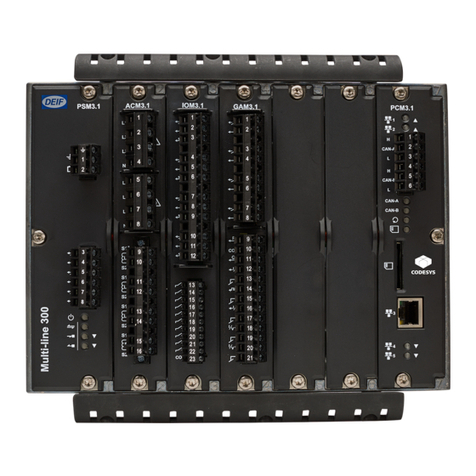

GPC, PPU Option O1, Water turbine control

DEIF A/S Page 2 of 19

Table of contents

1. WARNINGS AND LEGAL INFORMATION........................................................................3

ELECTROSTATIC DISCHARGE AWARENESS.....................................................................................3

SAFETY ISSUES............................................................................................................................3

DEFINITIONS ................................................................................................................................3

2. DESCRIPTION OF OPTION ..............................................................................................4

OPTION O1..................................................................................................................................4

TERMINAL DESCRIPTION ...............................................................................................................4

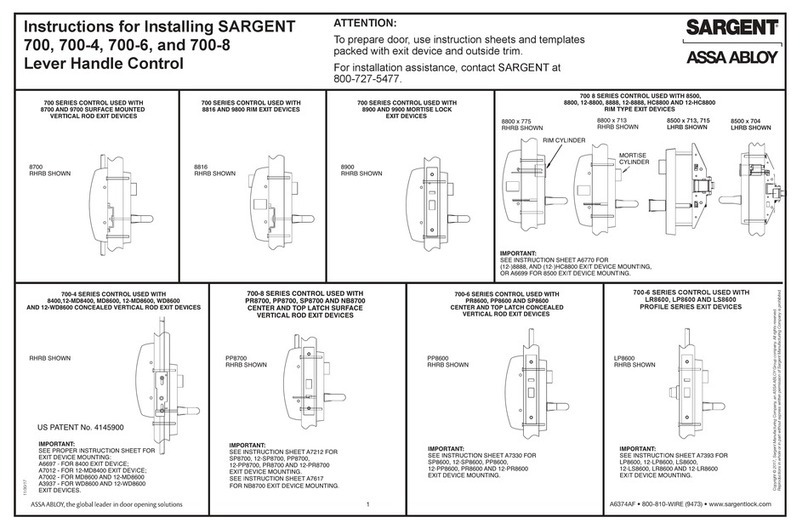

WIRING........................................................................................................................................6

3. FUNCTIONAL DESCRIPTION...........................................................................................8

TURBINE OPERATION....................................................................................................................8

WATER LEVEL REGULATION ..........................................................................................................8

REGULATION PRINCIPLE..............................................................................................................10

JET DEFLECTOR .........................................................................................................................12

TURBINE REGULATION ................................................................................................................14

SEQUENCES...............................................................................................................................15

DIGITAL INPUT............................................................................................................................16

INHIBIT.......................................................................................................................................17

4. PARAMETER LIST ..........................................................................................................19

This manual is valid for standard multi-line 2 PPU/GPC units with firmware version 2.32.0 or later.