4 Menu operation RC8CE202 © Danfoss 03/2013 AK-PC 781 Version 4.1x

Main settings

Measurements AK error When “ON”, the controller is in alarm condition.

Comp. ctrl. temp °C Actual temperature for control sensor (Po or S4)

Comp. ctrl. ref. °C Actual reference temp. for compressor capacity

(incl. external reference signal, if any)

Compressor cap. % Cut-in compressor capacity in % (of total capacity)

Request Compr. Cap % Reference for compressor capacity (deviations may be due to time delays)

P0 °C Suction pressure in °C. (Measured with the pressure transmitter)

Ss Suction gas °C Actual suction gas temperature

Cond. ctrl. temp °C Actual temperature for control sensor (Pc or S7)

Cond. ctrl. ref. °C Actual reference temp. for condenser capacity

(incl. external contributions, if any)

Cond. cap. % Cut-in condenser capacity in % (of total capacity)

Request Cond. cap % Reference for condenser capacity

Pc Bar Condensing pressure (measured with the pressure transmitter)

Tc °C Condensing pressure in °C. (measured with the pressure transmitter)

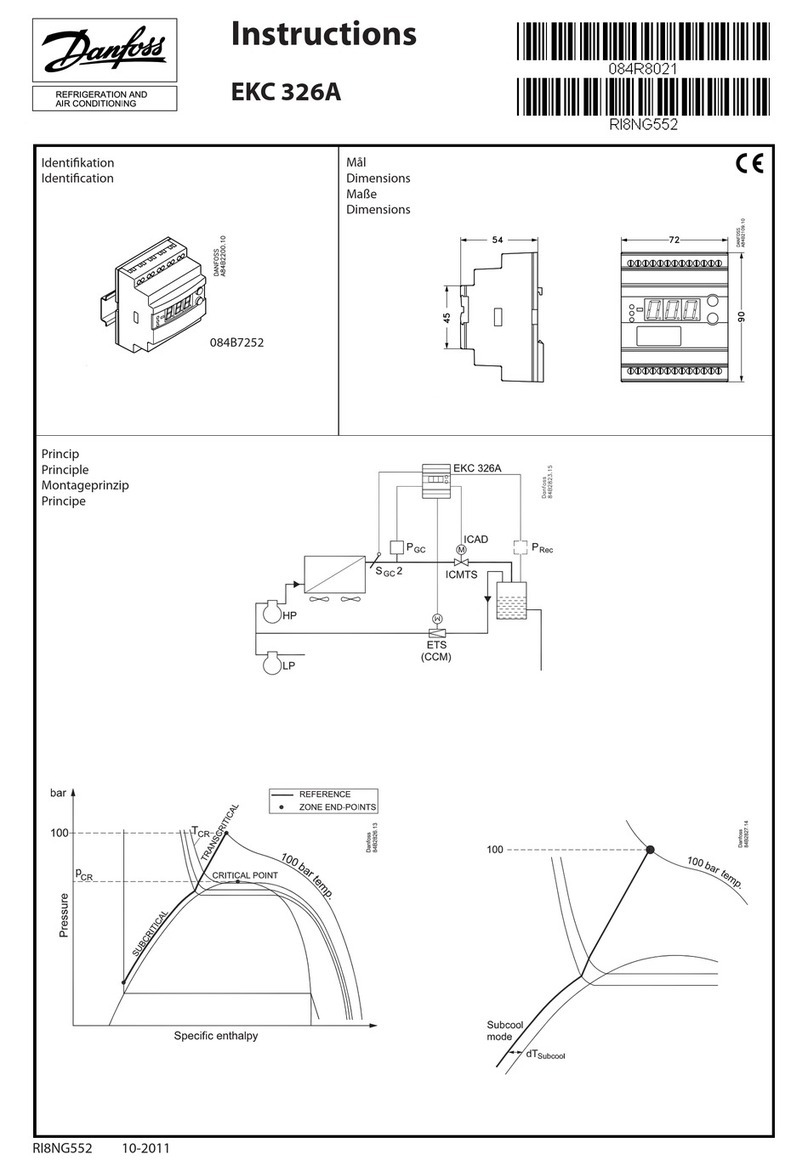

Gc status Actual gas cooler operation:

0=O. 1=Standby. 2=Max COP operation. 3=Heat recovery. 4=Extra capacity.

5=Manual control.

Pgc Bar Actual gas cooler pressure

Pgc reference bar Actual reference for gas cooler pressure

Sd discharge gas °C Actual discharge gas temperature

Sgc °C Actual temperature at outlet from the gas cooler

External Main Switch Status of input “Extern Main Switch”. In pos.“OFF”the regulation is stopped by force

Settings Main switch Main switch: ON: Regulation

OFF: Controller stopped

Conguration lock Lock of conguration.

In order to select quick setup or select refrigerant type, the conguration lock must

be “open”. Note: ”Main switch”must be OFF in order to set conguration lock in “open”

position

0: Open

1: Locked

Refrigerant type Po Select refrigerant type

0= not selected, 1=R12. 2=R22. 3=R134a. 4=R502. 5=R717. 6=R13. 7=R13b1.

8=R23. 9=R500. 10=R503. 11=R114. 12=R142b. 13=User dened 14=R32. 15=R227.

16=R401A. 17=R507. 18=R402A. 19=R404A. 20=R407C. 21=R407A. 22=R407B.

23=R410A. 24=R170. 25=R290. 26=R600. 27=R600a. 28=R744. 29=R1270. 30=R417A.

31=R422A. 32=R413A. 33=R422D. 34=R427A. 35=R438A. 36=XP10. 37=R407F.

Suction capacity control

Measurements AK error When “ON”, the controller is in alarm condition.

Comp. ctrl. temp °C Actual temperature for control sensor (Po or S4)

Comp. ctrl. ref. °C Actual reference temp. for compressor capacity

(incl. external reference signal, if any)

Compressor cap. % Cut-in compressor capacity in % (of total capacity)

Request Compr. Cap % Reference for compressor capacity (deviations may be due to time delays)

P0 °C Suction pressure in °C. (Measured with the pressure transmitter)

Ss Suction gas °C Actual suction gas temperature

Cond. ctrl. temp °C Actual temperature for control sensor (Pc or S7)

Cond. ctrl. ref. °C Actual reference temp. for condenser capacity

(incl. external contributions, if any)

Cond. cap. % Cut-in condenser capacity in % (of total capacity)

Request Cond. cap % Reference for condenser capacity

Pc Bar Condensing pressure (measured with the pressure transmitter)

Tc °C Condensing pressure in °C. (measured with the pressure transmitter)

Gc status Actual gas cooler operation:

0=O. 1=Standby. 2=Max COP operation. 3=Heat recovery. 4=Extra capacity.

5=Manual control.

Pgc Bar Actual gas cooler pressure

Pgc reference Bar Actual reference for gas cooler pressure

Sd discharge gas °C Actual discharge gas temperature

Sgc °C Actual temperature at outlet from the gas cooler

MC dP0 oset K Actual displacement value for the suction pressure in connection with a “P0

Optimiser” function (Master control function in AKA gateway)