Data sheet Actuator for modulating control AME 55 QM

© Danfoss | 2016.09 | 3

VD.CV.A2.02

DIP switch setting

The actuator has a function selection DIP switch

under the removable cover. In particular, if SW6

is set to ON, the actuator will perform as 3-point

actuator.

The switch provides the following functions:

•SW1: U/I - Input signal type selector:

If set to OFF position, voltage input is selected. If

set to ON position, current input is selected.

•SW2: 0/2 - Input signal range selector:

If set to OFF position, the input signal is in the

range from 2 V to 10 V (voltage input)

or from 4 mA to 20 mA (current input). If set to

ON position, the input signal is in the range from

0 V to 10 V (voltage input) or from 0 mA to 20 mA

(current input).

•SW3: D/I - Direct or inverse acting selector:

If set to OFF position, the actuator is direct acting

(stem contracts as voltage increases). If actuator

is set to ON position the actuator is inverse

acting (stem extracts as voltage increases).

•SW4: —/Seq - Normal or sequential mode

selector:

If set to OFF position, the actuator is working

in range 0(2)..10V or 0(4)..20mA. If set to ON

position, the actuator is working in sequential

range; 0(2)..5 (6)V or (0(4)..10 (12)mA) or (5(6)..10V)

or (10(12)..20mA).

•SW5: 0..5V/5...10V - Input signal range in

sequential mode:

If set to OFF position, the actuator is working in

sequential range 0(2)..5 (6)V or 0(4)..10 (12)mA.

If set to ON position, the actuator is working in

sequential range; 5(6)..10V or 10(12)..20mA.

•SW6: Prop./3-pnt - Modulating or 3-point mode

selector:

If set to OFF position, the actuator is working

normally according to control signal. If set to

ON position, the actuator is working as 3-point

actuator.

For this operation please refer to page 2

(wiring 3-point control).

When DIP switch SW6 is set to ON than all

functions from other DIP switch become inactive.

•SW7: LOG/LIN - Equal percentage or linear flow

through valve selector:

If set to OFF position, the ow through valve

is equal percentage. If set to ON position, the

ow through valve is linear according to control

signal.

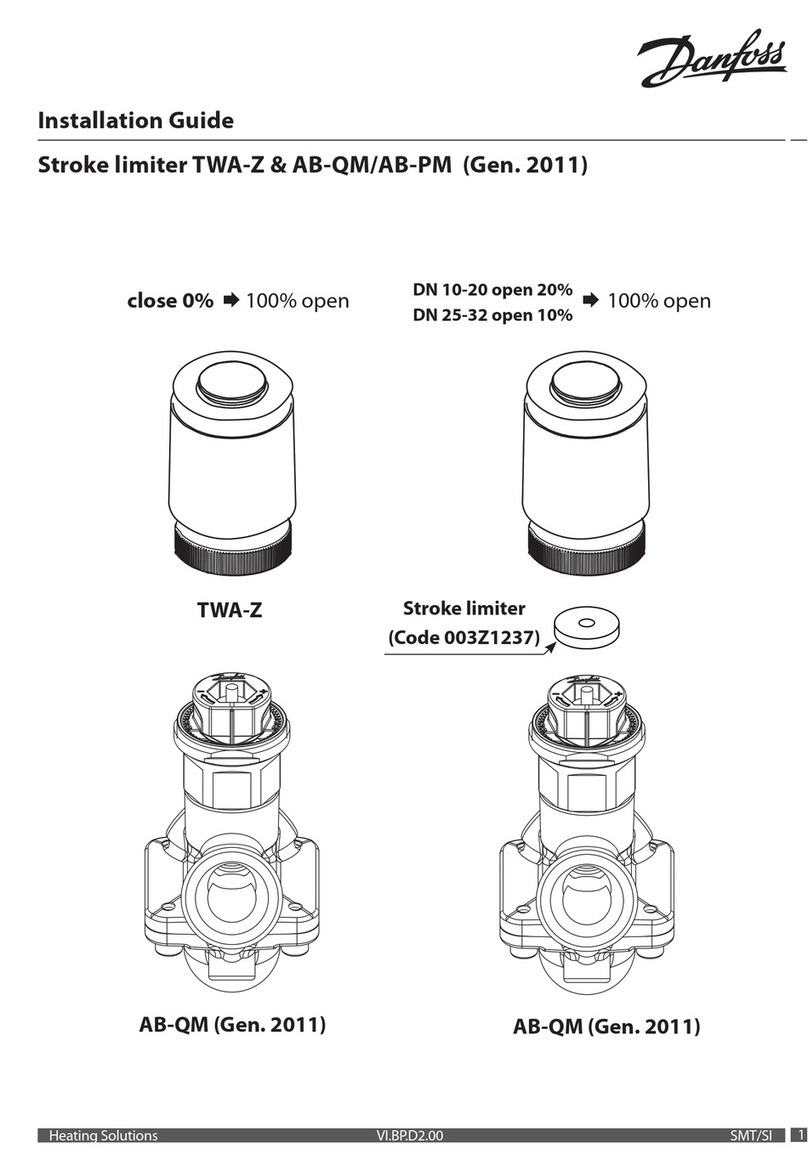

•SW8: 100% KVS/Reduced KVS:

To be set to OFF position (no sense in combination

with AB-QM).

•SW9: Reset:

Changing this switch position will cause the

actuator to go through a self stroking cycle.

Complete the mechanical and electrical

installation and perform the necessary checks

and tests:

• Isolate control medium. (e.g. self stroking

in a steam application without suitable

mechanical isolation could cause a hazard).

• Apply the power. Note that the actuator will

now perform the self stroking function.

• Apply the appropriate control signal and

check the valve stem direction is correct for

the application.

• Ensure that the actuator drives the valve over

its full stroke, by applying the appropriate

control signal. This action will set the valve

stroke length.

The unit is now fully commissioned.

Commissioning Commissioning / testing feature

The actuator can be driven to the fully open or

closed positions (depending on valve type) by

connecting SN to terminals 1 or 3.