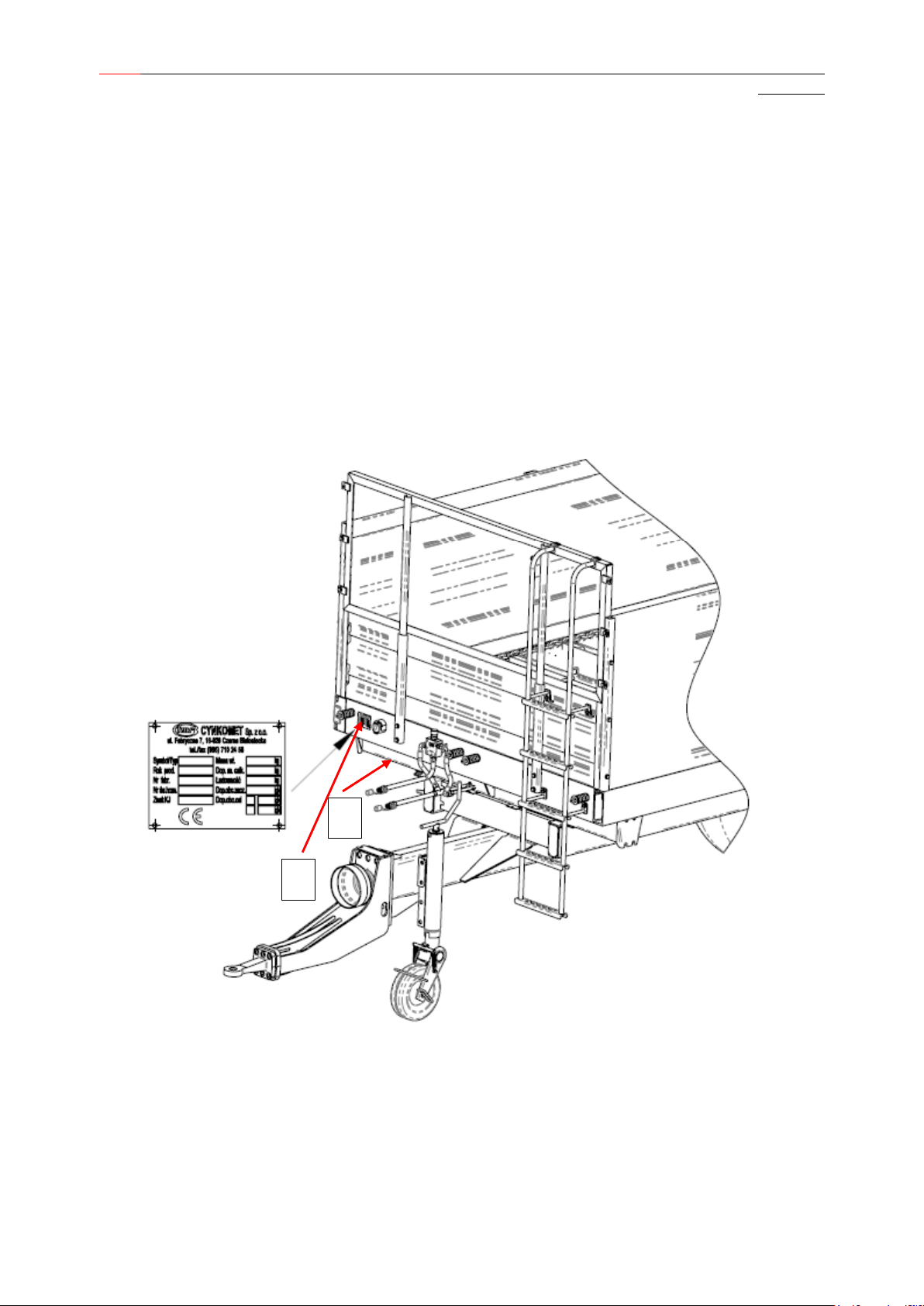

2. Purpose of the spreader

The spreader is a universal agricultural machine designed for spreading

manure of any kind, lime, peat and compost, after mounting extensions (the

mounting method is further in the manual - Section 4,2,7 Extensions,

Conveyor) and replacing the rear wall adapter it can be used as a volumetric

dump trailer. Suspension springs on 2 axles ensure optimal driving

properties. The adapter with 4 vertical shafts (N-221/3-3) or 2 horizontal

shafts (N-221/4-3) guarantees precise application of fertilizer. The machine is

also equipped with a hydraulic wall, which allows you to adjust the dosage of

the material located on the loading box. The spreader consists of a support

frame, floor with a thickness of 4mm and a wall with a height of 0.8 meter,

which are constructed from sheet metal with a thickness of 2mm. The N-

221/3-3 spreader may be equipped with a deflector (a.k.a. spread limiter

deflector), which provides a wide range of potential operating settings,

guaranteeing precise application of the fertilizer, and the deflector itself

provides protection for adapters.

The brake system and lighting and signaling system meet the requirements

arising from the “Regulation of the Minister of Infrastructure of 31 December

2002 on technical conditions of vehicles and the range of their necessary

equipment”.

Failure to follow the transport and loading of goods specifications

described by the Manufacturer and the rules on road transport in force in the

country in which the spreader is used, will void the warranty service and is

regarded as use of the machine incompatibly with its purpose.

The spreader is adapted to cooperation with agricultural tractors equipped

with an external hydraulic system and lower trailer hitch with capacity of 2000

kg.