Danfoss SET3M User manual

Other Danfoss Remote Control manuals

Danfoss

Danfoss FP975 Assembly Instructions

Danfoss

Danfoss MP08A User manual

Danfoss

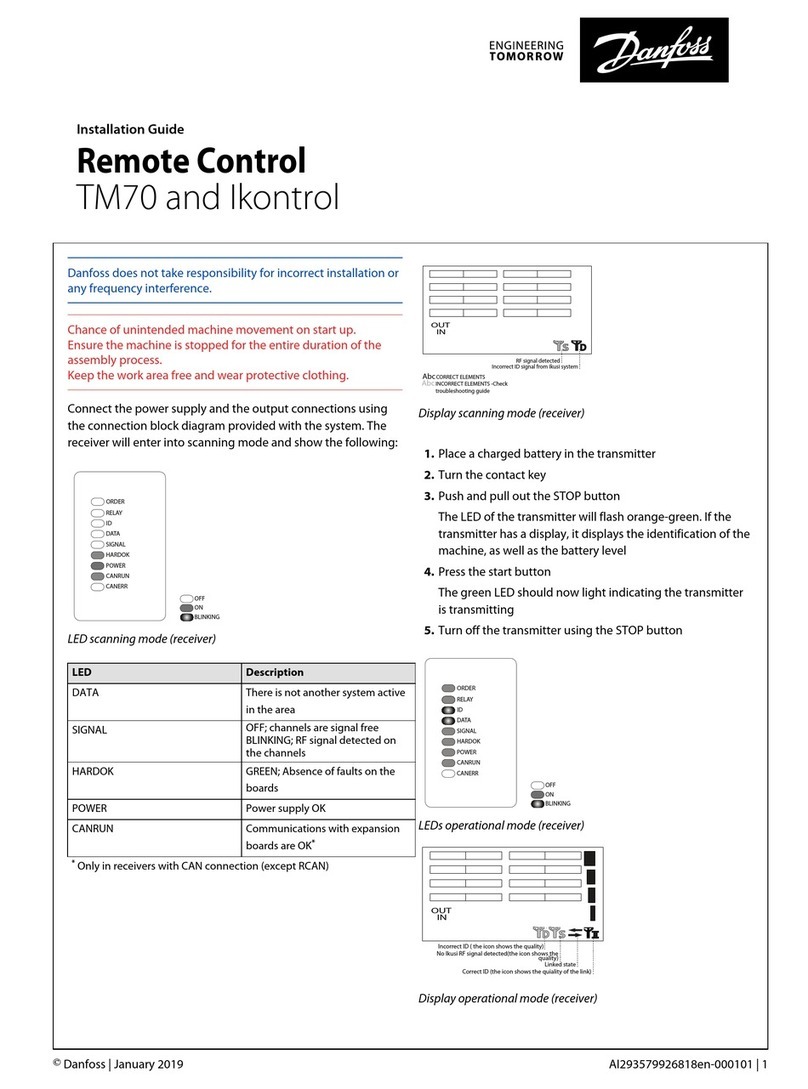

Danfoss TM70 User manual

Danfoss

Danfoss CF-RC User manual

Danfoss

Danfoss WS103 User manual

Danfoss

Danfoss Ikargo2 User manual

Danfoss

Danfoss IKORE B User manual

Danfoss

Danfoss IK2 User manual

Danfoss

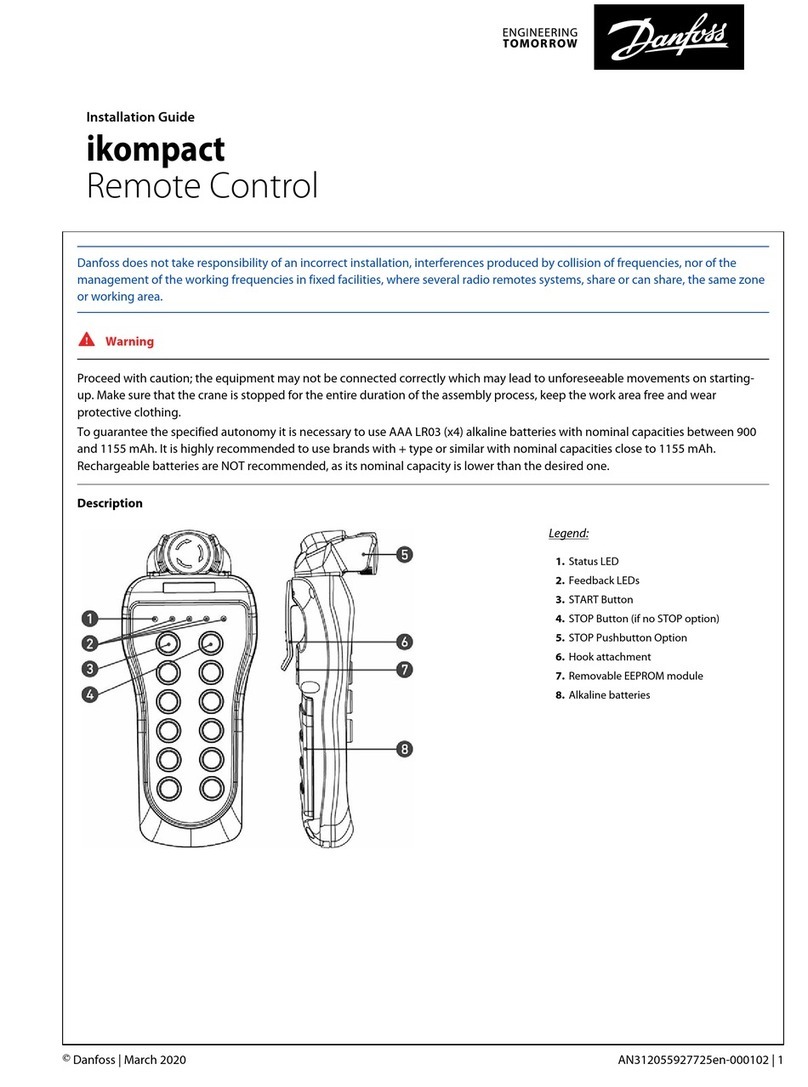

Danfoss Ikompact User manual

Danfoss

Danfoss MPCAN User manual

Danfoss

Danfoss CF-RC User manual

Danfoss

Danfoss T70 1 HALL User manual

Danfoss

Danfoss R06 User manual

Danfoss

Danfoss 102E7 User manual

Danfoss

Danfoss IKP1000 User manual

Danfoss

Danfoss Ikompact User manual

Danfoss

Danfoss CF-RC User manual

Danfoss

Danfoss 103E7 Assembly Instructions

Danfoss

Danfoss R13 F User manual

Danfoss

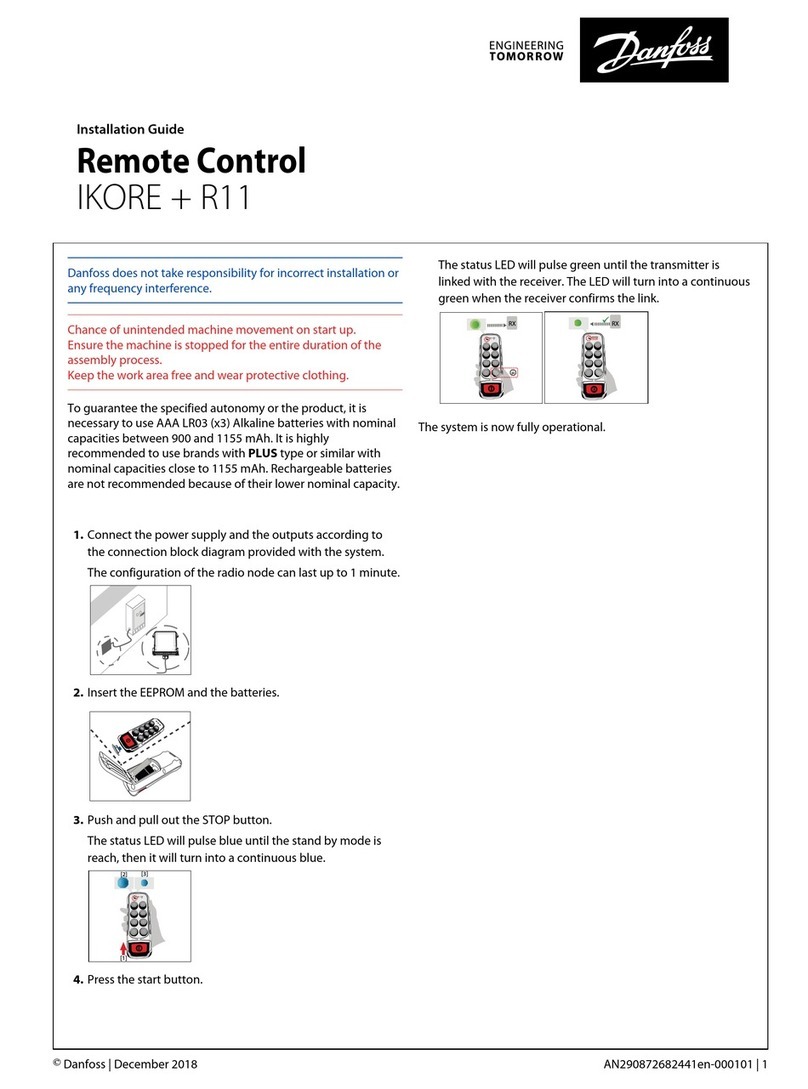

Danfoss IKORE User manual