DeFelsko PosiTest AT-A User manual

Other manuals for PosiTest AT-A

2

Table of contents

Languages:

Other DeFelsko Test Equipment manuals

DeFelsko

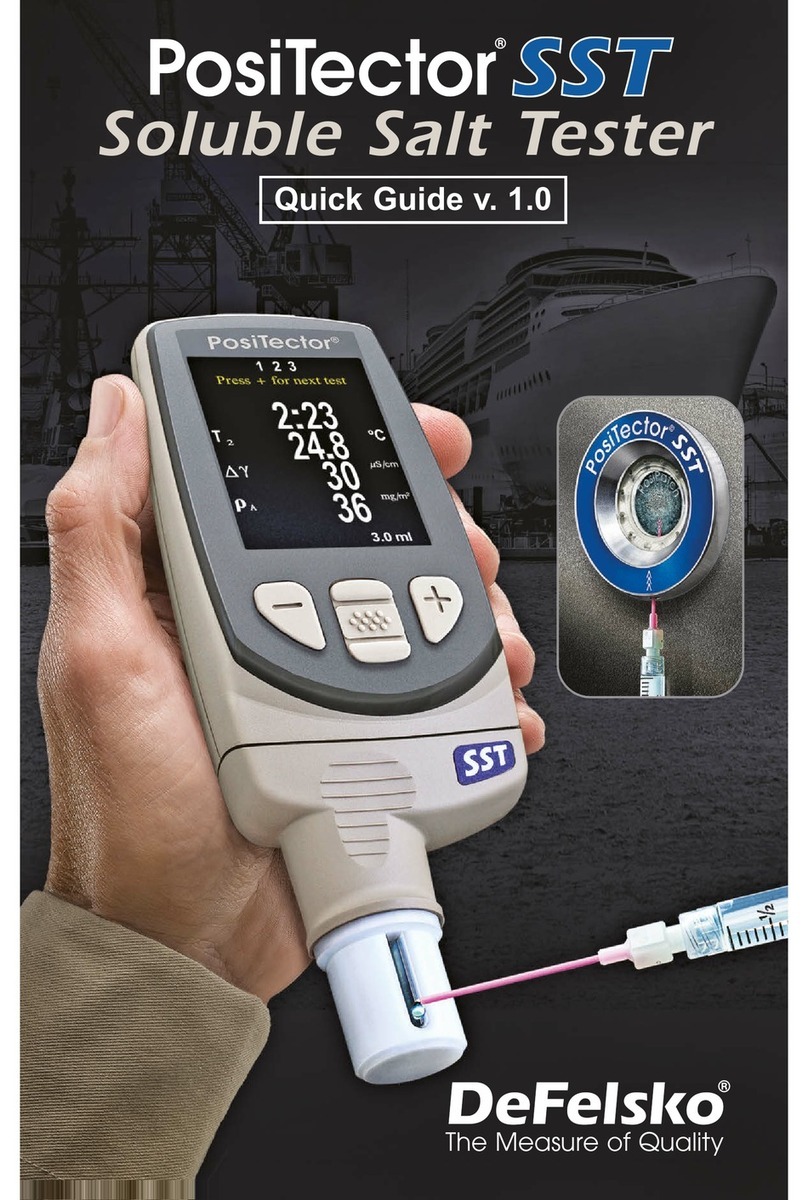

DeFelsko PosiTector SST User manual

DeFelsko

DeFelsko PosiTest AT User manual

DeFelsko

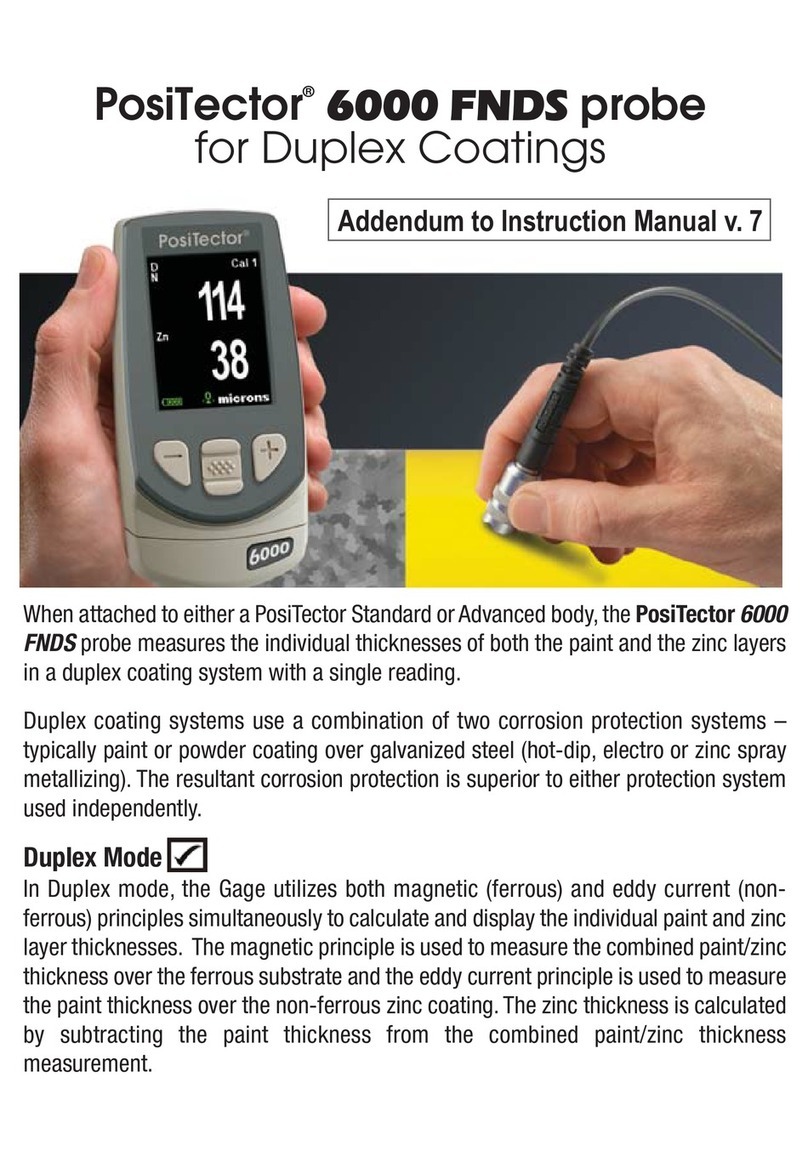

DeFelsko PosiTector 6000 FNDS Installation and operating instructions

DeFelsko

DeFelsko PosiTector SST User manual

DeFelsko

DeFelsko PosiTest AT-A User manual

DeFelsko

DeFelsko PosiTest DT User manual

DeFelsko

DeFelsko PosiTest AIR User manual

DeFelsko

DeFelsko PosiTest AIR User manual

DeFelsko

DeFelsko PosiTector SHD Verifier User manual

DeFelsko

DeFelsko PosiTector 200 User manual

Popular Test Equipment manuals by other brands

Audio Precision

Audio Precision AECM206 USER GUIDE AND SPECIFICATIONS

MEIRUIKE

MEIRUIKE RK267M Series manual

Huazheng

Huazheng HZJD-2Z Operating instruction

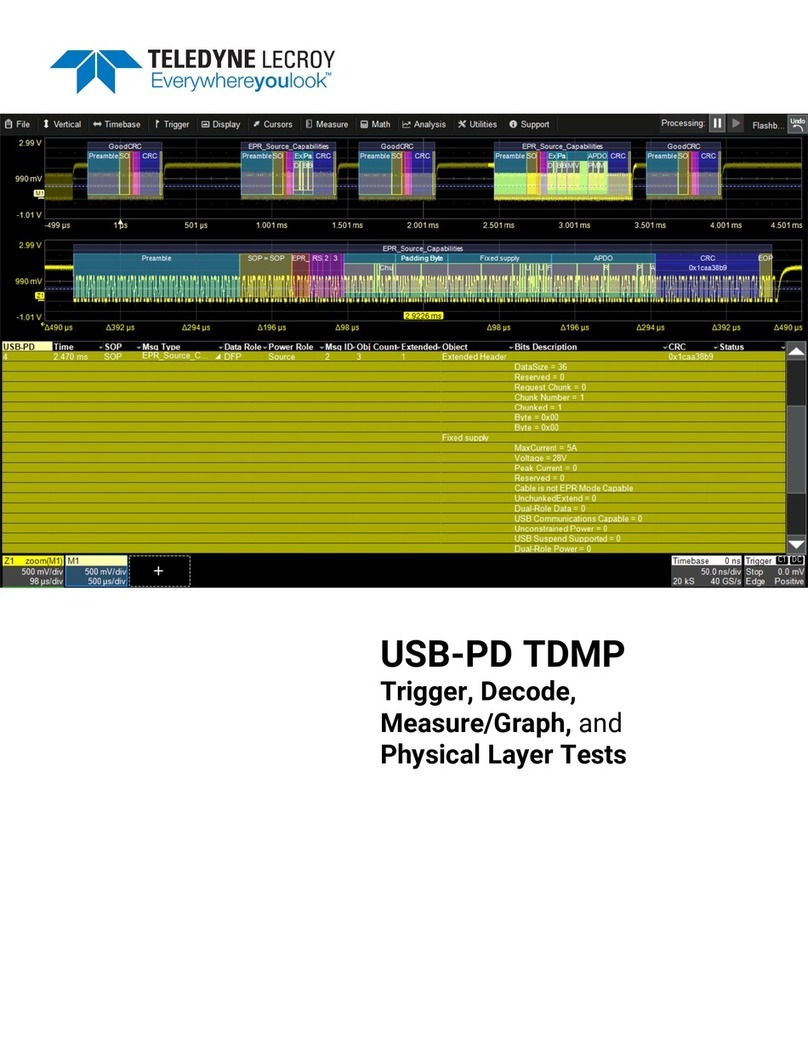

Teledyne

Teledyne USB-PD TDMP instruction manual

DAKOTA ULTRASONICS

DAKOTA ULTRASONICS PR-8V Operation manual

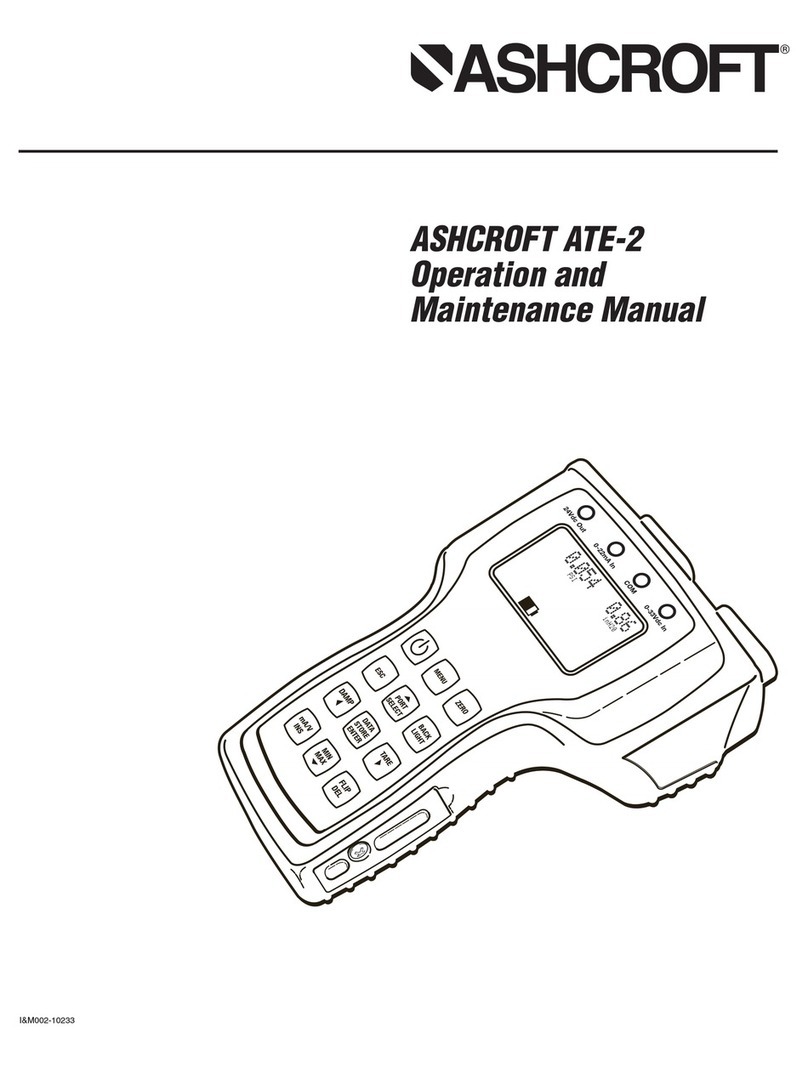

Ashcroft

Ashcroft ATE-2 Operation and maintenance manual