Delabie TEMPOMATIC 4 443406 User manual

Other Delabie Plumbing Product manuals

Delabie

Delabie TEMPOMIX 3 794150 User manual

Delabie

Delabie TEMPOMATIC 3 User manual

Delabie

Delabie TEMPOMIX 3 User manual

Delabie

Delabie TEMPOMATIC PRO 20164 User manual

Delabie

Delabie TEMPOMIX 3 User manual

Delabie

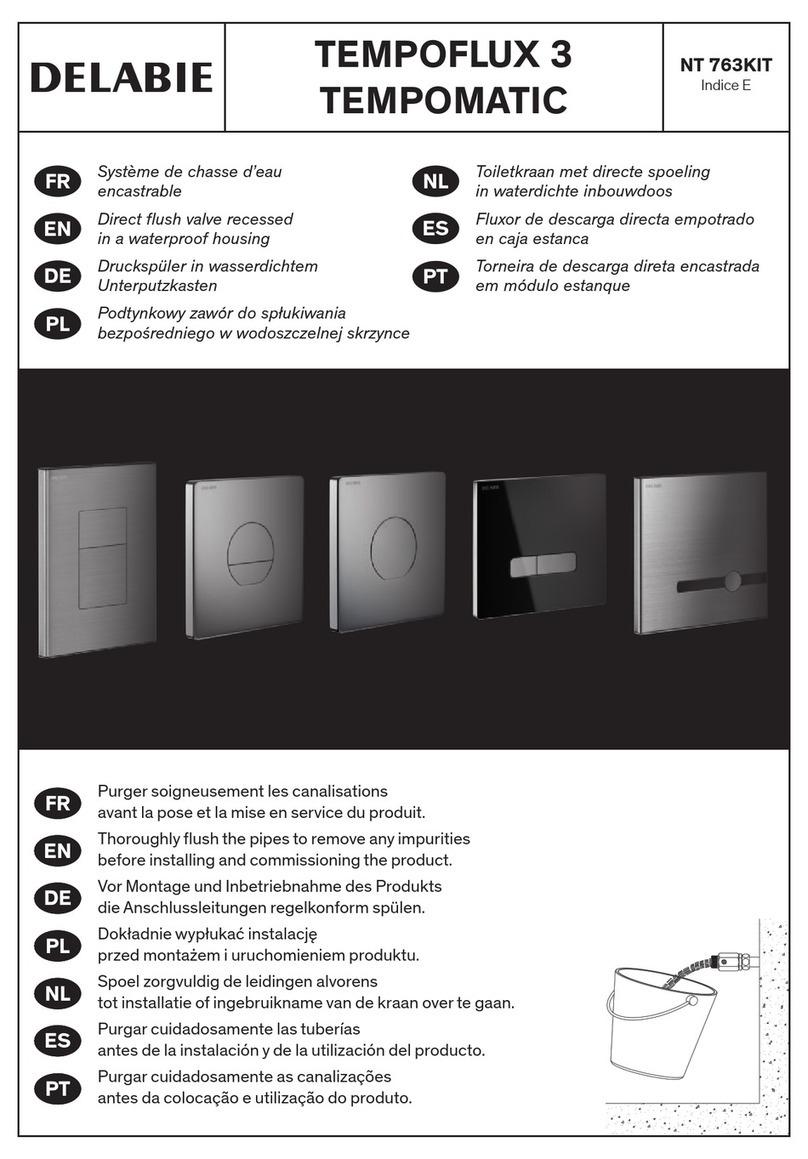

Delabie TEMPOFLUX 3 TEMPOMATIC User manual

Delabie

Delabie HYBRIMATIC FINO User manual

Delabie

Delabie TEMPOMATIC BINOPTIC User manual

Delabie

Delabie TEMPOMIX 795000 User manual

Delabie

Delabie SECURITHERM NT 792 KIT User manual

Delabie

Delabie SECURITHERM SECURITHERM NT H9600 User manual

Delabie

Delabie TEMPOMATIC 3 User manual

Delabie

Delabie 2543 User manual

Delabie

Delabie TEMPOMATIC WC User manual

Delabie

Delabie Bioclip User manual

Delabie

Delabie BIOSAFE User manual

Delabie

Delabie TEMPOSTOP User manual

Delabie

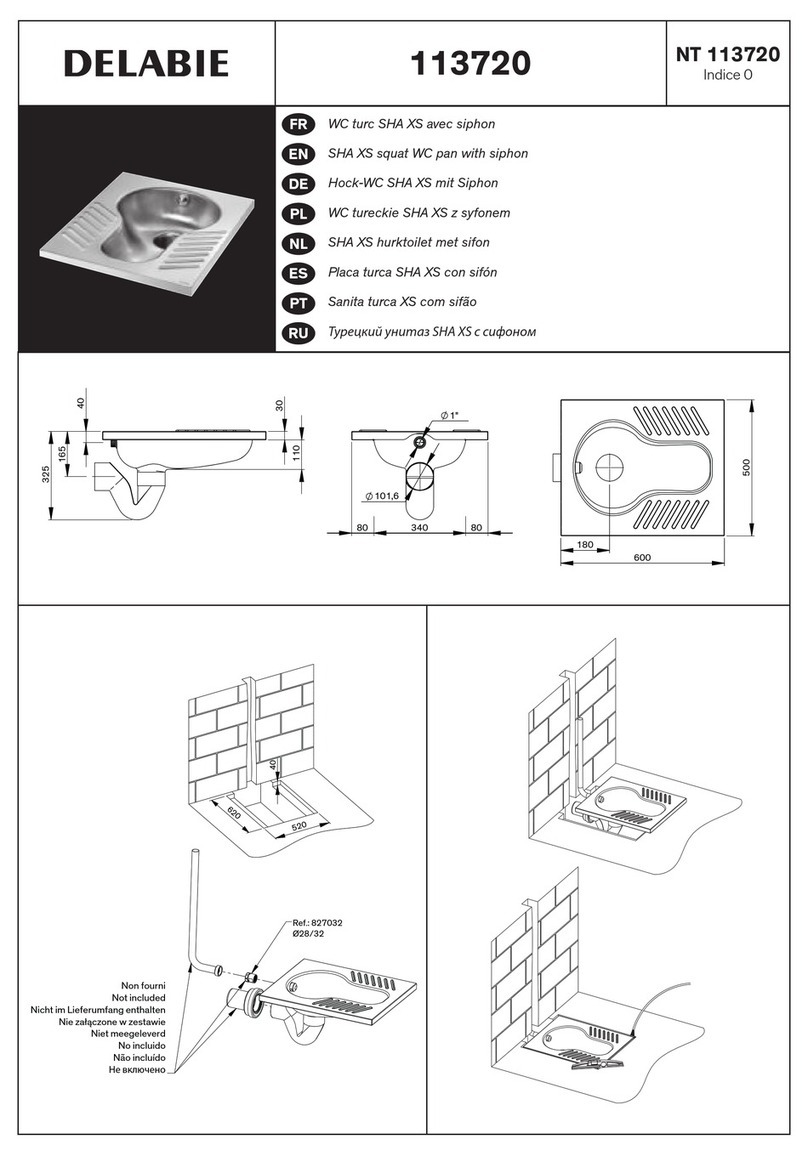

Delabie 113720 User manual

Delabie

Delabie H96BOX User manual

Delabie

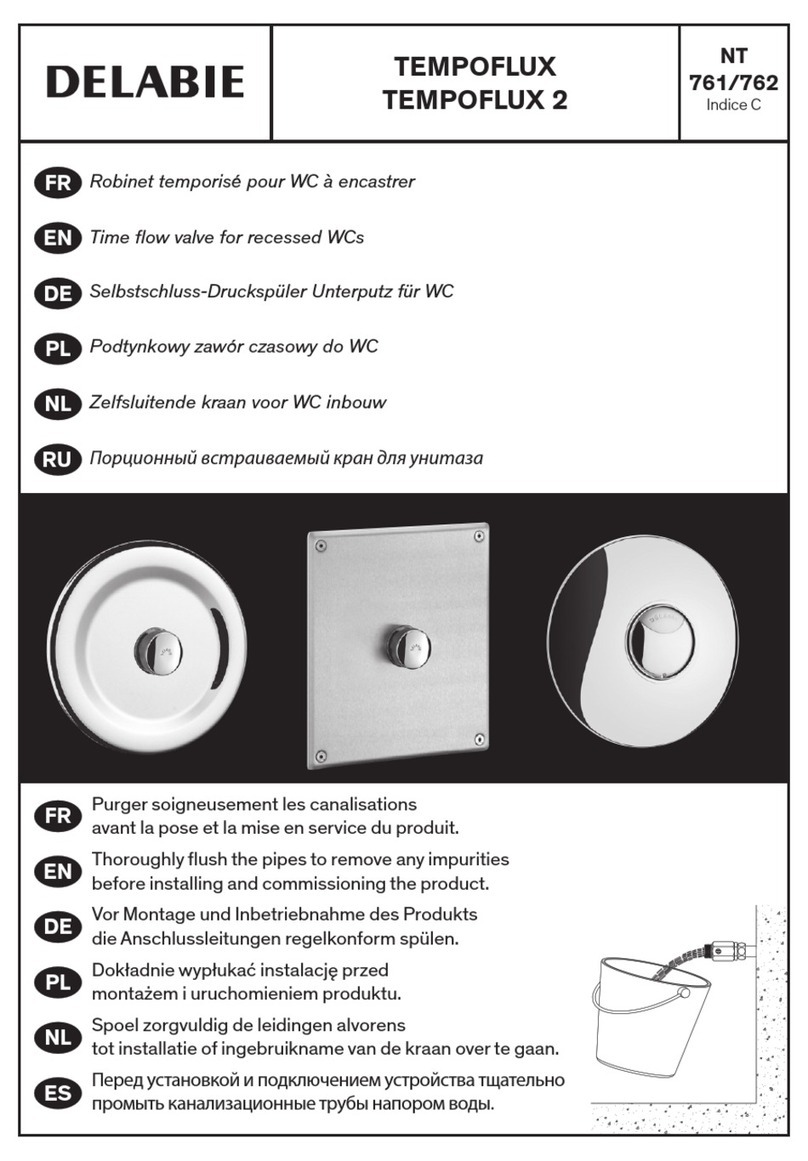

Delabie TEMPOFLUX User manual

Popular Plumbing Product manuals by other brands

Weka

Weka 506.2020.00E ASSEMBLY, USER AND MAINTENANCE INSTRUCTIONS

American Standard

American Standard DetectLink 6072121 manual

Kohler

Kohler K-6228 Installation and care guide

Uponor

Uponor Contec TS Mounting instructions

Pfister

Pfister Selia 49-SL Quick installation guide

Fortis

Fortis VITRINA 6068700 quick start guide

Elkay

Elkay EDF15AC Installation, care & use manual

Hans Grohe

Hans Grohe AXOR Citterio E 36702000 Instructions for use/assembly instructions

baliv

baliv WT-140 manual

Kohler

Kohler Mira Eco Installation & user guide

BELLOSTA

BELLOSTA romina 0308/CC Installation instruction

Bristan

Bristan PS2 BAS C D2 Installation instructions & user guide