Datcon DT9000 N User manual

DT9000 N

Process Indicator

Operating Instructions

DT9000 N

Contents

1. About this document.....................................................4

1.1. Function.....................................................................................4

1.2. Target group..............................................................................4

1.3. Symbo ism used........................................................................4

2. For our safet ..............................................................5

2.1. Authorised personne .................................................................5

2.2. Appropriate use.........................................................................5

2.3. Warning about misuse...............................................................5

2.4. Genera safety instructions........................................................5

2.5. CE conformity............................................................................5

2.6. Environmenta instructions........................................................5

3. Product description.......................................................6

3.1. De ivery configuration................................................................6

3.2. Princip e of operation.................................................................7

3.3. Adjustment.................................................................................8

3.4. Storage and transport................................................................8

4. Mounting........................................................................9

4.1. Genera instructions...................................................................9

4.2. Main dimensions of the instrument............................................9

4.3. Mounting as a wa -instrument.................................................10

4.4. Mounting as a pane -instrument..............................................13

5. Connecting...................................................................15

5.1. Connecting into the current oop.............................................15

6. Displa and manual controls......................................20

6.1. The first start-up.......................................................................20

6.2. Characters and mnemonics appearing on the disp ay............21

6.3. Manua contro s.......................................................................24

220180614-V020180614-V0

DT9000 N

7. Setting-up.....................................................................27

7.1. Typing the code (password) in................................................27

7.2. The menu.................................................................................29

7.3. Disp ay modes of imit output status (01. menu item).............30

7.4. Setting up the imit outputs (02. and 03. menu items)............32

7.5. Limit output a arm mode..........................................................38

7.6. Decima point position (04. menu item)...................................40

7.7. The physica va ue assigned to 4 mA (05. menu item)...........41

7.8. The physica va ue assigned to 20 mA (06. menu item).........43

7.9. The number of averaged measurements (07. menu item).....45

7.10. Disp ay refresh time (08. menu item)....................................47

7.11. Tests (09. menu item)............................................................49

7.12. Changing the user code (10. menu item)..............................51

7.13. Changing the supervisor code (11. menu item)....................53

7.14. Disp ay operating modes (12. menu item)............................55

7.15. Disab e disp aying the eader zeros (13. menu item)............57

7.16. C ear minimum and maximum va ues (14. menu item)........59

7.17. Resetting the defau t settings (15. menu item).....................60

8. Fault rectification.........................................................61

8.1. Fau t finding.............................................................................61

8.2. Repairing..................................................................................61

9. Dismounting................................................................61

9.1. Dismounting procedure...........................................................61

9.2. Disposa ...................................................................................61

10. Appendix....................................................................62

10.1. Technica specifications.........................................................62

10.2. App ication examp e..............................................................64

10.3. Error messages.....................................................................65

10.4. Messages of critica errors.....................................................66

10.5. Description of the menu items...............................................67

10.6. Messages and error messages during setting up.................70

10.7. Setting up the instrument (Examp e).....................................71

10.8. The imit outputs (training materia ).......................................73

20180614-V0 3

DT9000 N

1. About this document

1.1. Function

This operating instructions manua has a the information

you need for quick set-up and safe operation of DT9000 N.

P ease read this manua before you start setup.

1.2. Target group

This operating instructions manua is directed to trained

personne . The contents of this manua shou d be made

avai ab e to these personne and put into practice by them.

1.3. S mbolism used

Information, tip, note

This symbo indicates he pfu additiona information.

Caution, warning, danger

This symbo informs you of a dangerous situation that cou d

occur. Ignoring this cautionary note can impair the person

and/or the instrument.

•

List

The dot set in front indicates a ist with no imp ied

sequence.

→

Action

This arrow indicates a sing e action.

1

Sequence

Numbers set in front indicate successive steps in a

procedure.

420180614-V020180614-V0

DT9000 N

2. For our safet

2.1. Authorised personnel

A operations described in this operating instructions

manua must be carried out on y by trained and authorised

specia ist personne . For safety and warranty reasons, any

interna work on the instruments must be carried out on y by

DATCON personne .

2.2. Appropriate use

The DT9000 N is a 4-20 mA oop-powered process

indicator. Detai ed information on the app ication range of

the DT9000 N is avai ab e in chapter „Product description”.

2.3. Warning about misuse

Inappropriate or incorrect use of the instrument can give

rise to app ication-specific hazards, or demage to system

components through incorrect mounting or adjustment.

2.4. General safet instructions

The DT9000 N is a high-tech instrument requiring the strict

observance of standard regu ations and guide ines. The

user must take note of the safety instructions in this

operating instructions manua , the country-specific

insta ation standard as we as a prevai ing safety

regu ations and accident prevention ru es.

2.5. CE conformit

A DT9000 N is in conformity with the provisions of the

fo owing standards:

EN 61326-1:2006 (EMC)

2.6. Environmental instructions

Protection of the environment is one of our most important

duties.

P ease take note of the instructions written in the fo owing

chapters:

• Chapter 3.4. Storage and transport

• Chapter 9.2. Disposal

20180614-V0 5

DT9000 N

3. Product description

3.1. Deliver configuration

Delivered items The scope of de ivery encompasses:

• DT9000 N

• 2 pcs. of srew c amps (on y pane mounting version)

• 2 pcs. Pg 11 cab e entries

• instrument sea ing (on y pane mounting version)

• documentation:

this oparating instructions manua

certification

warranty

Main parts The instrument is bui t from the fo owing main parts:

1. instrument case

2. front pane with 3 mambrane push buttons

620180614-V020180614-V0

DT9000 N

3.2. Principle of operation

Area of application DT9000 N is an process indicator enab e inear process

variab es to be disp ayed.Two iso ated outputs are avai ab e

with different operating modes for imit signa ing or for

simp e contro purposes.

DT9000 N is housed in a mou ded po ycarbonate case

hauseproof to IP65 for insta ation in the fie d or on the

contro pane .

Operating principle The 4-20 mA current f ows through a measuring resistor

and is converted by a 16 bit A/D converter into digita va ue.

The digita va ue is processed by a microcontro er. The

user may set up the the configuration parameters: sca ing,

decima point position, disp ay refresh rate, signa fi tering,

imit modes, imit va ues, etc. through the front pane

membrane keypad and the parameters stored in EEPROM.

A two eve password protects the settings from

unauthorised changes.

Large 4 ½-digit, 20.5 mm height iquid crysta disp ay make

process variab es easi y visib e at a distance. A abe

defining the appropriate engineering unit may be attached

to the right of the disp ay.

DT9000 N has two optica y iso ated transistor outputs for

imit signa ing or for simp e contro purposes.

Power suppl DT9000 N is oop-powered from 4-20 mA signa , dropping

ess than 2 V at 20 mA.

20180614-V0 7

DT9000 N

3.3. Adjustment

DT9000 N can be adjusted through the 3 button front pane

keypad. A configuration parameters are stored in the

instrument EEPROM for un imited period of time, even

when the oop current beeng switched off.

In factory setting the DT9000 N disp ays the 4-20 mA oop

current with a reso ution of three decima s.

The instrument doesn’t need any interna adjustment.

3.4. Storage and transport

This instrument shou d be stored and transport in p aces

whose c imatic conditions are in accordance with Chapter

10.1. Technical specifications, as described under the

tit e: Environmenta conditions.

The packaging of DT9000 N consist of enviroment-friend y,

recyc ab e cardboard is used to protect the instrument

against the impacts of norma stresses occurring during

transportation. The corrugated cardboard box is made from

environment-friend y, recyc ab e paper. The inner protective

materia is po yfoam and ny on, which shou d be disposed of

via specia ised recyc ing companies.

820180614-V020180614-V0

DT9000 N

4. Mounting

4.1. General instructions

Use the enc osed sea when mounting DT9000 N on pane

to assure IP 65 protection between the instrument and the

pane from the front side (on y pane mounting version).

Mounting positions Se ect a mounting position you can easi y read the disp ay

reach for mounting and connecting the instrument and that

minimises the hazard of water, dust or dump getting into the

instrument.

Mounting cable entries The insrument is equipped with one PG11 cab e entry and

two additiona ho e equipped with sea ing p ugs. Two PG11

cab e entry is accessory. If required more than one cab e

entry (see chapter 5.) put out the sea ing p ug turning it in

antic ockwise direction. To put in the cab e entry use the

sea ing turn it in c ockwise direction. Tighten the screws so

much that ensures the desired sea ing. Use on y appropriet

too s.

4.2. Main dimensions of the instrument

20180614-V0 9

DT9000 N

4.3. Mounting as a wall-instrument

Removing the front

cover

In order to remove the front cover, first remove the four

fixing screws as shown in the drawing. A screwdriver of

appropriate head-size on y shou d be used. Using

screwdrivers with inappropriate head-size may cause a

damage in the screws’ heads or in the instrument front

pane .

Remove the screws by turning them in antic ockwise

direction as shown in the drawing Step (1). The screws are

secured against fa ing out. After this you can simp y take

away the front cover from the housing (2) and you can open

it by turning it downwards (3). P astic ties are used to fasten

the front cover to the housing, preventing it from fa ing.

10 20180614-V020180614-V0

DT9000 N

Preparator steps There are four through-ho es, shown by arrows in the

fo owing drawing, for the fastening of the housing. The

diameters of the ho es are made for M3 screws.

Holes for mounting

1. Mark the p aces of the ho es in accordance with the

drawing.

2. Make the ho es for mounting ready.

3. Remove any burrs from the ready-made ho es.

P ease observe the safety ru es throughout the operation.

20180614-V0 11

DT9000 N

Mounting the instrument Four M3 threaded screws are needed for mounting the

instrument (these are not accessories). The type of the

screws depends on the wa -materia , whi e the dimensions

depend on the wa -thickness. The use of cross recessed

pan head screws is recommended to make the mounting

easier. The minimum screw- ength shou d be the wa -

thickness + 10 mm.

During mounting, p ease observe a safety ru es, and use

on y appropriate too s.

Secure the screws against getting oose. For this purpose

you may use spring ock or serrated ock washers.

Depending on the materia of the wa , and in order to

ensure the most practicab e mounting method, it is not

mandatory, of course, to use the above-described threaded

joints. Depending on the situation, specia screw types for

wood or for meta sheets can a so be used, or the joint can

be riveted too.

Mounting the front cover

back to its place

1. Check if there are a ien materia s eft in the housing, ike

sma too s, wire or meta pieces, p astic chips, etc. If there

are, remove them.

2. Put back the front cover of the apparatus, taking care that

the sea ing shou d get to its p ace. There shou d be no gap,

nor cab es caught between the housing and the front cover.

3. Tighten the front cover.

Turn the screws in c ockwise direction. Tighten the screws

so much that ensures the desired sea ing.

12 20180614-V020180614-V0

DT9000 N

4.4. Mounting as a panel-instrument

Preparator steps 1. Cut-out the pane according to the figure shows be ow.

The cut-out needs spetia too s, it must be carried out by

trained specia ist personne .

Cut-out dimensions

20180614-V0 13

DT9000 N

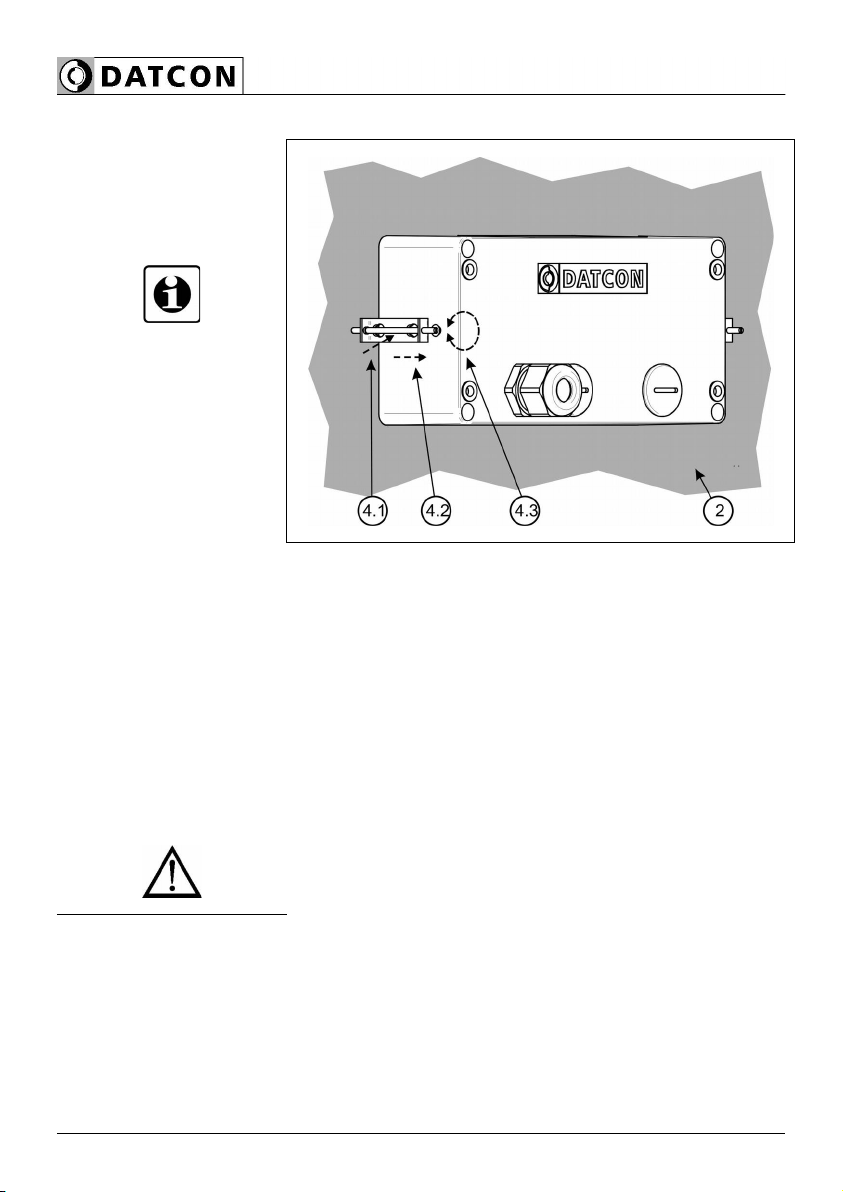

Mounting b the

screw clamps

2. Put on the enc osed sea onto the instrument case from

the rear side and fit it to the instrument ho ding frame

(Figure step 2).

3. Put the instrument into the prepared cut-out unti it

possib e and check the fitting of the sea between case and

mounting surface.

4. Put on the enc osed screw c amps onto the sides of the

instrument case (Figure step 4.1, 4.2).

Fix the instrument by turning the srews in c ockwise

direction (Figure step 4.3).

Pay attention not to et pointed, sharp meta parts cause

accidents.

14 20180614-V020180614-V0

DT9000 N

5. Connecting

5.1. Connecting into the current loop

Wiring plan, connecting

the DT9000 N as a

terminal device:

(see a so “App ication

examp e”)

Be carefu the po arity of

the cab e.

20180614-V0 15

DT9000 N

Connecting the cables • The DT9000 N is situated in the „midd e” of the current

oop. In this case one cab e comes from the signa source

and another cab e goes to the processing unit(s).

The fo owing figure shows this case.

Wiring plan, connecting

the instrument as an

intermediate device

(see a so “App ication

examp e”)

Be carefu the po arity of

the cab es.

Wiring plan, connecting

the limit outputs

(see a so “App ication

examp e”)

Be carefu the po arity of

the cab es.

16 20180614-V020180614-V0

DT9000 N

Select connection cable Take note the suitabi ity of the connecting cab e.

We recommend the use of screened twisted pair cab e. The

wire cross-section shou d be 0.25-1.5 mm2.

Select connection cable In particu ar, make sure that no potentia equa isation

currents f ow over the cab e screen. In case of grounding on

both sides (for suppress the inf uence of high frequency

interference signa s) this can be achived by use of a

capacitor (e.g. ceramic capacitor 1 nF, 1500 V) or separate

potentia equa isation. The ow frequency potentia

equa isation currents are thus supressed, but the protective

effect against high frequency interference signa s remains.

Inserting the cable into

the instrument

1. Prepare the cab e for the connection.

Remove approx. 30 mm of cab e mant e, strip approx.

8 mm insu ation.

2. Remove the instrument front cover (see chapter 4.3.).

3. Loosen compression nut of the cab e entry.

4. Insert the cab e into the instrument through the cab e

entry.

20180614-V0 17

DT9000 N

Connecting the cables

into the terminal

assemblies

Make sure before connection that the current oop is

switched off.

The push-in direct connector assemb ies used a ow a fast

connection of the cab es.

Their proper usage is shown by the fo owing figure:

1. Push the stripped cab e-end unti it possib e into the

termina assemb y. In the case of f exib e cab e-ends, you

can faci itate opening the connection part by pushing down

the white button.

2. By pushing the wire in, the se f-c osing connection is

being estab ished. Check it by pu ing it outwards s ight y.

(3. When you disassemb e the cab e, push down the white

button by a screwdriver, and pu the cab e-end out.)

There is no need to use great force for pushing the cab e in,

neither for remova . The button can be pushed down easi y.

P ease do not exercise forces higher than necessary, as it

may cause damages to the termina assemb y.

18 20180614-V020180614-V0

DT9000 N

Finishing step 1. Check if the cab es are connected proper y (have you

connected a the cab es; have you connected them to the

right p ace; is the connection stab e; do not the cab e-ends

touch each other).

2. Pu out the cab e s igh y trough the cab e entry to eave

on y the proper cab e- ength in the instrument inside.

3. Tighten the compession nut of the cab e entry, the sea

ring must comp ete y ancirc e the cab e.

Checking the

connections

After you have comp eted the connections, put the current

oop under vo tage, in such a way that the nomina 4-20 mA

current shou d f ow in the oop. If the connection is correct,

numbers or a characters has to appear on the disp ay.

If nothing appears on the disp ay, most probab y there is no

current f owing in the oop. Check if the current is present by

using an ampermeter. If the current va ue is in the

4-20 mA range, check if everything has been done in

accordance with Chapter 5.1 Connecting into the current

loop.

You may check the vo tage at the pins 5 and 6 of the

termina assemb y, the vo tage shou d be a va ue between

1.5 and 2.2 V, whi e pin 6 is the positive one, if the

connection is correct. In the case of reverse po arity, the

vo tage va ue is ess than 1 V, and 5 is the positive pin.

With this you have comp eted the connection of DT9000 N.

20180614-V0 19

DT9000 N

6. Displa and manual controls

6.1. The first start-up

The displa

The disp ay is indicated by the arrow (1)

After the instrument has been insta ed and connected into

the current oop, first you see on the disp ay the type of

instrument: , , than the current in mA, with a

reso ution of 3 decima s.

In the case of an error

message

If anything e se appears on the disp ay instead of the

numbers showing the current va ue (e.g. a message with

b inking etters), then it is an error message of the

instrument.

In order to define the error more accurate y, p ease go to

Chapter 10.3. Error messages or 10.4. Messages of

critical errors, found at the end of this Manua , in the

Appendix.

20 20180614-V020180614-V0

Table of contents

Other Datcon Measuring Instrument manuals

Datcon

Datcon DT4120 Series User manual

Datcon

Datcon DT9000 User manual

Datcon

Datcon DT4200 User manual

Datcon

Datcon DT4260 Series User manual

Datcon

Datcon DT1102 V User manual

Datcon

Datcon DT7000 User manual

Datcon

Datcon DT920 User manual

Datcon

Datcon DT4240 Series User manual

Datcon

Datcon DT4220 E Series User manual

Datcon

Datcon PQRM5300 33 U I Series User manual