8 Commissioning

Installation manual

41

RWEQ96~432TAYCU

VRV W T-Series water-cooled system air conditioner

4P540122-1B – 2018.11

Error code (Auto

backup possible) Error contents

H9

Outside unit inside air thermistor (R1T) abnormality

HC Water inlet thermistor (R9T) abnormality

Water outlet thermistor (R10T) abnormality

J3 Discharge pipe thermistor (R12T) abnormality

Compressor body thermistor (R13T) abnormality

J4 Plate heat exchanger gas thermistor (R4T)

abnormality

J5 Suction pipe thermistor (R3T) abnormality

J6 Plate heat exchanger liquid thermistor (R7T)

abnormality

J7 Receiver outlet liquid pipe thermistor (R6T)

abnormality

Subcooling heat exchanger outlet liquid pipe

thermistor (R8T) abnormality

Injection pipe thermistor (R11T) abnormality

J9 Subcooling heat exchanger outlet gas pipe

thermistor (R5T) abnormality

Exhaust heat cancellation heat exchanger gas

pipe thermistor (R2T) abnormality

JA High pressure sensor abnormality

JC Lowpressuresensorabnormality

L1 Inverter PCB abnormality

L3 Reactor temperature rise abnormality

L4

Inverter radiation fin temperature rise abnormality

L5 Inverter compressor instantaneous overcurrent

L8 Inverter compressor overcurrent

L9 Inverter compressor startup abnormality

LC Transmission error between inverter PCB and

outside unit main PCB

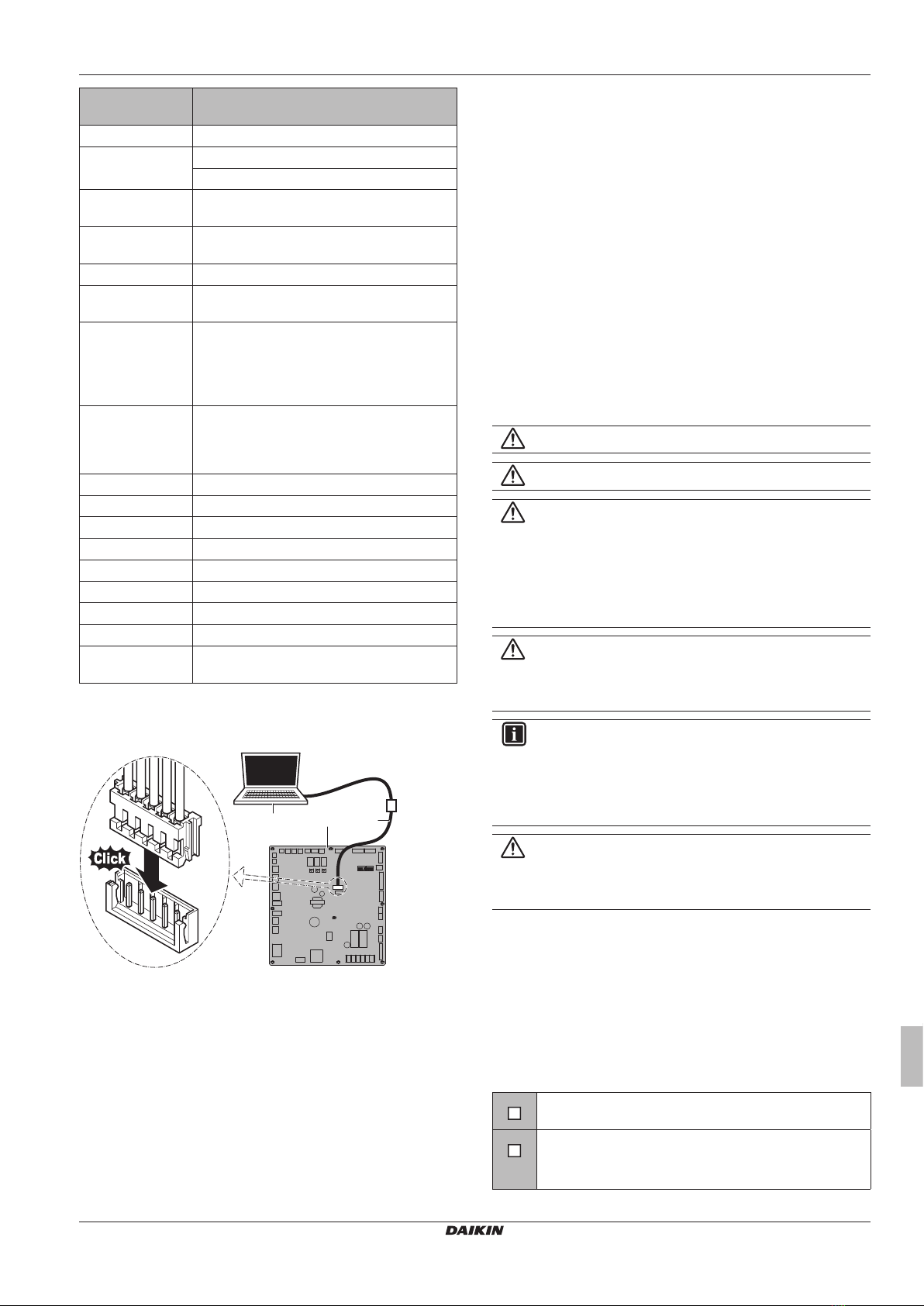

7.2.9 To connect the PC configurator to the

outside unit

X27A

ab

c

2

345

HJ S T

X27A

A1P

aPC

bCable (999482P3)

cOutside unit main PCB

8 Commissioning

8.1 Overview: Commissioning

After installation and once the field settings are defined, the installer

is obliged to verify correct operation. Therefore a test run must be

performed according to the procedures described below.

This chapter describes what you have to do and know to

commission the system after it is configured.

Commissioning typically consists of the following stages:

1 Checking the "Checklist before commissioning".

2 Performing a test run.

3 If necessary, correcting errors after abnormal completion of the

test run.

4 Operating the system.

8.2 Precautions when commissioning

DANGER: RISK OF ELECTROCUTION

DANGER: RISK OF BURNING

CAUTION

Do not perform the test operation while working on the

indoor units.

When performing the test operation, not only the outside

unit, but the connected indoor unit will operate as well.

Working on an indoor unit while performing a test operation

is dangerous.

CAUTION

Do not insert fingers, rods or other objects into the air inlet

or outlet. Do not remove the fan guard. When the fan is

rotating at high speed, it will cause injury.

INFORMATION

During the first running period of the unit, the required

power may be higher than stated on the nameplate of the

unit. This phenomenon is caused by the compressor, that

needs a continuous run time of 50 hours before reaching

smooth operation and stable power consumption.

NOTE

Be sure to turn on the power 6 hours before operation in

order to have power running to the crankcase heater and

to protect the compressor.

During test operation, the outside unit and the indoor units will start

up. Make sure that the preparations of all indoor units are finished

(field piping, electrical wiring, air purge, ...). See installation manual

of the indoor units for details.

8.3 Checklist before commissioning

After the installation of the unit, first check the following items. Once

all below checks are fulfilled, the unit must be closed, only then can

the unit be powered up.

You read the complete installation and operation

instructions, as described in the installation manual.

Installation

Check that the unit is properly installed, to avoid abnormal

noises and vibrations when starting up the unit.