1. Introduction

1.1. About the Installation and commissioning instructions...........................................................................3

1.1.1. General purpose ...........................................................................................................................3

1.1.2. Intended users ..............................................................................................................................3

1.1.3. Revision information .....................................................................................................................3

1.1.4. Software version ...........................................................................................................................3

1.1.5. Getting technical support...............................................................................................................3

1.1.6. Other technical documentation......................................................................................................3

1.2. Warnings, safety and legal information..................................................................................................4

1.2.1. Warnings and notes.......................................................................................................................4

1.2.2. Safety issues ................................................................................................................................4

1.2.3. Factory settings ............................................................................................................................5

1.2.4. Electrostatic discharge awareness ...............................................................................................5

1.2.5. Legal information ..........................................................................................................................5

2. Installation

2.1. Tools.......................................................................................................................................................6

2.1.1. Tools required................................................................................................................................6

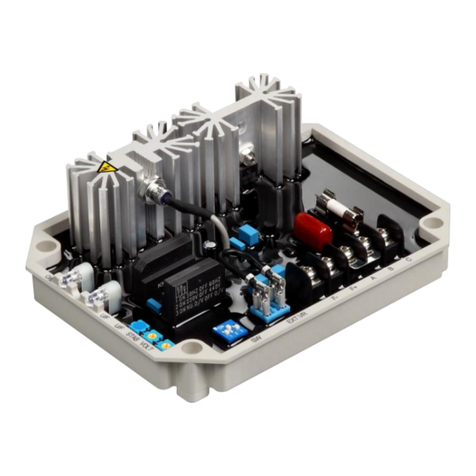

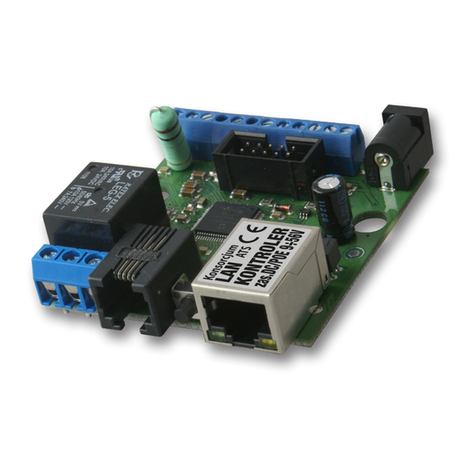

2.2. Wiring and terminals...............................................................................................................................6

2.2.1. Connection of 1-phase voltage .....................................................................................................6

2.2.2. Wiring diagram...............................................................................................................................7

2.2.3. Digital inputs .................................................................................................................................7

2.2.4. List of terminal connections ..........................................................................................................8

2.2.5. Connecting the terminals...............................................................................................................9

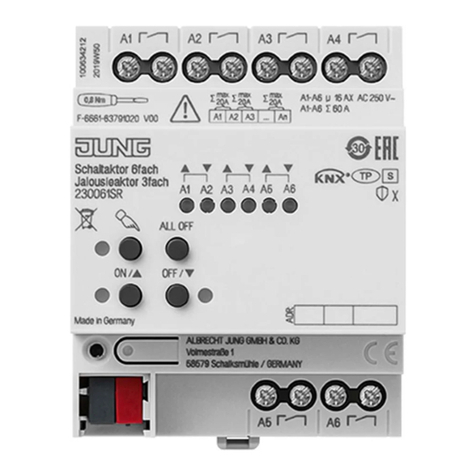

3. Mounting

3.1. CGC 200 mounting...............................................................................................................................10

3.1.1. Mounting of the unit.....................................................................................................................10

3.1.2. Unit dimensions and panel cutout................................................................................................10

3.1.3. Tightening torques.......................................................................................................................10

4. Commissioning

4.1. Overview and parameter list.................................................................................................................11

4.1.1. Sequence.....................................................................................................................................11

4.1.2. People and preparation...............................................................................................................11

4.1.3. Parameter list...............................................................................................................................12

4.2. Wiring...................................................................................................................................................16

4.2.1. Checking the wiring.....................................................................................................................16

4.3. Commissioning using the Utility Software............................................................................................16

4.3.1. Installing the Utility Software .......................................................................................................16

4.3.2. Starting the Utility Software ........................................................................................................19

4.3.3. Utility Software pages and icons..................................................................................................22

4.3.4. Parameters page.........................................................................................................................23

4.3.5. Configuring inputs and outputs....................................................................................................26

4.3.6. Changing parameters..................................................................................................................26

4.3.7. Writing to the controller................................................................................................................27

4.3.8. Other Utility Software pages .......................................................................................................28

4.4. Commissioning using the front panel...................................................................................................28

4.4.1. Changing parameters using the front panel.................................................................................28

5. Glossary

5.1. Abbreviations and terms.......................................................................................................................30

5.1.1. Abbreviations...............................................................................................................................30

5.1.2. Terms...........................................................................................................................................31

5.1.3. Units.............................................................................................................................................32

CGC 200 installation and commissioning

instructions 4189340806 UK

DEIF A/S Page 2 of 32