Deif AGC-4 User manual

OPERATOR'S MANUAL

AGC-4

DEIF A/S · Frisenborgvej 33 · DK-7800 Skive

Tel.: +45 9614 9614 · Fax: +45 9614 9615

[email protected] · www.deif.com

Document no.: 4189340690E

SW version: 4.79.x or later

1. General information

1.1 About the Operator's manual.............................................................................................................................................................................................. 3

1.2 Warnings, safety and legal information.........................................................................................................................................................................3

1.2.1 Warnings and notes.......................................................................................................................................................................................................... 3

1.2.2 Factory settings...................................................................................................................................................................................................................3

1.2.3 Legal information and disclaimer.................................................................................................................................................................................3

2. DU-2 buttons and LEDs

2.1 Display layouts for AGC-4.....................................................................................................................................................................................................5

2.2 Button functions.........................................................................................................................................................................................................................8

2.3 Modes.............................................................................................................................................................................................................................................10

2.4 LED functions............................................................................................................................................................................................................................ 11

2.4.1 LED colour schemes...................................................................................................................................................................................................... 12

3. LCD display and menus

3.1 LCD display................................................................................................................................................................................................................................ 13

3.2 Menus.............................................................................................................................................................................................................................................13

3.2.1 Entry window..................................................................................................................................................................................................................... 13

3.3 Password management....................................................................................................................................................................................................... 14

3.3.1 Parameter access........................................................................................................................................................................................................... 15

3.4 Setup.............................................................................................................................................................................................................................................. 15

3.5 Views.............................................................................................................................................................................................................................................. 16

3.5.1 Configurable views V1 and V2...................................................................................................................................................................................17

3.5.2 Dynamic view V3............................................................................................................................................................................................................. 17

3.5.3 View menu example....................................................................................................................................................................................................... 17

3.6 Status texts.................................................................................................................................................................................................................................18

3.7 Alarm handling......................................................................................................................................................................................................................... 22

3.8 Log list...........................................................................................................................................................................................................................................23

4. Maintenance and disposal

4.1 Maintenance............................................................................................................................................................................................................................... 24

4.2 Disposal of waste electrical and electronic equipment..................................................................................................................................... 24

OPERATOR'S MANUAL 4189340690E EN Page 2 of 24

1. General information

1.1 About the Operator's manual

This AGC-4 Operator's Manual describes the DU-2 display unit buttons and LEDs, LCD display, alarm handling and the log list.

A TDU 107 can be used instead of a DU-2. This touch screen display unit has its own operator's manual.

CAUTION

Read this document before starting to work with the controller. Failure to do this could result in human injury or damage to

the equipment.

1.2 Warnings, safety and legal information

1.2.1 Warnings and notes

Throughout this document, a number of warnings and notes with helpful user information will be presented. To ensure that these are

noticed, they will be highlighted as follows in order to separate them from the general text.

Warnings

DANGER!

This highlights dangerous situations. If the guidelines are not followed, these situations could result in death, serious

personal injury, and equipment damage or destruction.

CAUTION

This highlights potentially dangerous situations. If the guidelines are not followed, these situations could result in personal

injury or damaged equipment.

Notes

INFO

Notes provide general information, which will be helpful for the reader to bear in mind.

1.2.2 Factory settings

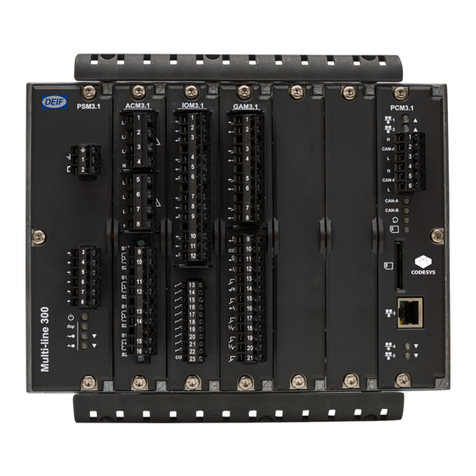

The Multi-line 2 unit is delivered from factory with certain factory settings. These are based on average values and are not

necessarily the correct settings for matching the engine/generator set in question. Precautions must be taken to check the settings

before running the engine/generator set.

1.2.3 Legal information and disclaimer

DEIF takes no responsibility for installation or operation of the generator set or switchgear. If there is any doubt about how to install

or operate the engine/generator or switchgear controlled by the Multi-line 2 unit, the company responsible for the installation or the

operation of the equipment must be contacted.

INFO

The Multi-line 2 unit is not to be opened by unauthorised personnel. If opened anyway, the warranty will be lost.

Disclaimer

DEIF A/S reserves the right to change any of the contents of this document without prior notice.

OPERATOR'S MANUAL 4189340690E EN Page 3 of 24

The English version of this document always contains the most recent and up-to-date information about the product. DEIF does not

take responsibility for the accuracy of translations, and translations might not be updated at the same time as the English document.

If there is a discrepancy, the English version prevails.

OPERATOR'S MANUAL 4189340690E EN Page 4 of 24

2. DU-2 buttons and LEDs

2.1 Display layouts for AGC-4

INFO

The display dimensions are H × W = 115 × 220 mm (4.528” × 8.661”).

Engine and generator breaker control (island) (option Y1)

Automatic Gen-set Controller

multi-line AGC

VIEW

LOG

Auto

Alarm Inh.

Self check ok

Power

SEL

BACK

MODE

JUMP

START

INFO

STOP

Alarm

Alarm

OnRun

G

Load

Generator breaker and mains breaker control (option Y3)

Automatic Gen-set Controller

VIEW

LOG

Auto

Alarm Inh.

Self check ok

Power

SEL

BACK

MODE

JUMP

START

INFO

STOP

Alarm

Alarm

multi-line AGC

On On

Load

Run

G

OPERATOR'S MANUAL 4189340690E EN Page 5 of 24

Tie breaker and mains breaker control (option Y4)

Automatic Gen-set Controller

VIEW

LOG

Auto

Alarm Inh.

Self check ok

Power

SEL

BACK

MODE

JUMP

START

INFO

STOP

Alarm

Alarm

multi-line AGC MAINS

On On

Load

Bus tie breaker control (option Y5)

Automatic Gen-set Controller

multi-line AGC BUS TIE

VIEW

LOG

Auto

Alarm Inh.

Self check ok

Power

SEL

BACK

On

INFO

JUMP

Alarm

Alarm

MODE

OPERATOR'S MANUAL 4189340690E EN Page 6 of 24

Group control (option Y8)

AUTO

SEMI

LOG

VIEW

BACK

JUMP

INFO

On

Alarm

Alarm

SEL

AGC-4

Group Controller

Power

Self check ok

PM CAN

Plant control (option Y9)

AUTO

SEMI

AGC-4

Plant Controller

LOG

VIEW

BACK

STOP

START

JUMP

INFO

On

Power

Self check ok

PM CAN

Alarm

Alarm

SEL

PF Control

Voltage support

OPERATOR'S MANUAL 4189340690E EN Page 7 of 24

2.2 Button functions

Standard AGC-4 folio

AUTO

SEMI

Automatic Gen-set Controller

multi-line AGC

LOG

VIEW

MODE

BACK

G

STOP

START

JUMP

INFO

Run On

Load

On Auto

Power

Self check ok

Alarm Inh.

Alarm

Alarm

SEL

AGC - GER (German) folio

Alarm

Alarm

Ein Ein

TEST

HAND

AUTO

KANAL

Power

Selbstest ok

Alarmunt.

Automatic Gen-set Controller

G

multi-line AGC - GER

LOG

START

AUS

Run

LAST

LAMP TEST

1. Shifts the first line displaying in the setup menus. If more than one DU-2 is connected to the controller, push for 2 seconds to

make this DU-2 the master display.

2. Moves the cursor left.

3. Up button: Function depends on context.

• V1: Scrolls the view lines.

OPERATOR'S MANUAL 4189340690E EN Page 8 of 24

• Setup menu: Displays a different value in the second line.

• A parameter: Increases the set point.

4. Selects the underscored entry in the fourth line of the display.

5. Moves the cursor right.

6. Down button: Function depends on context.

• V1: Scrolls the view lines.

• Setup menu: Displays a different value in the second line.

• A parameter: Decreases the set point.

7. Changes the menu line (line four) in the display to mode selection.

• Not present in group and plant controllers.

8. Jumps one step backwards in the menu (to previous display or to the entry window).

9. Displays the LOG SETUP window where you can choose between the Event, Alarm and Battery logs. The logs are not deleted

when the auxiliary supply is switched off.

10. Manual activation of close/open breaker sequence if SEMI is selected.

11. Manual activation of close/open breaker sequence if SEMI is selected.

12. Stops the genset/plant if SEMI or MANUAL* is selected.

13. Starts the genset/plant if SEMI or MANUAL* is selected.

14. Enables the user to use the menu number to select and display any setting.

15. Shifts the display three lower lines to show the alarm list. By holding the button, all alarms will be acknowledged.

16. Group and plant controllers: Select AUTO and SEMI mode.

17. German AGC only: Test button.

*Note: MANUAL mode is not available in German controllers.

OPERATOR'S MANUAL 4189340690E EN Page 9 of 24

2.3 Modes

If the MODE button is pushed, a selection of possible running modes appears in the fourth display line.

Using the and buttons moves the cursor, and the appropriate mode can be selected by pressing the SEL button:

Mode Description

SEMI • The display buttons (START, STOP, GB ON, GB OFF) are active and can be used by the operator.

• The regulators are also active, that is, the speed control will bring the generator to nominal speed upon start.

• When pushing a breaker button for closing, the AGC will synchronise (if allowed) the breaker. When the breaker

closes, the controls stop.

TEST • The controller will start the generator, carry out the test sequence (pre-defined time period) and stop the generator

again. Subsequently, the generator will return to AUTO or SEMI-AUTO mode. The mains breaker will remain closed,

and the generator breaker will remain open. NOTE: The test running can be: Simple test: starting the genset without

closing the GB; Load test: parallel to the mains and take load to a pre-defined value; Full test: transfer the load to the

genset and open the MB.

AUTO • The controller will automatically carry out the control type selected (AMF, fixed power, and so on).

• The display control buttons (START, STOP, GB ON, GB OFF) are disabled.

• Mains controller in local (parameter 8021): If the selected running mode is fixed power, mains power export, load

takeover or island, timer start/stop (week watch) or binary input, then start/stop can be used.

MAN* • The display buttons (START, STOP) are active and can be used by the operator.

• The regulators are not active, that is, speed (and voltage) control has to take place using binary inputs for UP and

DOWN control.

• The breakers will be able to open or close at any time. A synchronisation check will always be performed to ensure

safe closing of the breakers.

BLOCK • The controller will not be able to start the equipment. BLOCK mode can be selected during standstill and the

password is needed to exit BLOCK mode. If BLOCK mode is selected while the genset is running, the mode will have

no effect until the genset is stopped. To select another mode after BLOCK mode, the password must be entered.

*Note: Manual mode is not available on the German controller.

To return to the other display functions from MODE selection, press the BACK button.

OPERATOR'S MANUAL 4189340690E EN Page 10 of 24

2.4 LED functions

Standard AGC-4 folio

Automatic Gen-set Controller

VIEW

LOG

Auto

Alarm Inh.

Self check ok

Power

SEL

BACK

MODE

JUMP

START

INFO

STOP

Alarm

Alarm

multi-line AGC

On On

Load

Run

G

AGC - GER (German) folio

Alarm

Alarm

Ein Ein

TEST

HAND

AUTO

KANAL

Power

Selbstest ok

Alarmunt.

Automatic Gen-set Controller

G

multi-line AGC - GER

LOG

START

AUS

Run

LAST

LAMP TEST

1. LED indicates that the auxiliary supply is switched on.

2. LED indicates that the controller is OK.

3. See Alarm inhibit in the Designer's reference handbook.

• In group and plant controllers, this is the power management CAN bus communication status.

4. LED indicates that auto mode is selected.

• In group and plant controllers, this is replaced by the status LEDs next to the AUTO and SEMI buttons.

5. LED is green if the mains is present and OK. LED is red for a measured mains failure. LED is flashing green when the mains

returns during the "mains OK delay" time.

OPERATOR'S MANUAL 4189340690E EN Page 11 of 24

6. LED green light indicates that the mains breaker is closed. LED is flashing yellow if the "MB spring loaded" signal from the

breaker is missing or the MB load time has not expired.

7. LED green light indicates that the generator breaker is closed. LED yellow light indicates that the generator breaker has received

a command to close on a black bus, but the breaker is not yet closed due to interlocking of the GB. LED is flashing yellow if the

"enable GB black close" or the "GB spring loaded" signal is missing or the GB load time has not expired.

8. LED green light indicates that the voltage/frequency is present and OK.

9. LED indicates that the generator is running.

10. LED flashing indicates that unacknowledged alarms are present. LED fixed light indicates that ALL alarms are acknowledged,

but some are still present.

11. German AGC only: TEST LED.

2.4.1 LED colour schemes

There are two colour schemes for the display LEDs. If LED colour scheme 2 is required, use parameter 6082 (DU-2 only) to select it.

Breaker or bus status Colour scheme 1 (default) Colour scheme 2

Breaker closed Green Red

Breaker open White/no color Green

Mains fail 0-30% Red Green

Mains above 30% but not inside “Hz/V OK” window. Red Red

Mains inside “Hz/V OK” window Green Red

Busbar fail 0-30% No color Green

Busbar above 30% but not side “Hz/V OK” window Red Red

Busbar inside “Hz/V OK” window Green Red

DG fail 0-30% No color Green

DG above 30% but not inside “Hz/V OK” window Red Red

DG inside “Hz/V OK” window Green Red

OPERATOR'S MANUAL 4189340690E EN Page 12 of 24

3. LCD display and menus

3.1 LCD display

The display is a backlit LCD text display. It has four lines with 20 characters in each line. Use parameter 9150 to increase or

decrease the brightness.

3.2 Menus

The display includes two menu systems.

• Setup

◦ The operator can see the controller's parameters.

◦ Changes to the parameter configuration require a password.

• View

◦ The operator can see the operating status and values.

Automatic Gen-set Controller

multi-line AGC

G 400 400 400V

PROTECTION SETUP

PROT CTRL I/O SYST

f-L1 50.00HZ

1

2

3

4

Display line Use Description

1 Daily use Status or operating values.

2

Daily use Operating values.

Setup menu Information for the parameter number.

Alarm/log The latest alarm/event.

3

Daily use Details for the line 4 cursor selection.

Setup menu The selected setting. When changes are made, the minimum and maximum values.

4

Daily use Select setup or view 1, 2 or 3. Press SEL to enter.

Setup menu Sub-functions for the parameter, for example, limit.

3.2.1 Entry window

When the controller is powered up, the window shown below appears.

Automatic Gen-set Controller

multi-line AGC

SETUP MENU

SETUP V3 V2 V1

AGC V 4.79.0

2020-06-06 16:11:59

P01

This window is the gateway to the other menus. View V3 can always be reached by pushing the BACK button three times.

OPERATOR'S MANUAL 4189340690E EN Page 13 of 24

For Genset and Group controllers, the priority is shown in the lower right corner of the display. You can use the PC utility software to

change the priority.

3.3 Password management

The controller includes three password levels. All levels can be adjusted in the PC software.

Password level Factory setting Access

Customer Service Master

Customer 2000 X

Service 2001 X X

Master 2002 X X X

A parameter cannot be entered with a password that is ranking too low. But the settings can be displayed without password entry.

Each parameter can be protected by a specific password level. To do so, the PC utility software must be used. Enter the parameter

to be configured and select the correct password level.

The password level can also be changed from the parameter view in the column "Level". Right-click the field, select "Change access

level" and then select the required password level.

OPERATOR'S MANUAL 4189340690E EN Page 14 of 24

3.3.1 Parameter access

To change parameters, the user must be logged on with the required access level (master, service or customer). If the user is not

logged on at the correct access level, it is not possible to change the parameters.

INFO

The customer password can be changed in jump menu 9116. The service password can be changed in jump menu 9117.

The master password can be changed in jump menu 9118.

INFO

The factory passwords must be changed if the operator is not allowed to change the parameters.

INFO

It is not possible to change the password for a higher level than the password entered.

3.4 Setup

The setup menu system is used to configure the controller. It includes information that is not available in the view menu system.

From the entry window, select SETUP in the line 4.

These are the setup sub-menus:

• Protection setup

• Control setup

• I/O setup

• System setup

Setup structure

2010-01-02 09.35.54

SETUP V3 V2 V1

AGC V.4.00.0

PROT CTRL I/O SYST

G 400 400 400V

f-L1 50.00HZ

PROTECTION SETUP

f-L1 50.00HZ

CONTROL SETUP

G 400 400 400V

PROT CTRL I/O SYST

f-L1 50.00HZ

INPUT/OUTPUT SETUP

G 400 400 400V

PROT CTRL I/O SYST

f-L1 50.00HZ

SYSTEM SETUP

G 400 400 400V

PROT CTRL I/O SYST

SP DEL OA OB ENA FC

1000 G -P> 1

Setpoint -5.0%

G 400 400 400V

SYNC REG

CONTROL SETUP

SYNCHRONISE SETUP

G 400 400 400V

BIN AIN OUT

INPUT/OUTPUT SETUP

BINARY INPUT SETUP

G 400 400 400V

GEN MAINS COMM PM

SYSTEM SETUP

GENERAL SETUP

G 400 400 400V

BACK SEL

BACK SEL BACK SEL BACK SEL BACK SEL

OPERATOR'S MANUAL 4189340690E EN Page 15 of 24

Setup example

This example shows how a reverse power protection set point is changed.

First entry

Increase no.

Decrease no.

Increases setting

Decreases setting

Moves the cursor

YES

NO

PROT CTRL I/O SYST

G 400 400 400V

G f-L1 50.00HZ

PROTECTION SETUP

G 400 400 400V

SP DEL OA OB ENA FC

1000 G -P> 1

Setpoint -5.0%

G 400 400 400V

SP DEL OA OB ENA FC

1010 G -P> 2

Setpoint -5.0%

ENTER

Enter passw. 2010

G 400 400 400V

RESET SAVE

1001 G -P> 1

-50.0 -5.0 0.0%

G 400 400 400V

BACK

BACK SEL

SEL

3.5 Views

The view menus (V1, V2 and V3) display a variety of measured values.

1

2

3

4

Automatic Gen-set Controller

multi-line AGC

G-L1 50 Hz 440V

SETUP V3 V2 V1

G 400 400 400V

G-L1 50 Hz 440V

1. Measurements (V1 and V2) or status (V3)

2. Measurements

3. Measurements

4. Selection of setup and view menus

Navigation

The operator can select the view by moving the cursor (line 4) using the and buttons. The cursor is the underscore (V1 in

the drawing above).

OPERATOR'S MANUAL 4189340690E EN Page 16 of 24

3.5.1 Configurable views V1 and V2

V1 and V2 consist of 20 windows to display the values selected during configuration. V1 and V2 are identical. Select the window to

display using the and buttons.

More information

See the Designer’s reference handbook for information about configuration.

3.5.2 Dynamic view V3

The V3 display is dynamic:

• First display line: Status text. This shows the controller running status.

• Second and third display lines: Relevant measured values.

• Fourth display line: Selection line.

INFO

V3 is not configurable. The information shown is determined by the running status.

3.5.3 View menu example

The following is an example of a configured view menu system. In this example, four of the 20 windows in view 1 are shown.

MANUAL

B 440 438 440V

SETUP V3 V2 V1

4.79.0

09.35.542020-01-02

PROT CTRL I/O SYST

f-L1 50.00HZ

PROTECTION SETUP

G-L1 50 Hz

B-L1 50 Hz

440V

440V

I-L1 150A

I-L2 140A

I-L3 150A

G 150 140 150A

U-SUPPLY 24V

SETUP V3 V2 V1

G 439 438 440V

SETUP V3 V2 V1 SETUP V3 V2 V1

B 440 438 440V

G 440 438 440V

G 150 140 150A G 400 438 400V

G 439 440 440V

SETUP V3 V2 V1

SETUP V3 V2 V1

SETUP V3 V2 V1

G 0.90PF 130KW

SEL BACK

SETUP MENU

AGC

OPERATOR'S MANUAL 4189340690E EN Page 17 of 24

3.6 Status texts

Status text Description

ACCESS LOCK The configurable input is activated, and the operator presses one of the blocked keys.

ADAPT IN PROGRESS The AGC is receiving the application that it has just connected to.

AMF ACTIVE The controller is in auto mode during a mains failure.

AMF AUTO The mains controller is in auto mode and ready to respond.

AMF MAN The controller is in manual mode and waiting for operator input.

AMF SEMI The controller is in semi-automatic mode and waiting for operator input.

Applying IP config. The IP settings have been changed, so the controller is updating the configuration (this takes

about 30 seconds).

AUTO OPERATION Power management, BTB controller: Controller in Auto, but not ready for breaker operation (due

to an active BTB trip alarm).

Aux. test ##.#V ####s The battery test is activated.

BB A BLOCKING Due to a problem on busbar A, the BTB controller cannot close the BTB.

BB B BLOCKING Due to a problem on busbar B, the BTB controller cannot close the BTB.

BB BLOCKED BY GB## Power management: GB## has a position failure.

BB BLOCKED BY MB## Power management: MB## has a position failure.

BB BLOCKED BY TB## Power management: TB## has a position failure.

BLACKOUT ENABLE Genset controller: There is a CAN failure in a power management application.

BLOCKED FOR CLOSING Power management, BTB controller: Last open BTB in a ring busbar.

BROADCAST ABORTED Power management: Broadcast terminated.

BROADCAST COMPLETED Power management: Successful broadcast of an application.

BROADCASTING APPL. # Power management: Broadcast one of the four applications from one controller to the other AGCs

in the power management system, through the CAN line.

BTB XX DIVIDING SEC. Power management, Genset controller: BTB XX is dividing two sections in an island application.

BTB TRIP EXTERNALLY Some external equipment has tripped the breaker. An external trip is logged in the event log.

BTB## BLOCKED Power management: # is replaced by A or B depending on where the problem is located.

BLOCK Block mode is activated.

BTB RACKED OUT The Breaker racked out digital input is actived. Position failure and external trip alarms from the

racked out breaker will not interfere with the rest of the system.

XXXX Busbar blocked Power management: Power sources cannot connect because breaker feedback is missing.

CBE config relay/DVC CBE is enabled in parameter 2254, but no AVR relay or DVC 310/D510C/DVC 550 is configured.

The CBE sequence will not be executed.

CHANGING PRIORITY A manual priority change is being applied.

COMPENSATION FREQ. Compensation is active. The frequency is not at the nominal setting

COOLING DOWN Cooling down period is activated and indefinite (the cooling down timer is set to 0.0 s).

COOLING DOWN ###s Cooling down period is activated.

DELOAD The controller is decreasing the load of the genset in order to open the breaker.

DELOADING BTB XX Genset controllers are load sharing asymmetrically to de-load BTB XX.

DELOADING MB XX Genset controllers are increasing their load to de-load MB XX.

DELOADING TB XX Genset controllers are decreasing their load to de-load TB XX.

OPERATOR'S MANUAL 4189340690E EN Page 18 of 24

Status text Description

DERATED TO #####kW Displays the ramp down set point.

DG BLOCKED FOR START The generator has stopped and has active alarm(s).

DIVIDING SEC IN ###s The BTB will open in ###s.

DIVIDING SECTION Power management: A BTB controller is dividing two sections in an island application.

DRY ALTERNATOR AUTO The mains controller is in auto mode and ready to respond.

DRY ALTERNATOR MAN The controller is in manual mode and waiting for operator input.

DRY ALTERNATOR SEMI The controller is in semi-automatic mode and waiting for operator input.

DRYING ALTERNATOR The controller is in auto mode and drying the alternator.

EXTERNAL START ORDER A planned AMF sequence is activated (without a mains failure).

EXT. STOP TIME ###s

FIXED POWER ACTIVE The controller is in auto mode and supplying fixed power.

FIXED POWER AUTO The mains controller is in auto mode and ready to respond.

FIXED POWER MAN The controller is in manual mode and waiting for operator input.

FIXED POWER SEMI The controller is in semi-automatic mode and waiting for operator input.

FULL TEST Test mode is activated.

FULL TEST ###.#min Test mode activated and test timer counting down.

GB AND MB RACKED OUT The Breaker racked out digital input is activated. Position failure and external trip alarms from the

racked out breakers will not interfere with the rest of the system.

GB ON BLOCKED The generator is running, the GB is open and there is an active Trip GB alarm.

GB RACKED OUT The Breaker racked out digital input is activated. Position failure and external trip alarms from the

racked out breaker will not interfere with the rest of the system.

GB TRIP EXTERNALLY Some external equipment (not the controller) has tripped the breaker. An external trip is logged in

the event log.

GENSET STOPPING Cooling down has finished.

Hz/V OK IN ###s The voltage and frequency on the genset is OK. When the timer runs out the generator breaker

can be closed.

IDLE RUN The Idle run function is active. The genset will not stop until the timer has expired.

IDLE RUN ###.#min The timer in the Idle run function is active.

ISLAND ACTIVE The controller is in auto mode and supplying power while not connected to a mains supply.

ISLAND AUTO The mains controller is in auto mode and ready to respond.

ISLAND MAN The controller is in manual mode and waiting for operator input.

ISLAND SEMI The controller is in semi-automatic mode and waiting for operator input.

LOAD TAKEOVER AUTO The mains controller is in auto mode and ready to respond.

LOAD TAKEOVER MAN The controller is in manual mode and waiting for operator input.

LOAD TAKEOVER SEMI The controller is in semi-automatic mode and waiting for operator input.

LOAD TEST Test mode is activated.

LOAD TEST ###.#min Test mode activated and test timer counting down.

LTO ACTIVE The controller is in auto mode and taking over the load.

MAINS FAILURE Mains failure and mains failure timer expired.

OPERATOR'S MANUAL 4189340690E EN Page 19 of 24

Status text Description

MAINS FAILURE IN ###s The frequency or voltage measurement is outside the limits. The timer shown is the Mains failure

delay.

MAINS f OK DEL ####s Mains frequency is OK after a mains failure. The timer shown is the Mains OK delay.

MAINS P EXPORT AUTO The mains controller is in auto mode and ready to respond.

MAINS P EXPORT MAN The controller is in manual mode and waiting for operator input.

MAINS P EXPORT SEMI The controller is in semi-automatic mode and waiting for operator input.

MAINS U OK DEL ####s The mains voltage is OK after a mains failure. The timer shown is the Mains OK delay.

MB RACKED OUT The Breaker racked out digital input is activated. Position failure and external trip alarms from the

racked out breaker will not interfere with the rest of the system.

MB TRIP EXTERNALLY Some external equipment (not the controller) has tripped the breaker. An external trip is logged in

the event log.

MOUNT CAN CONNECTOR Connect the power management CAN line.

MPE ACTIVE The controller is in auto mode and exporting power to the mains.

PEAK SHAVING ACTIVE The controller is in auto mode and doing peak shaving.

PEAK SHAVING AUTO The mains controller is in auto mode and ready to respond.

PEAK SHAVING MAN The controller is in manual mode and waiting for operator input.

PEAK SHAVING SEMI The controller is in semi-automatic mode and waiting for operator input.

PREPARING ENGINE IF Preparing the engine interface. The EIC values are not yet available.

PREPARING ETHERNET Preparing the Ethernet connection. Communication with USW or over Modbus TCP/IP is not yet

possible.

PROGRAMMING LANGUAGE Downloading the language file, using the PC utility software.

PROGRAMMING M-LOGIC Downloading M-Logic to the controller.

QUICK SETUP ERROR Quick setup of the application failed.

RAMP TO #####kW The power ramp is ramping in steps. The next step that will be reached after the timer has expired

is displayed.

RECEIVE COMPLETED Power management: Application received successfully.

RECEIVE ERROR Power management: Application is not received correctly.

RECEIVING APPL. # Power management: The AGC is receiving an application.

READY AMF AUTO The genset controller is in auto mode and the genset is stopped.

READY AUTO OPERATION BTB controller in Auto and ready for breaker operation (no active BTB trip alarm).

READY DRY ALT. AUTO The genset controller is in auto mode and the genset is stopped.

READY FIXED P AUTO The genset controller is in auto mode and the genset is stopped.

READY ISLAND AUTO The genset controller is in auto mode and the genset is stopped.

READY LTO AUTO The genset controller is in auto mode and the genset is stopped.

READY MPE AUTO The genset controller is in auto mode and the genset is stopped.

READY PEAK SHAV AUTO The genset controller is in auto mode and the genset is stopped.

READY VENTIL. AUTO The genset controller is in auto mode and the genset is stopped.

REDUNDANT CONTROLLER This controller is redundant. Use the other controller for operator actions.

REMOVE CAN CONNECTOR Remove the power management CAN lines.

Request BTB in ###s A BTB close will be requested in ###s.

OPERATOR'S MANUAL 4189340690E EN Page 20 of 24

Other manuals for AGC-4

3

Table of contents

Other Deif Controllers manuals

Deif

Deif AGC-3 User manual

Deif

Deif GC-1F User manual

Deif

Deif GC-1F User manual

Deif

Deif SGC 420 User manual

Deif

Deif AWC 500 Quick start guide

Deif

Deif PPU 300 User manual

Deif

Deif AGC 150 User manual

Deif

Deif SGC 420 User manual

Deif

Deif DVC 310 Installation and operation manual

Deif

Deif AGC 100 User manual

Popular Controllers manuals by other brands

Honeywell

Honeywell S9200U1000 installation instructions

Broadcom

Broadcom NetXtreme/NetLink BCM5718 Series Programmer's guide

Eltako electronics

Eltako electronics FSB71-230V manual

Unitronics

Unitronics UniStream USC-B10-RA28 installation guide

Blue Sky Energy

Blue Sky Energy IPN Remote Installation and operation manual

ComAp

ComAp InteliVision 5 CAN Global Guide