Datcon DT4200 User manual

DT4200

Process Indicator

Operating Instructions

DT4200

2 20181113-V0

Contents

1. About this document .....................................................4

1.1. Function ................................................................................... 4

1.2. Target group............................................................................. 4

1.3. Symbolism used....................................................................... 4

2. For your safety ...............................................................5

2.1. Authorised personnel ............................................................... 5

2.2. Appropriate use........................................................................ 5

2.3. Warning about misuse ............................................................. 5

2.4. General safety instructions....................................................... 5

2.5. CE conformity........................................................................... 5

2.6. Environmental instructions ....................................................... 5

3. Product description .......................................................6

3.1. Delivery configuration............................................................... 6

3.2. Principle of operation ............................................................... 7

3.3. Adjustment ............................................................................... 8

3.4. Storage and transport .............................................................. 8

4. Mounting.........................................................................9

4.1. General instructions ................................................................. 9

4.2. Main dimensions of the instrument .......................................... 9

4.3. Mounting ................................................................................ 10

5. Connecting ...................................................................12

5.1. Preparing the connection ....................................................... 12

6. Display and manual controls ......................................16

6.1. The first start-up ..................................................................... 16

6.2. Characters and mnemonics appearing on the display ........... 17

6.3. Manual controls...................................................................... 20

DT4200

20181113-V0 3

7. Setting-up .....................................................................23

7.1. Typing the code (password) in ............................................... 23

7.2. The menu ............................................................................... 25

7.3. Display modes of limit output status (01. menu item) ............ 26

7.4. Setting up the limit outputs (02. and 03. menu items)............ 28

7.5. Limit output alarm mode......................................................... 34

7.6. Decimal point position (04. menu item).................................. 36

7.7. The physical value assigned to 4 mA (05. menu item) .......... 37

7.8. The physical value assigned to 20 mA (06. menu item) ........ 39

7.9. The number of averaged measurements (07. menu item)..... 41

7.10. Display refresh time (08. menu item) ................................... 43

7.11. Tests (09. menu item) .......................................................... 45

7.12. Changing the user code (10. menu item)............................. 47

7.13. Changing the supervisor code (11. menu item) ................... 49

7.14. Display operating modes (12. menu item) ........................... 51

7.15. Disable displaying the leader zeros (13. menu item) ........... 53

7.16. Clear minimum and maximum values (14. menu item)........ 55

7.17. Resetting the default settings (15. menu item)..................... 56

8. Fault rectification .........................................................57

8.1. Fault finding............................................................................ 57

8.2. Repairing................................................................................ 57

9. Dismounting .................................................................57

9.1. Dismounting procedure .......................................................... 57

9.2. Disposal ................................................................................. 57

10. Appendix.....................................................................58

10.1. Technical specifications ....................................................... 58

10.2. Application example ............................................................. 60

10.3. Error messages.................................................................... 61

10.4. Messages of critical errors ................................................... 62

10.5. Description of the menu items.............................................. 63

10.6. Messages and error messages during setting up ................ 67

10.7. Setting up the instrument (Example).................................... 68

10.8. The limit outputs (training material)...................................... 70

DT4200

4 20181113-V0

1. About this document

1.1. Function

This operating instructions manual has all the information

you need for quick set-up and safe operation of DT4200.

Please read this manual before you start setup.

1.2. Target group

This operating instructions manual is directed to trained

personnel. The contents of this manual should be made

available to these personnel and put into practice by them.

1.3. Symbolism used

Information, tip, note

This symbol indicates helpful additional information.

Caution, warning, danger

This symbol informs you of a dangerous situation that could

occur. Ignoring this cautionary note can impair the person

and/or the instrument.

•

List

The dot set in front indicates a list with no implied sequence.

→

Action

This arrow indicates a single action.

1

Sequence

Numbers set in front indicate successive steps in a

procedure.

DT4200

20181113-V0 5

2. For your safety

2.1. Authorised personnel

All operations described in this operating instructions

manual must be carried out only by trained and authorised

specialist personnel. For safety and warranty reasons, any

internal work on the instruments must be carried out only by

DATCON personnel.

2.2. Appropriate use

The DT4200 is a 4-20 mA loop-powered process indicator.

Detailed information on the application range of the DT4200

is available in chapter „Product description”.

2.3. Warning about misuse

Inappropriate or incorrect use of the instrument can give rise

to application-specific hazards, or demage to system

components through incorrect mounting or adjustment.

2.4. General safety instructions

The DT4200 is a high-tech instrument requiring the strict

observance of standard regulations and guidelines. The

user must take note of the safety instructions in this

operating instructions manual, the country-specific

installation standard as well as all prevailing safety

regulations and accident prevention rules.

2.5. CE conformity

A DT4200 is in conformity with the provisions of the

following standards:

EN 61326:2000 (EMC)

2.6. Environmental instructions

Protection of the environment is one of our most important

duties.

Please take note of the instructions written in the following

chapters:

•Chapter 3.4. Storage and transport

•Chapter 9.2. Disposal

DT4200

6 20181113-V0

3. Product description

3.1. Delivery configuration

Delivered items The scope of delivery encompasses:

•DT4200

•1 pc. panel sealing (1)

•2 pc. mounting clamps (enclosed in a nylon bag)

•documentation:

this oparating instructions manual

certification

warranty

The instrument is built from the following main parts:

Main parts

1. instrument case

DT4200

20181113-V0 7

3.2. Principle of operation

Area of application DT4200 is an process indicator enable linear process

variables to be displayed.Two isolated outputs are available

with different operating modes for limit signaling or for

simple control purposes.

Use the enclosed seal between the instrument and the

panel when mounting the instrument to assure IP 65 from

the front.

Operating principle

The 4-20 mA current flows through a measuring resistor

and is converted by a 16 bit A/D converter into digital value.

The digital value is processed by a microcontroller. The use

r

may set up the the configuration parameters: scaling,

decimal point position, display refresh rate, signal filtering,

limit modes, limit values, etc. through the front panel

membrane keypad and the parameters stored in EEPROM.

A two level password protects the settings from

unauthorised changes.

The 4 ½-digit liquid crystal display make process variables

easily visible at a distance. A label defining the appropriate

engineering unit may be attached to the right of the display.

DT4200 has two optically isolated transistor outputs for limit

signaling or for simple control purposes.

Power supply DT4200 is loop-powered from 4-20 mA signal, dropping less

than 2 V at 20 mA.

DT4200

8 20181113-V0

3.3. Adjustment

DT4200 can be adjusted through the 3 button front panel

keypad. All configuration parameters are stored in the

instrument EEPROM for unlimited period of time, even

when the loop current beeng switched off.

In factory setting the DT4200 displays the 4-20 mA loop

current with a resolution of three decimals.

The instrument doesn’t need any internal adjustment.

3.4. Storage and transport

This instrument should be stored and transport in places

whose climatic conditions are in accordance with Chapter

10.1. Technical specifications, as described under the

title: Environmental conditions.

The packaging of DT4200 consist of enviroment-friendly,

recyclable cardboard is used to protect the instrument

against the impacts of normal stresses occurring during

transportation. The corrugated cardboard box is made from

environment-friendly, recyclable paper. The inner protective

material is polyfoam and nylon, which should be disposed of

via specialised recycling companies.

DT4200

20181113-V0 9

4. Mounting

4.1. General instructions

Use the enclosed seal between the instrument and the

panel when mounting the instrument to assure IP 65 from

the front.

Mounting positions

Select a mounting position you can easily read the display

reach for mounting and connecting the instrument and that

minimises the hazard of water, dust or dump getting into the

instrument.

4.2. Main dimensions of the instrument

DT4200

10 20181113-V0

4.3. Mounting

The instrument is housed in a DIN standard 96 x 48 x 50

mm ABS case. It can be fix in the panel with the two

enclosed mounting clamps.

Preparatory steps

Dimensions of panel

cutout

1. Cut-out the panel according to the figure shows above.

The cut-out needs special tools, it must be carried out by

trained specialist personnel.

DT4200

20181113-V0 11

Mounting with the

mounting clamps

2. Put on the enclosed seal onto the instrument case from

the rear side and fit it to the instrument holding frame

(Figure step 2).

3. Put the instrument into the prepared cut-out until it

possible and check the fitting of the seal between case and

mounting surface.

4. Put one of the enclosed mounting clamp onto the tip of a

screwdriver (A) and put the clamp with the help of the

screwdriwer into the hole on the side of the instrument.

5. Push the mounting clamp with your finger tip as far as

you can while keeping the case in it’s position.

Repeat the 4., 5. steps with the other clamp.

Please do not exercise forces higher than necessary, as it

may cause damages to the clamp.

DT4200

12 20181113-V0

5. Connecting

5.1. Preparing the connection

Always observe the following safety instructions:

• Connect or disconnect only in the complete absence of

line voltage

• Take note the data concerning on the

overcurrent protection in installation.

• Use only a screwdriver with appropriate head

Select connecting

cable

Preparing cables

Take note the suitability of the connecting cable

(wire cross-section, insulation, etc.).

You may use either solid conductor or flexible conductor.

In case of using flexible conductor use crimped wire end.

In case of mains connection the wire cross-section should

be 0.25-1.5 mm2.

In case of connection communication cables take note the

concerning prescriptions (www.modbus.org).

It’s an important rule that the power cables and signal

cables should lead on a separate way.

Prepare the cable for the connection.

Strip approx. 8 mm insulation.

In case of using flexible cable, use crimped wire end.

Wiring plan, connecting

the DT4200 as a terminal

device:

(see also “Application

example”)

Be careful the polarity of

the cable.

DT4200

20181113-V0 13

Connecting the cables •The DT4200 is situated in the „middle” of the current loop.

In this case one cable comes from the signal source and

another cable goes to the processing unit(s).

The following figure shows this case.

Wiring plan, connecting

the instrument as an

intermediate device

(see also “Application

example”)

Be careful the polarity of

the cables.

Wiring plan, connecting

the limit outputs

(see also “Application

example”)

Be careful the polarity of

the cables.

DT4200

14 20181113-V0

Make sure before connection that the current loop is

switched off.

The push-in direct connector assemblies used allow a fast

connection of the cables.

Their proper usage is shown by the following figure:

Connecting the cables

into the terminal

assemblies

1. Push the stripped cable-end until it possible into the

terminal assembly. In the case of flexible cable-ends, you

can facilitate opening the connection part by pushing down

the white button.

2. By pushing the wire in, the self-closing connection is

being established. Check it by pulling it outwards slightly.

(3. When you disassemble the cable, push down the white

button by a screwdriver, and pull the cable-end out.)

There is no need to use great force for pushing the cable in,

neither for removal. The button can be pushed down easily.

Please do not exercise forces higher than necessary, as it

may cause damages to the terminal assembly.

DT4200

20181113-V0 15

Finishing step 1. Check if the cables are connected properly (have you

connected all the cables; have you connected them to the

right place; is the connection stable; do not the cable-ends

touch each other).

Checking the

connections

After you have completed the connections, put the current

loop under voltage, in such a way that the nominal 4-20 mA

current should flow in the loop. If the connection is correct,

numbers or a characters has to appear on the display.

If nothing appears on the display, most probably there is no

current flowing in the loop. Check if the current is present by

using an ampermeter. If the current value is in the

4-20 mA range, check if everything has been done in

accordance with Chapter 5.1 Connecting into the current

loop.

You may check the voltage at the pins 5and 6of the

terminal assembly, the voltage should be a value between

1.5 and 2.2 V, while pin 6is the positive one,

if the connection is correct. In the case of reverse polarity,

the voltage value is less than 1 V, and 5is the positive pin.

With this you have completed the connection of DT4200.

DT4200

16 20181113-V0

6. Display and manual controls

6.1. The first start-up

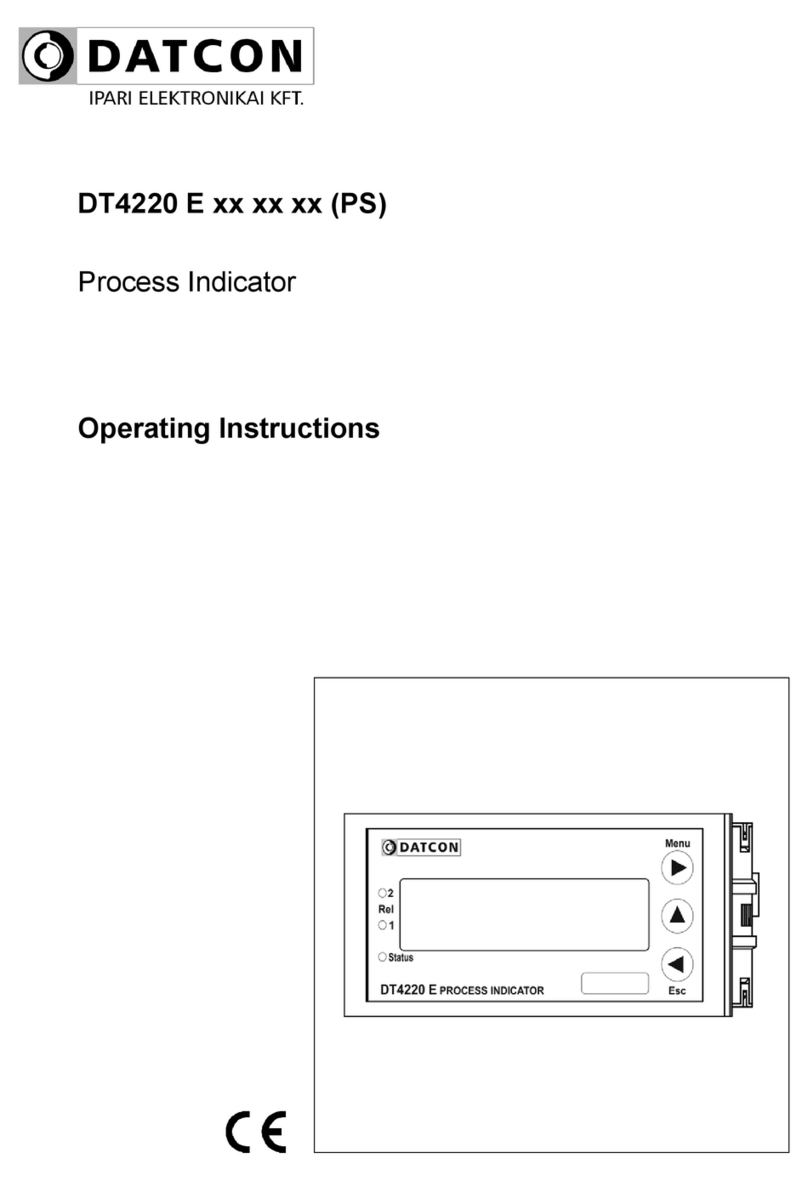

The display

The display is indicated by the arrow (1)

After the instrument has been installed and connected into

the current loop, first you see on the display the type of

instrument: , , than the current in mA, with a

resolution of 3 decimals.

In the case of an error

message

If anything else appears on the display instead of the

numbers showing the current value (e.g. a message with

blinking letters), then it is an error message of the

instrument.

In order to define the error more accurately, please go to

Chapter 10.3. Error messages or 10.4. Messages of

critical errors, found at the end of this Manual, in the

Appendix.

DT4200

20181113-V0 17

6.2. Characters and mnemonics appearing on the

display

DT4200 has a 7-segment type display. It means that

maximum 7 bars are used to form each characters. The

numbers can be read easily, some of the letters, marks

however, looks unusual:

= A, = B, = C, = D, = E, = F, = G,

= H,= I, = J, = K, = L, = M, = N,

= O, = P, = Q, = R, = S, = T, = U,

= V, = W, = X, = Y, = Z

All mnemonics (code words) presented on the display

comes from English expressions in abbreviated form.

The following part gives a list of the possible mnemonics

and their meaning. The left-side column shows the

characters appearing on the display. The right-side column

gives first the meaning, then the full English word in

brackets and, after the hyphen, and explanation may be

given.

Login text

DT - Datcon instrument

4200 - Type of the instrument

Error messages

A/D overflow (Error: A/D Overflow)

Loop current < 3.5 mA

Loop current > 20.5 mA

Scaling error (Error: Scale)

Underflow (Error: Underflow)

Overflow (Error: Overflow)

Minimum-maximum (Error: Missing Minimum-Maximum)

DT4200

18 20181113-V0

Messages of critical

errors

A/D failure (Service: AD Hardware)

EEPROM failure (Service: EEPROM Hardware)

EEPROM write error (Service: EEPROM Protected)

Calibration error (Service: Calibration)

Default factory settings (Service: Default Factory Settings)

The last saving was not successful (Error: Last Save)

During measuring

20000 - The value presented on the display is twenty-

thousand

-20000 The value presented on the display is minus twenty-

thousand

During code writing

Code? (Code)

Bad Code (Bad Code)

A User login took place (User)

A Supervisor login took place (Supervisor)

During setting up

The typed number is lower than allowed (Low Limit)

The typed number is higher than allowed (High Limit)

Low numeric value not possible to display

High numeric value not possible to display

Re-type it please (Re-type)

Automatic escaping (Auto Escape) - after 1 minute

Exit from the setting (Exit)

The instrument is making calculations, please wait

(Busy)

The requested operation has been completed (Ready)

The saving of the settings is being done (Save)

No, I don’t want this menu (No)

Yes, the menu can be started (Yes)

DT4200

20181113-V0 19

Minimum-maximum

values on the display

(▲button)

Minimum value (MINimum)

Maximum value (MAXimum)

Firmware version (FiRMwareE)

Low numeric value not possible to display

High numeric value not possible to display

Limit values on the

display

Both limit outputs are switched off

The limit output No.1 is switched on (Limit 1)

The limit output No.2 is switched on (Limit 2)

Both limit outputs are switched on

DT4200

20 20181113-V0

6.3. Manual controls

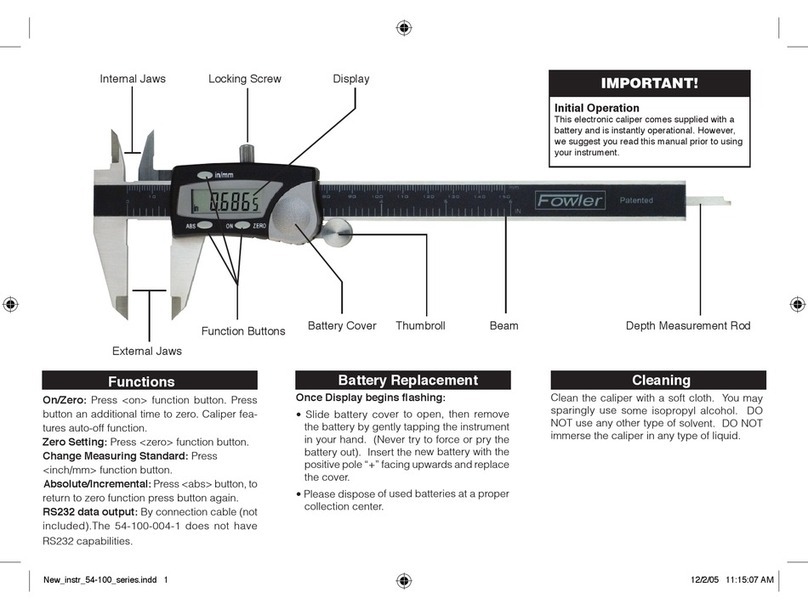

DT4200 can be adjusted by the membrane push-buttons

indicated by (1), (2), and (3) in the drawing.

Functions of the push-buttons during measurement

(1) MENU button: Entering the menu

When you push this button, the device will ask for a

password (code) in accordance with Chapter 7.1. Typing

the code (password) in, when the right code has been

given, it enters into the menu. During this time the

measurement is suspended, and the limit outputs don’t

change. If no keys are pressed for a period of one minute,

the instrument restarts and the measurement goes on.

(2) ▲button: displaying minimum value, maximum value,

firmware version. The above values and the firmware

version remains on the display as long as the button is

being pressed. During this time the measurement is

suspended, and the limit outputs don’t change.

Table of contents

Other Datcon Measuring Instrument manuals

Datcon

Datcon DT4220 E Series User manual

Datcon

Datcon DT4120 Series User manual

Datcon

Datcon DT7000 User manual

Datcon

Datcon DT4227 UI User manual

Datcon

Datcon DT9000 User manual

Datcon

Datcon DT9002 User manual

Datcon

Datcon DT4240 Series User manual

Datcon

Datcon DT9500 User manual

Datcon

Datcon DT9502 User manual

Datcon

Datcon DT1102 V User manual