Danfoss VLT MCD 200 User manual

Other Danfoss Controllers manuals

Danfoss

Danfoss AFP 2/VFG 2 User manual

Danfoss

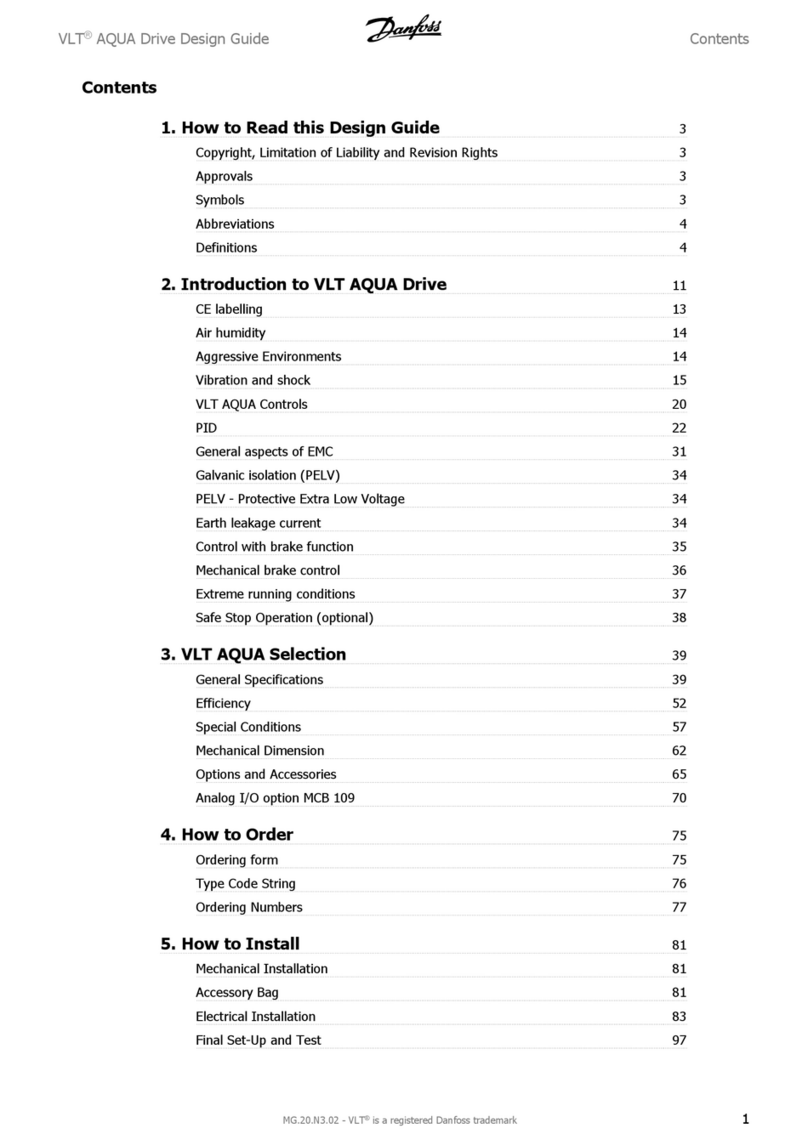

Danfoss vlt aqua Guide

Danfoss

Danfoss VFQ 2 User manual

Danfoss

Danfoss ECL Comfort 300 User manual

Danfoss

Danfoss VTL MCD 203 Series User manual

Danfoss

Danfoss ADAP-KOOL AK-PC 572 User manual

Danfoss

Danfoss AME 110 NLX User manual

Danfoss

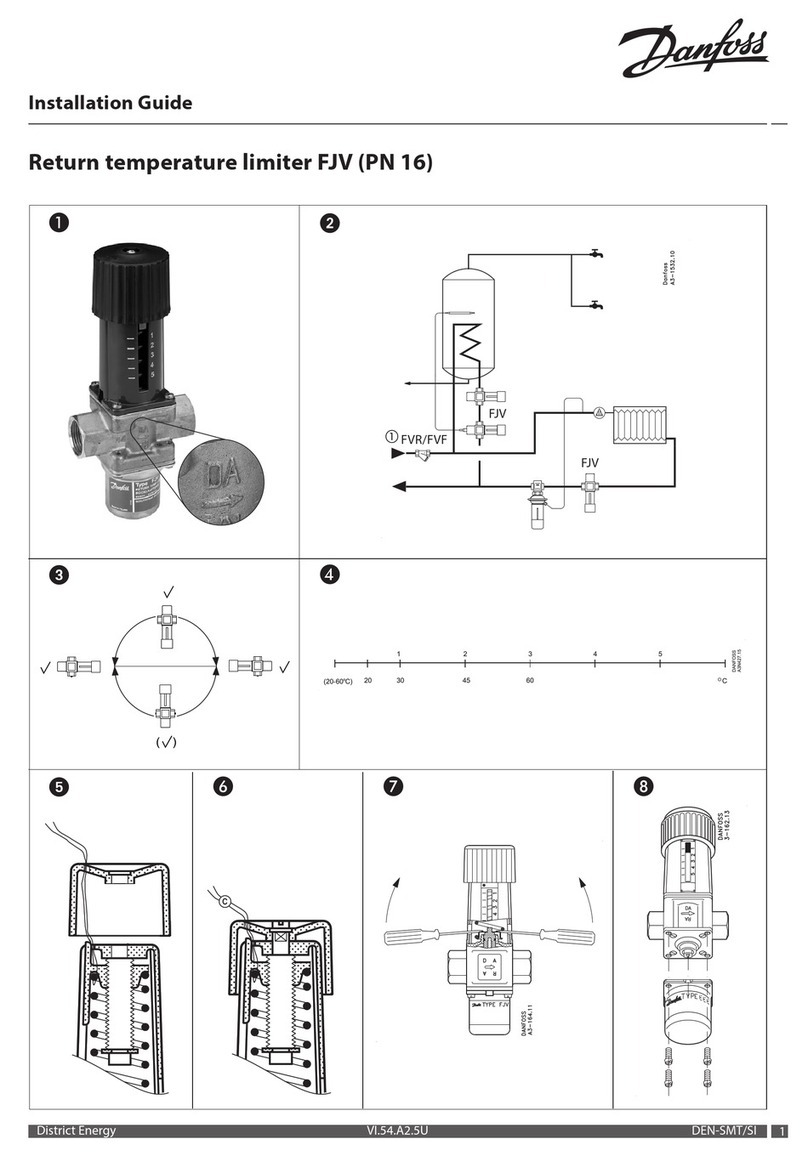

Danfoss FJV Series User manual

Danfoss

Danfoss AK-CC55 User manual

Danfoss

Danfoss AK-PC 351 User manual

Danfoss

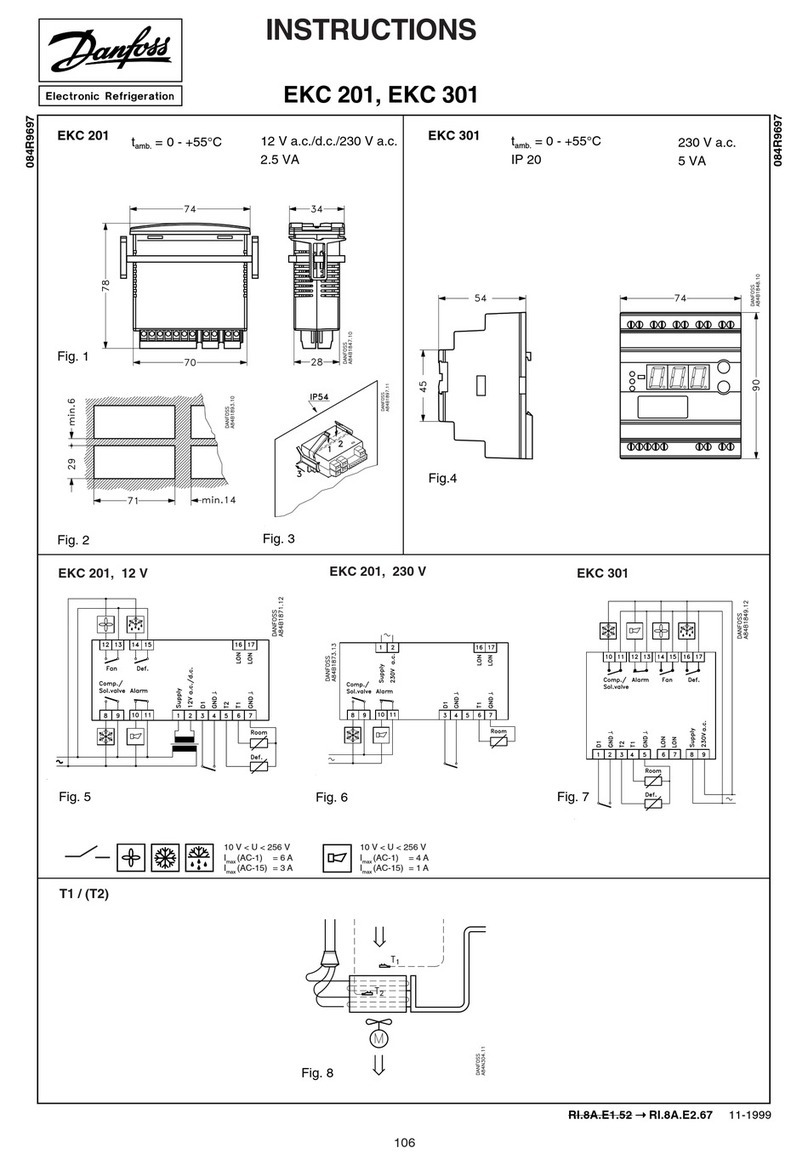

Danfoss EKC 201 User manual

Danfoss

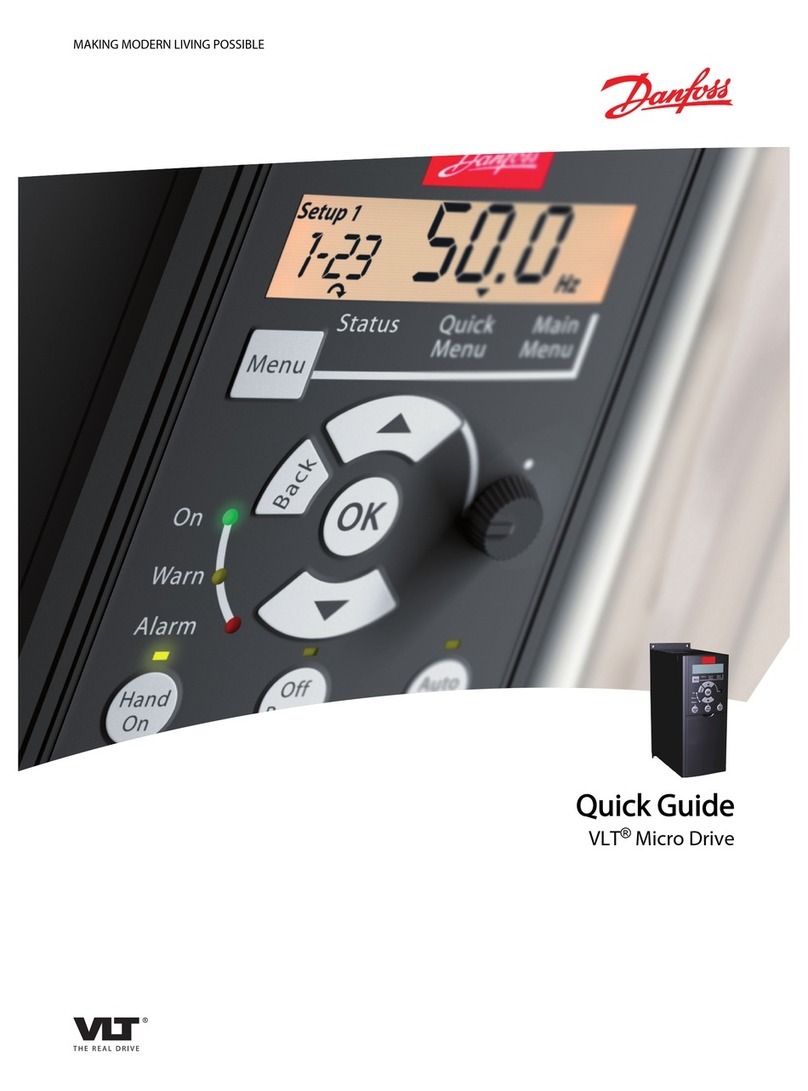

Danfoss VLT Micro Drive FC 51 Series User manual

Danfoss

Danfoss VLT Soft Starter MCD 600 User manual

Danfoss

Danfoss AK-CC55 User manual

Danfoss

Danfoss VLT HVAC Drive FC 102 User manual

Danfoss

Danfoss ECL Comfort 210 User manual

Danfoss

Danfoss vlt soft starter mcd 500 User manual

Danfoss

Danfoss NovoCon S User manual

Danfoss

Danfoss Link HC User manual

Danfoss

Danfoss 140F1139 User manual

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions