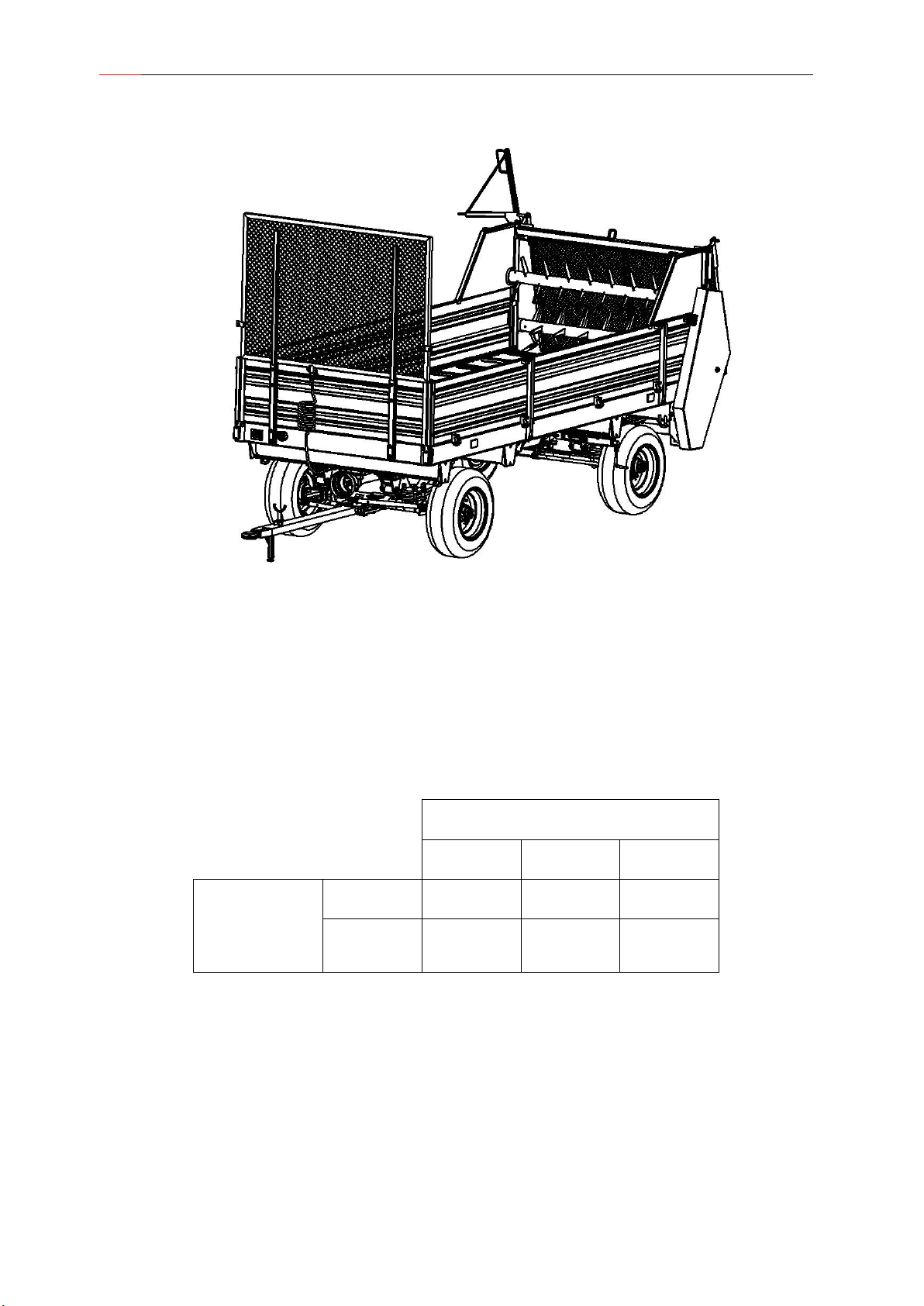

CynkoMet N-233

6

4.3.2 Preparation for the spreader’s work................................................ 38

4.3.3 Preparation for operating the spreader as a transporter. ................ 39

4.3.4 Loading the spreader...................................................................... 40

4.3.5 Connecting and disconnecting with the tractor. .............................. 40

4.3.6 Loading the cargo box. ................................................................... 42

4.3.7 Load transport................................................................................. 49

4.3.8 Unloading of the crate serving as a transporter. ............................. 50

5. Equipment and accessories .....................................................................51

6. Technical Support ...................................................................................52

6.1 Regulation of driving wheel bearings backlash...........................................54

6.2 Brake adjustment. ....................................................................................55

6.3 Handling the pneumatic brake system.......................................................56

6.4 Handling of the hydraulic system of the rear wall and brakes......................57

6.5 Maintenance of the drive axle...................................................................58

6.6 Mounting the adapter's drum guard.........................................................58

6.7 Adapter maintenance...............................................................................60

6.8 Operation of the floor conveyor ...............................................................61

6.9 Handling electrical equipment. .................................................................62

6.10 Lubrication. .............................................................................................62

6.11 Storage and maintenance.........................................................................67

6.12 Adjustment of conveyor drive and adapter drive chain tension...................68

6.13 Blockade of adapter drums ......................................................................69

6.14 Troubleshooting.......................................................................................71

7. Transport.................................................................................................74

8. Spreader cassation ..................................................................................76

9. Guarantee ...............................................................................................76