Deif PICUS PPM 300 User manual

INSTALLATION INSTRUCTIONS

Protection and Power Management

PPM 300

DEIF A/S · Frisenborgvej 33 · DK-7800 Skive

Tel.: +45 9614 9614 · Fax: +45 9614 9615

[email protected] · www.deif.com Document no.: 4189340909I

1. Introduction

1.1 About the Installation instructions...................................................................................................................................................................................7

1.1.1 General purpose.................................................................................................................................................................................................................7

1.1.2 Intended users of the Installation instructions........................................................................................................................................................7

1.1.3 Technical support............................................................................................................................................................................................................... 7

1.1.4 List of technical documentation for PPM 300.........................................................................................................................................................7

1.2 Warnings and safety.................................................................................................................................................................................................................9

1.2.1 Safety during installation and operation................................................................................................................................................................... 9

1.2.2 Disable the breakers.........................................................................................................................................................................................................9

1.2.3 Disable the engine start...................................................................................................................................................................................................9

1.2.4 Metal fragments and other objects............................................................................................................................................................................. 9

1.2.5 Electrostatic discharge.....................................................................................................................................................................................................9

1.2.6 Controller power supply................................................................................................................................................................................................ 10

1.2.7 Connect the controller protective earth.................................................................................................................................................................. 10

1.2.8 Switchboard control........................................................................................................................................................................................................ 10

1.2.9 Factory settings................................................................................................................................................................................................................ 10

1.2.10 Automatic and remote-controlled starts...............................................................................................................................................................10

1.2.11 Data security....................................................................................................................................................................................................................10

1.2.12 Do not use unsupported hardware modules..................................................................................................................................................... 10

1.3 Legal information.....................................................................................................................................................................................................................11

1.3.1 Third party equipment.................................................................................................................................................................................................... 11

1.3.2 Warranty...............................................................................................................................................................................................................................11

1.3.3 Open source software....................................................................................................................................................................................................11

1.3.4 Trademarks.........................................................................................................................................................................................................................11

1.3.5 Disclaimer............................................................................................................................................................................................................................11

1.3.6 Copyright............................................................................................................................................................................................................................. 11

2. Preparing for the installation

2.1 Tools............................................................................................................................................................................................................................................... 12

2.1.1 Tools required for mounting and installation.........................................................................................................................................................12

2.2 Materials....................................................................................................................................................................................................................................... 13

2.2.1 Materials required............................................................................................................................................................................................................13

2.3 Site...................................................................................................................................................................................................................................................14

2.3.1 Site requirements............................................................................................................................................................................................................ 14

3. Mounting the equipment

3.1 Introduction................................................................................................................................................................................................................................ 15

3.1.1 Introduction to mounting the equipment................................................................................................................................................................ 15

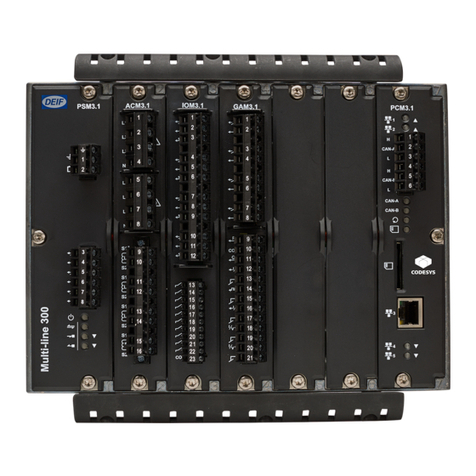

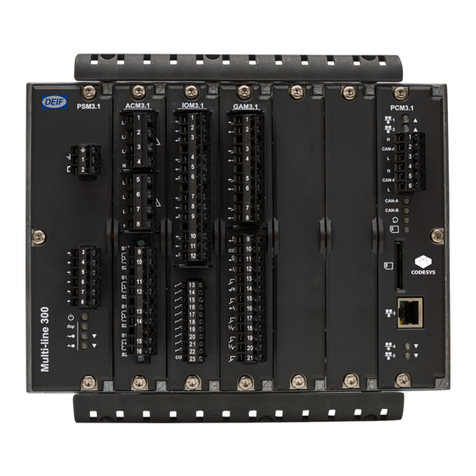

3.2 Mounting modules..................................................................................................................................................................................................................15

3.2.1 Rack slots and their requirements............................................................................................................................................................................15

3.2.2 Mounting hardware modules in the rack................................................................................................................................................................16

3.3 Mounting the controller rack.............................................................................................................................................................................................17

3.3.1 Rack dimensions..............................................................................................................................................................................................................17

3.3.2 Rack drilling template.....................................................................................................................................................................................................18

3.3.3 Mounting the rack............................................................................................................................................................................................................19

3.3.4 Rack cable strain relief..................................................................................................................................................................................................22

3.4 Mounting the display unit................................................................................................................................................................................................... 24

3.4.1 Display unit dimensions................................................................................................................................................................................................ 24

3.4.2 Display unit panel cutout.............................................................................................................................................................................................. 24

INSTALLATION INSTRUCTIONS 4189340909I UK Page 2 of 144

3.4.3 Mounting the display unit..............................................................................................................................................................................................25

3.4.4 Display unit cable strain relief.....................................................................................................................................................................................27

4. Default wiring for controller types

4.1 Introduction................................................................................................................................................................................................................................ 29

4.1.1 Introduction to default wiring.......................................................................................................................................................................................29

4.2 Hardware configuration....................................................................................................................................................................................................... 30

4.2.1 Hardware configuration.................................................................................................................................................................................................30

4.3 PSM3.1 terminal connections and default wiring..................................................................................................................................................31

4.3.1 PSM3.1 terminal connections.....................................................................................................................................................................................31

4.3.2 Default wiring for controller PSM3.1........................................................................................................................................................................32

4.4 ACM3.1 terminal connections and default wiring................................................................................................................................................. 32

4.4.1 ACM3.1 terminal connections.................................................................................................................................................................................... 32

4.4.2 Mounting voltage encoding pins................................................................................................................................................................................34

4.4.3 Default wiring for GENSET controller ACM3.1................................................................................................................................................... 36

4.4.4 Default wiring for EMERGENCY genset controller ACM3.1......................................................................................................................... 37

4.4.5 Default wiring for SHAFT generator controller ACM3.1.................................................................................................................................. 38

4.4.6 Default wiring for SHORE connection controller ACM3.1.............................................................................................................................. 39

4.4.7 Default wiring for BUS TIE breaker controller ACM3.1................................................................................................................................... 40

4.5 PCM3.1 terminal connections and default wiring..................................................................................................................................................41

4.5.1 PCM3.1 terminal connections.................................................................................................................................................................................... 41

4.5.2 PCM3.1 Ethernet connections................................................................................................................................................................................... 41

5. Default wiring for the optional modules

5.1 IOM3.1 terminal connections and default wiring................................................................................................................................................... 43

5.1.1 IOM3.1 terminal connections......................................................................................................................................................................................43

5.1.2 Default wiring for GENSET controller IOM3.1.....................................................................................................................................................45

5.1.3 Default wiring for EMERGENCY genset controller IOM3.1...........................................................................................................................46

5.1.4 Default wiring for SHAFT generator controller IOM3.1....................................................................................................................................47

5.1.5 Default wiring for SHORE connection controller IOM3.1................................................................................................................................48

5.1.6 Default wiring for BUS TIE breaker controller IOM3.1.....................................................................................................................................49

5.2 IOM3.4 terminal connections and default wiring................................................................................................................................................... 50

5.2.1 IOM3.4 terminal connections......................................................................................................................................................................................50

5.2.2 Default wiring for input/output module IOM3.4....................................................................................................................................................50

5.3 EIM3.1 terminal connections and default wiring....................................................................................................................................................51

5.3.1 EIM3.1 terminal connections...................................................................................................................................................................................... 51

5.3.2 Default wiring for GENSET controller EIM3.1..................................................................................................................................................... 52

5.3.3 Default wiring for EMERGENCY genset controller EIM3.1........................................................................................................................... 53

5.4 GAM3.1 terminal connections and default wiring................................................................................................................................................. 54

5.4.1 GAM3.1 terminal connections.................................................................................................................................................................................... 54

5.4.2 Default wiring for GAM3.1............................................................................................................................................................................................55

5.4.3 Default wiring for EMERGENCY genset controller GAM3.1......................................................................................................................... 56

5.5 GAM3.2 terminal connections and default wiring................................................................................................................................................. 56

5.5.1 GAM3.2 terminal connections.................................................................................................................................................................................... 56

5.5.2 Default wiring for GAM3.2............................................................................................................................................................................................58

6. Wiring the controller hardware modules

6.1 Introduction................................................................................................................................................................................................................................ 59

6.1.1 Introduction.........................................................................................................................................................................................................................59

INSTALLATION INSTRUCTIONS 4189340909I UK Page 3 of 144

6.2 Power supply module PSM3.1..........................................................................................................................................................................................59

6.2.1 PSM3.1 terminal overview...........................................................................................................................................................................................59

6.2.2 Frame ground wiring...................................................................................................................................................................................................... 59

6.2.3 Power supply wiring........................................................................................................................................................................................................60

6.2.4 Relay output wiring......................................................................................................................................................................................................... 61

6.2.5 Internal communication connections.......................................................................................................................................................................62

6.3 Alternating current module ACM3.1..............................................................................................................................................................................63

6.3.1 ACM3.1 terminal overview...........................................................................................................................................................................................63

6.3.2 Voltage measurements wiring.................................................................................................................................................................................... 63

6.3.3 Current measurements wiring.................................................................................................................................................................................... 63

6.4 Input output module IOM3.1..............................................................................................................................................................................................64

6.4.1 IOM3.1 terminal overview............................................................................................................................................................................................ 64

6.4.2 Relay output wiring......................................................................................................................................................................................................... 65

6.4.3 Digital inputs wiring.........................................................................................................................................................................................................66

6.5 Input/output module IOM3.4..............................................................................................................................................................................................70

6.5.1 IOM3.4 terminal overview............................................................................................................................................................................................ 70

6.5.2 Transistor output wiring.................................................................................................................................................................................................71

6.5.3 Digital inputs wiring.........................................................................................................................................................................................................71

6.6 Engine interface module EIM3.1..................................................................................................................................................................................... 75

6.6.1 EIM3.1 terminal overview.............................................................................................................................................................................................75

6.6.2 Frame ground wiring...................................................................................................................................................................................................... 76

6.6.3 Power supply wiring........................................................................................................................................................................................................76

6.6.4 Relay output wiring......................................................................................................................................................................................................... 78

6.6.5 Relay output with wire break detection...................................................................................................................................................................78

6.6.6 Digital inputs wiring.........................................................................................................................................................................................................81

6.6.7 Magnetic pickup unit (MPU) input wiring............................................................................................................................................................... 85

6.6.8 W input wiring....................................................................................................................................................................................................................85

6.6.9 Analogue current or resistance inputs wiring.......................................................................................................................................................87

6.7 Governor and AVR module GAM3.1..............................................................................................................................................................................91

6.7.1 GAM3.1 terminal overview.......................................................................................................................................................................................... 91

6.7.2 Relay output wiring......................................................................................................................................................................................................... 92

6.7.3 Load sharing wiring.........................................................................................................................................................................................................93

6.7.4 Analogue current or voltage outputs wiring.......................................................................................................................................................... 93

6.7.5 Pulse width modulation (PWM) output wiring......................................................................................................................................................94

6.7.6 Analogue current or voltage input wiring............................................................................................................................................................... 94

6.8 Governor and AVR module GAM3.2..............................................................................................................................................................................95

6.8.1 GAM3.2 terminal overview.......................................................................................................................................................................................... 95

6.8.2 Frame ground wiring...................................................................................................................................................................................................... 96

6.8.3 Power supply wiring........................................................................................................................................................................................................96

6.8.4 Analogue current or voltage outputs wiring.......................................................................................................................................................... 98

6.8.5 Pulse width modulation (PWM) output wiring......................................................................................................................................................99

6.8.6 Digital inputs wiring.........................................................................................................................................................................................................99

6.8.7 Relay output wiring.......................................................................................................................................................................................................103

6.9 Processor and communication module PCM3.1................................................................................................................................................. 104

6.9.1 PCM3.1 terminal overview........................................................................................................................................................................................ 104

6.9.2 CAN bus communication wiring..............................................................................................................................................................................105

6.9.3 Ethernet connections...................................................................................................................................................................................................105

INSTALLATION INSTRUCTIONS 4189340909I UK Page 4 of 144

7. Wiring examples for controller functions

7.1 Introduction..............................................................................................................................................................................................................................107

7.1.1 Introduction......................................................................................................................................................................................................................107

7.2 AC measurement wiring....................................................................................................................................................................................................107

7.2.1 System AC configuration........................................................................................................................................................................................... 107

7.2.2 [Source] AC configuration.......................................................................................................................................................................................... 111

7.2.3 [Busbar] AC configuration..........................................................................................................................................................................................112

7.3 Breaker wiring.........................................................................................................................................................................................................................114

7.3.1 Pulse breaker..................................................................................................................................................................................................................114

7.3.2 Continuous breaker...................................................................................................................................................................................................... 114

7.3.3 Compact breaker...........................................................................................................................................................................................................115

7.3.4 External breaker.............................................................................................................................................................................................................116

7.3.5 Redundant breaker feedback...................................................................................................................................................................................117

7.4 Regulation.................................................................................................................................................................................................................................117

7.4.1 Using a current output for voltage regulation.................................................................................................................................................... 117

7.5 Power management wiring.............................................................................................................................................................................................. 118

7.5.1 Heavy consumer............................................................................................................................................................................................................118

8. Wiring the communication

8.1 DEIF Ethernet network communication................................................................................................................................................................... 121

8.1.1 Communication..............................................................................................................................................................................................................121

8.1.2 Connecting the communication...............................................................................................................................................................................121

8.1.3 Topology restrictions....................................................................................................................................................................................................125

8.1.4 Topology examples.......................................................................................................................................................................................................126

9. Wiring the display unit

9.1 Display unit overview and wiring.................................................................................................................................................................................129

9.1.1 Display unit terminal overview.................................................................................................................................................................................129

9.1.2 Frame ground wiring....................................................................................................................................................................................................130

9.1.3 Power supply wiring.....................................................................................................................................................................................................130

9.1.4 Relay output wiring.......................................................................................................................................................................................................131

9.1.5 Ethernet connections...................................................................................................................................................................................................132

10. Multi-line 300 as a safety system

10.1 Fast over-current protection (ANSI 50/50TD)......................................................................................................................................................133

10.1.1 Introduction to safety system for ANSI 50/50TD...........................................................................................................................................133

10.1.2 Current transformer requirements.......................................................................................................................................................................133

10.1.3 Power supply requirements....................................................................................................................................................................................133

10.1.4 Function requirements..............................................................................................................................................................................................133

10.1.5 Parameter requirements..........................................................................................................................................................................................134

11. Glossary

11.1 Terms and abbreviations................................................................................................................................................................................................135

11.1.1 Terms and abbreviations..........................................................................................................................................................................................135

11.2 Units...........................................................................................................................................................................................................................................139

11.2.1 Units................................................................................................................................................................................................................................. 139

11.3 Symbols...................................................................................................................................................................................................................................140

11.3.1 Symbols for notes.......................................................................................................................................................................................................140

11.3.2 Controller and component symbols.................................................................................................................................................................... 140

11.3.3 Drawing symbols.........................................................................................................................................................................................................141

INSTALLATION INSTRUCTIONS 4189340909I UK Page 5 of 144

11.3.4 Module faceplate symbols...................................................................................................................................................................................... 143

INSTALLATION INSTRUCTIONS 4189340909I UK Page 6 of 144

1. Introduction

1.1 About the Installation instructions

1.1.1 General purpose

These are the Installation instructions for DEIF’s Protection and Power Management controller, PPM 300. The Installation

instructions provide information for the correct installation of PPM 300. The primary focus of these instructions is the physical

installation of the equipment.

DANGER!

Read these instructions before you install the PPM 300 controllers, to avoid personal injury and damage to the equipment.

The information in the Installation instructions is for default configurations. If the system deviates from the default configuration,

record the differences, and communicate this information as part of the system documentation.

The Data sheet includes all the hardware and system technical specifications. Design information is included in the Designer's

handbook, while commissioning information is included in the Commissioning guidelines.

INFO

The Installation instructions include nominal hardware ratings. Refer to the Data sheet for the most accurate and complete

specifications.

1.1.2 Intended users of the Installation instructions

The Installation instructions are primarily for the people who mount and wire up the controllers and display units. The Installation

instructions can be used during commissioning to check the installation. Designers may also find it useful to refer to the Installation

instructions when developing the system's wiring diagrams. Operators may find it useful to refer to the Installation instructions while

troubleshooting.

1.1.3 Technical support

You can read about service and support options on the DEIF website, www.deif.com. You can also find contact details on the DEIF

website.

You have the following options if you need technical support:

• Help: The display unit includes context-sensitive help.

• Technical documentation: Download all the product technical documentation from the DEIF website: www.deif.com/

documentation

• Training: DEIF regularly offers training courses at the DEIF offices worldwide.

• Support: DEIF offers 24-hour support. See www.deif.com for contact details. There may be a DEIF subsidiary located near you.

You can also e-mail [email protected].

• Service: DEIF engineers can help with design, commissioning, operating and optimisation.

1.1.4 List of technical documentation for PPM 300

Document Contents

Data sheet

• System description and functions

• Controller applications, functions, hardware and protections

• Technical specifications

• Hardware modules, display unit, and accessories

INSTALLATION INSTRUCTIONS 4189340909I UK Page 7 of 144

Document Contents

• Ordering information

Quick start guide

• Mounting

• Connecting wiring

• PICUS (PC software)

◦ Download and install

◦ Controller configuration

• Display unit overview

Designer's handbook

• System principles

• Busbar sections and load sharing

• AC configuration and nominal settings

• Protections and alarms

• Regulation

• Breakers, synchronisation and de-loading

• Power management

• Controller types

• Hardware characteristics and configuration

• PICUS

• CustomLogic

• Emulation

• Modbus

◦ See the Modbus tables for the Modbus address associations

Installation instructions

• Tools and materials

• Mounting

• Default wiring for the controller

• Wiring for hardware module terminals

• Wiring for controller functions

• Wiring communication

• Wiring the display unit

Commissioning guidelines

• Tools, software and information required

• Controller, system and equipment checks

• Regulator tuning

• System testing

• Troubleshooting

Operator's manual

• Controller equipment (push-buttons and LEDs)

• Operating the system

• Alarms and log

• Using the display unit

• Troubleshooting and maintenance

PICUS manual Using PICUS and CustomLogic

Modbus tables

• Modbus address list

◦ PLC addresses

◦ Corresponding controller functions

• Descriptions for function codes, function groups

INSTALLATION INSTRUCTIONS 4189340909I UK Page 8 of 144

1.2 Warnings and safety

1.2.1 Safety during installation and operation

Installing and operating the equipment may require work with dangerous currents and voltages. The installation must only be carried

out by authorised personnel who understand the risks involved in working with electrical equipment.

DANGER!

Hazardous live currents and voltages. Do not touch any terminals, especially the AC measurement inputs and the relay

terminals. Touching the terminals could lead to injury or death.

1.2.2 Disable the breakers

Disconnect or disable the breakers BEFORE connecting the controller power supply.

Do not enable the breakers until AFTER the wiring and controller operation are thoroughly tested.

DANGER!

Unintended breaker closing can cause deadly and/or dangerous situations.

1.2.3 Disable the engine start

Disconnect or disable or block the engine start (the crank, and, if present, the run coil) BEFORE connecting the controller power

supply.

Do not enable the engine start until AFTER the wiring and controller operation are thoroughly tested.

DANGER!

Unintended engine starts can cause deadly and/or dangerous situations.

1.2.4 Metal fragments and other objects

Do not allow metal fragments or other objects to fall into the controller rack or display unit. Be especially careful during installation,

for example, when shortening wires.

To prevent metal fragments from falling into the controller rack, it is recommended to place a cover over the top ventilation holes of

the controller rack. The controller is supplied with a disposable cover to protect it from metal fragments and other objects during the

first installation.

CAUTION

Keep metal fragments out of the controller. Metal fragments can damage the controller.

CAUTION

Remember to remove the cover for the controller rack ventilation holes after work has been completed. Failure to do so can

damage the controller.

1.2.5 Electrostatic discharge

You must protect the equipment terminals from electrostatic discharge when not installed in a grounded rack. Electrostatic discharge

can damage the terminals.

INSTALLATION INSTRUCTIONS 4189340909I UK Page 9 of 144

1.2.6 Controller power supply

The controller must have a reliable power supply, which must include a backup power supply. In addition, the switchboard design

must ensure that the system is sufficiently protected if the controller power supply fails.

If the controller has no power supply, it is OFF and does not provide any protection. The controller cannot enforce any trips,

shutdowns or latches when it is off. The controller does not provide any control or power management. All the controller relays de-

energise.

1.2.7 Connect the controller protective earth

You must ground the controller rack to create a protective earth.

DANGER!

Failure to ground the controller rack could lead to injury or death.

1.2.8 Switchboard control

Under Switchboard control, the operator controls and operates the equipment from the switchboard. When Switchboard control is

activated:

• The controller trips the breaker and/or shuts down the engine, if an alarm situation arises that requires a trip and/or shutdown.

• The controller does not respond to a blackout.

• The controller does not provide any power management.

• The controller does not accept operator commands.

• The controller cannot and does not prevent any manual operator actions.

The switchboard design must therefore ensure that the system is sufficiently protected when the controller is under Switchboard

control.

1.2.9 Factory settings

The controller is delivered pre-programmed from the factory with a set of default settings. These settings are based on typical values

and may not be correct for your system. You must therefore check all parameters before using the controller.

1.2.10 Automatic and remote-controlled starts

The power management system automatically starts gensets when more power is needed. It can be difficult for an inexperienced

operator to predict which gensets will start. In addition, gensets can be started remotely (for example, by using an Ethernet

connection, or a digital input). To avoid personal injury, the genset design, the layout, and maintenance procedures must take this

into account.

1.2.11 Data security

To minimise the risk of data security breaches DEIF recommends:

• As far as possible, avoid exposing controllers and controller networks to public networks and the Internet.

• Use additional security layers like a VPN for remote access, and install firewall mechanisms.

• Restrict access to authorised persons.

1.2.12 Do not use unsupported hardware modules

CAUTION

Only use the hardware modules that are listed in the controller data sheet. Unsupported hardware modules can make the

controller malfunction.

INSTALLATION INSTRUCTIONS 4189340909I UK Page 10 of 144

1.3 Legal information

1.3.1 Third party equipment

DEIF takes no responsibility for the installation or operation of any third party equipment, including the genset. Contact the genset

company if you have any doubt about how to install or operate the genset.

1.3.2 Warranty

CAUTION

The rack may only be opened to remove, replace, and/or add a hardware module. The procedure in the Installation

instructions must be followed. If the rack is opened for any other reason, and/or the procedure is not followed, then the

warranty is void.

CAUTION

If the display unit is opened, then the warranty is void.

1.3.3 Open source software

This product contains open source software licensed under, for example, the GNU General Public License (GNU GPL) and GNU

Lesser General Public License (GNU LGPL). The source code for this software can be obtained by contacting DEIF at

[email protected]. DEIF reserves the right to charge for the cost of the service.

1.3.4 Trademarks

DEIF is a trademark of DEIF A/S.

Bonjour® is a registered trademark of Apple Inc. in the United States and other countries.

CANopen® is a registered community trademark of CAN in Automation e.V. (CiA).

CODESYS® is a trademark of 3S-Smart Software Solutions GmbH.

EtherCAT® is a registered trademark and patented technology, licenced by Beckhoff Automation GmbH, Germany.

Modbus® is a registered trademark of Schneider Automation Inc.

Windows® is a registered trademark of Microsoft Corporation in the United States and other countries.

All trademarks are the properties of their respective owners.

1.3.5 Disclaimer

DEIF A/S reserves the right to change any of the contents of this document without prior notice.

The English version of this document always contains the most recent and up-to-date information about the product. DEIF does not

take responsibility for the accuracy of translations, and translations might not be updated at the same time as the English document.

If there is a discrepancy, the English version prevails.

1.3.6 Copyright

© Copyright DEIF A/S 2019. All rights reserved.

INSTALLATION INSTRUCTIONS 4189340909I UK Page 11 of 144

2. Preparing for the installation

2.1 Tools

2.1.1 Tools required for mounting and installation

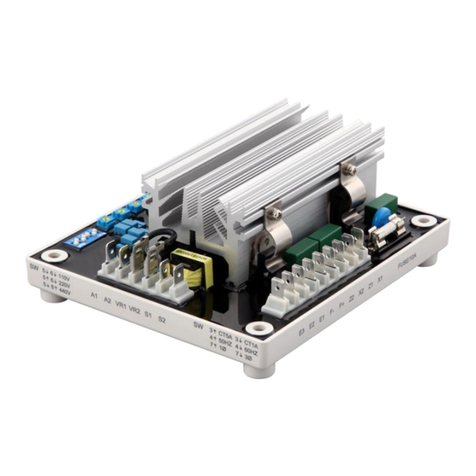

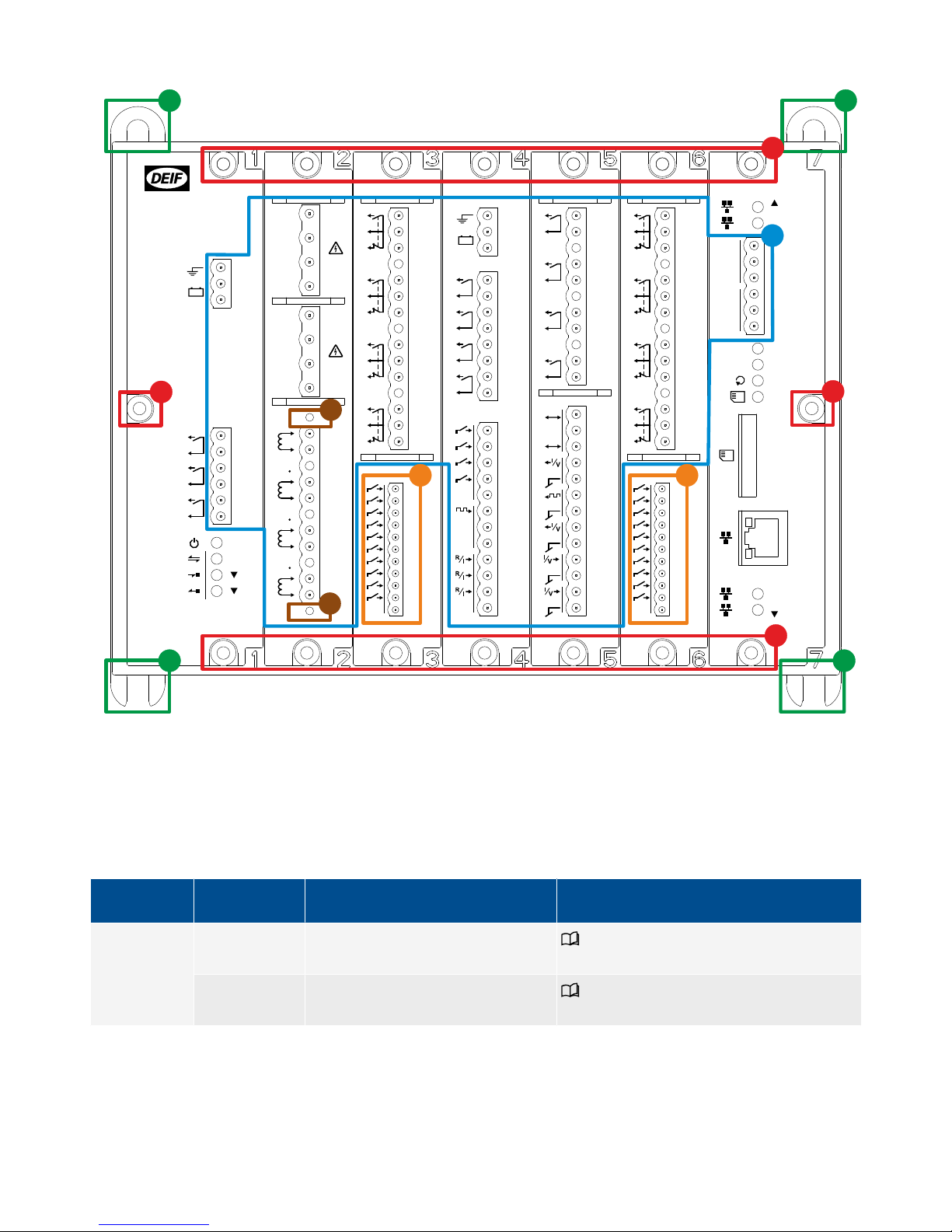

Tool Attachment Torque Used to Diagram

Safety equipment - - Personal protection, according to local

standards and requirements. -

OPTIONAL:

Conducting wrist

strap

- - Prevent electrostatic discharge damage to

modules during mounting. -

Torque screwdriver TX20 bit 0.5 N·m (4.4 lb-in)

Remove modules, or screw extra modules

into the rack. Not required if the required

modules are already mounted in the rack.

1 (red)

Torque screwdriver TX10 bit 0.5 N·m (4.4 lb-in)

Remove, or remount the cable strain relief

plates. The rack is delivered with the cable

strain relief plates already mounted.

-

Torque wrench*

10 mm hex socket for 6 mm

nuts (7/16 in hex socket for

1/4 in nuts)

5 N·m (44 lb-in) Tighten the nuts on the rack mounting bolts. 2 (green)

Torque screwdriver PH2 bit or a 5 mm (0.2 in)

flat-bladed bit

0.15 N·m (1.3 lb-in)

Tighten the display unit fixing screw clamps. -

Torque screwdriver 3.5 mm (0.14 in) flat-bladed

bit 0.5 N·m (4.4 lb-in) Connect the wiring to all the 2.5 mm²

terminals. 3 (blue)

Torque screwdriver 2.5 mm (0.1 in) flat-bladed

bit

0.25 N·m (2.2 lb-in)

Connect the wiring to the 1.5 mm² terminals. 4 (orange)

Torque screwdriver 3.5 mm (0.14 in) flat-bladed

bit 0.25 N·m (2.2 lb-in)

Remove or secure the current measurement

terminal block to the ACM3.1 module

faceplate. ACM3.1 is delivered with the

current measurement terminal block already

secured.

5 (brown)

Wire stripper, pliers

and cutters - - Prepare wiring.

Trim cable ties. -

*Note: The size of the torque wrench attachment depends on the nut and bolt size of the mounting bolts. These parts are not

supplied by DEIF and the sizes mentioned are only a recommendation.

CAUTION

Do not use power tools during the installation. Too much torque will damage the equipment.

INSTALLATION INSTRUCTIONS 4189340909I UK Page 12 of 144

Figure 2.1 Tools required to install a controller rack

PSM3.1

Multi‐line 300

+

‐

L3

S1

S2

L2

S1

S2

L1

S1

S2

L1

L1

L2

L2

L3

L3

N

N

ACM3.1

*

S1

S2

4

COM

IOM3.1

COM

IOM3.1

+

-

COM

EIM3.1

COM

COM

W

*

GAM3.1

COM

Q

P

CAN-A

PCM3.1

CAN-B

CAN-A

CAN-B

1

2

3

4

5

L

H

H

L

22

2

1

1

3

1

1

5

5

44

2

2.2 Materials

2.2.1 Materials required

The following additional materials are required to install the controllers and display units.

Installation

step Materials Purpose More information

Mounting

Four fasteners

per rack Mount the controller rack See Mounting the controller rack for more

information.

Grounding wire Ground the controller rack See Mounting the controller rack for more

information.

INSTALLATION INSTRUCTIONS 4189340909I UK Page 13 of 144

Installation

step Materials Purpose More information

Wiring

Wires

Wire the measurement points,

switchboard and/or third party equipment

to the controller/display unit terminals

See the Data sheet for the wiring

specifications for each terminal.

See the drawings from the system designer.

Ethernet cables

Connect the controller communication to:

• The display unit (2 m cable provided)

• Between controllers

• External systems

See the Data sheet for the Ethernet cable

specifications.

See the communication drawings from the system

designer.

Cable ties

Secure the rack wiring and Ethernet

cables

Secure the display unit wiring and

Ethernet cables

See Rack cable strain relief and Display

unit cable strain relief for more information.

2.3 Site

2.3.1 Site requirements

The equipment is designed to be installed and operated in a clean and dry environment as specified in the Data sheet. If the

equipment is installed in an area subject to constant high vibrations, sufficient precautions should be taken to isolate the equipment

from the vibrations. As a minimum requirement it is recommended that the installation environment complies with the electrical,

mechanical and environmental specifications of the equipment as described in the Data sheet.

CAUTION

If during or after installation of the equipment the electrical, mechanical or environmental specifications are exceeded, the

lifetime of the equipment will be reduced.

INSTALLATION INSTRUCTIONS 4189340909I UK Page 14 of 144

3. Mounting the equipment

3.1 Introduction

3.1.1 Introduction to mounting the equipment

The controller rack is delivered from the factory with all the required hardware modules. However, if you need to mount an additional

hardware module, or to replace a hardware module, read this chapter.

INFO

Hardware modules are standardised, replaceable printed circuit boards that are mounted in the rack. For example, PSM3.1

is a hardware module that supplies power to the rest of the rack.

The controller rack is mounted in an enclosure, while the display unit is mounted in a panel.

This chapter describes how to mount or replace hardware modules, as well as mount the rack and display unit.

CAUTION

Replacing a hardware module with a different type will cause the controller to lose its class approvals. Replacing with a

module of the same type will not affect class approvals.

Deviating from the default configuration

You can mount the hardware modules in a different order from that recommended in these instructions. If you choose to do this,

DEIF recommends that you document where you have chosen to deviate from the default configuration and ensure that this

information is included in the system documentation. Record the following for each hardware module:

• Module name

• Module's rack slot number in the default configuration

• Module's rack slot number in your customised configuration

INFO

CAD drawings for both the controller rack and display unit can be downloaded from the DEIF homepage. The download is

available as either an AutoCAD file or a stp file.

3.2 Mounting modules

3.2.1 Rack slots and their requirements

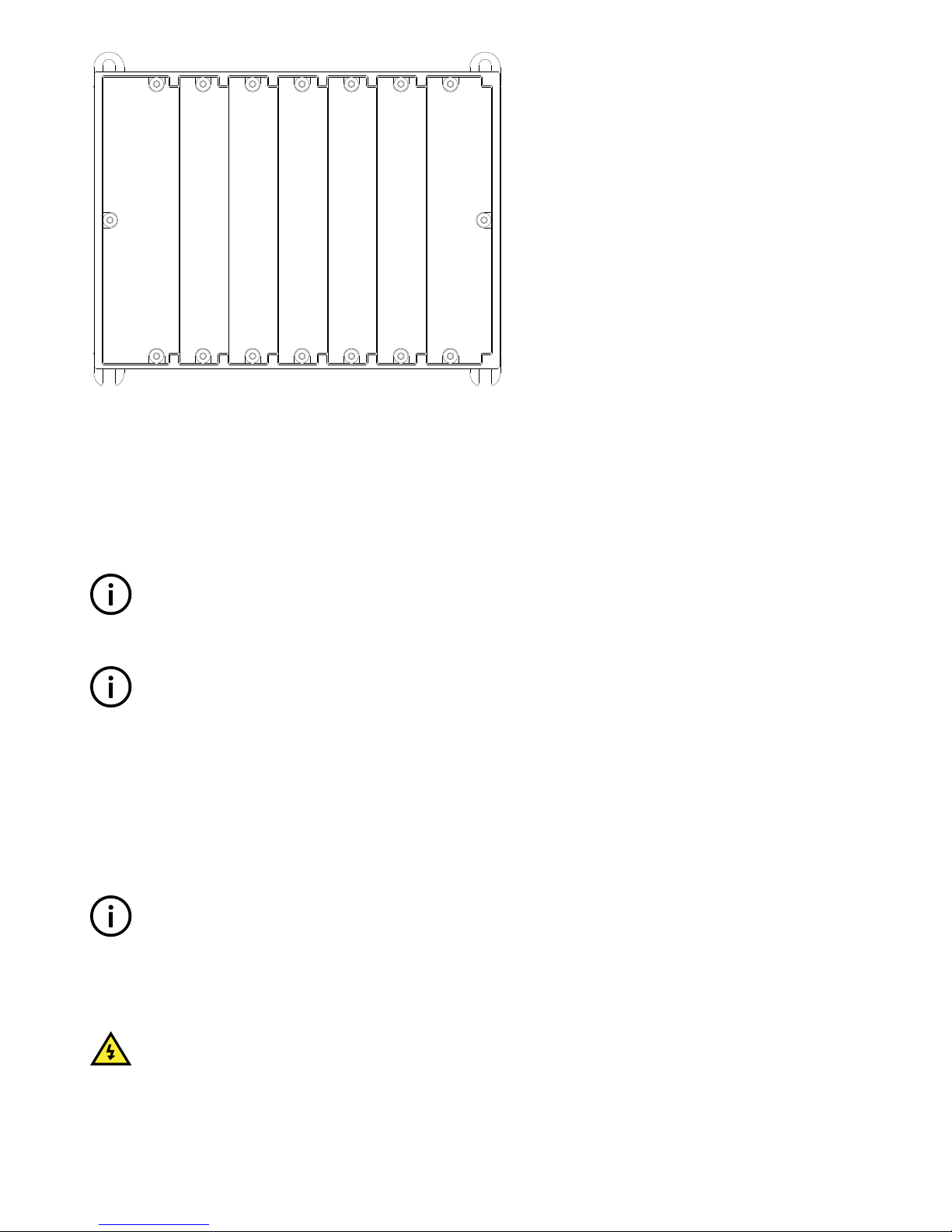

The following diagram shows the slot numbering in the rack. The power supply module (PSM) is always mounted in slot 1. If a

processor and communication module (PCM) is present, it is always mounted in slot 7.

INSTALLATION INSTRUCTIONS 4189340909I UK Page 15 of 144

PSM PCM

17

56

3 42

17

56

3 42

1 432 5 6 7

The controller hardware modules can be arranged in any order in the rack, as long as they comply with these requirements:

• Apart from PSM and PCM, the hardware modules are slotted into the rack from slot 2 onwards, without leaving any empty slots

between the hardware modules.

• If a PCM is not present, slot 7 may be used for other hardware modules.

• Blind modules (these consist of the module faceplates only) must be installed over empty slots, to protect the controller

electronics.

INFO

If there are one or more empty slots between the hardware modules in the rack, the hardware modules after the empty

slot(s) cannot communicate with the PCM module. The software will not recognise or communicate with these hardware

modules either.

INFO

If you rearrange the order of the hardware modules, you may lose some/all of the module configuration information. You

should therefore always make a backup of the configuration before rearranging the hardware modules.

3.2.2 Mounting hardware modules in the rack

The controller will normally be supplied with the hardware modules already mounted. However, it may occasionally be necessary for

you to add or replace a hardware module. If you need to add a hardware module, you can use the first empty slot from the left of the

rack.

Legal

INFO

The manufacturer's warranty will not apply if the rack has been opened by unauthorised persons. However, you are

allowed to replace or add hardware modules (dedicated printed circuit boards) supplied by DEIF. To retain the warranty,

each hardware module must be mounted by a qualified person, in accordance with these written instructions.

Safety

DANGER!

Hazardous live currents and voltages may be present in a rack that is already installed. Contact with these could kill you.

Only authorised personnel, who understand the precautions needed and the risks involved in working with live electrical

equipment, may do this work.

INSTALLATION INSTRUCTIONS 4189340909I UK Page 16 of 144

DANGER!

Working on the rack may disrupt the control of the generator, busbar or connection. Take the necessary precautions.

Equipment protection

CAUTION

Disconnect all power supplies before removing or adding a hardware module. The hardware modules are not designed for

hot swapping.

CAUTION

Protect the hardware modules against static discharge during installation. Protect the rack against static discharge if it has

not yet been mounted and the frame ground has not yet been connected.

Hardware support

CAUTION

Only use the hardware modules that are listed in the controller data sheet. Unsupported hardware modules can make the

controller malfunction.

Physical mounting of hardware modules

1. Disconnect all power supplies (that is, the PSM and, if present, other modules with independent power supplies), to protect the

hardware modules and personnel.

2. Optional: Test the resistance of the wrist strap and the resistance of the wrist strap connection. Do not continue if the wrist strap

connection is faulty. Use the wrist strap at all times while installing or uninstalling the hardware modules to protect them against

static discharge.

3. If applicable, remove the hardware module to be replaced from the rack:

a. Remove the terminal blocks, and make sure that there are no wires in the way of removing the hardware module.

• Where relevant, disconnect the Ethernet cables from the top and bottom of the hardware module.

b. Loosen the hardware module faceplate screws using a screwdriver with a TX20 bit.

• Do not force the screws to unscrew completely. The screws are built-in and therefore normally remain attached to the

faceplate.

c. Use pliers or your fingers to pull the faceplate screws, and carefully slide the hardware module out of the rack.

• Only pull the screws. Do not pull any other part of the faceplate.

d. If you want to re-use the hardware module, or send it in for testing, be careful to only handle it by its faceplate. Put the

hardware module in ESD protective packaging after removing it.

4. To install the new hardware module:

a. Open the ESD protective packaging, and remove the new hardware module, holding it only by its faceplate.

b. Make sure that the hardware module is the right way up, and slide it into the correct slot. The hardware module should slide

in easily.

c. Tighten the screws on the hardware module faceplate using a screwdriver with a TX20 bit, and 0.5 N·m (4.4 lb-in) of torque.

d. Replace all the terminal blocks, including any Ethernet cables to the module.

5. If the rack has not yet been mounted, return the rack to its protective packaging.

3.3 Mounting the controller rack

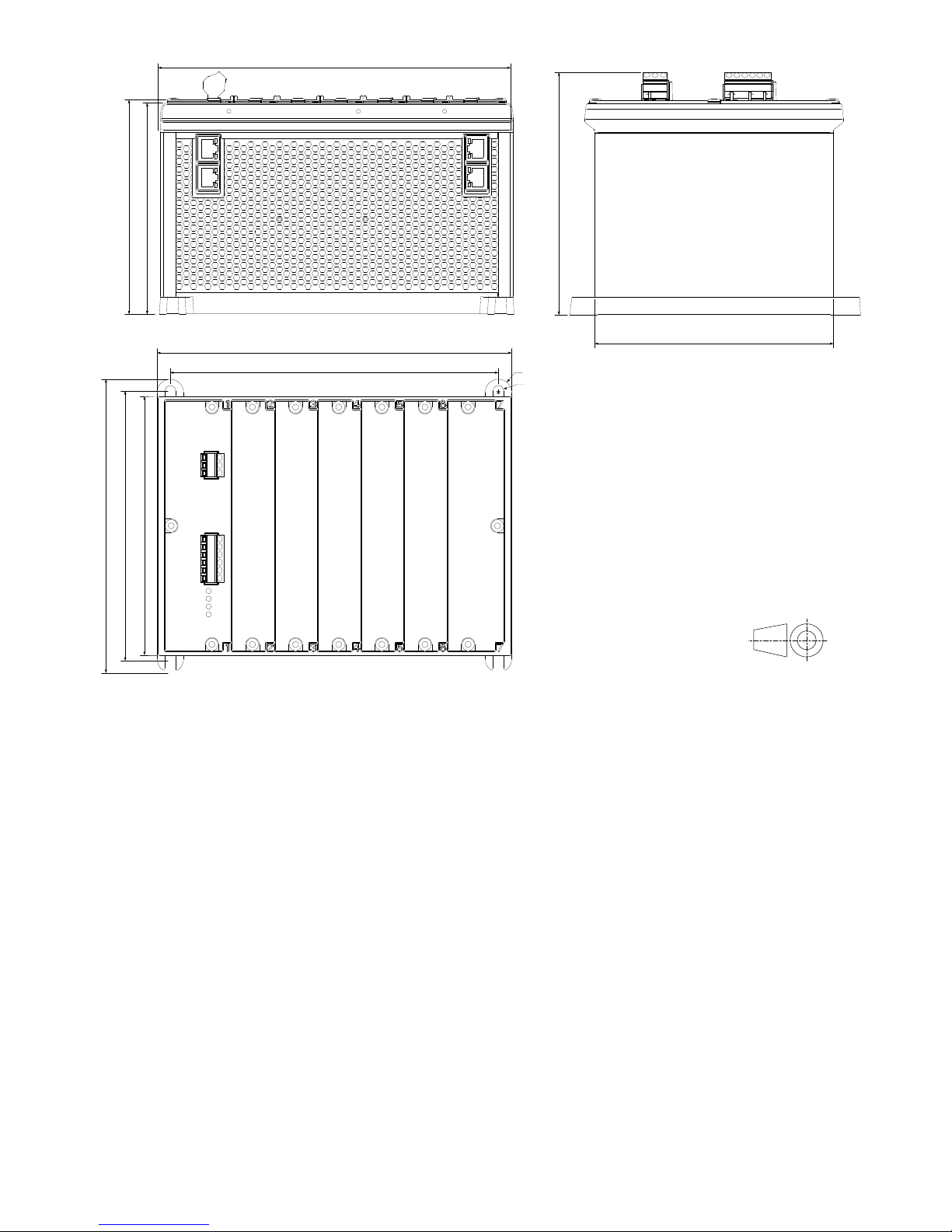

3.3.1 Rack dimensions

The following drawing shows a first-angle projection of the rack, with dimensions. Dimensions are in mm (followed by approximate

dimensions in inches). The rack is supplied with the cable strain relief plates mounted (not shown on the drawing).

INSTALLATION INSTRUCTIONS 4189340909I UK Page 17 of 144

228.9 (9.01)

230.1 (9.06)

212.9 (8.38)

172.0 (6.77)

190.2 (7.49)

139.3 (5.48)

137.3 (5.40)

168.0 (6.61)

157.5 (6.20)

155.0 (6.10)

Ø17.2 (0.68)

Ø7.0 (0.28)

3.3.2 Rack drilling template

Use the dimensions given in the drawing below to create a drilling template. You cannot create an accurate drilling template by

printing this page.

INSTALLATION INSTRUCTIONS 4189340909I UK Page 18 of 144

212.9 (8.38)

Ø7.0 (0.28) × 4

172.0 (6.77)

3.3.3 Mounting the rack

The rack is designed to be mounted in an enclosure.

For UL/cUL listing, the rack must be:

• Mounted on a flat surface of a type 1 enclosure.

• Installed in accordance with the NEC (US) or the CEC (Canada).

MORE INFORMATION

See the Data sheet for more information about the electrical specifications.

CAUTION

• Dust accumulation may damage the controller or cause overheating. DEIF recommends mounting the rack in a cabinet

with a filter on the air supply.

• Protect the controller terminals from static discharge during installation, especially while the frame ground is not

connected.

Spacing around the controller

•For ventilation: A minimum of 20 mm (0.8 in) free space above and below the rack frame is required.

INSTALLATION INSTRUCTIONS 4189340909I UK Page 19 of 144

•For cables: Ensure that there is enough space in front of, above and below the rack for the cables. As an example, Ethernet

cables may require a minimum bend radius of around 40 mm (1.6 in) and an additional 40 mm (1.6 in) for the plug = a total of 80

mm (3.2 in).

INFO

DEIF recommends that you always follow the cable manufacturer's bend radius requirements.

Free space

80.0 (3.16)

PSM3.1

Multi-line 300

+

-

CAN-A

PCM3.1

CAN-B

CAN-A

CAN-B

1

2

3

4

5

L

H

H

L

17

56

32

17

56

3 42

This side up

Free space

80.0 (3.16)

4

Fasteners for mounting the rack

Fasteners for mounting are not supplied with the rack. The rack fasteners must be able to support the weight of the rack and the

wiring.

Example: Calculating minimum bolt length

Mounting the rack using four Ø6 mm (1/4 in) bolts, four nuts and four Ø6 mm (1/4 in) washers.

For bolts, the minimum length is 12 mm (0.47 in) for the rack mounting loop. Length is also needed for the washer

thickness (typically 1.5 mm), the nut (typically 4 mm), and the cabinet back plate thickness.

INSTALLATION INSTRUCTIONS 4189340909I UK Page 20 of 144

Other manuals for PICUS PPM 300

2

Table of contents

Other Deif Controllers manuals