BA022301-en

Pos: 3 / -----F or m at---- -/In ha ltsv er z eic hn is - 3 Eb e ne n @ 5\m od_ 11 6 8867 4 410 46_ 7 5.d ocx @ 72920 @ @ 1

Contents

1Safety ......................................................................................................................5

1.1 Introduction......................................................................................................................................... 5

1.2 Symbols .............................................................................................................................................. 5

1.3 Intended Use....................................................................................................................................... 5

1.4 Inappropriate Use................................................................................................................................ 5

1.5 Requirements on Operating and Service Personnel............................................................................. 5

1.6 Safety Instructions for Installation and Initial Operation ........................................................................ 6

1.7 Safety Instructions for Operation ......................................................................................................... 6

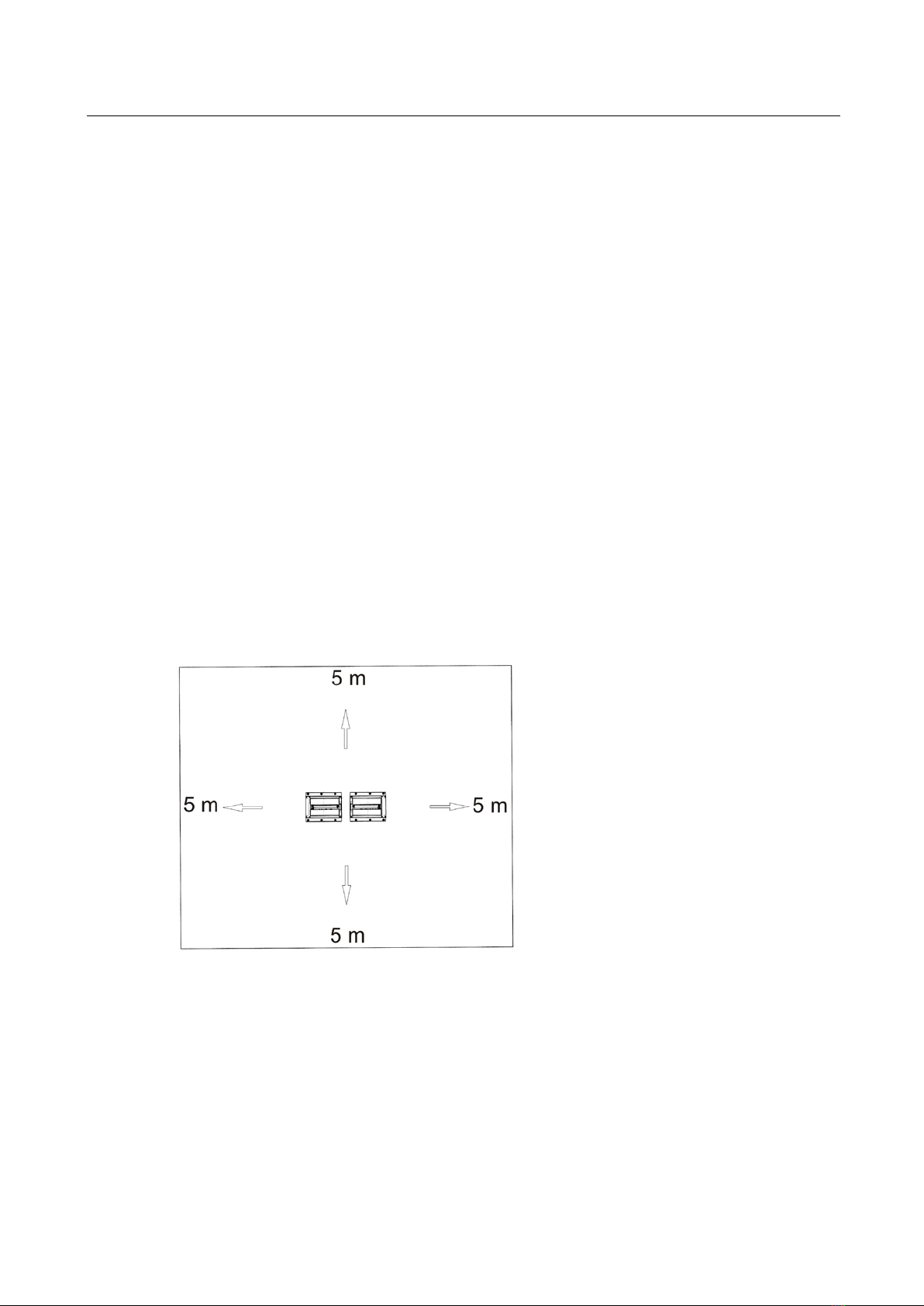

1.8 Danger Zone ....................................................................................................................................... 7

1.9 Safety Instructions for Servicing........................................................................................................... 7

1.10 Safety Features ................................................................................................................................... 8

1.11 Accessories......................................................................................................................................... 9

1.12 What to Do in the Event of an Accident............................................................................................... 9

2Description.............................................................................................................10

2.1 General Information ........................................................................................................................... 10

2.2 Noise Emission.................................................................................................................................. 10

2.3 Specifications .................................................................................................................................... 11

3Transport and Storage ...........................................................................................18

4Installation and Initial Operation ..............................................................................18

5Operation...............................................................................................................18

5.1 Main Switch....................................................................................................................................... 18

5.2 Analog Displays................................................................................................................................. 19

5.3 Remote Control................................................................................................................................. 24

5.4 Menu Structure ................................................................................................................................. 27

5.5 Car Brake Tester with MAH-DOT and IFB ......................................................................................... 30

5.6 Car Brake Tester with MAH-DOT and RECO 1.................................................................................. 31

5.7 Truck Brake Tester with MAH-DOT and FFB..................................................................................... 33

5.8 Truck Brake Tester with MAH-DOT and RECO 1 .............................................................................. 35

5.9 Option Drive Control.......................................................................................................................... 36

5.10 Noise Detection with IFB / FFB / RECO 1.......................................................................................... 38

5.11 MSD 3000......................................................................................................................................... 40

5.12 Clock Changing between Daylight Saving Time/Standard Time......................................................... 42

5.13 Test Procedure with Software ........................................................................................................... 43

6Maintenance ..........................................................................................................46

6.1 Annual Inspection.............................................................................................................................. 46

6.2 Care Instructions ............................................................................................................................... 46

6.3 Spare Parts ....................................................................................................................................... 46

6.4 Chain Drive Maintenance: Cleaning, Retensioning, Lubricating.......................................................... 47

6.5 Greasing the Sensor Roller Hinges .................................................................................................... 51