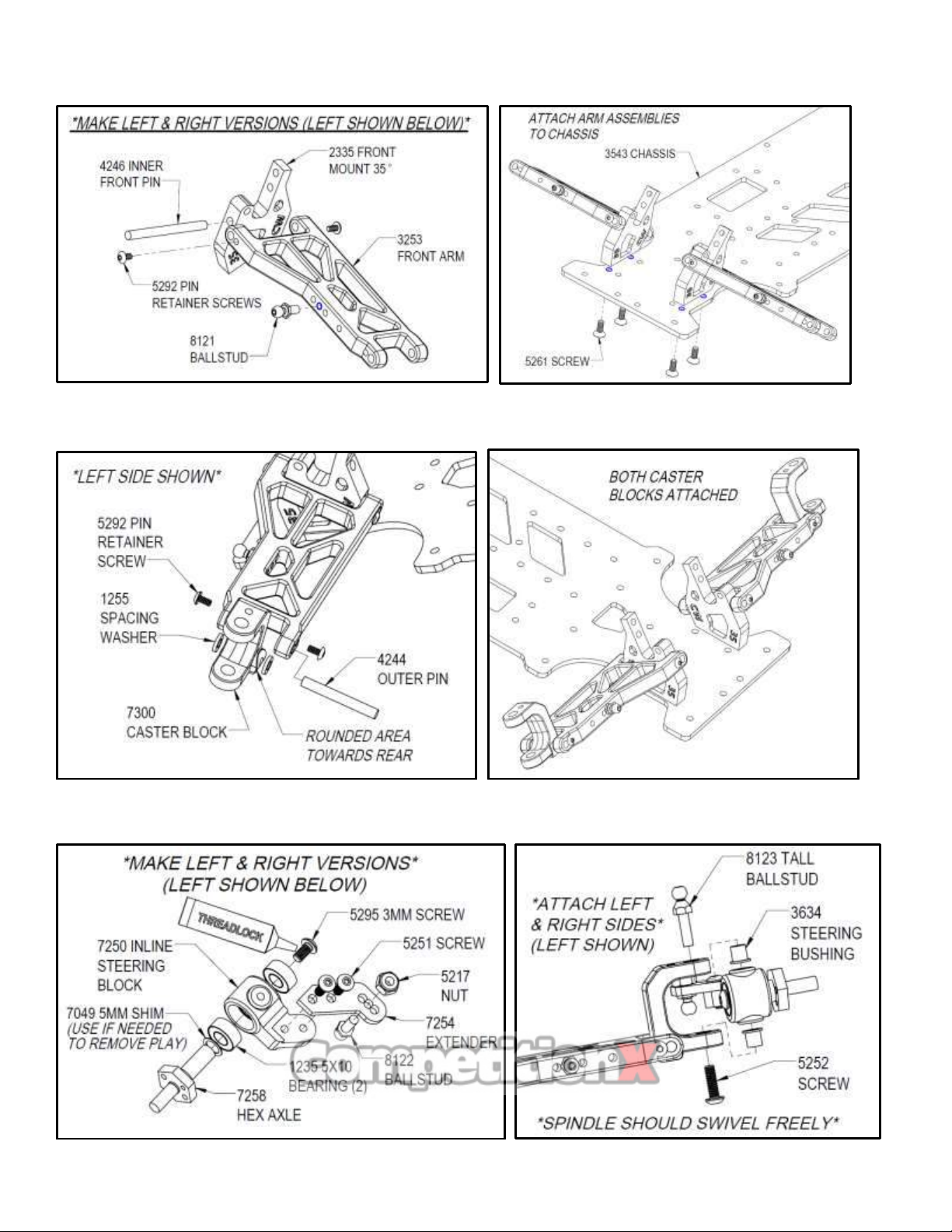

Parts are made with tight tolerance and held to the side of a “snug” fit as wear is expected over time. Try as we

may, occasionally a burr may remain in a part and fit more tightly than desired. It is ok to use 400 Grit Sandpaper

or a .125” drill to SLOWLY relieve a part from time to time. Suspension components should always pivot and swivel

freely but without too much slop.

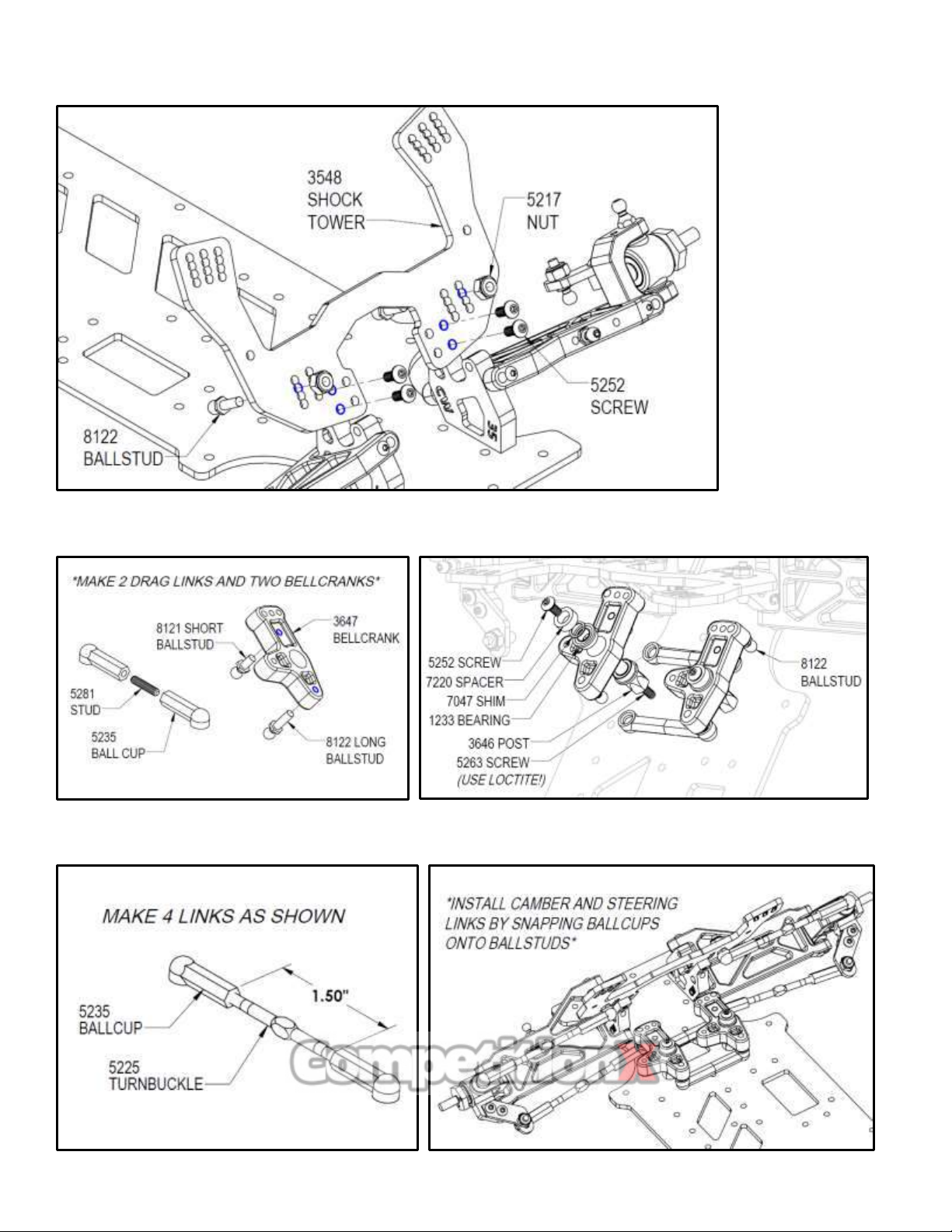

A lite to medium strength (usually the blue variety) thread locking fluid is suggested for all parts where metal screws

thread into other metal parts. This will keep the screws from vibrating loose during operation and still allow the screw to

be removed if needed. Remember it only takes a very small amount of thread-lock to secure the screw.

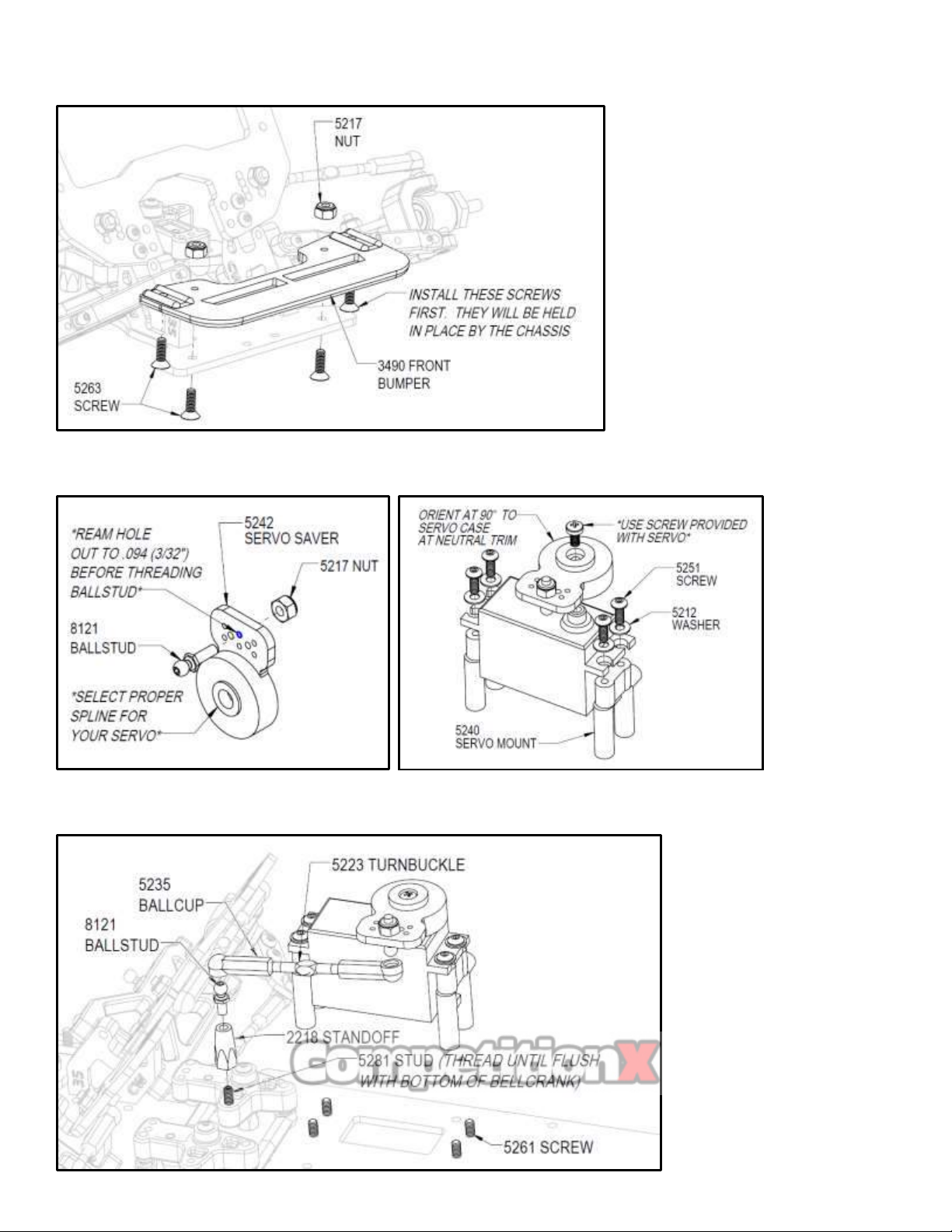

Do NOT use power screwdrivers to drive screws into parts. The fast rotation speed can melt and strip plastic parts

or cross-thread into the aluminum parts.

Lightly sand the edges of the carbon fiber pieces using a medium grade sandpaper to avoid splinters. A thin bead of

Super Glue can be used to seal the edges of the carbon fiber for more protection against chips and splinters.