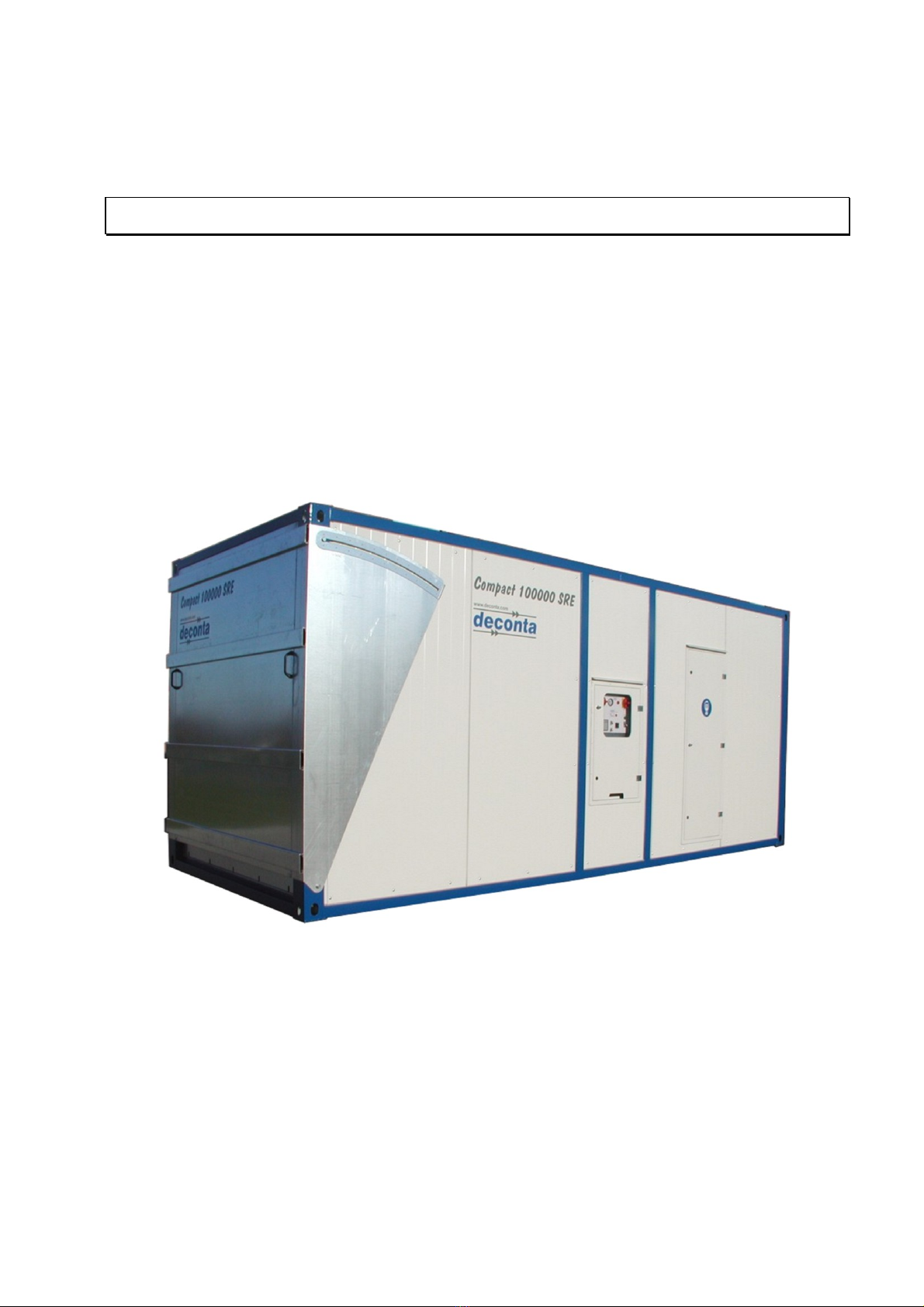

deconta Compact 100.000 User manual

Instruction manual

Negative pressure unit

Compact 100.000

Manufacturer: deconta GmbH

Im Geer 20, 46419 Isselburg

Description / Type No.: NPU Compact 100.000 Type 389

Serial-No.: .................

Instruction manual

Negative Pressure Unit Compact 100.000

Page 2

Introduction

Thank you for choosing a deconta product!

With this device you obtain a practical solution with simple operation, which was

completed in a compact and functional way.

The deconta products guarantee:

Stability, Long life and aptness on site

Mechanics with „kick“

Pleasing design

Command with technical „acuteness“

With products of deconta you are sure to be one-upmanship towards your competitors.

For your protection, the use of the engineered equipment outside of the asbestos

removal should be agreed upon beforehand with deconta. deconta will help you with

pleasure and will take then also the liability by the external original use

In case of damages (mechanical or electric) or in a breakdown, deconta can help you in

a short term with his express service.

We have to point out to you that the non-observance of this guide book causes the

expiration of your warranty claims.

In case of damage (mechanical or electrical) or a malfunction, the deconta-express

service can remedy the situation in a short term.

For more information on our products, please see our website www.deconta.com.

Your company deconta

Instruction manual

Negative Pressure Unit Compact 100.000

Page 3

Table of contents

on page

1 Introduction 4

2 Safety 5

2.1 Basic safety advice 5

3 Transport and storage 6

3.1 Transport 6

3.2 Storage 6

4 Scope of delivery for purchase and rent 6

4.1 Scope of delivery 6

4.2 Return delivery after renting 6

5 Technical description 7

5.1 Intended use 7

5.2 Unit description 7

5.3 Control cabinet 7

5.4 Filter description 8

5.4.1 Prefilter 8

5.4.2 Bag filter 8

5.4.3 Main filter 9

5.5 Change of filter 10

6 Technical data 11

6.1 Air performance 11

6.2 Performance data 12

6.3 Connections, dimensions, weights 12

7 Installation instructions 13

8 Initial operation 14

8.1 SRE control (Motor 1 and 2) 14

9 Maintenance 16

9.1 Maintenance 16

9.2 Filter monitoring 16

9.3 Filter change 17

10 Specifications 18

11 Circuit diagram 19

12 Option 1 silencer 21

12.1 Measurement of sound volume 23

13 Option 2 remote de-energisation 24

14 Declaration of conformity

25

Instruction manual

Negative Pressure Unit Compact 100.000

Page 4

1 Introduction

These manual instructions facilitate it to become acquainted with the Compact 100.000

and to use it in his intended uses.

The instructions contain important information about the device to operate safely,

properly and economically. Your attention helps to avoid dangers, reduce repairs and

downtime, and increase reliability and lifetime of the device.

We have to point out to you that the non-observance of this guide book causes the

expiration of your warranty claims

Technical changes in images and information that are necessary to achieve an

improvement in the NPU compact 100.000 are reserved.

The copyright of this instruction manual remains with deconta. This manual is intended

for assembly, operation and maintenance personnel. It contains instructions and drafts of

technical nature which may neither be distributed nor used in any unauthorised way for

competitive purposes or passed on to others.

Instruction manual

Negative Pressure Unit Compact 100.000

Page 5

2 Safety

2.1 Basic safety advice

The device should be used only in good condition and in accordance with the guide

book. Furthermore, the device technology may only be used as intended and not in an

inappropriate way. The non-observance of the safety instructions in this manual can

cause personal injury or property damage in or on the device. In the event of non-

observance, deconta assumes no liability!

The handling of the device technology is only allowed for trained personnel as

contaminated materials and equipment are to be regarded as dangerous. The exact

knowledge of the operating instructions for your staff is an important prerequisite in using

the device. The guide book must be available at the location of the N.P.U Compact

100.000.

We refer specifically to the legally required safety measures during construction and

dismantling and maintenance of equipment technology. The construction and operation

of the device is to be performed only in the operating manual or in consultation with

deconta

Necessary repairs, maintenance and cleaning, in particular in the field of electrical

equipment should be realized by qualified staff or if necessary by the express service

deconta in order to guarantee and keep the function and the security.

In order not to impair safety, changes to the equipment are not allowed. Changes may be

implemented only after consultation with deconta.

The safety and protective equipments have to be treated with care and the indicated

safety advices have to be kept in a readable state.

The review of the exhaust air at initial acceptance, and in at least three years of distance,

is carried out by the operator.

Supplementary to this guide book, the standard, legal and remaining binding rules

concerning the accident prevention and the protection of the environment have to be

observed

Instruction manual

Negative Pressure Unit Compact 100.000

Page 6

3 Transport and storage

3.1 Transport

To unload a crane is required with a Minimum load of 4.5 tons. The unloading place

should be firm and flat.

Transport damages have to be documented at once during the handing over of the

carrier or another supplier. Please note the possible damages additionally on the way

bill.

3.2 Storage

Storage only in areas inaccessible to unauthorized persons.

Seal the flap on the exhaust side.

Attach the transport lid at the sucking side and, if used filters are installed, tape them

additionally

4 Scope of delivery at purchase and rent

4.1 Scope of delivery

The delivery of the Compact is 100 000, regardless of whether a device is purchased or

rented, unless other arrangements have been made:

N.P.U. Compact 100.000

Transport lid

Complete set of filters

25 m measuring tube

Guide book

4.2 Return delivery after renting

To protect our customers and in terms of dangerous goods transport regulations, we

must insist on following return delivery conditions:

thoroughly cleaned (readyfor use)

without residual fiber bonding

completely as in 4.1 but without filter

without damage

Instruction manual

Negative Pressure Unit Compact 100.000

Page 7

5 Technical description

5.1 Intended use

The negative pressure unit Compact 100.000 serves for the filtration of non-condensing

asbestos contaminated air, in temperature rage up +45 °C, with external exhaust for the

air. During asbestos sanitation works within closed rooms, you must avoid that asbestos

fibres leave the sanitation area and in this way endanger humans and the environment.

For these reasons, the sanitation areas (also called dirty area) have to be separated from

the clean area with the help of a negative pressure unit and kept under dynamic negative

pressure.

An integrated filtering system establishes the conditions that the asbestos concentration

in the exhausted air does not exceed max. 1000F/m³. The exhausted air is blown in the

open air.

The device is not appropriate for the filtration of flammable gas or dust.

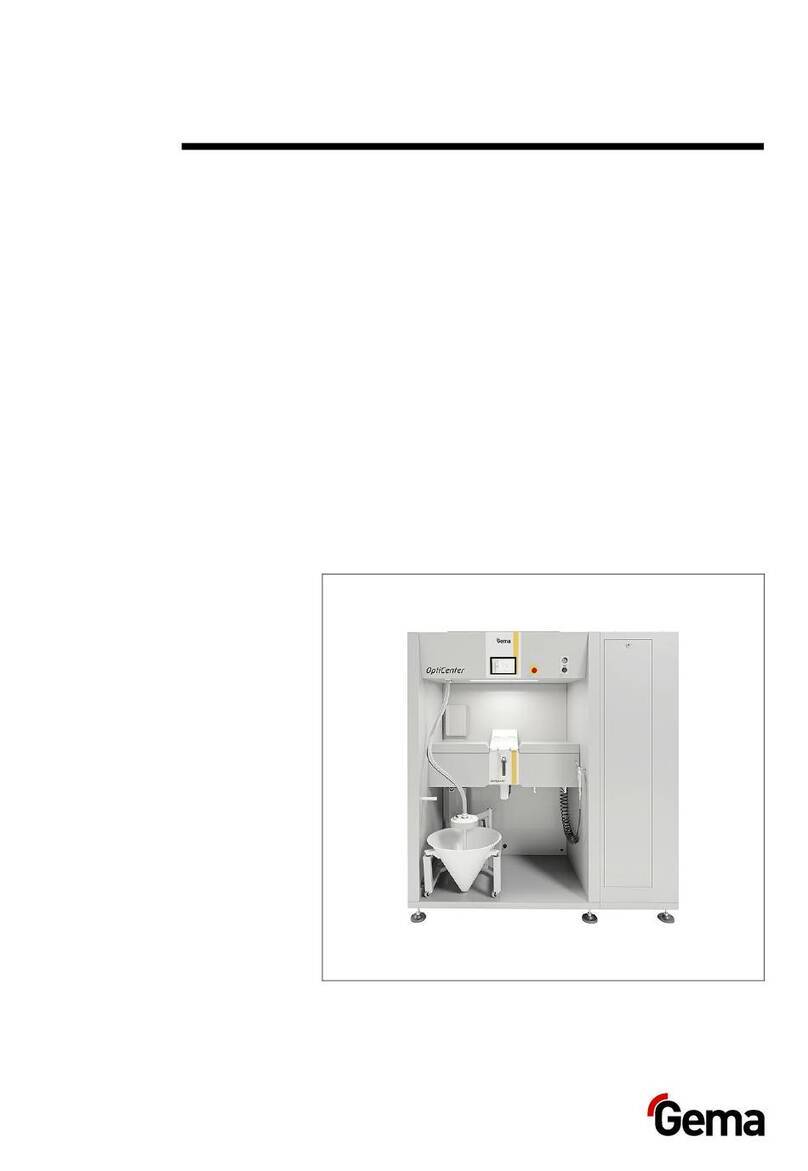

5.2 Unit description

NPU as container plant

2 independently controlled continuously variable motors, with an effective total air

capacity of 100,000 m³ / h (SRE-control)

Three filter stages consisting of HEPA filter, bag filter and prefilter

Filter change on the side service door

Automatic or manual under pressure control

Automatic soft start

External dimension 6110 x 2495 x 2655 mm (L x W x H)

5.3 Control cabinet

Main switch Motor 2

Manometer

Filter monitoring

Control SRE

O

p

eratin

g

hour counte

r

Measurin

g

p

ointSRE

Filter monitorin

g

Main switch Motor 1

Remote de-energisation

(Option)

Instruction manual

Negative Pressure Unit Compact 100.000

Page 8

5.4 Filter description / Classification

A 3-stage filter combination is integrated in the device

5.4.1 Prefilter:

Filter class pursuant DIN 24185 / EN

779 G3 / EU3

Frame Cardboard Frame, 47 mm width

Filter medium Glass fiber

Degree of separation(Am) 85 %

Nominal rated current 5400 m³/h/m²

Nominal velocity in blower stream by

nominal volume 1,5 m/s

Difference of initial pressure 30 Pa

Recommended difference of final

pressure 450 Pa

Temperature / humidity 100 °C / 100 % RF (relative humidity)

Filter dimensions 610 x 610 x 47 mm

5.4.2 Bag filter:

Filter class pursuant DIN EN 779 F5

Degree of separation (Am) 96 %

Nominal rated current 3400 m³/h

Difference od initial pressure 48 Pa

Recommended difference of final

pressure 250 Pa

Temperature / himidity 55 °C / 100 % RF (relative humidity)

Filter surface 5,1 m²

Filter dimensions 592 x 592 x 600 mm

Instruction manual

Negative Pressure Unit Compact 100.000

Page 9

5.4.3 Main filter:

Frame 12-ply glued wooden frame

or plastic frame

(humidity proof)

Separator Aluminium

Filter medium Glass fiber

Sealing mass Polyurethane (2-components glue)

Seal Polyurethane, foamed

Filter surface 31 m²

Filter class „S“ according to DIN 24184, H13 according to

DIN EN 1822

Degree of separation > 99,95 % Most Penetrated Particle Size

Temperature / humidity 110 °C / 100 % RF (relative humidity)

Filter dimensions 610 x 610 x 292 mm

Protective grid Grip wire painted in white, on both sides

Instruction manual

Negative Pressure Unit Compact 100.000

Page 10

5.5 Information about the filter change

The frequency of the change of filter depends on the degree of pollution of the filter. If the

clogging of the filter increases (contamination of the filter), the air capacity decreases.

For the control of the filter during the operation, the device is equipped with a manometer

and a signal light.

Important: Use only authorised, faultless filter!

With filter of new condition, approximately 950 Pascal are displayed on the gauge.

(Evaluated at 100 % capacity)

We recommend a filter change at about 1400 Pascal (indicator light filter monitoring is

on)

To determine which filter (main filter, bag filter or pre-filter) is dirty, at a value on the

pressure gauge of about 1400 Pascal, do as follows:

1. Exchange the pre and bag filter and switch on the unit

2. Pressure gauge value 950 - 1150 Pascal => continue to operate the unit

3. Pressure gauge value > 1150 Pascal => exchange the main filter

Instruction manual

Negative Pressure Unit Compact 100.000

Page 11

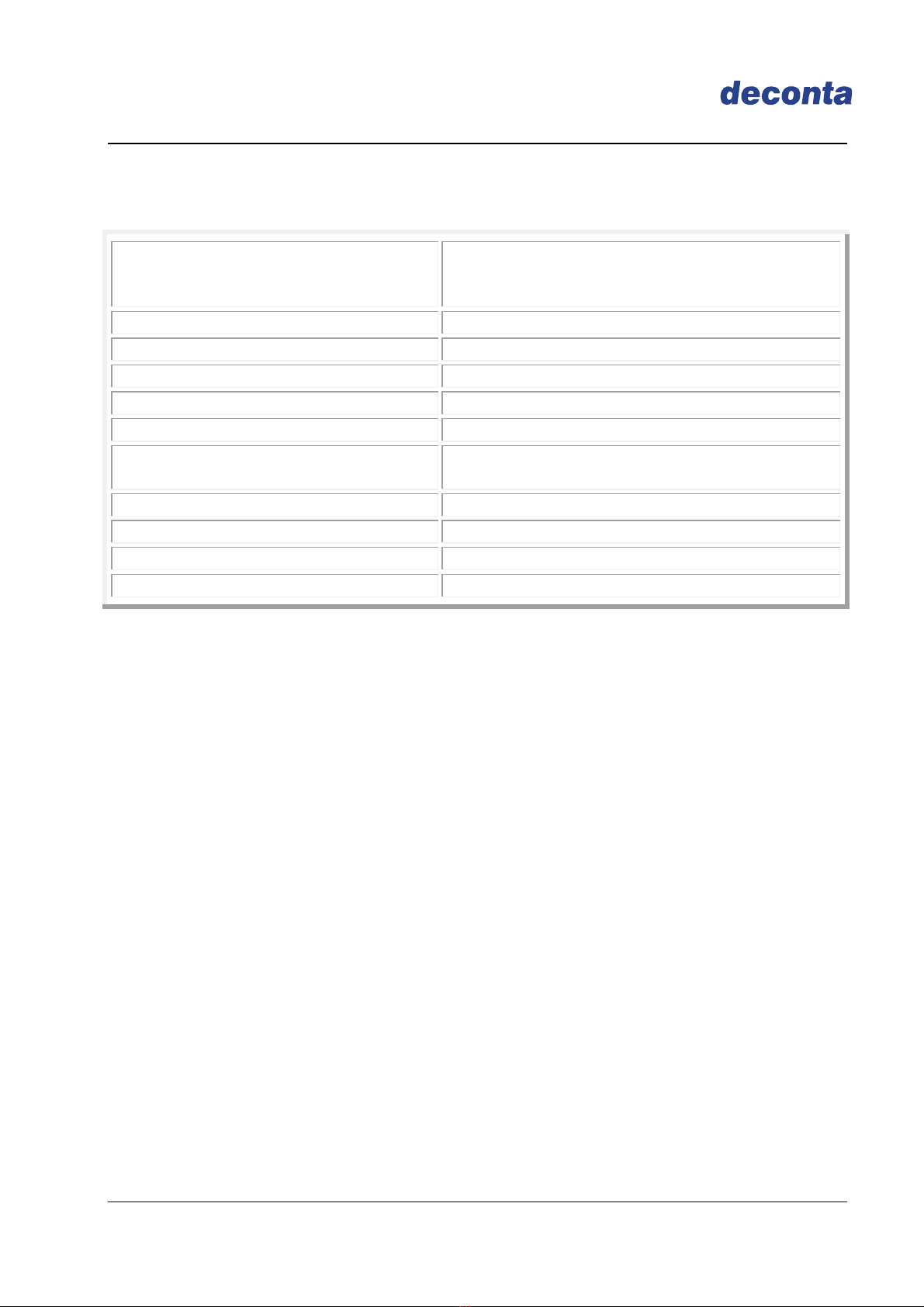

6 Technical data

All data on air performance and volume flows are taking into account a measuring

tolerance of ± 15% based on the measuring range end value, determined in a multi-point

measuring method with a calibrated vane anemometer.

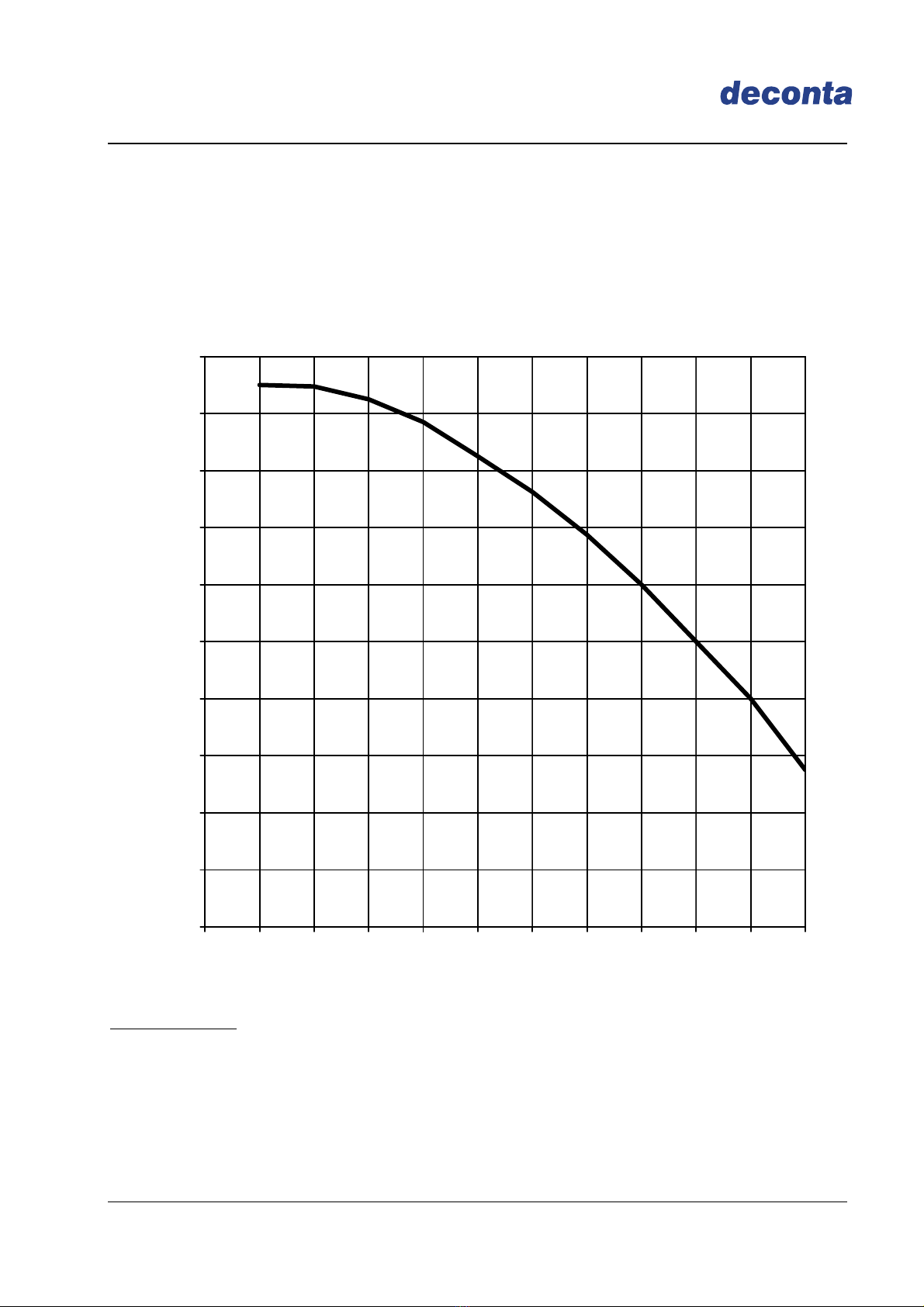

6.1 Blower performance curve

0

200

400

600

800

1000

1200

1400

1600

1800

2000

5000 10000 15000 20000 25000 30000 35000 40000 45000 50000 55000 60000

Volumen flow in m³/h

Pressure difference in Pa

Technical data:

Voltage: 400 V

Frequency: 50 Hz

Speed: 1465 U/min

Max. air temperature: 45°C

Instruction manual

Negative Pressure Unit Compact 100.000

Page 12

6.2 Power data

Air power with filters 100000 m³/h

Power connection 2 x 400 Volt, 50 Hz

Current consumption 2 x 42 Ampere

Thanks to the use of frequency converters, the power peaks are avoided (Soft

start, max. 42 A).

Motor-power 2 x 22 KW

Filter system 3-steps

Pre-filter EU3 dimensions: 610 x 610 x 47

Bag filter F5 dimensions: 592 x 592 x 600

Main filter dimensions: 610 x 610 x 292

6.3 Connections, dimensions, weights

Power supply 2 x 400 Volt, 63 Ampere

CEE-connector plug 5-pins

Length x Width x Height 6110 x 2495 x 2655 mm

Total weight approx. 4200 kg

Instruction manual

Negative Pressure Unit Compact 100.000

Page 13

7 Installation instructions

This NPU is delivered ex factory in a ready-to-use condition and is intended for

immediate operation. Do not operate the unit if it is visibly damaged. In that case, please

inform deconta GmbH immediately.

Connect the container to the sanitation area

Seal the container with the sanitation area

Ensure that sufficient fresh air arrives in the sanitation area

Connect earth to ground connector (see picture on page 7)

Remove transport lid

Open fully the exhaust air damper

Sanitation

area

Exhaust air dam

p

e

r

Instruction manual

Negative Pressure Unit Compact 100.000

Page 14

8 Operation

IMPORTANT: During the operation, always close the maintenance side doors!

SRE control

The NPU Compact 100,000 is supplied as standard with two engines: two engines

with electronic control for a control range of each 0-50.000 m³ / h

The SRE control developed for the NPU has the principal task to measure out and settle,

from the machine, the required vacuum in the removal of asbestos.

If the LED light Fanis on, the maximum fan capacity is reached.

Panel:

LED

„

Fan“

Display 1 Display 2

Ke

y

„

ON / OFF“

Taste

„

+“

Ke

y

„

AUTO / MANU“

Ke

y

„

-“

Instruction manual

Negative Pressure Unit Compact 100.000

Page 15

Starting position:

Connect to power

Choose a measuring point in the dirty area and connect the PE-tube 8 x 1 to the

negative pressure connection

Choose the measuring point in the clean area (adjoining room) and connect the PE-

tube 8 x 1 to the connection atmosphere

The unit is now ready-to-operate.

Power switch to „ON“

Press key ON/OFFIMPORTANT: Press and hold the key for about 3 seconds

The last saved mode (AUTO / MANU)is automatically set and the fan starts

Automatic – operating

Select the mode AUTO with the key AUTO / MANU, LED AUTO lights.

In automatic - operating the set point is selected with the keys - + in steps of one

Pascal (Nominal value in the display 2).

With the speed control of the fan, the negative pressure is now automatically regulated.

On the display 1 the actual negative pressure is displayed.

Connection

Atmos

p

here Connection

N

e

g

ative

p

ressure

Instruction manual

Negative Pressure Unit Compact 100.000

Page 16

Manual - operation

Select the mode MANU with the key AUTO / MANU, LED MANU lights

In manual operation the power of the ventilator is given with the keys -and +in steps

of one percent. The display 2 represents this value in %

In the display 1 you can see which negative pressure is created with the adjusted power.

Important:

In „Manual“ operation, the device does not regulate!

Switch off

Press key ON/OFFIMPORTANT: Press and hold the key for about 3 seconds.

The device down-regulates itself automatically. After about 40 seconds switch the main

switch off.

9 Maintenance

9.1 Maintenance

The ventilator plants (deduster, industrial vaccum cleaners and devices for the

deaeration or keaping in negative pressure) have to be overhauled or controlled once a

year at least or if necessary by an expert. The Test result must be produced on request.

9.2 Filter control

During the operation the filter state has to be controlled as described under 5.5

Instruction manual

Negative Pressure Unit Compact 100.000

Page 17

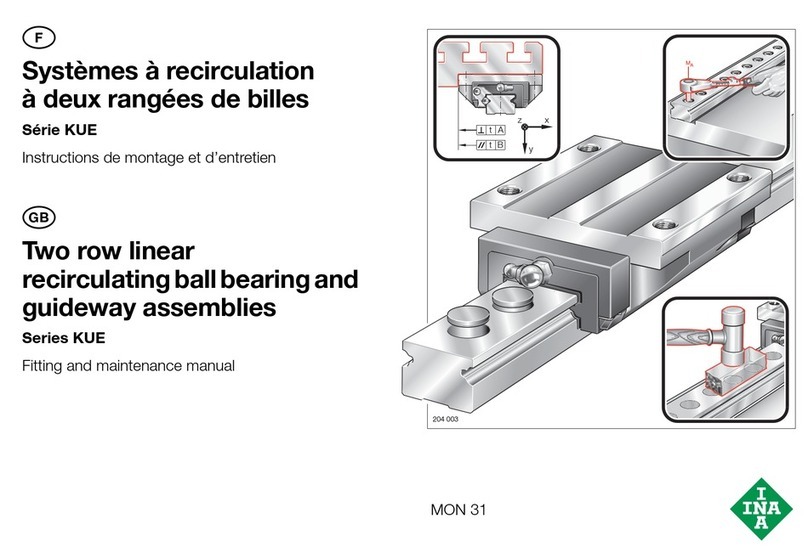

9.3 Change of filter

Attention:

Contaminated filters have to be changed under all corresponding safety

measures

Filter change only when maschine is switched off

Use only authorised filters

Do not use bonding agents on the machine

Prefilter change:

Remove the locking plates

Gently remove and discard the filter

Insert the new filter

Replace the locking plates

Bag filter change:

The change of the bag filter takes place within the

container

Connect the lock to the service door and enter

in the container through this door.

Open the pressure spring

Remove the bag filter

Insert the new filter

the bags should be perpendicular

Lock pressure spring again

Change of the HEPA filter:

The change of the HEPA filter takes place within the

container .

Connect the lock to the service door and enter

in the container through this door.

Unscrew the nut M10 and remove the

tension bar.

Remove the HEPA filter and discard it

Check and clean the sealing surfaces on the unit

Insert the new HEPA filter

Reattach the tension bar

Pressure s

p

rin

g

N

ut M10

Tension ba

r

Instruction manual

Negative Pressure Unit Compact 100.000

Page 18

10 Tender text

Negative pressure unit as a container plant with an effective capacity of 100,000 m³ / h,

HEPA air filter with protection grid and test certificate pursuant DIN 24184, Class S, two

pre-filter steps, consisting of pre-filter and bag filter, filter monitoring, automatic negative

pressure system and starting current limitation by "soft start“.

Instruction manual

Negative Pressure Unit Compact 100.000

Page 19

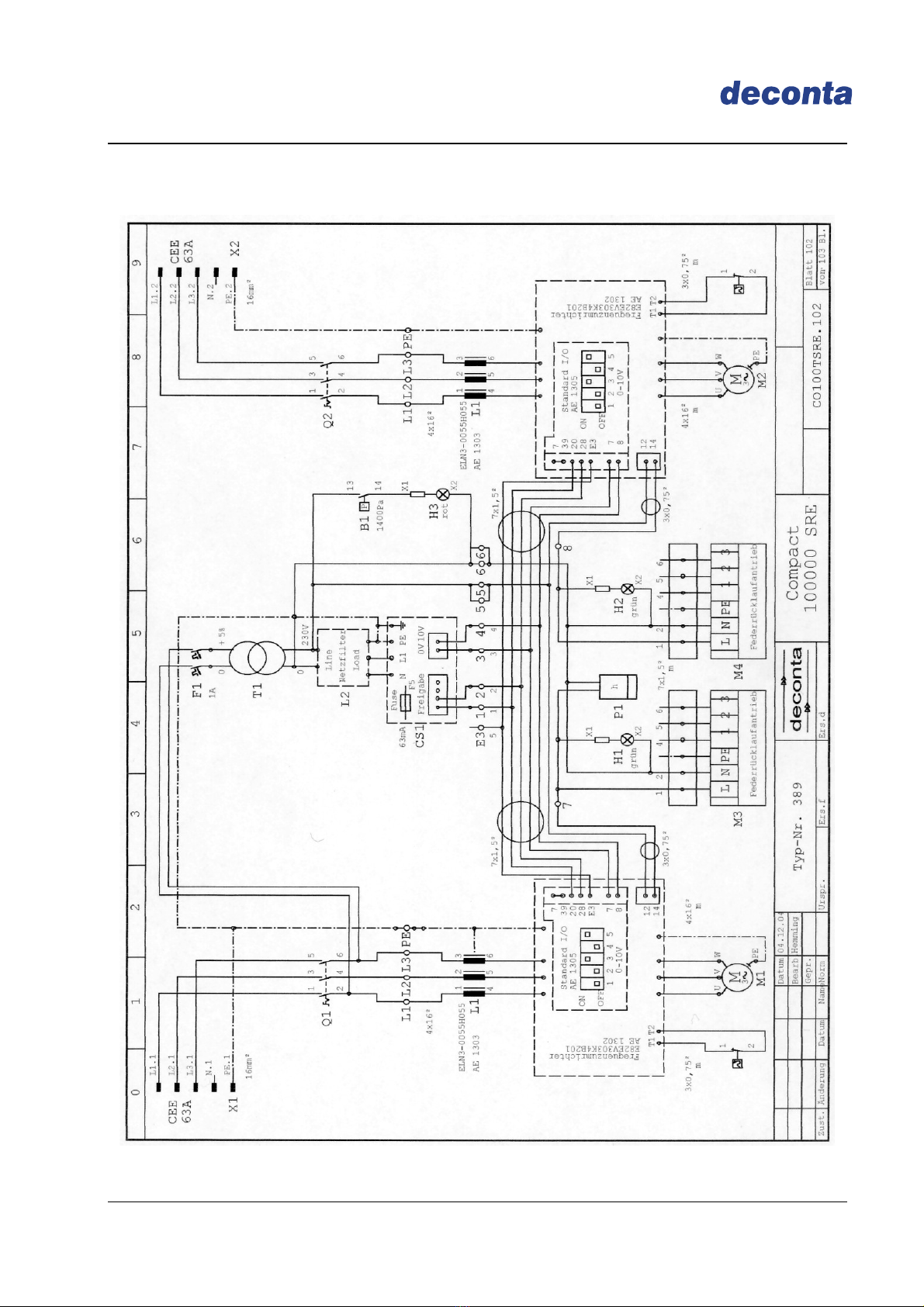

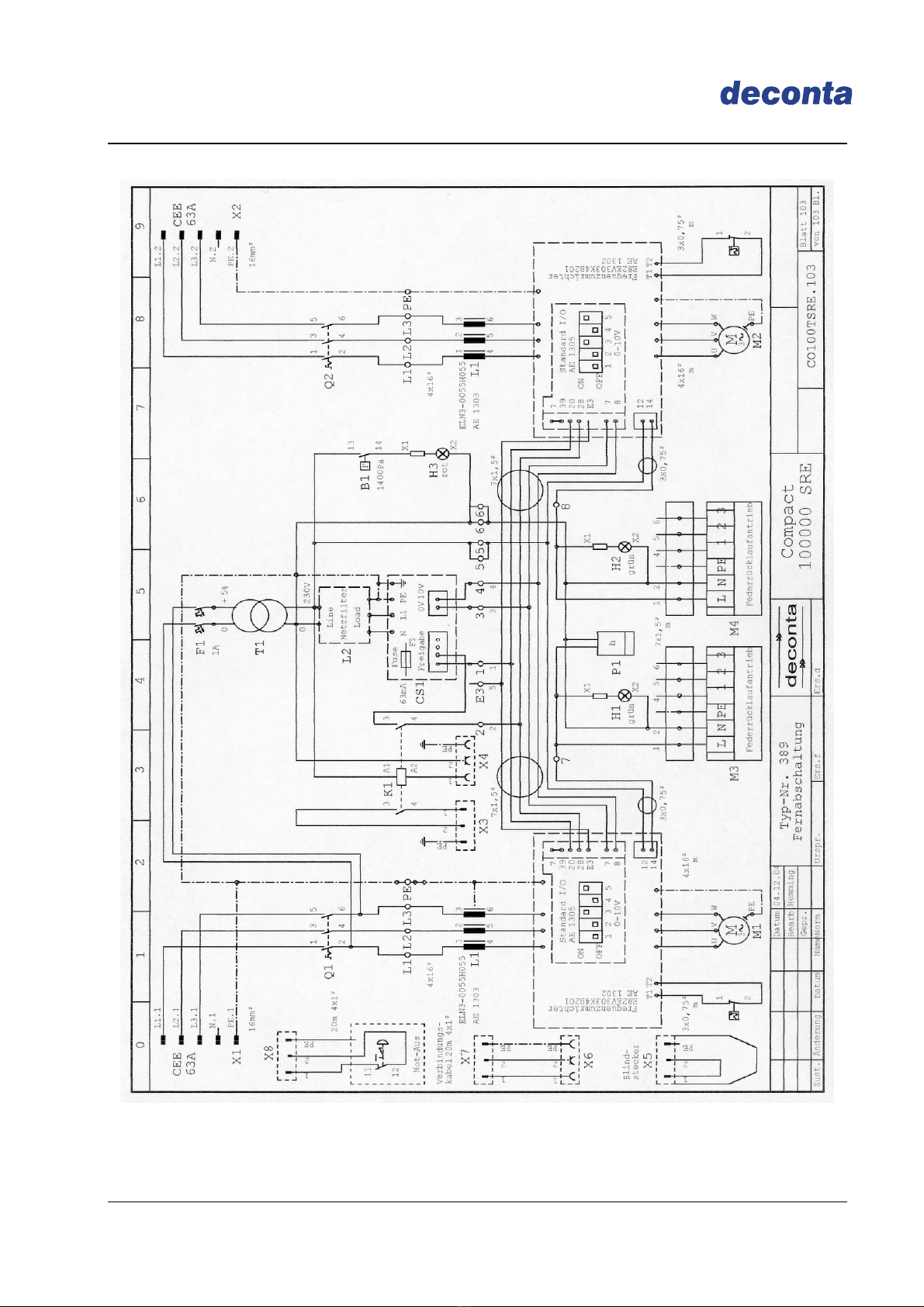

11 Circuit diagram

Instruction manual

Negative Pressure Unit Compact 100.000

Page 20

Table of contents

Other deconta Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Deltatherm

Deltatherm LT 5 Series Assembly instructions

Versa-Matic

Versa-Matic VDA Service & operating manual

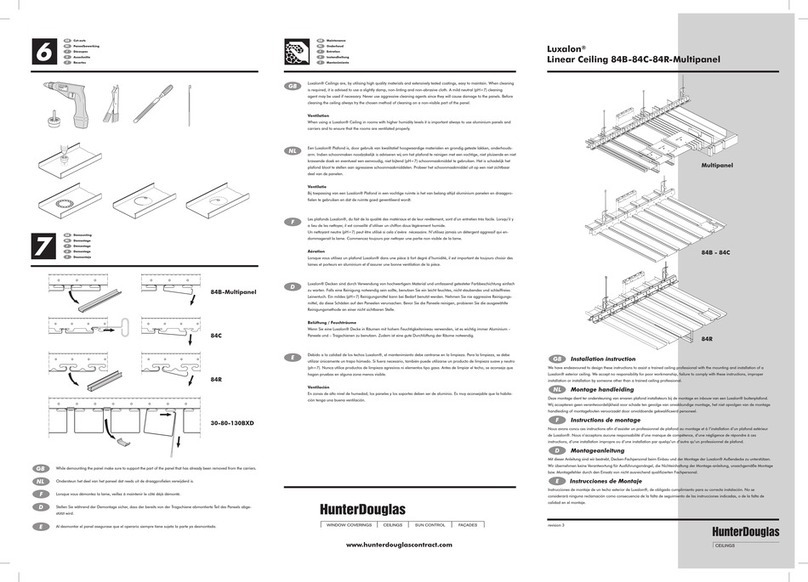

HunterDouglas

HunterDouglas Luxalon 84B installation instructions

Cold Jet

Cold Jet i3 MICROCLEAN 2 manual

Con-form

Con-form EasyMechMR Assembly & instruction manual

Power-Tronics

Power-Tronics PT-3000 user manual